IPS-E-PM-110(2)

ﭘﻴﺶ ﮔﻔﺘﺎر

FOREWORD

The Iranian Petroleum Standards (IPS) reflect the

views of the Iranian Ministry of Petroleum and

are intended for use in the oil and gas production

facilities,

oil

refineries,

chemical

and

petrochemical plants, gas handling and processing

installations and other such facilities.

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and

the local market availability. The options which

are not specified in the text of the standards are

itemized in data sheet/s, so that, the user can

select his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the user.

This addendum together with the relevant IPS

shall form the job specification for the specific

project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the relevant

technical committee and in case of approval will

be incorporated in the next revision of the

standard.

Standards and Research department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran .

Postal Code- 1585886851

Tel: 88810459-60 & 66153055

Fax: 88810462

Email: Standards@nioc.org

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ ﻧﻔﺖ

، واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﺋﻲ و ﭘﺘﺮوﺷﻴﻤﻲ، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ

.ﺷﺪه اﺳﺖ

ﺑﺮاﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل ﺑﻴﻦ،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

اﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﺋﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي ﻣﺮﺟﻊ

ﻫﻤﭽﻨﻴﻦ ﺑﺮاﺳﺎس ﺗﺠﺮﺑﻴﺎت ﺻﻨﻌﺖ ﻧﻔﺖ ﻛﺸﻮر و.ﻣﻲﺑﺎﺷﺪ

ﻣﻮاردي،ﻗﺎﺑﻠﻴﺖ ﺗﺎﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ ﺑﺮﺣﺴﺐ ﻧﻴﺎز

.ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ ﺷﺪه اﺳﺖ

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ آورده ﻧﺸﺪه

اﺳﺖ در داده ﺑﺮگﻫﺎ ﺑﺼﻮرت ﺷﻤﺎره ﮔﺬاري ﺷﺪه ﺑﺮاي اﺳﺘﻔﺎده

.ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را ﭘﻮﺷﺶ

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي ﺧﺎص.ﻧﺪﻫﻨﺪ

اﻳﻦ اﻟﺤﺎﻗﻴﻪ.آﻧﻬﺎ را ﺗﺎﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه و ﻳﺎ ﻛﺎر،ﻫﻤﺮاه ﺑﺎ اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.ﺧﺎص را ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ ﻗﺮار

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

66153055 و88810459 - 60 : ﺗﻠﻔﻦ

88810462 : دور ﻧﮕﺎر

Standards@nioc.org

ﭘﺴﺖ اﻟﻜﺘﺮوﻧﻴﻚ

General Definitions:

Throughout this Standard

definitions shall apply.

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

the

following

Company :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian

Gas

Company,

and

National

Petrochemical Company etc.

Purchaser :

Means the "Company" Where this standard is part

of direct purchaser order by the "Company", and

the "Contractor" where this Standard is a part of

contract documents.

Vendor And Supplier:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

Contractor:

Refers to the persons, firm or company whose

tender has been accepted by the company.

Executor :

Executor is the party which carries out all or part

of construction and/or commissioning for the

project.

Inspector :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

Shall:

Is used where a provision is mandatory.

Should:

Is used where a provision is advisory only.

Will:

Is normally used in connection with the action by

the “Company” rather than by a contractor,

supplier or vendor.

May:

Is used where a provision is completely

discretionary.

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲ رود

: ﺷﺮﻛﺖ

ﺑﻪ ﺷﺮﻛﺖ ﻫﺎي اﺻﻠﻲ و واﺑﺴﺘﻪ وزارت ﻧﻔﺖ ﻣﺜﻞ ﺷﺮﻛﺖ ﻣﻠﻲ

ﺷﺮﻛﺖ ﻣﻠﻲ ﺻﻨﺎﻳﻊ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان،ﻧﻔﺖ اﻳﺮان

.ﭘﺘﺮوﺷﻴﻤﻲ و ﻏﻴﺮه اﻃﻼق ﻣﻴﺸﻮد

:ﺧﺮﻳﺪار

ﻳﻌﻨﻲ "ﺷﺮﻛﺘﻲ" ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش

ﺧﺮﻳﺪ ﻣﺴﺘﻘﻴﻢ آن "ﺷﺮﻛﺖ" ﻣﻴﺒﺎﺷﺪ و ﻳﺎ "ﭘﻴﻤﺎﻧﻜﺎري" ﻛﻪ اﻳﻦ

. اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮارداد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪه

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

. ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺎﻣﻴﻦ ﻣﻴﻨﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

ﻣﻮﺳﺴﻪ وﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش ﺑﺮاي، ﺑﻪ ﺷﺨﺺ

.ﻣﻨﺎﻗﺼﻪ وﻳﺎ ﻣﺰاﻳﺪه ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

:ﻣﺠﺮي

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از ﻛﺎرﻫﺎي

.اﺟﺮاﺋﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد ﻳﺎ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ

ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ ﺳﺎﺧﺖ و ﻧﺼﺐ ﺗﺠﻬﻴﺰات

.ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

.ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ اﺳﺘﻔﺎده ﻣﻴﺸﻮد

:ﺗﻮﺻﻴﻪ

ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد

:ﺗﺮﺟﻴﺢ

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮاﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

. ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري ﻣﻴﺒﺎﺷﺪ

IPS-E-PM-110(2)

ENGINEERING STANDARD

FOR

TECHNICAL EVALUATION

OF

MACHINERIES

SECOND REVISION

JULY 2009

اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

ﺑﺮاي

ارزﻳﺎﺑﻲ ﻓﻨﻲ ﻣﺎﺷﻴﻦ آﻻت دوار

وﻳﺮاﻳﺶ دوم

1388 ﻣﺮداد

This Standard is the property of Iranian Ministry of

Petroleum. All rights are reserved to the owner. Neither

whole nor any part of this document maybe disclosed to any

third party, reproduced, stored in any retrieval system or

transmitted in any form or by any means without the prior

written consent of the Iranian Ministry of Petroleum.

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ ﺑﻪ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم ﻳﺎ ﺑﺨﺸﻲ،ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

، اﻧﺘﻘﺎل، ذﺧﻴﺮه ﺳﺎزي، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ ازﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ،از اﻳﻦ اﺳﺘﺎﻧﺪارد

.ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد

Jul. 2009/ 1388 ﻣﺮداد

CONTENTS:

Page

No

IPS-E-PM-110 (2)

:ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

0. INTRODUCTION .............................................2

2 ............................................................. ﻣﻘﺪﻣﻪ-0

1. SCOPE ................................................................3

3 ..................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

2. REFERENCES...................................................3

3 ............................................................. ﻣﺮاﺟﻊ-2

3. GENERAL REQUIREMENTS........................5

5 ................................................. اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ-3

3.1 Delivery Time ..............................................5

5 ............................................... زﻣﺎن ﺗﺤﻮﻳﻞ1-3

3.2 Vendor’s Experience and Reputation .......5

5 ........................... ﺗﺠﺮﺑﻴﺎت و اﻋﺘﺒﺎر ﻓﺮوﺷﻨﺪه2-3

3.3 Interchangeability.......................................5

5 .......................................... ﺟﺎﻧﺸﻴﻦ ﭘﺬﻳﺮي3-3

3.4 Guarantee and Warranty...........................6

6 ........................................... ﺿﻤﺎﻧﺖ و ﺗﻌﻬﺪ4-3

3.5 After Sales Services..................................... 6

6 .................................. ﺧﺪﻣﺎت ﭘﺲ از ﻓﺮوش5-3

3.6 Spare Parts Supply ..................................... 6

6 .................................... ﺗﺎﻣﻴﻦ ﻗﻄﻌﺎت ﻳﺪﻛﻲ6-3

3.7 Size and Weight...........................................6

6 .............................................. اﻧﺪازه و وزن7-3

3.8 Ease of Dismantling and Repair ................ 6

6 .............. ﺳﻬﻮﻟﺖ ﭘﻴﺎده ﺳﺎزي اﺟﺰاء و ﺗﻌﻤﻴﺮات8-3

3.9 Efficiency and Energy Consumption ........ 6

6 ....................... راﻧﺪﻣﺎن و ﻣﻴﺰان ﻣﺼﺮف اﻧﺮژي9-3

4. COMPLIANCE WITH STANDARDS ............7

7 ................................. ﻣﻴﺰان اﻧﻄﺒﺎق ﺑﺎ اﺳﺘﺎﻧﺪاردﻫﺎ-4

5. SUMMARY ........................................................7

7 ............................................................ ﭼﻜﻴﺪه-5

APPENDICES:

:ﭘﻴﻮﺳﺖﻫﺎ

APPENDIX A QUOTATION ANALYSIS

REPORTS ....................................8

8 ......... ﭘﻴﻮﺳﺖ اﻟﻒ ﮔﺰارﺷﺎت ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﻫﺎي ﺧﺮﻳﺪ

APPENDIX B CENTRIFUGAL PUMPS

TECHNICAL BID

EVALUATION ...........................9

ﭘﻴﻮﺳﺖ ب ارزﻳﺎﺑﻲ ﻣﻨﺎﻗﺼﺎت ﻓﻨﻲ در ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ

9 ................................................... از ﻣﺮﻛﺰ

1

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

ﻣﻘﺪﻣﻪ-0

0. INTRODUCTION

The aim of this Standard is to provide a general

guidance for technical bid evaluation of

machineries.

اراﺋﻪ راﻫﻜﺎرﻫﺎي ﻋﻤﻮﻣﻲ در ارزﻳﺎﺑﺒﻲ ﻓﻨﻲ، ﻫﺪف از اﻳﻦ اﺳﺘﺎﻧﺪارد

.ﻣﻨﺎﻗﺼﺎت ﻣﺎﺷﻴﻦ آﻻت دوار ﻣﻲ ﺑﺎﺷﺪ

General requirements to be concerned in

technical evaluation of machineries are covered

in Section 3 and specific requirements in

Appendix A.

اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ ﻛﻪ در ارزﻳﺎﺑﻲ ﻓﻨﻲ ﻣﺎﺷﻴﻦ آﻻت ﻣﺪ ﻧﻈﺮ ﻗﺮار

ﻣﻲﮔﻴﺮﻧﺪ در ﺑﺨﺶ ﺳﻮم ﻣﻮرد ﺑﺮرﺳﻲ ﻗﺮار ﮔﺮﻓﺘﻪ اﻧﺪ و اﻟﺰاﻣﺎت

.ﺧﺎص در ﭘﻴﻮﺳﺖ اﻟﻒ ذﻛﺮ ﺷﺪه اﻧﺪ

ﺟﺪاول ﮔﺰارﺷﻬﺎي ﺗﺤﻠﻴﻞ ﺑﻪ ﻋﻨﻮان ﻣﺮﺟﻌﻲ ﺟﻬﺖ ﻣﻘﺎﻳﺴﻪ

در ﭘﻴﻮﺳﺖ اﻟﻒ آورده ﺷﺪه،ﭘﻴﺸﻨﻬﺎدات ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪﮔﺎن ﻣﺨﺘﻠﻒ

.اﻧﺪ

در ﻣﻨﺎﻗﺼﺎت ﻓﻨﻲ اراﺋﻪ ﺷﺪه ﺑﺮاي ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻣﻲ

Quotation Analysis Report Tables are given in

Appendix A as a reference for comparison of

different supplier’s offers.

Appendix B provides assistance in evaluating

the received technical bids of centrifugal

pumps.

.ﺗﻮان از ﭘﻴﻮﺳﺖ ب اﺳﺘﻔﺎده ﻧﻤﻮد

Although many subjects regarding technical

evaluation of machinery are discussed in this

standard, it is the project engineer to complete

the Quotation Analysis Reports (QARs) in

accordance with specific requirements of the

projects.

اﮔﺮ ﭼﻪ ﺑﺴﻴﺎري از ﻣﻮﺿﻮﻋﺎت ﻣﺮﺗﺒﻂ ﺑﺎ ارزﺷﻴﺎﺑﻲ ﻓﻨﻲ ﻣﺎﺷﻴﻦ آﻻت

اﻣﺎ ﮔﺰارﺷﺎت.دوار در اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪ اﻧﺪ

( ﺑﺎﻳﺪ ﺗﻮﺳﻂ ﻣﻬﻨﺪس ﭘﺮوژه و ﻣﻄﺎﺑﻖ ﺑﺎQAR) ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم

.اﻟﺰاﻣﺎت ﺧﺎص ﭘﺮوژه ﺗﻜﻤﻴﻞ ﺷﻮد

"Project Engineer" is the person charged with

the project responsibility of supplying design

documents and/or procurement services.

"ﻣﻬﻨﺪس ﭘﺮوژه" ﻓﺮدي اﺳﺖ ﻛﻪ ﻣﺴﺌﻮل ﺗﻬﻴﻪ ﻣﺪارك ﻃﺮاﺣﻲ

.ﻳﺎ ﺧﺪﻣﺎت ﻛﺎﻻﺳﺖ/و

2

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺷﺎﻣﻞ اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ و راﻫﻨﻤﺎﻳﻲ ﺟﻬﺖ ارزﻳﺎﺑﻲ

ﻓﻨﻲ ﻣﺎﺷﻴﻦ آﻻت دوار ﻣﻮرد اﺳﺘﻔﺎده در وزارت ﻧﻔﺖ اﻳﺮان ﻣﻲ

.ﺑﺎﺷﺪ

This Standard covers general requirements and

guidance

for

technical

evaluation

of

machineries, used within Iranian ministry of

petroleum.

:1 ﻳﺎدآوري

Note 1:

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ در ﺑﻬﻤﻦ ﻣﺎه ﺳﺎل

از اﻳﻦ.( ﻣﻨﺘﺸﺮ ﺷﺪه اﺳﺖ1) ﺑﺎزﻧﮕﺮي و ﺑﻪ ﺻﻮرت وﻳﺮاﻳﺶ1384

.( اﻳﻦ اﺳﺘﺎﻧﺪارد داراي اﻋﺘﺒﺎر ﻧﻴﺴﺖ0) ﭘﺲ وﻳﺮاﻳﺶ

This is a revised version of the standard

specification by the relevant technical

committee on Feb. 2005, which is issued as

revision (1). Revision (0) of the said standard

specification is withdrawn.

:2 ﻳﺎدآوري

Note 2:

ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه اﺳﺘﺎﻧﺪارد ﻓﻮق،اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ1388 ﻣﻲﺑﺎﺷﺪ ﻛﻪ در ﻣﺮداد ﻣﺎه ﺳﺎل

از اﻳﻦ ﭘﺲ وﻳﺮاﻳﺶ.( اراﻳﻪ ﻣﻲﮔﺮدد2) ﺗﺎﻳﻴﺪ و ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.( اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ1)

This bilingual standard is a revised version of

the standard specification by the relevant

technical committee on July 2009, which is

issued as revision (2). Revision (1) of the said

standard specification is withdrawn.

:3 ﻳﺎدآوري

Note 3:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

ﻣﺮاﺟﻊ-2

2. REFERENCES

Throughout this Standard the following dated

and undated standards / codes are referred to.

These referenced documents shall, to the extent

specified herein, form a part of this Standard.

For dated references, the edition cited applies.

The applicability of changes in dated references

that occur after the cited date shall be mutually

agreed upon by the Company and the Vendor.

For undated references, the latest edition of the

referenced

documents

(including

any

supplements and amendments) applies.

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﺋﻴﻦ ﻧﺎﻣﻪ ﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و ﺑﺪون

ﺗﺎ ﺣﺪي ﻛﻪ در اﻳﻦ، اﻳﻦ ﻣﺮاﺟﻊ.ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ اﺳﺘﺎﻧﺪارد،اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪاﻧﺪ

وﻳﺮاﻳﺶ ﮔﻔﺘﻪ ﺷﺪه ﻣﻼك، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

،ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ و وﻳﺮاﻳﺶ در آﻧﻬﺎ داده ﺷﺪه اﺳﺖ

در.ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ اﺟﺮا ﻣﻲﺑﺎﺷﺪ

آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ اﻧﻀﻤﺎم ﻛﻠﻴﻪ اﺻﻼﺣﺎت،ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ

.و ﭘﻴﻮﺳﺖﻫﺎي آن ﻣﻼك ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

IPS(IRANIAN PETROLEUM STANDARDS)

( )اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS-M-PM-105 "Material and Equipment

Standard for Centrifugal

Pumps

for

Petroleum,

Petrochemical and Natural

Gas Industries "

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺗﻠﻤﺒﻪ ﻫﺎيIPS-M-PM-105

ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﺑﺮاي ﺻﻨﺎﻳﻊ ﻧﻔﺖ و ﮔﺎز

"ﭘﺘﺮوﺷﻴﻤﻲ

IPS-M-PM-115 "Material and Equipment

Standard for Centrifugal

Pumps for General Services"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺗﻠﻤﺒﻪ ﻫﺎيIPS-M-PM-115

"ﮔﺮﻳﺰ از ﻣﺮﻛﺰ در ﺳﺮوﻳﺴﻬﺎي ﻋﻤﻮﻣﻲ

IPS-M-PM-125 "Material and Equipment

Standard for Centrifugal Fire

Water Pumps"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﺗﻠﻤﺒﻪIPS-M-PM-125

"ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ آب آﺗﺶ ﻧﺸﺎﻧﻲ

3

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

IPS-M-PM-130 "Material and Equipment

Standard

for

Positive

Displacement

Pumps

Reciprocating"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﺗﻠﻤﺒﻪIPS-M-PM-130

"ﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ –رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

IPS-M-PM-135 "Material and Equipment

Standard for Light Duty

Centrifugal Pumps"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﺗﻠﻤﺒﻪIPS-M-PM-135

"ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ در ﻛﺎرﺑﺮدﻫﺎي ﺳﺒﻚ

IPS-M-PM-140 "Material and Equipment

Standard

for

Positive

Displacement

Pumps

Rotary"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﺗﻠﻤﺒﻪIPS-M-PM-140

"ﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ – دوار

IPS-M-PM-150 "Material and Equipment

Standard

for

Positive

Displacement

Pumps

Controlled Volume"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﺗﻠﻤﺒﻪIPS-M-PM-150

ﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ – ﺑﺎ ﺣﺠﻢ ﻛﻨﺘﺮل

"ﺷﺪه

IPS-M-PM-160 "Material and Equipment

Standard

for

Positive

Displacement, Oil SealedRotary Vacuum Pumps"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﺗﻠﻤﺒﻪIPS-M-PM-160

ﺑﺎ ﻧﺸﺖ،ﻫﺎي ﺧﻼء دوار ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ

"ﺑﻨﺪ روﻏﻨﻲ

IPS-M-PM-170 "Material and Equipment

Standard for Axial and

Centrifugal Compressors and

Expander Compressors for

Petroleum Chemical and Gas

Industry Services"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰ ﺑﺮايIPS-M-PM-170

ﮔﺮﻳﺰ از ﻣﺮﻛﺰ و،ﻛﻤﭙﺮﺳﻮرﻫﺎي ﻣﺤﻮري

ﻛﻤﭙﺮﺳﻮرﻫﺎي اﻧﺒﺴﺎﻃﻲ ﺑﺮاي اﺳﺘﻔﺎده در

" ﺷﻴﻤﻴﺎﻳﻲ و ﮔﺎز،ﺻﻨﺎﻳﻊ ﻧﻔﺖ

IPS-M-PM-180 "Material and Equipment

Standard

for

Package

Integrally Geared Centrifugal

Compressors for Utility &

Instrument "

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﻛﻤﭙﺮﺳﻮرﻫﺎيIPS-M-PM-180

ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﭼﻨﺪ ﻣﺤﻮر ﺗﺮﻛﻴﺒﻲ ﺑﺮاي

"ﺳﻴﺴﺎﺗﻲ و اﺑﺰار دﻗﻴﻖĤﺳﺮوﻳﺴﻬﺎي ﺗ

IPS-M-PM-200 "Material and Equipment

Standard for Reciprocating

Compressors for Process

Services"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-200

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ در

"ﺳﺮوﻳﺴﻬﺎي ﻓﺮاﻳﻨﺪي

IPS-M-PM-211 "Material and Equipment

Standard for Reciprocating

Compressors for Utility &

Instrument Air Services"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-211

ﺳﻴﺴﺎتĤﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ در ﺗ

"و ﺳﺮوﻳﺴﻬﺎي ﻫﻮاي اﺑﺰار دﻗﻴﻖ

IPS-M-PM-220 "Material and Equipment

Standard

for

Positive

Displacement CompressorsRotary"

ﺑﺮاي

IPS-M-PM-230 "Material and Equipment

Standard for Special Purpose

Centrifugal Fans"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﻓﻦ ﻫﺎيIPS-M-PM-230

"ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﺑﺮاي ﻣﺼﺎرف وﻳﮋه

4

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰاتIPS-M-PM-220

" دوار-ﻛﻤﭙﺮﺳﻮرﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

IPS-M-PM-235 "Material and Equipment

Standard for General Purpose

Centrifugal Fans"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﻓﻦ ﻫﺎيIPS-M-PM-235

"ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﺑﺮاي ﻣﺼﺎرف ﻋﻤﻮﻣﻲ

IPS-M-PM-240 "Material and Equipment

Standard for General Purpose

Steam Turbines"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات در ﺗﻮرﺑﻴﻨﻬﺎيIPS-M-PM-240

"ﺑﺨﺎر ﻣﻮرد اﺳﺘﻔﺎده در ﻣﺼﺎرف ﻋﻤﻮﻣﻲ

IPS-M-PM-250 "Material and Equipment

Standard for Special Purpose

Steam

Turbines"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات در ﺗﻮرﺑﻴﻨﻬﺎيIPS-M-PM-250

"ﺑﺨﺎر ﺑﺎ ﻣﺼﺎرف وﻳﮋه

IPS-M-PM-260 "Material and Equipment

Standard for Gas Turbines"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات در ﺗﻮرﺑﻴﻨﻬﺎيIPS-M-PM-260

"ﮔﺎزي

IPS-M-PM-290 "Material and Equipment

Standard for Reciprocating

Internal Combustion Engines

ﺗﺠﻬﻴﺰات ﺑﺮاي

"اﺳﺘﺎﻧﺪارد ﻣﻮاد وIPS-M-PM-290

"ﻣﻮﺗﻮرﻫﺎي اﺣﺘﺮاق داﺧﻠﻲ رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

IPS-M-PM-320 "Material and Equipment

Standard for Lubrication,

Shaft Sealing and Control oil

Systems an Auxiliaries for

Process Services"

ﺗﺠﻬﻴﺰات ﺑﺮاي

"اﺳﺘﺎﻧﺪارد ﻣﻮاد وIPS-M-PM-320

ﺳﻴﺴﺘﻤﻬﺎي، ﻧﺸﺖ ﺑﻨﺪي ﺷﻔﺖ،رواﻧﻜﺎري

روﻏﻦ ﻛﻨﺘﺮل و ﺗﺠﻬﻴﺰات ﺟﺎﻧﺒﻲ ﺑﺮاي

"ﺳﺮوﻳﺴﻬﺎي ﻓﺮاﻳﻨﺪي

IPS-M-PM-330 "Material and Equipment

Standard for Mixers"

" "اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮاي ﻫﻤﺰنﻫﺎIPS-M-PM-330

اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ-3

3. GENERAL REQUIREMENTS

زﻣﺎن ﺗﺤﻮﻳﻞ1-3

3.1 Delivery Time

در.زﻣﺎن ﺗﺤﻮﻳﻞ ﺑﺎﻳﺪ ﺑﺎ زﻣﺎﻧﺒﻨﺪي ﭘﺮوژه ﻫﻤﺨﻮاﻧﻲ داﺷﺘﻪ ﺑﺎﺷﺪ

ﺻﻮرﺗﻴﻜﻪ زﻣﺎن ﺗﺤﻮﻳﻞ ﺧﺪﺷﻪ اي دردوره ﺿﻤﺎﻧﺖ ﻛﺎﻻ وارد ﻧﺴﺎزد

ﺑﺎﻳﺪ ﻧﺰدﻳﻜﺘﺮ ﺑﻮدن زﻣﺎن ﺗﺤﻮﻳﻞ ﺑﻪ زﻣﺎﻧﺒﻨﺪي ﭘﺮوژه را ﺑﻪ ﻋﻨﻮان

.اوﻟﻮﻳﺖ در ارزﻳﺎﺑﻲ ﺗﺠﻬﻴﺰات ﺗﻠﻘﻲ ﻧﻤﻮد

Delivery time shall meet project schedule. The

closer delivery times to project schedule shall

be considered as priority in evaluation of

equipment provided that this does not

jeopardize the guarantee period.

ﺗﺠﺮﺑﻴﺎت و اﻋﺘﺒﺎر ﻓﺮوﺷﻨﺪه2-3

3.2 Vendor’s Experience and Reputation

ﻓﺮوﺷﻨﺪه ﺑﺎﻳﺪ از ﺗﺠﺮﺑﻪ و اﻋﺘﺒﺎر ﻣﻨﺎﺳﺒﻲ در ﺳﺎﺧﺖ ﺗﺠﻬﻴﺰات و

ﻓﺮوﺷﻨﺪه ﻫﺎي اﺻﻠﻲ و ﻓﺮﻋﻲ ﺑﺎ.ﻟﻮازم ﺟﺎﻧﺒﻲ ﺑﺮﺧﻮردار ﺑﺎﺷﺪ

ﺗﺠﺮﺑﻴﺎت و اﻋﺘﺒﺎر ﺑﻴﺸﺘﺮ و ﺑﻬﺘﺮ ﺑﺎﻳﺪ در ارزﻳﺎﺑﻴﻬﺎ اوﻟﻮﻳﺖ و ارﺟﻌﻴﺖ

.داﺷﺘﻪ ﺑﺎﺷﻨﺪ

و ﻳﺎ،آﻧﻬﺎ ﻫﻤﭽﻨﻴﻦ ﺑﺎﻳﺪ در ﻟﻴﺴﺖ ﻓﺮوﺷﻨﺪه ﻫﺎي ﻣﻮرد ﺗﺎﻳﻴﺪ ﺑﻮده

ﺧﻮد را از ﺷﺮﻛﺘﻬﺎي ﻣﻄﺮح ﺑﺎزرﺳﻲAPI ﮔﻮاﻫﻴﻨﺎﻣﻪ اﻧﻄﺒﺎق ﺑﺎ

.ﺷﺨﺺ ﺛﺎﻟﺚ ﺑﻴﻦ اﻟﻤﻠﻠﻲ درﻳﺎﻓﺖ ﻧﻤﻮده ﺑﺎﺷﻨﺪ

Vendors shall be well reputed and experienced

in manufacturing of equipment and ancillaries.

The more reputed and experienced vendors and

sub vendors are preferred and shall have

preference in evaluation.

They shall be in Purchaser’s Approved Vendor

List, or have API conformity certificate from a

well-known international third party Inspection

Company.

ﺟﺎﻧﺸﻴﻦ ﭘﺬﻳﺮي3-3

3.3 Interchangeability

، ﺟﺎﻧﺸﻴﻦ ﭘﺬﻳﺮي ﻗﻄﻌﺎت ﺗﺠﻬﻴﺰات، ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ ﺻﺮﻓﻪ اﻗﺘﺼﺎدي

اﻧﺘﺨــــــﺎب.ﻓﺎﻛﺘﻮر ﻣﻬﻤﻲ در ارزﻳــﺎﺑﻲ ﻣﻨﺎﻗﺼﺎت ﺗﻠﻘﻲ ﻣﻲ ﮔﺮدد

Regarding cost saving, the interchangeability of

equipment parts is an important factor at the

time of bid evaluation. Selection of those

5

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

ﺗﺠﻬﻴﺰاﺗﻲ ﻛﻪ ﻋﻤﻠﻜﺮد آﻧﻬﺎ در وزارت ﻧﻔﺖ اﻳﺮان رﺿﺎﻳﺘﺒﺨﺶ ﺑﻮده

اﺳﺖ ﺑﺎﻳﺪ ﻧﺴﺒﺖ ﺑﻪ ﺷﺮﻛﺘﻬﺎي ﺑﺎ ﻋﻤﻠﻜﺮد ﻣﺤﺪود در ﻣﻨﻄﻘﻪ

.اوﻟﻮﻳﺖ داﺷﺘﻪ ﺑﺎﺷﻨﺪ

equipment whose operation have been

satisfactory in Iranian ministry of petroleum

shall take precedence over those with limited

references in the region.

ﺿﻤﺎﻧﺖ و ﺗﻌﻬﺪ4-3

3.4 Guarantee and Warranty

ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ اﻳﻨﻜﻪ ﺗﺠﻬﻴﺰات ﺗﺎﻣﻴﻦ ﺷﺪه ﺑﺎﻳﺪ در ارﺗﺒﺎط ﺑﺎ ﻋﻤﻠﻜﺮد

ﺿﻤﺎﻧﺘﻬﺎي ﻃﻮﻻﻧﻲ ﺗﺮ، ﺟﻨﺲ و ﻛﺎراﻳﻲ ﺗﻀﻤﻴﻦ ﺷﻮد،ﻣﻨﺎﺳﺐ

ﺑﻬﻤﺮاه داﻣﻨﻪ ﭘﻮﺷﺶ وﺳﻴﻌﺘﺮ ارﺟﻊ ﺧﻮاﻫﺪ ﺑﻮد و ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد ﺑﻪ

.ﻋﻨﻮان اﻣﺘﻴﺎز ﻣﺜﺒﺖ در ﺗﺤﻠﻴﻞ ﻓﻨﻲ ﻣﻨﺎﻗﺼﺎت در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد

Regarding that, supplied equipment shall be

guaranteed for proper performance, material

and workmanship, longer guarantee presides

with extended scopes are preferred and should

be positively weighted in technical bid analysis.

ﺧﺪﻣﺎت ﭘﺲ از ﻓﺮوش5-3

3.5 After Sales Services

ﻓﺮوﺷﻨﺪه ﻫﺎ ﺑﺎﻳﺪ ﺧﺪﻣﺎت ﭘﺲ از ﻓﺮوش ﺗﺠﻬﻴﺰات را ﺿﻤﺎﻧﺖ

ﺷﺮﻛﺘﻬﺎﻳﻲ ﻛﻪ ﻛﺎرﮔﺎﻫﻬﺎي ﺧﺪﻣﺎت در اﻳﺮان دارﻧﺪ داراي.ﻧﻤﺎﻳﻨﺪ

.ارﺟﻌﻴﺖ ﻣﻲ ﺑﺎﺷﻨﺪ

راﻫﻨﻤﺎﻳﻲ ﻫﺎي ﻓﻨﻲ ﺗﻮﺳﻂ،ﺧﺪﻣﺎت ﭘﺲ از ﻓﺮوش ﺷﺎﻣﻞ ﺗﻌﻤﻴﺮات

ﺳﺎزﻧﺪه و رﻓﺘﺎر ﮔﺬﺷﺘﻪ ﺳﺎزﻧﺪه ﺑﻪ ﻋﻨﻮان اوﻟﻮﻳﺖ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﻣﻲ

.ﺷﻮﻧﺪ

Regarding that, vendors shall guarantee after

sale services of the equipment. Those

companies which have service shops in I.R. of

Iran are preferred.

After sale services including any repair and

technical guidance by the manufacturer and its

previous behavior as a preference.

ﺗﺎﻣﻴﻦ ﻗﻄﻌﺎت ﻳﺪﻛﻲ6-3

3.6 Spare Parts Supply

از آﻧﺠﺎﺋﻴﻜﻪ ﻓﺮوﺷﻨﺪه ﺑﺎﻳﺪ ﺗﺎﻣﻴﻦ ﻗﻄﻌﺎت ﻳﺪﻛﻲ ﺗﺠﻬﻴﺰات ﺧﺮﻳﺪاري

ﺷﺪه و ﺗﺠﻬﻴﺰات ﺟﺎﻧﺒﻲ آﻧﺮا ﺣﺪاﻗﻞ ﺑﻪ ﻣﺪت زﻣﺎن ﻣﺸﺨﺺ ﺷﺪه

ﻟﺬا ﺳﺎزﻧﺪﮔﺎﻧﻲ ﻛﻪ،در ﻣﺪارك درﺧﻮاﺳﺖ ﻛﺎﻻ ﺗﻀﻤﻴﻦ ﻧﻤﺎﻳﺪ

اﻳﻨﮕﻮﻧﻪ ﺧﺪﻣﺎت را ﺑﺮاي ﻣﺪت زﻣﺎن ﻃﻮﻻﻧﻲ ﺗﺮي ﺗﻀﻤﻴﻦ

.ﻣﻲﻧﻤﺎﻳﻨﺪ ﺑﺎﻳﺪ در اوﻟﻮﻳﺖ ﻗﺮار ﮔﻴﺮﻧﺪ

Since the vendor shall warrant the supply of

spare parts for the purchased equipment and

auxiliaries at least for the time specified in the

material requisition, those vendors that warrant

these services for longer period shall considered

as a preference.

اﻧﺪازه و وزن7-3

3.7 Size and Weight

ﻣﻬﻨﺪس ﭘﺮوژه ﺑﺎﻳﺪ در ارﺗﺒﺎط ﺑﺎ ﻣﺎﺷﻴﻦ آﻻت ﻛﻠﻴﻪ ﺟﻮاﻧﺐ اﻧﺪازه و

وزن ﺗﺠﻬﻴﺰات را ﻣﺪ ﻧﻈﺮ ﮔﺮﻓﺘﻪ و اوﻟﻮﻳﺘﻬﺎي ﻣﻨﺎﺳﺐ را اﻋﻤﺎل

.ﻧﻤﺎﻳﺪ

For each machine the project engineer shall

study all aspects of size and weight of

equipment and consider any suitable

preferences.

ﺳﻬﻮﻟﺖ ﭘﻴﺎده ﺳﺎزي اﺟﺰاء و ﺗﻌﻤﻴﺮات8-3

3.8 Ease of Dismantling and Repair

ﺑﺎ ﻃﺮاﺣﻲ ﻣﻨﺎﺳﺐ ﻣﻤﻜﻦ اﺳﺖ زﻣﺎن و ﻫﺰﻳﻨﻪ ﻫﺎي ﻧﺎﺷﻲ از

ﺗﻌﻤﻴﺮات در ﺗﺠﻬﻴﺰاﺗﻲ ﻛﻪ ﭘﻴﺎده ﺳﺎزي اﺟﺰاء و ﺗﻌﻤﻴﺮ آﻧﻬﺎ آﺳﺎﻧﺘﺮ

ﻣﻬﻨﺪس ﭘﺮوژه ﺑﺎﻳﺪ ﺟﺰﺋﻴﺎت ﭘﻴﺎده ﺳﺎزي اﺟﺰاء. ﻛﺎﻫﺶ ﻳﺎﺑﺪ،اﺳﺖ

ﺗﺠﻬﻴﺰاﺗﻲ ﻛﻪ ﺑﻪ.و ﺗﻌﻤﻴﺮ ﺗﺠﻬﻴﺰات را ﻣﻮرد ﻣﻄﺎﻟﻌﻪ ﻗﺮار دﻫﺪ

آﺳﺎﻧﻲ ﭘﻴﺎده ﺳﺎزي و ﺗﻌﻤﻴﺮ ﻣﻲ ﺷﻮﻧﺪ ﺑﺎﻳﺪ در ارزﻳﺎﺑﻲ ﻓﻨﻲ

.ﻣﻨﺎﻗﺼﺎت در اوﻟﻮﻳﺖ ﺑﺎﺷﻨﺪ

Repair time and costs may be reduced by proper

design of equipment for ease of dismantling and

repair. Project Engineer shall study repair and

disassembling details of the equipment.

Equipment that is easily disassembled and

repaired shall be preceded in technical

evaluation.

راﻧﺪﻣﺎن و ﻣﻴﺰان ﻣﺼﺮف اﻧﺮژي9-3

3.9 Efficiency and Energy Consumption

ﻧﻈﺮ ﺑﻪ اﻓﺰاﻳﺶ ﻫﺰﻳﻨﻪﻫﺎي ﻋﻤﻠﻴﺎﺗﻲ در ﺗﺠﻬﻴﺰاﺗﻲ ﻛﻪ راﻧﺪﻣﺎن ﻛﻢ و

ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﺗﺠﻬﻴﺰات ﺑﺎ راﻧﺪﻣﺎن،ﻣﺼﺮف اﻧﺮژي ﺑﺎﻻﻳﻲ دارﻧﺪ

.ﺑﺎﻻ و ﻣﻴﺰان ﻣﺼﺮف اﻧﺮژي ﻛﻤﺘﺮ در اوﻟﻮﻳﺖ ﻗﺮار ﮔﻴﺮﻧﺪ

Since low efficiency and high energy

consumption of the equipment will increase the

operation costs, equipment with high efficiency

and low energy consumption should be

considered as a preference.

6

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

ﻣﻴﺰان اﻧﻄﺒﺎق ﺑﺎ اﺳﺘﺎﻧﺪاردﻫﺎ-4

4. COMPLIANCE WITH STANDARDS

ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﻣﻬﻨﺪس ﭘﺮوژه اﻧﻄﺒﺎق ﺗﺠﻬﻴﺰ ﺑﺎ داده ﺑﺮﮔﻪ ﻫﺎ و

( را ﺑﺮرﺳﻲ ﻧﻤﺎﻳﺪ و در2 اﺳﺘﺎﻧﺪاردﻫﺎي ذﻳﺮﺑﻂ )ﻣﻨﺪرج در ﺑﻨﺪ

،ﺻﻮرﺗﻴﻜﻪ ﺗﻔﺎوﺗﻬﺎﻳﻲ ﺑﺎ اﺳﺘﺎﻧﺪاردﻫﺎي ﻣﺮﺑﻮﻃﻪ ﻣﺸﺎﻫﺪه ﺷﻮد

. ﻣﺮﺑﻮﻃﻪ آﻧﺮا ذﻛﺮ ﻧﻤﺎﻳﺪQAR ﻣﻬﻨﺪس ﭘﺮوژه ﺑﺎﻳﺪ در

project Engineer should check the compliance

of the equipment with appropriate data sheets

and Standards(refer to clause 2). In case of

deviations from related standard, project

engineer shall indicate them in respective QAR.

ﭼﻜﻴﺪه-5

5. SUMMARY

ﻣﻬﻨﺪس ﭘﺮوژه ﺑﺎﻳﺪ ارﺟﺤﻴﺖ ﻫﺎ و اوﻟﻮﻳﺖ ﻫﺎي ﻫﺮ ﺗﺠﻬﻴﺰ را ﺑﺎ

ﺗﻮﺟﻪ ﺑﻪ اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ ﻛﻪ در ﺑﻨﺪ دوم ذﻛﺮ ﺷﺪه ﻣﺸﺨﺺ ﻧﻤﺎﻳﺪ و

ﻫﻤﭽﻨﻴﻦ اﻟﺰاﻣﺎت ﺧﺎص آن را ﺑﺮ اﺳﺎس اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮط در

. ﻣﺘﺬﻛﺮ ﺷﻮدQAR ﮔﺰارش

ﻣﺎﺷﻴﻦ آﻻت دوار را ﻣﻲ ﺗﻮان ﺑﺮ اﺳﺎس ﻣﻴﺰان اﻧﻄﺒﺎق آﻧﻬﺎ ﺑﺎ

رده ﺑﻨﺪي ﻧﻤﻮد ﺗﺎ ﻓﺮاﻳﻨﺪ ﺗﻬﻴﻪ آﻧﻬﺎ ﺗﺴﻬﻴﻞIPS اﺳﺘﺎﻧﺪاردﻫﺎي

.ﺷﻮد

Project engineer shall indicate in Quotation

Analysis Report the preference of equipment

quoted, according to general requirements noted

in clause 2 and also specific requirements

indicated in appropriate standard.

Rotating machines may be sorted according to

their compliance with IPS Standards in order to

facilitate procurement procedure.

7

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

APPENDICES

ﭘﻴﻮﺳﺖﻫﺎ

APPENDIX A

ﭘﻴﻮﺳﺖ اﻟﻒ

QUOTATION ANALYSIS REPORTS

ﮔﺰارﺷﺎت ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﻫﺎي ﺧﺮﻳﺪ

ﮔﺰارﺷﻬﺎي ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﻫﺎ در ﻣﺎﺷﻴﻦ آﻻت ﻣﺨﺘﻠﻒ ﺑﻪ ﺻﻮرت

:زﻳﺮ ﻣﻲ ﺑﺎﺷﻨﺪ

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از1-اﻟﻒ

ﻣﺮﻛﺰ

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي ﺗﻠﻤﺒﻪ ﻫﺎي رﻓﺖ و2-اﻟﻒ

ﺑﺮﮔﺸﺘﻲ

Quotation analysis reports for different

machineries are as follows:

A1- QUOTATION ANALYSES REPORT

FOR CENTRIFUGAL PUMPS

A2- QUOTATION ANALYSIS REPORT FOR

RECIPROCATING PUMPS

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و3-اﻟﻒ

ﺑﺮﮔﺸﺘﻲ

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻣﺼﺎرف4-اﻟﻒ

ﻋﻤﻮﻣﻲ

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻣﺼﺎرف5-اﻟﻒ

وﻳﮋه

A3- QUOTATION ANALYSIS REPORT FOR

RECIPROCATING COMPRESSOR

A4- QUOTATION ANALYSIS REPORT FOR

GENERAL PURPOSE STEAM TURBINE

A5- QUOTATION ANALYSIS REPORT FOR

SPECIAL PURPOSE STEAM TURBINE

A6- QUOTATION ANALYSIS REPORT FOR

RECIPROCATING INTERNAL

COMBUSTION ENGINES

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي ﻣﻮﺗﻮرﻫﺎي اﺣﺘﺮاق6-اﻟﻒ

داﺧﻠﻲ رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

A7- QUOTATION ANALYSIS REPORT FOR

FANS AND BLOWERS

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﻓﻦ ﻫﺎ و دﻣﻨﺪه ﻫﺎ7-اﻟﻒ

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﻛﻤﭙﺮﺳﻮرﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ8-اﻟﻒ

A8- QUOTATION ANALYSIS REPORT FOR

CENTRIFUGAL COMPRESSORS

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﺗﻮرﺑﻴﻦ ﮔﺎزي9-اﻟﻒ

A9- QUOTATION ANALYSIS REPORT FOR

GAS TURBINE

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﺗﻮرﺑﻴﻦ اﻧﺒﺴﺎﻃﻲ10-اﻟﻒ

A10- QUOTATION ANALYSIS REPORT

FOR TURBO-EXPANDER

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي ﻫﻤﺰنﻫﺎ11-اﻟﻒ

A11- QUOTATION ANALYSIS REPORT

FOR MIXERS

8

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

APPENDIX B

ﭘﻴﻮﺳﺖ ب

CENTRIFUGAL PUMPS TECHNICAL

BID EVALUATION

ارزﻳﺎﺑﻲ ﻣﻨﺎﻗﺼﺎت ﻓﻨﻲ در ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

ﻣﻘﺪﻣﻪ1-ب

B.1 INTRODUCTION

اﻳﻦ ﭘﻴﻮﺳﺖ ﺑﻪ ﻣﻨﻈﻮر اراﺋﻪ راﻫﻜﺎرﻫﺎﻳﻲ ﺟﻬﺖ ارزﻳﺎﺑﻲ ﻣﻨﺎﻗﺼﺎت

ﺑﻪ. ﺗﻬﻴﻪ ﺷﺪه اﺳﺖ،ﻓﻨﻲ درﻳﺎﻓﺖ ﺷﺪه در ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

ﻧﻜﺎت ذﻳﻞ ﺑﺎﻳﺪ ﻣﻮرد،ﻃﻮر ﻛﻠﻲ در ﻓﺮآﻳﻨﺪ اﻧﺘﺨﺎب ﺗﻠﻤﺒﻪ ﻣﻨﺎﺳﺐ

:ﺑﺮرﺳﻲ ﻗﺮار ﮔﻴﺮﻧﺪ

This appendix is intended to provide assistance

in evaluating the received technical bids of

centrifugal pumps. Generally following points

should be investigated in a proper pump

selection:

ﻗﺎﺑﻠﻴﺖ اﻃﻤﻴﻨﺎن-I

I. Reliability

ﺳﺎدﮔﻲ

اﺳﺘﺤﻜﺎم

ﻳﺎﺗﺎﻗﺎن و رواﻧﻜﺎري

• Simplicity

• Rigidity

• Bearing and lubrication

راﻧﺪﻣﺎن-II

II. Efficiency

ﺳﺮﻋﺖ ﻣﺤﺮك

ﺳﺮﻋﺖ ﺗﻠﻤﺒﻪ

ﻣﻮاد و روﺷﻬﺎي رﻳﺨﺘﻪ ﮔﺮي

• Drive speed

• Pump speed

• Materials and Casting Techniques

ﺳﻬﻮﻟﺖ ﻧﮕﻬﺪاري-III

III. Ease of Maintenance

ﭘﺎﻳﺶ ﻋﻤﻠﻜﺮد ﺗﻠﻤﺒﻪ

• Monitoring of Pump Performance

ﻫﺰﻳﻨﻪ-IV

IV. Cost

ﻫﺰﻳﻨﻪ ﺳﺮﻣﺎﻳﻪ اي

ﻫﺰﻳﻨﻪ ﻋﻤﻠﻴﺎﺗﻲ

ﺗﺤﻠﻴﻞ ﻫﺰﻳﻨﻪ در ﻋﻤﺮ ﻛﺎري

ﺧﺪﻣﺎت ﻓﻨﻲ و ﭘﺲ از ﻓﺮوش

• Capital Expenditure (CAPEX)

• Operating Expenditure (OPEX)

• Performing Life Cycle Cost Analysis

• After Sales and Technical Services

،دو ﻋﺎﻣﻞ ﻣﻬﻢ در ارﺗﺒﺎط ﺑﺎ ارزﻳﺎﺑﻲ ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

در اداﻣﻪ ﺑﻪ ﺗﺸﺮﻳﺢ.ﺳﺮﻋﺖ وﻳﮋه و ﺳﺮﻋﺖ وﻳﮋه ﻣﻜﺶ ﻣﻲ ﺑﺎﺷﻨﺪ

اﻳﻦ دو ﻋﺎﻣﻞ ﻣﻬﻢ ﭘﺮداﺧﺘﻪ و راﻫﻜﺎرﻫﺎي اﺳﺘﻔﺎده ﻣﺆﺛﺮ از اﻳﻦ

.ﻋﻮاﻣﻞ ﻋﻨﻮان ﺷﺪه اﺳﺖ

There are two important parameters, namely,

specific speed and suction specific speed, which

are extremely useful in evaluating centrifugal

pumps. Hereunder, it is devoted to make a

better understanding of these two key factors

and provide a guideline in using them

effectively.

ﺳﺮﻋﺖ وﻳﮋه2-ب

B.2 SPECIFIC SPEED

ﺳﺮﻋﺖ وﻳﮋه ﻋﺎﻣﻞ ﻛﻠﻴﺪي در ﻣﻘﺎﻳﺴﻪ ﺗﻠﻤﺒﻪ ﻫﺎي ﻣﺨﺘﻠﻒ ﺑﻮده و

در اﻧﺘﺨﺎب ﭘﺮﺑﺎزده ﺗﺮﻳﻦ و اﻗﺘﺼﺎدي ﺗﺮﻳﻦ ﺗﻠﻤﺒﻪ ﻫﺎ ﺗﻌﻴﻴﻦ ﻛﻨﻨﺪه

.اﺳﺖ

:ﺳﺮﻋﺖ وﻳﮋه از ﻃﺮﻳﻖ ﻓﺮﻣﻮل ذﻳﻞ ﺗﻌﺮﻳﻒ ﻣﻲ ﺷﻮد

Specific speed is a key factor in comparing

various pumps and selecting the most efficient

and economical pumping equipment.

Specific speed is defined by the formula:

(Eq. 1)

Ns

N Q

H 0.75

9

(1 )ﻣﻌﺎدﻟﻪ

)IPS-E-PM-110 (2

ﻣﺮداد Jul. 2009/ 1388

ﻛﻪ در آن

Where,

: Nﺳﺮﻋﺖ ﻛﺎري در واﺣﺪ دور در دﻗﻴﻘﻪ

: Qﻧﺮخ ﺟﺮﻳﺎن ﺳﻴﺎل در واﺣﺪ ﻣﺘﺮ ﻣﻜﻌﺐ ﺑﺮ ﺳﺎﻋﺖ

: Hارﺗﻔﺎع ﺗﻮﻟﻴﺪ ﺷﺪه در واﺣﺪ ﻣﺘﺮ

N= operating speed in rpm

Q= flow rate in m3/h

H= head developed in meters

Specific speed is always calculated at the best

efficiency point (BEP) with maximum impeller

diameter and single stage only.

ﺳﺮﻋﺖ وﻳﮋه ﻫﻤﻮاره در ﻧﻘﻄﻪ ﺑﻬﺘﺮﻳﻦ ﺑﺎزدﻫﻲ و ﺣﺪاﻛﺜﺮ ﻗﻄﺮ ﭘﺮواﻧﻪ

و ﺗﻠﻤﺒﻪ ﻫﺎي ﺗﻚ ﻣﺮﺣﻠﻪ اي ﻣﺤﺎﺳﺒﻪ ﻣﻲ ﺷﻮد.

For multistage pumps, specific speed is

calculated on a basis of head per stage, and

for a double suction impeller, specific speed

is calculated using half the flow rate.

در ﺗﻠﻤﺒﻪ ﻫﺎي ﭼﻨﺪ ﻣﺮﺣﻠﻪ اي ﺳﺮﻋﺖ وﻳﮋه ﺑﺮ ﭘﺎﻳﻪ ارﺗﻔﺎع ﺳﻴﺎل در

ﻫﺮ ﻣﺮﺣﻠﻪ ﻣﺤﺎﺳﺒﻪ ﻣﻲ ﮔﺮدد و در ﭘﺮواﻧﻪﻫﺎي دو ﻣﻜﺸﻪ ،ﺳﺮﻋﺖ

وﻳﮋه ﺑﺎ اﺳﺘﻔﺎده از ﻧﺼﻒ ﻧﺮخ ﺟﺮﻳﺎن ﻣﺤﺎﺳﺒﻪ ﻣﻲ ﺷﻮد.

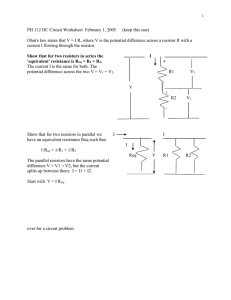

در واﻗﻊ ارﺗﺒﺎط ﻣﺸﺨﺼﻲ ﺑﻴﻦ ﺳﺮﻋﺖ وﻳﮋه ﺗﻠﻤﺒﻪ ،ﺷﻜﻞ ﻫﻨﺪﺳﻲ و

ﻛﺎراﺋﻲ آن وﺟﻮد دارد .ﺷﻜﻞ 1روﻧﺪ ﻛﻠﻲ ﺗﻐﻴﻴﺮات ﺷﻜﻞ ﻫﻨﺪﺳﻲ،

راﻧﺪﻣﺎن و ﺷﻜﻞ ﻣﻨﺤﻨﻲ ارﺗﻔﺎع ﻓﺸﺎري -ﻇﺮﻓﻴﺖ ﺑﺎ ﺳﺮﻋﺖ وﻳﮋه را

ﻧﻤﺎﻳﺶ ﻣﻲ دﻫﺪ .داده ﻫﺎي اراﺋﻪ ﺷﺪه در ﺷﻜﻞ 1دﻳﺪﮔﺎه ﻣﻨﺎﺳﺒﻲ

ﺟﻬﺖ ﺑﺮرﺳﻲ ﺻﺤﺖ ﻣﻴﺰان راﻧﺪﻣﺎن ﺗﻠﻤﺒﻪ ﻛﻪ ﺗﻮﺳﻂ ﺳﺎزﻧﺪه اراﺋﻪ

ﺷﺪه ،ﻣﻲ ﺑﺎﺷﺪ .ﺑﺮرﺳﻲ ﺻﺤﺖ ﻣﻴﺰان راﻧﺪﻣﺎن را ﻣﻲ ﺗﻮان ﺑﻪ

ﺳﺎدﮔﻲ از ﻃﺮﻳﻖ ﻛﻨﺘﺮل ﺳﺮﻋﺖ وﻳﮋه ،ﻧﺮخ ﺟﺮﻳﺎن و راﻧﺪﻣﺎن اراﺋﻪ

ﺷﺪه اﻧﺠﺎم داد .ﺑﻪ ﻋﻨﻮان ﻣﺜﺎل اﮔﺮ ﺗﻠﻤﺒﻪ اي ﺳﺮﻋﺖ وﻳﮋه اي

ﻣﻌﺎدل 40و ﻧﺮخ ﺟﺮﻳﺎﻧﻲ ﻣﻌﺎدل 115ﻣﺘﺮ ﻣﻜﻌﺐ ﺑﺮ ﺳﺎﻋﺖ داﺷﺘﻪ

ﺑﺎﺷﺪ و در ﺻﻮرﺗﻴﻜﻪ ﺳﺎزﻧﺪه ﻣﻴﺰان راﻧﺪﻣﺎن ﺗﻠﻤﺒﻪ را % 90اﻋﻼم

ﻧﻤﻮده ﺑﺎﺷﺪ ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﺧﺮﻳﺪار ﻧﺴﺒﺖ ﺑﻪ راﻧﺪﻣﺎن اﻋﻼم ﺷﺪه

ﺗﺮدﻳﺪ ﻛﻨﺪ .ﭼﻨﺎﻧﭽﻪ در ﺷﻜﻞ 1ﻣﺸﺎﻫﺪه ﻣﻲ ﺷﻮد ﺻﺤﺖ اﻳﻦ

ﻣﻴﺰان راﻧﺪﻣﺎن را ﻧﻤﻲ ﺗﻮان ﺗĤﻳﻴﺪ ﻧﻤﻮد .ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﺑﻪ ﻣﻨﻈﻮر

ﺣﺼﻮل اﻃﻤﻴﻨﺎن ﺧﺮﻳﺪار ﺑﺮرﺳﻲ راﻧﺪﻣﺎن از ﻃﺮﻳﻖ اﻧﺠﺎم آزﻣﻮن ﺑﺎ

ﺣﻀﻮر ﺷﺎﻫﺪ را از ﺳﺎزﻧﺪه درﺧﻮاﺳﺖ ﻧﻤﺎﻳﺪ.

The data presented in Fig.1 give a helpful view

in verifying the pump efficiency claimed by the

manufacturer. It may be simply achieved by

checking the specific speed, the flow rate and

instance,

considering a pump of a specific speed of 40 for

a flow rate of 115 m3/hr; if the manufacturer

claims that the efficiency of this pump is 90%,

the buyer should be suspicious As can be seen

in Fig.1, it is very doubtful as to whether this

efficiency is correct. For safety, the buyer

should demand that the claimed efficiency be

verified by a witnessed test.

ب 3-ﺳﺮﻋﺖ وﻳﮋه ﻣﻜﺶ

B.3 SUCTION SPECIFIC SPEED

ﺳﺮﻋﺖ وﻳﮋه ﻣﻜﺶ )(Nssرا ﻣﻲ ﺗﻮان ﺑﺎ ﻓﺮﻣﻮل اراﻳﻪ ﺷﺪه ﻗﺒﻠﻲ

ﻣﺤﺎﺳﺒﻪ ﻧﻤﻮد ﺑﺎ اﻳﻦ ﺗﻔﺎوت ﻛﻪ ﻣﻘﺪار NPSHﺑﻪ ﺟﺎي ﻣﺘﻐﻴﺮ H

ﻗﺮار داده ﻣﻲ ﺷﻮد.

Suction specific speed (Nss ) is calculated by the

same formula as pump specific speed (Nss) but

uses required NPSH values in place of (H).

The mathematical expression for the suction

specific speed (Nss) is:

راﺑﻄﻪ رﻳﺎﺿﻲ ﺳﺮﻋﺖ وﻳﮋه ﻣﻜﺶ ) (Nssﻋﺒﺎرﺗﺴﺖ از :

)ﻣﻌﺎدﻟﻪ (2

For

efficiency.

proposed

the

N Q

NPSHR 0.75

ﻛﻪ در آن

N SS

)(Eq. 2

Where,

: Nﺳﺮﻋﺖ ﻋﻤﻠﻴﺎﺗﻲ ﺑﺎ واﺣﺪ دور در دﻗﻴﻘﻪ

: Qﻧﺮخ ﺟﺮﻳﺎن ﻣﺘﺮ ﻣﻜﻌﺐ ﺑﺮ ﺳﺎﻋﺖ

N= operating speed in rpm

Q= flow rate in m3/h

: NPSHRﺣﺪاﻗﻞ ارﺗﻔﺎع ﻣﻜﺶ ﻣﺜﺒﺖ ﻣﻮرد ﻧﻴﺎز ﺑﻪ ﻣﺘﺮ

NPSHR= minimum required positive suction

head in meter

ﺑﻪ ﻃﻮر ﻛﻠﻲ در ﺗﻠﻤﺒﻪ ﻫﺎﻳﻲ ﻛﻪ ﻣﻴﺰان Nssﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ ،ﻛﺎراﻳﻲ

Generally, the higher Nss the value for a given

10

Jul. 2009/ 1388 ﻣﺮداد

pump, the better is its suction performance.

However, great attention should be paid in

using Nss values for comparing the suction

capabilities of different pumps.

IPS-E-PM-110 (2)

اﻟﺒﺘﻪ در ﻣﻘﺎﻳﺴﻪ ﻇﺮﻓﻴﺖ ﻣﻜﺶ ﺗﻠﻤﺒﻪ.ﻣﻜﺶ ﻧﻴﺰ ﺑﻬﺘﺮ ﺧﻮاﻫﺪ ﺑﻮد

آﻧﻬﺎ ﺑﺎﻳﺪ دﻗﺖ وﻳﮋهايNss ﻫﺎي ﻣﺨﺘﻠﻒ از ﻃﺮﻳﻖ ﻣﻘﺎﻳﺴﻪ ﻣﻘﺎدﻳﺮ

.ﺑﻪ ﺧﺮج داد

واﺑﺴﺘﻪNss ﻣﻴﺰان اﻓﺰاﻳﺶ، ﻣﺸﺎﻫﺪه ﻣﻲ ﺷﻮد2 ﭼﻨﺎﻧﭽﻪ در ﻣﻌﺎدﻟﻪ

در زﻣﺎنNss در واﻗﻊ ﻣﻘﺪار.ﺑﻪ ﻣﻴﺰان ﻧﺮخ ﺟﺮﻳﺎن ﻣﻲ ﺑﺎﺷﺪ

ﺻﻔﺮ اﺳﺖ و ﺑﺎ رﺳﻴﺪن ﻧﺮخ ﺟﺮﻳﺎن،ﻛﺎرﻛﺮد ﺑﺪون ﺟﺮﻳﺎن ﺗﻠﻤﺒﻪ

ﺟﺰﺋﻲ ﺑﻪ ﻣﻴﺰان ﻣﻌﻴﻨﻲ ﺑﻪ ﺣﺪاﻛﺜﺮ اﻓﺰاﻳﺶ ﻣﻲ ﻳﺎﺑﺪ و ﺳﭙﺲ

ﺗﺪرﻳﺠﺎ ﻛﺎﻫﺶ ﻳﺎﻓﺘﻪ و ﺑﻪ ﺻﻮرت ﻣﻨﺤﻨﻲ ﻣﺠﺎﻧﺐ ﺑﻪ ﻣﻘﺪار ﺻﻔﺮ

.ﻣﻴﻞ ﻣﻲ ﻛﻨﺪ

4500 و14000 Nssﺑﺮاي ﻣﺜﺎل اﮔﺮ دو ﺗﻠﻤﺒﻪ ﺑﺎ ﻣﻘﺎدﻳﺮ ﺣﺪاﻛﺜﺮ

در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮﻧﺪ اﻳﻦ ﻣﻘﺎدﻳﺮ ﻟﺰوﻣﺎً ﺑﻪ اﻳﻦ ﻣﻌﻨﻲ ﻛﻪ ﺗﻠﻤﺒﻪ اول

از. ﻧﻤﻲ ﺑﺎﺷﺪ،در ﻫﻨﮕﺎم ﻋﻤﻠﻜﺮد ﺑﺎ ارﺗﻔﺎع ﻣﻜﺶ ﻛﻤﺘﺮ ﺑﻬﺘﺮ اﺳﺖ

در ﻣﻘﺎدﻳﺮNss ﻃﺮﻓﻲ در ﺗﻠﻤﺒﻪ اول ﻣﻤﻜﻦ اﺳﺖ ﻛﻪ اﻧﺪازه ﺣﺪاﻛﺜﺮ

ﻧﺮخ ﺟﺮﻳﺎﻧﻲ داده ﺷﺪه ﺑﺎﺷﺪ ﻛﻪ ﺗﻠﻤﺒﻪ در ﺷﺮاﻳﻂ ﻋﻤﻠﻴﺎﺗﻲ ﻫﺮﮔﺰ ﺑﻪ

آن ﻧﻤﻲ رﺳﺪ و از ﻃﺮف دﻳﮕﺮ در ﻣﻮاردﻳﻜﻪ ﺷﺮاﻳﻂ ﻃﺒﻖ ﭘﻴﺶ

ﺑﻴﻨﻲ اﻧﺠﺎم ﺷﺪه ﺑﺎﺷﺪ ﻣﻤﻜﻦ اﺳﺖ ﺗﻠﻤﺒﻪ دوم ﻗﺎﺑﻠﻴﺘﻬﺎي ﻣﻜﺶ

.ﺑﻬﺘﺮي از ﺧﻮد ﻧﺸﺎن دﻫﺪ

درNPSH ،ﻧﻜﺘﻪ دﻳﮕﺮي ﻛﻪ ﺗﻮﺟﻪ ﺑﻪ آن ﺣﺎﺋﺰ اﻫﻤﻴﺖ اﺳﺖ

ﻣﻮرد ﻧﻴﺎزNPSH اﺳﺖ ﻛﻪ در واﻗﻊ ﺑﻪ ﻣﻴﺰان ﺣﺪاﻗﻞ2 ﻣﻌﺎدﻟﻪ

روش ﻣﺸﺨﺺ ﺟﻬﺖ ﺗﻌﻴﻴﻦ ﻣﻴﺰان ﺣﺪاﻗﻞ، در ﻣﻮاردي.دﻻﻟﺖ دارد

.ارﺗﻔﺎع ﻣﻜﺶ ﻣﻮرد ﻧﻴﺎز وﺟﻮد ﻧﺪارد

Nss اﻳﻦ ﻣﻮﺿﻮع ﻧﻴﺰ ﻣﻤﻜﻦ اﺳﺖ ﻣﻨﺠﺮ ﺑﻪ ﺣﺼﻮل ﻣﻘﺎدﻳﺮ ﻣﺨﺘﻠﻒ

ﺷﻮد ﻛﻪ ﻧﻤﻲ ﺗﻮاﻧﺪ دﻟﻴﻞ ﻣﻨﺎﺳﺒﻲ ﺑﺮاي ﻗﻀﺎوت در ﺑﻬﺘﺮ ﺑﻮدن

. ﺑﺎﻻﺗﺮ ﺑﺎﺷﺪNss ﺗﻠﻤﺒﻪ اي ﺑﺎ ﻣﻘﺪار اﺳﻤﻲ

ﺑﺮرﺳﻲ ﻧﺤﻮه ﺗﻌﻴﻴﻦ ﻣﻴﺰان،ﺑﻪ ﻣﻨﻈﻮر ﺟﻠﻮﮔﻴﺮي از ﭼﻨﻴﻦ ﺧﻄﺎﻳﻲ

ﻣﻮرد ﻧﻴﺎز و ﻣﻴﺰان ﻧﺮخ ﺟﺮﻳﺎن ﻣﻮرد اﺳﺘﻔﺎده درNPSH ﺣﺪاﻗﻞ

. ﻣﺆﻛﺪاً ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮدNss ﻣﺤﺎﺳﺒﻪ

As Eq. 2 shows, the magnitude of Nss varies

with flow rate. In fact, the Nss value of each

pump is zero at shutoff. It then rises quickly to a

certain maximum at a certain partial flow rate.

Afterwards, it starts to decrease gradually, again

asymptotically approaching the value of zero.

For instance, consider two pumps that the

maximum Nss value of one is 14000, and the

value of the other is 4500. This does not

necessarily mean that the first pump is better

than the second when operating under reduced

suction heads. On the one hand, the first pump

may be able to attain its maximum Nss value

only at a flow rate that the pump is never

expected to achieve under the given operating

conditions. On the other hand, while operating

within its assigned duties, the second pump may

possess better suction capabilities than the first.

Another pitfall may result because the NPSH

term in Eq. 2 refers to the minimum required

NPSH. There are cases in which there is no

absolute way to determine what is the minimum

required suction head.

This, again, may lead to different Nss values

without proving that the pump with the higher

value has better characteristics than pumps

with nominally lower Nss values.

To avoid such pitfalls, it is highly recommended

to check how the value of the minimum

required NPSH was determined, as well as the

flow rate to which the specified value

refers.

11

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110 (2)

Fig. 1- EFFECT OF SPECIFIC SPEED, THE IMPELLER'S-GEOMETRY, AND FLOW-RATE, ON

EFFICIENCY,

. ﺗﺎﺛﻴﺮ ﺳﺮﻋﺖ وﻳﮋه و دﺑﻲ ﺟﺮﻳﺎن روي ﺑﺎزده ﺗﻠﻤﺒﻪ-1 ﺷﻜﻞ

12

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

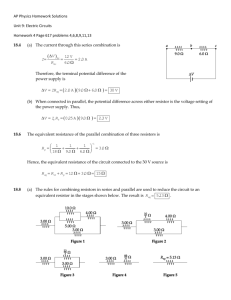

A1-QUOTATION ANALYSIS REPORT TABLE

FOR CENTRIFUGAL PUMPS

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ1-اﻟﻒ

ﺗﺎرﻳﺦ ﺻﺪور ــــــــــــ ﺻﻔﺤﻪ ــــــــــــــ ازـــــــــــــــــ وﻳﺮاﻳﺶ ـــــــــــــــــــــ

ISSUE DATE

--------

PREP'D. -----------

PAGE ------ OF-------

REV. ---------

CHE'D.- ------------

APP'D. -----------

ﺗﻬﻴﻪ ﻛﻨﻨﺪه ـــــــــــــــــــ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ــــــــــــــــــــ ﺗﺎﻳﻴﺪ ﻛﻨﻨﺪه ـــــــــــــــــ

OPERATING CONDITION

DATA

ﺷﺮاﻳﻂ ﻋﻤﻠﻴﺎﺗﻲ

دادهﻫﺎ

Pumping liquid

SITE CONDITION

QUOTATION ANALYSIS REPORT FOR

CENTRIFUGAL PUMP

ﺳﻴﺎل ﺗﻠﻤﺒﻪ ﺷﻮﻧﺪه

Pt (pumping temp.)

دﻣﺎي ﭘﻤﭙﺎژ

o

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم در

C

ﺷﺮاﻳﻂ ﺳﺎﻳﺖ

Range of Ambient Temps.:Max./Min.

Specific Gravity at PT.

وزن ﻣﺨﺼﻮص در دﻣﺎي ﭘﻤﭙﺎژ

Vapour Pressure at PT

ﻓﺸﺎر ﺑﺨﺎر در دﻣﺎي ﭘﻤﭙﺎژ

MPa(abs)

ﻟﺰﺟﺖ در دﻣﺎي ﭘﻤﭙﺎژ

Pa.s, cp

Viscosity at Pt

Altitude

Project: ------------------------------------ ﭘﺮوژه

Corrosion/ Erosion Caused by

: ﺳﺎﻳﺶ/ ﻋﻮاﻣﻞ ﺧﻮردﮔﻲ

Capacity: Normal

ﻇﺮﻓﻴﺖ ﻧﺮﻣﺎل

Rated

Differential Head

Location: ----------------------------------- ﻣﻜﺎن

ITEM No: --------------------------------- ﺷﻤﺎره دﺳﺘﮕﺎه

m

ﺷﺮاﻳﻂ ﻏﻴﺮ ﻣﻌﻤﻮل

Discharge Press

ﻓﺸﺎر ﺗﺨﻠﻴﻪ

Suction Press.

ﻓﺸﺎر ﻣﻜﺶ

MPa(ga)

اﺧﺘﻼف ﻓﺸﺎر

MPa

ﺗﻮان ﻫﻴﺪروﻟﻴﻚ

kW

Differential Press.

Hydraulic Power

Max.Suction Press.

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻣﻜﺶ

NPSH Available

ﻣﻮﺟﻮدNPSH

Others:

m

□ Dust

ﮔﺮد و ﻏﺒﺎر

Chloride Concentration

□

Fumes

دود

ppm

ﻏﻠﻈﺖ ﻛﻠﺮﻳﺪ

Elect. Area Classification

Cl ______ GR_________ DIV

□ Winterization

ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﺳﺮدﺳﻴﺮ

□ Tropicalization

ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﮔﺮﻣﺴﻴﺮ

□Not Req'd.

□ Req’d.

ﻏﻴﺮ ﻻزم

□ Not Req'd.

ﻻزم

Others

MPa(ga)

□Req’d.

ﻻزم

Service: ---------------------------------- ﻧﻮع ﺧﺪﻣﺎت

MPa(ga)

(%)

رده ﺑﻨﺪي ﻣﺤﻞ از ﻟﺤﺎظ اﻟﺰاﻣﺎت اﻟﻜﺘﺮﻳﻜﻲ

Unit no: ----------------------------------- ﺷﻤﺎره دﺳﺘﮕﺎه

m3/h

اﺧﺘﻼف ارﺗﻔﺎع

/

C

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ رﻃﻮﺑﺖ ﻧﺴﺒﻲ

------------------------------------ ﻛﺎرﻓﺮﻣﺎ

m3/h

ﻃﺮاﺣﻲ

o

ارﺗﻔﺎع از ﺳﻄﺢ درﻳﺎ

Relative Humidity: Max./Min.

Unusual Condition

Client:

/

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ دﻣﺎي ﻣﺤﻴﻂ

ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

ﻏﻴﺮ ﻻزم

ﺳﺎﻳﺮ ﻣﻮارد

Remarks:

:ﺗﻮﺿﻴﺤﺎت

m

ﺳﺎﻳﺮ ﻣﻮارد

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

دادهﻫﺎ

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

A

Manufacturer

B

C

ﺳﺎزﻧﺪه

Type:

ﻧﻮع

Model

ﻣﺪل

No.of Stages

□ HORIZ

□ VERT

اﻓﻘﻲ

□

YES

□ NO

□

YES

□ NO

□ N/A

□

□

YES

□ NO

□

YES

□

□ NO

□ N/A

□

YES

□ NO

□ N/A

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ N/A

□ YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□NO

□ N/A

ﻋﻤﻮدي

ﺗﻌﺪاد ﻣﺮاﺣﻞ

Rotation

ﺟﻬﺖ ﭼﺮﺧﺶ

Pump Speed

ﺳﺮﻋﺖ ﺗﻠﻤﺒﻪ

1ST ,2ND & 3RD Critical Speed

□ cw

□ ccw

ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

ﺧﻼف ﺟﻬﺖ ﻋﻘﺮﺑﻪ و ﺳﺎﻋﺖ

rpm

دوم و ﺳﻮم،ﺳﺮﻋﺖ ﺑﺤﺮاﻧﻲ اول

Case Split

ﻧﻮع ﺑﺮش ﭘﻮﺳﺘﻪ

□ RADIAL

□

ﺷﻌﺎﻋﻲ

Volute Type

ﻧﻮع ﺣﻠﺰوﻧﻲ

Case Support

ﺗﻜﻴﻪ ﮔﺎه ﭘﻮﺳﺘﻪ

□ SINGLE

□

ﻣﻨﻔﺮد

دوﺗﺎﻳﻲ

□ CENTERLINE

□ OTHER

در ﺻﻔﺤﻪ ﺷﺎﻣﻞ ﻣﺤﻮر

Shaft Support

ﺗﻜﻴﻪ ﮔﺎه ﻣﺤﻮر

Nozzle: Suc. ;Size, Rating,

Face & loc.

ﺟﻬﺖ و ﻣﺤﻞ،ﻛﻼس ﻓﺸﺎر، اﻧﺪازه،ﻧﺎزل ﻣﻜﺶ

Nozzle: Dis. ; Size, Rating,

Face & loc.

ﺟﻬﺖ و ﻣﺤﻞ،ﻛﻼس ﻓﺸﺎر، اﻧﺪازه،ﻧﺎزل ﻣﻜﺶ

Eff.At Rated/ Capacity at B.E.P.

DOUBLE

ﺳﺎﻳﺮ

□ OVERHUNG

□ BETWEEN BRG

ﻳﻚ ﺳﺮ درﮔﻴﺮ

دو ﺳﺮ درﮔﻴﺮ

%

B.E.P ﻇﺮﻓﻴﺖ در/راﻧﺪﻣﺎن ﻃﺮاﺣﻲ

Estimated Power: RATED

AXIAL

ﻣﺤﻮري

m 3 /h

@

kW

kW

ﻃﺮاﺣﻲ:ﺗﻮان ﺗﺨﻤﻴﻨﻲ

ﺣﺪاﻛﺜﺮ

MAX.

Npsh Required (IN WATER 3% H. DROP)

m

اﻓﺖ در ارﺗﻔﺎع آب%3 ﻣﻮرد ﻧﻴﺎز ﺑﺮاﺳﺎسNPSH

Suction Specific Speed

ﺳﺮﻋﺖ وﻳﮋه ﻣﻜﺶ

(WITH MAX IMPELLER)m3/min¸m,rpm

ﺑﺎ ﺑﺰرﮔﺘﺮﻳﻦ ﭘﺮواﻧﻪ

%

Head Rise to Shut-off/ Head @ Rated Cap.

ارﺗﻔﺎع در ﻇﺮﻓﻴﺖ ﻃﺮاﺣﻲ/ ﺣﺪاﻛﺜﺮ ارﺗﻔﺎع ﺗﻮﻟﻴﺪي در دﺑﻲ ﺻﻔﺮ

Min.flow rate :

Max.Allow. Work. Press

Temp.

ﺣﺪاﻗﻞ ﻧﺮخ ﺟﺮﻳﺎن

m3/h

. ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻛﺎري ﻣﺠﺎز

MPa(ga)

o

C

ﺣﺪاﻛﺜﺮ دﻣﺎي ﻛﺎري ﻣﺠﺎز

ydro. Test Press.(at 15oc)

MPa(ga)

15 oC ﻓﺸﺎر آزﻣﻮن ﻫﻴﺪرواﺳﺘﺎﺗﻴﻚ در

Preffered Operating Region (%rated)

(ﻣﺤﺪوده ﺗﺮﺟﻴﺤﻲ ﻋﻤﻠﻜﺮد )ﺑﺮاﺳﺎس درﺻﺪ دﺑﻲ ﻃﺮاﺣﻲ

Allowable Operating Region (% rated)

(ﻣﺤﺪوده ﻣﺠﺎز ﻋﻤﻠﻜﺮد )ﺑﺮاﺳﺎس درﺻﺪ دﺑﻲ ﻃﺮاﺣﻲ

Impeller:

ﭘﺮواﻧﻪ

□

Impeller Type

ﻧﻮع ﭘﺮواﻧﻪ

Impeller DIA. :M1N. /MAX.

Rated

ﺣﺪاﻛﺜﺮ/ﻗﻄﺮ ﭘﺮواﻧﻪ ﺣﺪاﻗﻞ

ﻃﺮاﺣﻲ

Mechanical Seal & Aux. Connection:

:ﻧﺸﺖ ﺑﻨﺪ ﻣﻜﺎﻧﻴﻜﻲ و اﺗﺼﺎﻻت ﺟﺎﻧﺒﻲ

OPEN

ﺑﺎز

□ CLOSE

ﺑﺴﺘﻪ

□ S.SUCTION □ ﻳﻚ ﻣﻜﺸﻪD.SUCTION

mm

دو ﻣﻜﺸﻪ

mm

mm

□ API CODE

API ﻛﺪ

□ MFR. Std.

ﺳﺎزﻧﺪه

اﺳﺘﺎﻧﺪارد

YES

13

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM

STANDARDS

A1-QUOTATION ANALYSIS

REPORT TABLE

FOR CENTRIFUGAL PUMPS

(CONTINUED)

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي1-اﻟﻒ

ﺗﻠﻤﺒﻪ ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

API Aux. Pipe Plan:

APIﻧﻘﺸﻪ ﻟﻮﻟﻪ ﻫﺎي ﺟﺎﻧﺒﻲ

ﺷﺴﺘﺸﻮ/ ﺧﻨﻚ ﻛﺎري ﻧﺸﺖ ﺑﻨﺪ

Seal Flush / Quench

Casing Drain Conn.

Provide with Valve & Flange

Casing Vent Conn.

Provide with Valve & Flange

اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت ﭘﻮﺳﺘﻪ

ﻫﻤﺮاه ﺑﺎ ﺷﻴﺮ و ﻓﻠﻨﺞ

□ REQUIRED

□NOT REQUIRED

□

YES

اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﮔﺎز ﭘﻮﺳﺘﻪ

ﻫﻤﺮاه ﺑﺎ ﺷﻴﺮ و ﻓﻠﻨﺞ

□ REQUIRED

□NOT REQUIRED

□

YES

□

YES

□ TILT-PAD

□ OIL RING

□

ﺣﻠﻘﻪ روﻏﻦ

Others:

□ NO

□ N/A

□ YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ NO

ﺳﺎﻳﺮ

BEARING & LUBRICATION

ﻳﺎﺗﺎﻗﺎن و رواﻧﻜﺎري

Bearing Type :

:ﻧﻮع ﻳﺎﺗﺎﻗﺎن

Radial:

Thrust:

ﺷﻌﺎﻋﻲ

□SLEEVE

ﻣﺤﻮري

□

ﻏﻼﻓﻲ

Lubrication System

ﺳﺎﻣﺎﻧﻪ رواﻧﻜﺎري

□TILT-PAD

ﺗﻮﭘﻲ

ﻟﻘﻤﻪاي

□ BALL

SLEEVE

□

□ BALL

FLINGER

ﭘﺮﺗﺎﺑﻲ

□ FORCED FEED

□ FLOOD

ﺗﻐﺬﻳﻪ ﺗﺤﺖ ﻓﺸﺎر

ﻏﻮﻃﻪ ور

:ﺳﺎﻳﺮ

Others

COUPLING

ﻛﻮﭘﻠﻴﻨﮓ

Coupling with Guard

ﻛﻮﭘﻠﻴﻨﮓ ﺑﺎ ﻣﺤﺎﻓﻆ

MFR. / Model No.

NON-LUBE FLEX. WITH NON-SPARK GUARD

ﺳﺎزﻧﺪه. /ﺷﻤﺎره ﻣﺪل

Others:

ﺳﺎﻳﺮ

ِ

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

داده ﻫﺎ

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

A

Driver

B

C

ﻣﺤﺮك

Type

ﻧﻮع

ELECT.

GAS TURBINE

ﺑﺮﻗﻲ

ﺗﻮرﺑﻴﻦ ﮔﺎز

ENGINE

STEAM TURBINE

ﻣﻮﺗﻮر

Manufacturer

ﺗﻮرﺑﻴﻦ ﺑﺨﺎر

ﺳﺎزﻧﺪه

Model

ﻣﺪل

دوم و ﺳﻮم،ﺳﺮﻋﺖ ﺑﺤﺮاﻧﻲ اول

rpm

Speed

ﺳﺮﻋﺖ

rpm

Power

ﺗﻮان

kW

Others:

ﺳﺎﻳﺮ

1ST ,2ND & 3RD Critical Speed

Baseplate:

ﺻﻔﺤﻪ ﭘﺎﻳﻪ

Type:

ﻧﻮع

COMMON

□

ﻣﻌﻤﻮﻟﻲ

□

HEAVY- DUTY□

REQUIRED□

STEEL FABR

W/Air Vent Holes

ﻣﻨﺎﻓﺬ ﺧﺮوج ﻫﻮا

Drain Connection

اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت

GEAR UNIT

□

ﻓﻮﻻدي

YES

□ NO

□ N/A

□

□ NO

□ NO

□N/A

□ N/A

□

□

YES

□ NO

□ N/A

□

□ NO

□ NO

□N/A

□ N/A

□

□

YES

□ NO

□ N/A

□ NO

□ NO

□ N/A

□ N/A

ﻣﺼﺎرف ﺳﻨﮕﻴﻦ

ﻻزم

□

REQUIRED

ﻻزم

□

□

YES

YES

YES

YES

YES

YES

ﺟﻌﺒﻪ دﻧﺪه

Manufacturer

ﺳﺎزﻧﺪه

Speed Reducer or Increaser

اﻓﺰاﻳﻨﺪه ﻳﺎ ﻛﺎﻫﻨﺪه ﺳﺮﻋﺖ

Type/ Model

TYPE/AGMA SF

ﻧﻮع/ ﻣﺪل

Gear Ratio

ﻧﺴﺒﺖ دﻧﺪه

Others:

ﺳﺎﻳﺮ

Noise Level

ﺳﻄﺢ ﺻﺪا

Materials: API Specification

MAX.

db(abs.)

API ﻣﺸﺨﺼﺎت:ﺟﻨﺲ

Casing / Impeller

/

/

/

/

/

/

/

/

ﻣﺤﻮر/ ﻏﻼف ﻣﺤﻮر

/

/

/

/

ﻗﻄﻌﺎت داﺧﻠﻲ/ ﭘﻮﺷﺶ ﮔﻠﻮﻳﻲ

/

/

/

/

ﭘﻮﺳﺘﻪ/ ﭘﺮواﻧﻪ

Impeller Wear ring/Case Wear ring

رﻳﻨﮓ ﺳﺎﻳﺸﻲ ﭘﻮﺳﺘﻪ/رﻳﻨﮓ ﺳﺎﻳﺸﻲ ﭘﺮواﻧﻪ

Shaft / Shaft Sleeve

Inner Parts / Throat Bush

Throttle Bush

ﭘﻮﺷﺶ ﺗﺮاﺗﻞ

Deviations from IPS STD.

IPSاﻧﺤﺮاف از اﺳﺘﺎﻧﺪارد

Test and Inspection

آزﻣﻮن و ﺑﺎزرﺳﻲ

Evaluation Ranking

اﻣﺘﻴﺎز ارزﻳﺎﺑﻲ

Total Price

Delivery (ex. Factory)

□A

اﻟﻒ

□B

□C

ب

ج

□D

د

ﻗﻴﻤﺖ ﻛﻞ

ﺗﺤﻮﻳﻞ از در ﻛﺎرﺧﺎﻧﻪ

Remarks

ﺗﻮﺿﻴﺤﺎت

14

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

A2-QUOTATION ANALYSIS REPORT TABLE

FOR RECIPROCATING PUMPS

اﺳﺘﺎﻧﺪارد ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي-2-اﻟﻒ

ﺗﻠﻤﺒﻪﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

ISSUE DATE ------- PAGE ------ OF----- REV. --------PREP'D. -----------

CHE'D.- -------------

ﺗﺎرﻳﺦ ﺻﺪور ــــــــــــ ﺻﻔﺤﻪ ــــــــــــــ ازـــــــــــــــــ وﻳﺮاﻳﺶ ـــــــــــــــــــــ

APP'D. -----------

ﺗﻬﻴﻪ ﻛﻨﻨﺪه ـــــــــــــــــــ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ــــــــــــــــــــ ﺗﺎﻳﻴﺪ ﻛﻨﻨﺪه ـــــــــــــــــ

OPERATING CONDITION

DATA

ﺷﺮاﻳﻂ ﻋﻤﻠﻴﺎﺗﻲ

دادهﻫﺎ

PUMPING LIQUID:

QUOTATION ANALYSIS REPORT FOR

RECIPROCATING PUMP

ﺳﻴﺎل ﺗﻠﻤﺒﻪ ﺷﻮﻧﺪه

PT (PUMPING TEMP.)

دﻣﺎي ﭘﻤﭙﺎژ

o

SITE CONDITION

ﺷﺮاﻳﻂ ﺳﺎﻳﺖ

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم در

ﺗﻠﻤﺒﻪﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

C

Range of ambient Temps.;Max./Min.

o

/

C

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ دﻣﺎي ﻣﺤﻴﻂ

SPECIFIC GRAVITY AT PUMPING TEMP.

وزن ﻣﺨﺼﻮص در دﻣﺎي ﺗﻠﻤﺒﻪ ﺷﺪن

VAPOUR PRESSURE AT PT

PROJECT:

--------------------------------------

CLIENT:

------------------------------------

ﭘﺮوژه

MPa(abs)

Unusual Condition

LOCATION ------------------------------------

CORROSION/ EROSION CAUSED BY:

Chloride Concentration

UNIT No:

------------------------------------ ﺷﻤﺎره واﺣﺪ

□ Dust

ﮔﺮد و ﻏﺒﺎر

(%)

□

Fumes

دود

ppm

ﻏﻠﻈﺖ ﻛﻠﺮﻳﺪ

Elect. Area Classification

Cl ______ GR_________ DIV

رده ﺑﻨﺪي ﻣﺤﻞ از ﻟﺤﺎظ اﻟﺰاﻣﺎت اﻟﻜﺘﺮﻳﻜﻲ

ﻇﺮﻓﻴﺖ ﻧﺮﻣﺎل

ﻃﺮاﺣﻲ ﻇﺮﻓﻴﺖ

m3/h

DIFFERENTIAL PRESS. اﺧﺘﻼف ﻫﺪ

Mpa

RATED

ﺷﺮاﻳﻂ ﻏﻴﺮ ﻣﻌﻤﻮل

ﻣﻜﺎن

ﻋﻮاﻣﻞ ﺧﻮردﮔﻲ/ ﺳﺎﻳﺶ

m3/h

CAPACITY:NORMAL

/

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ رﻃﻮﺑﺖ ﻧﺴﺒﻲ

ﻛﺎرﻓﺮﻣﺎ

Pa.s, cp

ﻟﺰﺟﺖ

m

ارﺗﻔﺎع از ﺳﻄﺢ درﻳﺎ

Relative Humidity: Max./Min.

ﻓﺸﺎر ﺑﺨﺎر

VISCOSITY AT PT

Altitude

ITEM No:

------------------------------------ ﺷﻤﺎره دﺳﺘﮕﺎه

SERVICE: ------------------------------------ ﻧﻮع ﺧﺪﻣﺎت

Winterization

Tropicalization

□ ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﺳﺮدﺳﻴﺮ

□ ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﮔﺮﻣﺴﻴﺮ

□Req’d.

□ Req’d.

ﻻزم

DISCHARGE PRESS.

ﻓﺸﺎر ﺗﺨﻠﻴﻪ

Mpa(ga)

SUCTION PRESS.

ﻓﺸﺎر ﻣﻜﺶ

Mpa(ga)

DIFFERENTIAL PRESS. اﺧﺘﻼف ﻓﺸﺎر

Mpa

HYDRAULIC POWER ﺗﻮان ﻫﻴﺪروﻟﻴﻚ

kW

MAX.SUCTION PRESS.

Others

□Not Req'd.

□Not Req'd.

ﻏﻴﺮ ﻻزم

ﺳﺎﻳﺮ ﻣﻮارد

REMARKS:

ﺗﻮﺿﻴﺤﺎت

Mpa(ga)

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻣﻜﺶ

NPSH AVAILABLE

m

ﻣﻮﺟﻮدNPSH

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

دادهﻫﺎ

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

A

MAUFACTURER

B

C

ﺳﺎزﻧﺪه

TYPE:/ MODEL

ﻣﺪل/:ﻧﻮع

NO.OF CYLINDER

ﺗﻌﺪاد ﺳﻴﻠﻨﺪر

TYPE OF DRIVER

ﻧﻮع ﻣﺤﺮك

ROTATION

ﺟﻬﺖ ﭼﺮﺧﺶ

□

□ ccw

cw

ﺧﻼف ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

DRIVER SPEED

CRANK SHAFT SPEED

SPEED REDUCER

ﺳﺮﻋﺖ ﻣﺤﺮك

rpm

ﺳﺮﻋﺖ ﻣﻴﻞ ﻟﻨﮓ

rpm

ﻛﺎﻫﻨﺪه ﺳﺮﻋﺖ

VARIABLE SPEED CHANGER

□

ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

ﻣﺘﻐﻴﻴﺮ ﻛﻨﻨﺪه ﺳﺮﻋﺖ

TYPE/AGMA SF

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

SF AGMA /ﻧﻮع

TYPE/ SF

SF / ﻧﻮع

PISTON SPEED RATED / MAX. ALLOW.

m/s

/

/

/

ﺣﺪاﻛﺜﺮ ﻣﺠﺎز/ ﺳﺮﻋﺖ ﻃﺮاﺣﻲ ﭘﻴﺴﺘﻮن

VALVE TYPE

ﻧﻮع ﺷﻴﺮ

□

□ BALL

DISC

دﻳﺴﻜﻲ

NO. OF VALVE

ﺗﻮﭘﻲ

□

YES

□ NO

□

YES

□

YES

□ NO

YES

□ NO

□ N/A

□

YES

□ NO

□

YES

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ N/A

□

YES

□ NO

□ N/A

□ N/A

□

YES

□ NO

□ N/A

ﺗﻌﺪاد ﺷﻴﺮ ﻫﺎ

NOZZLE: SUC. ;SIZE, RATING,

FACE & LOC.

NOZZLE: DIS. ;SIZE, RATING,

FACE & LOC.

، ﻛﻼس ﻓﺸﺎر، اﻧﺪازه: ﻧﺎزل ﻣﻜﺶ

ﺟﻬﺖ و ﻣﺤﻞ

، ﻛﻼس ﻓﺸﺎر، اﻧﺪازه: ﻧﺎزل دﻫﺶ

ﺟﻬﺖ و ﻣﺤﻞ

EFF. AT RATED / CAPACITY

%

راﻧﺪﻣﺎن ﻃﺮاﺣﻲ/ ﻇﺮﻓﻴﺖ

m 3 /h

@

VOLUMETRIC EFF.

راﻧﺪﻣﺎن ﺣﺠﻤﻲ

%

B.H.P.

MAX.

ﻃﺮاﺣﻲB.H.P

ﺣﺪاﻛﺜﺮ

kW

kW

DRIVER POWER

ﺗﻮان ﻣﺤﺮك

kW

: RATED

NPSH REQUIRED (IN WATER 3% H. DROP)

m

اﻓﺖ درﻫﺪ آب%3 ﻣﻮرد ﻧﻴﺎز ﺑﺮ اﺳﺎسNPSH

MIN.FLOW RATE :

MAX.ALLOW. WORK. PRESS.

TEMP.

HYDRO. TEST PRESS.(at 15oC)

RELIEF VALVE SETTING

RELIEF VALVE FEATURE

ﺣﺪاﻗﻞ ﻧﺮخ ﺟﺮﻳﺎن

m3/h

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ

ﺣﺪاﻛﺜﺮ دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ

MPa(ga)

o

C

15oCﻓﺸﺎر آزﻣﻮن ﻫﻴﺪرواﺳﺘﺎﺗﻴﻚ در

MPa(ga)

ﻓﺸﺎر ﺷﻴﺮ ﺗﺨﻠﻴﻪ

MPa(ga)

ﻣﻮﻗﻌﻴﺖ ﺷﻴﺮ ﺗﺨﻠﻴﻪ

□

BUILT-IN

داﺧﻠﻲ

□ FORCED FEED

LUBRICATION SYSTEM

COUPLING WITH GUARD :

ﺳﺎﻣﺎﻧﻪ رواﻧﻜﺎري

ﻛﻮﭘﻠﻴﻨﮓ ﺑﺎ ﻣﺤﺎﻓﻆ

AIR VENT HOLES

DRAIN CONNECTION

ANCHOR BOLTS

NOISE LEVEL

MATERIALS: API SPECIFICATION

□ BATH

ﺗﻐﺬﻳﻪ ﺗﺤﺖ ﻓﺸﺎر

□ GEAR TYPE

ﻧﻮع دﻧﺪهاي

روﻏﻦ ﺣﻤﺎم

□ DISC TYPE ﻧﻮع دﻳﺴﻜﻲ

□ ﻣﺤﺎﻓﻆ ﺿﺪ ﺟﺮﻗﻪ

□

□

YES

ﺳﺎزﻧﺪه/ ﺷﻤﺎره ﻣﺪل

/

□ COMMON

BASEPLATE: TYPE

ﺧﺎرﺟﻲ

□ OTHER-----------------------------------ﺳﺎﻳﺮ

NON-SPARK GUARD

MFR. / MODEL NO.

□

EXTERNAL

ﻧﻮع ﺻﻔﺤﻪ ﭘﺎﻳﻪ

ﻣﻌﻤﻮﻟﻲ

□ STEEL FABR.

□

□

ﻓﻮﻻدي

HEAVY- DUTY

ﻣﺼﺎرف ﺳﻨﮕﻴﻦ

ﭘﻴﭽﻬﺎي ﺗﻜﻴﻪ ﮔﺎﻫﻲ

□ REQUIRED

□ REQUIRED

□ REQUIRED

□ NOT REQUIRED

□ NOT REQUIRED

□ NOT REQUIRED

ﺳﻄﺢ ﺻﺪا

MAX. ﺣﺪاﻛﺜﺮ

ﻣﻨﺎﻓﺬﺧﺮوج ﻫﻮا

اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت

□

□

db(abs.)

API ﻣﺸﺨﺼﺎت/ﺟﻨﺲ

15

YES

YES

YES

/

□ NO

□ N/A

□

□ NO

□ NO

□ N/A

□ N/A

□

□

YES

YES

YES

/

□ NO

□ N/A

□

□ NO

□ NO

□ N/A

□ N/A

□

□

YES

YES

YES

□ NO

□ N/A

□ NO

□ NO

□ N/A

□ N/A

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

A2-QUOTATION ANALYSIS REPORT TABLE

FOR RECIPROCATING PUMPS

اﺳﺘﺎﻧﺪارد ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي-2-اﻟﻒ

ﺗﻠﻤﺒﻪﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

/

/

/

/

ﭘﻼﻧﺠﺮ ﻳﺎ ﭘﻴﺴﺘﻮن/ دﻳﺎﻓﺮاﮔﻢ

/

/

/

/

ﺷﻴﺮ/ ﺻﻔﺤﺎت ﺷﻴﺮ

/

/

/

/

CRANK SHAFT/ GEAR

ﻣﻴﻞ ﻟﻨﮓ/ ﺟﻌﺒﻪ دﻧﺪه

/

/

/

/

CAPACITY CONTROL:

ﻛﻨﺘﺮل ﻇﺮﻓﻴﺖ

CYL & COVER / CYL LINER

ﺳﻴﻠﻨﺪر و ﭘﻮﺷﺶ/ ﭘﻮﺷﺶ داﺧﻠﻲ ﺳﻴﻠﻨﺪر

PLUNGER OR PISTON / DIAPHRAGM

VALVE / VALVE SHEET

DEVIATIONS / EXCEPTION.

□STROKE

□ ﻛﻨﺎر ﮔﺬرBY-PASS ﺟﺎﺑﺠﺎﻳﻲ ﭘﻴﺴﺘﻮن

□ AUTOMATIC □ اﺗﻮﻣﺎﺗﻴﻚMANUAL دﺳﺘﻲ

□

□

YES

□ NO

□ NO

□ N/A

□ N/A

□

□

YES

YES

□ NO

□ NO

□ N/A

□ N/A

□

□

YES

YES

□ NO

□ NO

□ N/A

□ N/A

اﻧﺤﺮاﻓﺎت/ اﺳﺘﺜﻨﺎ

COMMENTS / REMARK

ACCESSORIES

YES

ﺗﻮﺿﻴﺤﺎت/ ﭘﻴﺸﻨﻬﺎدات

ﻟﻮازم ﺟﺎﻧﺒﻲ

PER REQ’D. IN THE DATA SHEET

ﻃﺒﻖ داده ﺑﺮگﻫﺎ و ﺑﻪ ﺗﻌﺪاد ﻻزم

TEST AND INSPECTION

EVALUATION RANKING

TOTAL PRICE

DELIVERY (EX. FACTORY)

آزﻣﻮن و ﺑﺎزرﺳﻲ

اﻣﺘﻴﺎز ارزﻳﺎﺑﻲ

□A

اﻟﻒ

□B

□C

□D

ب

ج

د

ﻗﻴﻤﺖ ﻛﻞ

ﺗﺤﻮﻳﻞ از در ﻛﺎرﺧﺎﻧﻪ

REMARKS:

: ﺗﻮﺿﻴﺤﺎت

COMMENTS:

: ﭘﻴﺸﻨﻬﺎدات

16

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

A3-QUOTATION ANALYSIS REPORT TABLE

FOR RECIPROCATING COMPRESSORS

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺧﺮﻳﺪ ﺑﺮاي-3-اﻟﻒ

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

ﺗﺎرﻳﺦ ﺻﺪورـــــــــ ﺻﻔﺤﻪ ــــــــ ازـــــــــــ وﻳﺮاﻳﺶ ـــــــــــــــــــــــــــــ

ISSUE DATE ------- PAGE ------ OF----- REV. --------PREP'D. -----------

CHE'D.- -------------

ﺗﻬﻴﻪ ﻛﻨﻨﺪه ـــــــــــــــ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ــــــــــــــــ ﺗﺎﻳﻴﺪ ﻛﻨﻨﺪه ــــــــــــــــ

APP'D. -----------

OPERATING CONDITION

DATA

ﺷﺮاﻳﻂ ﻋﻤﻠﻴﺎﺗﻲ

دادهﻫﺎ

GAS COMPRESSED:

QUOTATION ANALYSIS REPORT FOR

RECIPROCATING COMPRESSOR

MOL. WGT.AT INTAKE.

o

دﻣﺎي ورودي

ACTUAL DISCHARGE TEMP.

دﻣﺎي واﻗﻌﻲ ﺗﺨﻠﻴﻪ

INTAKE PRESSURE

ﻓﺸﺎر ﻣﻜﺶ

MPa(abs)

DISCHARGE PRESSURE

ﻓﺸﺎر دﻫﺶ

MPa(abs)

CORROSION/ EROSION CAUSED BY:

o

C

Range of ambient Temps.:Max/Min

PROJECT: ------------------------------

ﭘﺮوژه

ﻛﺎرﻓﺮﻣﺎ

LOCATION ------------------------------ﻣﻜﺎن

UNIT No: ------------------------------- ﺷﻤﺎره واﺣﺪ

ITEM No: ----------------------------- ﺷﻤﺎره ﻛﻤﭙﺮﺳﻮر

SERVICE: ------------------------------- ﻧﻮع ﺧﺪﻣﺎت

C

CLIENT:

ﺳﺎﻳﺶ/ﻋﻮاﻣﻞ ﺧﻮردﮔﻲ

CP CV VALUE: SUCTION / DISCHARGE

ﺷﺮاﻳﻂ ﺳﺎﻳﺖ

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

وزن ﻣﻮﻟﻜﻮﻟﻲ در ورودي

INTAKE TEMP.

SITE CONDITION

ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم در

ﮔﺎز ﻣﺘﺮاﻛﻢ ﺷﻮﻧﺪه

------------------------------

o

/

(%)

C

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ دﻣﺎي ﻣﺤﻴﻂ

Altitude

m

ارﺗﻔﺎع از ﺳﻄﺢ درﻳﺎ

Relative Humidity: Max/Min

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ رﻃﻮﺑﺖ ﻧﺴﺒﻲ

Unusual Condition

ﺷﺮاﻳﻂ ﻏﻴﺮ ﻣﻌﻤﻮل

Chloride Concentration

□ Dust

ﮔﺮد و ﻏﺒﺎر

□ Fumes

دود

ppm

ﻏﻠﻈﺖ ﻛﻠﺮﻳﺪ

Elect. Area Classification

ﻣﻘﺎدﻳﺮCV وCPﻣﻜﺶ در

/

Cl ______ GR_________ DIV

رده ﺑﻨﺪي ﻣﺤﻞ از ﻟﺤﺎظ اﻟﺰاﻣﺎت اﻟﻜﺘﺮﻳﻜﻲ

Winterization □

MIN. ∆ P BETWEEN STAGES

MPa

Tropicalization □

∆ ﺑﻴﻦ ﻣﺮاﺣﻞPﺣﺪاﻗﻞ

PRESSURE RATIO

ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﺳﺮدﺳﻴﺮ

□ Req’d.

□Not Req'd.

ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﮔﺮﻣﺴﻴﺮ

□ Req’d.

□Not Req'd.

Others

ﻧﺴﺒﺖ ﻓﺸﺎر

ﺳﺎﻳﺮ ﻣﻮارد

Z: SUCTION DISCHARGE

ﺿﺮﻳﺐ ﺗﺮاﻛﻢ ﭘﺬﻳﺮي ﻣﻜﺶ و دﻫﺶZ

MPa

DIFFERENTIAL PRESS. اﺧﺘﻼف ﻓﺸﺎر

REMARKS:

ﺗﻮﺿﻴﺤﺎت

RATED CAPACITY TOLERANCE – 0% RATED BHP TOLERANCE +0% (as per API)

kg.h, WET

*--------------------*--------------------() ﺗﺼﺤﻴﺢ ﺷﺪه

INLET m3/h, (CORRECTED)

Nm3/h

*--------------------(API –رواداري ﻇﺮﻓﻴﺖ ﻃﺮاﺣﻲ )ﺑﺮ اﺳﺎس0% رواداري ﺗﻮان ﺗﺮﻣﺰي ﻃﺮاﺣﻲ+0%

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

دادهﻫﺎ

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

A

MAUFACTURER

TYPE / MODEL

C

ﻣﺪل/ﻧﻮع

NO.OF STAGE

ﺗﻌﺪاد ﻣﺮاﺣﻞ

NO.OF CYL. / EACH STAGE

ﺗﻌﺪاد ﺳﻴﻜﻠﻬﺎ در ﻫﺮ ﻣﺮﺣﻠﻪ

TYPE OF DRIVER

ﻧﻮع ﻣﺤﺮك

ROTATION

ﺟﻬﺖ ﭼﺮﺧﺶ

□ cw

□ ccw

ﺧﻼف ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

DRIVER SPEED

ﻛﺎﻫﻨﺪه ﺳﺮﻋﺖ

VARIABLE SPEED CHANGER

ﻣﺘﻐﻴﻴﺮ ﻛﻨﻨﺪه ﺳﺮﻋﺖ

YES

TYPE/ SF

mm

/

ﻗﻄﺮ ﺳﻴﻠﻨﺪر/ﻛﻮرس ﭘﻴﺴﺘﻮن

□

□ BALL

DISC

دﻳﺴﻜﻲ

ﺗﻮﭘﻲ

OTHERS: --------------------------------- ﻣﻮارد دﻳﮕﺮ

NO. OF VALVE FOR EACH CYL.

VALVE MANUFACTURER

NOZZLE: SUC. ;SIZE, RATING,

FACE & LOC.

NOZZLE: DIS. ; SIZE, RATING,

FACE & LOC.

EFF. AT RATED / CAPACITY

%

ﻇﺮﻓﻴﺖ/راﻧﺪﻣﺎن ﻃﺮاﺣﻲ

DRIVER POWER

ﺗﻮان ﻣﺤﺮك

kW

HYDRO. TEST PRESS.(at 15oC)

RELIEF VALVE SETTING

RELIEF VALVE FEATURE

LUBRICATION SYSTEM

ﺣﺪاﻗﻞ ﻧﺮخ ﺟﺮﻳﺎن

m3/h

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻋﻤﺎﻳﺎﺗﻲ

ﺣﺪاﻛﺜﺮ دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ

MPa(ga)

o

C

15oCﻓﺸﺎر آزﻣﻮن ﻫﻴﺪرواﺳﺘﺎﺗﻴﻚ در

MPa(ga)

ﻓﺸﺎر ﺷﻴﺮ ﺗﺨﻠﻴﻪ

MPa(ga)

ﻣﻮﻗﻌﻴﺖ ﺷﻴﺮ ﺗﺨﻠﻴﻪ

□ BUILT-IN

□ EXTERNAL ﺧﺎرﺟﻲ

داﺧﻠﻲ

□ FORCED FEED

□ BATH

ﺗﻐﺬﻳﻪ ﺗﺤﺖ ﻓﺸﺎر

ﺳﺎﻣﺎﻧﻪ رواﻧﻜﺎري

روﻏﻦ ﺣﻤﺎم

… ﺳﺎﻳﺮ ﻣﻮارد

OTHER . . . . .

MAIN. OIL PUMP: DRIVER

ﻣﺤﺮك ﺗﻠﻤﺒﻪ اﺻﻠﻲ روﻏﻦ

□ CRANK CASE

□ELECT.MOTOR

ﭘﻮﺳﺘﻪ ﻟﻨﮓ

RELIEF VALVE / PIPING

ﺷﻴﺮ ﺗﺨﻠﻴﻪ/ﻟﻮﻟﻪ ﻛﺸﻲ

□ REQUIRED

ﻻزم

ﻣﻮﺗﻮر اﻟﻜﺘﺮﻳﻜﻲ

□ NOT REQUIRED

ﻏﻴﺮ ﻻزم

□ GEAR TYPE

COUPLING WITH GUARD :

□ N/A

□

YES

/

/

/

/

/

/

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

□ N/A

□ YES

□ NO

□ N/A

m 3 /h

@

MAX.

TEMP.

□ NO

ﻛﻼس ﻓﺸﺎر، اﻧﺪازه:ﻧﺎزل دﻫﺶ

ﺟﻬﺖ و ﻣﺤﻞ

%

MAX.ALLOW. WORK. PRESS.

□ YES

ﺳﺎزﻧﺪه ﺷﻴﺮ

kW

kW

MIN.FLOW RATE :

□ N/A

ﻛﻼس ﻓﺸﺎر، اﻧﺪازه:ﻧﺎزل ﻣﻜﺶ

ﺟﻬﺖ و ﻣﺤﻞ

ﺗﻮان ﻃﺮاﺣﻲ

ﺣﺪاﻛﺜﺮ

: RATED

□ NO

ﺗﻌﺪاد ﺷﻴﺮﻫﺎ در ﻫﺮ ﻣﺮﺣﻠﻪ

راﻧﺪﻣﺎن ﺣﺠﻤﻲ

VOLUMETRIC EFF.

YES

SF / ﻧﻮع

m/s

ﻧﻮع ﺷﻴﺮ

□

SF AGMA /ﻧﻮع

ﺣﺪاﻛﺜﺮ ﻣﺠﺎز/ﺳﺮﻋﺖ ﻃﺮاﺣﻲ ﭘﻴﺴﺘﻮن

VALVE TYPE

□ N/A

rpm

TYPE/AGMA SF

PISTON SPEED RATED /MAX. ALLOW.

CYL. BORE / STROKE

□ NO

rpm

ﺳﺮﻋﺖ ﻣﻴﻞ ﻟﻨﮓ

SPEED REDUCER

□

ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

ﺳﺮﻋﺖ ﻣﺤﺮك

CRANK SHAFT SPEED

B.H.P.

B

ﺳﺎزﻧﺪه

ﻛﻮﭘﻠﻴﻨﮓ ﻳﺎ ﻣﺤﺎﻓﻆ

□

YES

□ NO

□ N/A

□

YES

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

ﻣﻮﻗﻌﻴﺖ ﺷﻴﺮ

ﺗﺨﻠﻴﻪ

□ DISC TYPE

ﻧﻮع ﭼﺮخ دﻧﺪهاي

NON-SPARK GUARD

RELIEF

VALVE

FEATURE

□

ﻧﻮع دﻳﺴﻜﻲ

ﻣﺤﺎﻓﻆ ﺿﺪ ﺟﺮﻗﻪ

17

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

A3-QUOTATION ANALYSIS REPORT TABLE

FOR RECIPROCATING COMPRESSORS

(CONTINUED)

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي-3-اﻟﻒ

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

دادهﻫﺎ

MFR. / MODEL NO.

ﺷﻤﺎره ﻣﺪل/ ﺳﺎزﻧﺪه

BASEPLATE: TYPE

ﻧﻮع ﺻﻔﺤﻪ ﭘﺎﻳﻪ

□ COMMON

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

□ STEEL FABR.

ﻣﻌﻤﻮﻟﻲ

ﻓﻮﻻدي

□

HEAVY- DUTY

AIR VENT HOLES

DRAIN CONNECTION

ANCHOR BOLTS

NOISE LEVEL

B

C

/

/

/

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

ﻣﺼﺎرف ﺳﻨﮕﻴﻦ

ﻣﻨﺎﻓﺬ ﺧﺮوج ﻫﻮا

□ REQUIRED

□ NOT REQUIRED

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت

□ REQUIRED

□ NOT REQUIRED

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

ﭘﻴﭽﻬﺎي ﺗﻜﻴﻪ ﮔﺎﻫﻲ

□ REQUIRED

□ NOT REQUIRED

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

ﺳﻄﺢ ﺻﺪا

MATERIALS:

A

db(abs.)

MAX. ﺣﺪاﻛﺜﺮ

ﺟﻨﺲ

CYL. / CYL. HEAD

ﺳﺮ ﺳﻴﻠﻨﺪر/ ﺳﻴﻠﻨﺪر

CYL. LINER / PISTON

ﭘﻴﺴﺘﻮن/ ﺑﻮش داﺧﻠﻲ ﺳﻴﻠﻨﺪر

/

/

PISTON RING / RIDER RING ﺣﻠﻘﻪ در ﺑﺮ ﮔﻴﺮﻧﺪه ﭘﻴﺴﺘﻮن/ ﺣﻠﻘﻪ ﭘﻴﺴﺘﻮن

VALVE / VALVE SHEET / SPRING

/

ﻓﻨﺮ/ﺻﻔﺤﻪ ﺷﻴﺮ/ﺷﻴﺮ

CRANK SHAFT/ CRANK SHAFT

ﻣﻴﻞ ﻟﻨﮓ/ﻣﻴﻞ ﻟﻨﮓ

CROSS HEAD

راﺑﻂ رﻓﺖ و ﺑﺮﮔﺸﺘﻲ

CAPACITY CONTROL:

ﻛﻨﺘﺮل ﻇﺮﻓﻴﺖ

ENTIRE UNLOADER SYSTEM

ﺳﺎﻣﺎﻧﻪ ﺑﺎرﺑﺮداري

CLEARANCE POCKET

ﺣﺠﻢ ﻟﻘﻲ ﺳﺮ ﺳﻴﻠﻨﺪر

DISTANCE PIECE

ﭘﻮﺳﺘﻪ ﻓﺎﺻﻠﻪ اﻧﺪاز

COVER

ﭘﻮﺷﺶ

ACCESSORIES:

/

/

/

/

/

/

/

/

/

/

□ STEP

□ ﭘﻠﻪايPNEUMATIC ﺑﺎدي

□AUTOMATIC □ اﺗﻮﻣﺎﺗﻴﻚMANUAL دﺳﺘﻲ

□ REQUIRED

□ NOT REQUIRED

□ REQUIRED

□ NOT REQUIRED

EXTRA LONG

□ ﺧﻴﻠﻲ ﺑﻠﻨﺪ

□ ﻗﺴﻤﺘﻬﺎ

WO. COMPARTMENTS

SOLID □

ﺟﺎﻣﺪ

ﻧﺎزل ﺗﺨﻠﻴﻪ/□ﺷﻴﺮ

VALVED / DRAIN

□

□

□

□

YES

□ N/A

□ N/A

□ N/A

□ N/A

□

□

□

□

□

YES

□ NO

□ N/A

□

YES

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

YES

YES

/

/

/

/

□ NO

□ NO

□ NO

□ NO

YES

/

YES

□ NO

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□ N/A

□

□

□

□

□

YES

□ NO

□ N/A

□ N/A

□

YES

□ NO

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□

□

□

□

□

□

□

□

□

□

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

YES

YES

YES

/

/

YES

□ NO

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□ N/A

□

YES

□ NO

□ N/A

□ N/A

□

YES

□ NO

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□

□

□

□

□

□

□

□

□

□

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

□ N/A

YES

YES

YES

ﻟﻮازم ﺟﺎﻧﺒﻲ

SUC. / DIS. SNUBBER

□

□

□

□

□

□

□

□

□

□

اﻧﺒﺎره ورودي و ﺧﺮوﺟﻲ

INTER STAGE PIPING / RELIEF VALVE

ﺷﻴﺮ ﺗﺨﻠﻴﻪ/ ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﻴﻦ ﻣﺮاﺣﻞ

SEPARATE MOISTURE WITH TRAPS

رﻃﻮﺑﺖ ﮔﻴﺮ

INTER CONNECTING AUX. PIPING

ﻟﻮﻟﻪ ﻛﺸﻲ ﺗﺠﻬﻴﺰات ﺟﺎﻧﺒﻲ

AIR RECEIVER

ﻣﺨﺰن ﻫﻮا

AIR DRYER

ﺧﺸﻚ ﻛﻦ ﻫﻮا

AIR FILTER

ﻓﻴﻠﺘﺮ ﻫﻮا

SPECIAL / TOOLS WITH BOXES

اﺑﺰار ﺧﺎص ﺑﻪ ﻫﻤﺮاه ﺟﻌﺒﻪ

COMMISSIONING SPARE PARTS

ﻗﻄﻌﺎت ﻳﺪﻛﻲ راه اﻧﺪازي

TWO YEARS SPARE PARTS

ﻗﻄﻌﺎت ﻳﺪﻛﻲ دو ﺳﺎل

DEVIATIONS / EXCEPTION.

اﺳﺘﺜﻨﺎء/ اﻧﺤﺮاﻓﺎت

COMMENTS / REMARK

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

: ﺗﻮﺿﻴﺤﺎت/ ﭘﻴﺸﻨﻬﺎدات

ACCESSORIES:

:ﻟﻮازم ﺟﺎﻧﺒﻲ

PER REQ’D. IN THE DATA SHEET

ﻃﺒﻖ داده ﺑﺮگﻫﺎ و ﺑﻪ ﺗﻌﺪاد ﻻزم

TEST AND INSPECTION

آزﻣﻮن و ﺑﺎزرﺳﻲ

EVALUATION RANKING

اﻣﺘﻴﺎز ارزﻳﺎﺑﻲ

TOTAL PRICE

□A

اﻟﻒ

□B

□C

□D

ب

ج

د

ﻗﻴﻤﺖ ﻛﻞ

COST OF COMMISSIONING SPARE PARTS

ﻗﻴﻤﺖ ﻗﻄﻌﺎت ﻳﺪﻛﻲ راه اﻧﺪازي

COST OF TWO YEARS SPARE PARTS

DELIVERY (EX. FACTORY)

ﻗﻴﻤﺖ ﻗﻄﻌﺎت ﻳﺪﻛﻲ دو ﺳﺎل

ﺗﺤﻮﻳﻞ از در ﻛﺎرﺧﺎﻧﻪ

REMARKS:

: ﺗﻮﺿﻴﺤﺎت

COMMENTS:

: ﭘﻴﺸﻨﻬﺎدات

18

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

A4-QUOTATION ANALYSIS REPORT TABLE FOR

GENERAL PURPOSE STEAM TURBINE

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي-4-اﻟﻒ

ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻣﺼﺎرف ﻋﻤﻮﻣﻲ

ﺗﺎرﻳﺦ ﺻﺪورـــــــــ ﺻﻔﺤﻪ ــــــــــــ ازـــــــــ وﻳﺮاﻳﺶ ـــــــــــــــ

ISSUE DATE

PAGE

PREP'D.-----------

CHE'D.

OF

REV.

--------

ﺗﻬﻴﻪ ﻛﻨﻨﺪه ــــــــــ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ــــــــــ ﺗﺎﻳﻴﺪ ﻛﻨﻨﺪه ــــــــــــــ

APP'D.

---------

OPERATING CONDITION

DATA

ﺷﺮاﻳﻂ ﻋﻤﻠﻴﺎﺗﻲ

دادهﻫﺎ

INLET TEMP. RATED

SITE CONDITION

o

دﻣﺎي ﻃﺮاﺣﻲ ورودي

MIN. / MAX.

INLET PRESSURE : RATED

o

/

ﺣﺪاﻛﺜﺮ/ﺣﺪاﻗﻞ

C

PROJECT:

C

------------------------------------- ﭘﺮوژه

MPa(ga)

ﻓﺸﺎر ﻃﺮاﺣﻲ ورودي

MIN. / MAX.

QUOTATION ANALYSIS REPORT FOR

GENERAL PURPOSE STEAM TURBINE

Altitude

Unusual Condition

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ رﻃﻮﺑﺖ ﻧﺴﺒﻲ

ﺷﺮاﻳﻂ ﻏﻴﺮ ﻣﻌﻤﻮل

LOCATION ------------------------------------------ ﻣﻜﺎن

EXHAUST PRESSURE

ﻓﺸﺎر ﺧﺮوﺟﻲ

EXHAUST TEMP.

دﻣﺎي ﺧﺮوﺟﻲ

MPa(ga)

o

UNIT No:

------------------------------------------ ﺷﻤﺎره واﺣﺪ

CALCULATED OUT-PUT POWER: RATED @ rpm

rpm

ﺗﻮان ﻃﺮاﺣﻲ ﺧﺮوﺟﻲ ﻣﺤﺎﺳﺒﻪ ﺷﺪه

kW @ rpm

ITEM No:

------------------------------------------ ﺷﻤﺎره ﺗﻮرﺑﻴﻦ

NORMAL @ rpm

kW @ rpm

/

(%)

C

m

□ Dust

ﮔﺮد و ﻏﺒﺎر

Chloride Concentration

C

o

ارﺗﻔﺎع از ﺳﻄﺢ درﻳﺎ

------------------------------------------ ﻛﺎرﻓﺮﻣﺎ

MPa(ga)

/

ﺣﺪاﻛﺜﺮ و ﺣﺪاﻗﻞ دﻣﺎي ﻣﺤﻴﻂ

Relative Humidity: Max./Min.

CLIENT:

/

ﺣﺪاﻛﺜﺮ/ ﺣﺪاﻗﻞ

ﺷﺮاﻳﻂ ﺳﺎﻳﺖ

Range of ambient Temps.:Max./Min.

□

Fumes

دود

ppm

ﻏﻠﻈﺖ ﻛﻠﺮﻳﺪ

Elect. Area Classification

Cl ______ GR_________ DIV

رده ﺑﻨﺪي ﻣﺤﻞ از ﻟﺤﺎظ اﻟﺰاﻣﺎت اﻟﻜﺘﺮﻳﻜﻲ

ﺗﻮان ﻧﺮﻣﺎل

SERVICE: ------------------------------------------- ﻧﻮع ﺧﺪﻣﺎت

MPa(ga)

OTHERS:

Winterization

□

ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﺳﺮدﺳﻴﺮ

□ Req’d.

□ Not Req'd.

Tropicalization

□

ﺗﻤﻬﻴﺪات در ﻣﻨﺎﻃﻖ ﮔﺮﻣﺴﻴﺮ

□ Req’d.

□ Not Req'd.

Others

ﺳﺎﻳﺮ

kW

:ﺳﺎﻳﺮ

REMARKS:

REMARKS:

: ﺗﻮﺿﻴﺤﺎت

:ﺗﻮﺿﻴﺤﺎت

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

دادهﻫﺎ

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

A

MANUFACTURER

B

C

ﺳﺎزﻧﺪه

TYPE:

ﻧﻮع

MODEL

ﻣﺪل

NO.OF STAGES

□ HORIZ.

□ VERT.

اﻓﻘﻲ

ﻋﻤﻮدي

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

ﺗﻌﺪاد ﻣﺮاﺣﻞ

STEAM RATE : NORMAL / RATE

STEAM CONSUMPTION

ﻃﺮاﺣﻲ/ ﻧﺮﻣﺎل:ﻧﺮخ ﺑﺨﺎر

NORMAL / RATED

kg/h

ﻃﺮاﺣﻲ/ﻧﺮﻣﺎل

MAXIMUM ALLOWABLE PRESSURE

kg/kW.h

:ﻣﺼﺮف ﺑﺨﺎر

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻣﺠﺎز ورودي

MPa(g)

o

MAXIMUM ALLOWABLE TEMP.INLET / EXHAUST

C

ﺣﺪاﻛﺜﺮ دﻣﺎي ﻣﺠﺎز ﺧﺮوﺟﻲ

POTENTIAL MAX.

ﺣﺪاﻛﺜﺮ ﭘﺘﺎﻧﺴﻴﻞ

ROTATION

ﺟﻬﺖ ﭼﺮﺧﺶ

kW

□

□

Cw

Ccw

ﺳﺮﻋﺖ ﻃﺮاﺣﻲ ﻣﺤﻮر

rpm

دوم و ﺳﻮم،ﺳﺮﻋﺖ ﺑﺤﺮاﻧﻲ اول

rpm

ﺣﺪاﻛﺜﺮ ﺳﺮﻋﺖ در ﻋﻤﻠﻜﺮد ﻣﺪاوم

rpm

SHAFT SPEED: RATED

1ST, 2ND, 3RD, CRITICAL SPEED

MAX. CONTINUOUS SPEED

CASE SPLIT

NOZZLE: INLET;SIZE, RATING,

NOZZLE: OUTLET;SIZE, RATING

FACE & LOC.

□AXIAL

ﺷﻌﺎﻋﻲ

ﻣﺤﻮري

ﻛﻼس ﻓﺸﺎر،اﻧﺪازه:ﻧﺎزل دﻫﺶ

ﺟﻬﺖ و ﻣﺤﻞ

ADIABATIC EFF.

%

راﻧﺪﻣﺎن آدﻳﺎﺑﺎﺗﻴﻚ

ﻧﺮخ ورودي

OUTLET FLOW

□ RADIAL

ﻛﻼس ﻓﺸﺎر،اﻧﺪازه:ﻧﺎزل ﻣﻜﺶ

ﺟﻬﺖ و ﻣﺤﻞ

FACE & LOC.

INLET FLOW

ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

ﺧﻼف ﺟﻬﺖ ﻋﻘﺮﺑﻪ ﺳﺎﻋﺖ

ﻧﺮخ ﺧﺮوﺟﻲ

RATED

ﻃﺮاﺣﻲ

kg/h

MAX.

ﺣﺪاﻛﺜﺮ

kg/h

MIN.

ﺣﺪاﻗﻞ

kg/h

RATED

ﻃﺮاﺣﻲ

kg/h

MAX.

ﺣﺪاﻛﺜﺮ

kg/h

MIN.

ﺣﺪاﻗﻞ

kg/h

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ

ﺣﺪاﻛﺜﺮ دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ

Mpa(ga)

o

C

ﻓﺸﺎر آزﻣﻮن ﻫﻴﺪرواﺳﺘﺎﺗﻴﻚ

Mpa(ga)

MAX.ALLOW. WORK. PRESS.

TEMP.

HYDRO. TEST PRESS.(at 15oC)

MIN. SHAFT DIAMETER

ﺣﺪاﻗﻞ ﻗﻄﺮ ﻣﺤﻮر

اﺗﺼﺎﻻت ﻣﻨﺎﻓﺬ ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت ﭘﻮﺳﺘﻪ

PROVIDE WITH VALVE & FLANGE

ﺑﻪ ﻫﻤﺮاه ﺷﻴﺮ و ﻓﻠﻨﺞ

CASING VENT CONN.

اﺗﺼﺎﻻت ﻣﻨﺎﻓﺬ ﺗﺨﻠﻴﻪ ﮔﺎز ﭘﻮﺳﺘﻪ

PROVIDE WITH VALVE & FLANGE

ﺑﻪ ﻫﻤﺮاه ﺷﻴﺮ و ﻓﻠﻨﺞ

CASING DRAIN CONN.

□ REQUIRED

□ NOT REQUIRED

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□ REQUIRED

□ NOT REQUIRED

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

NO. OF HAND VALVE / NO. OPEN FOR RATED:

OTHERS

ﺳﺎﻳﺮ

GOVERNOR:

:ﮔﺎورﻧﺮ

MANUFACTURER

ﺳﺎزﻧﺪه

MODEL

ﻣﺪل

TYPE

□ ELECT. □ HYDRO.

ﻧﻮع

اﻟﻜﺘﺮﻳﻜﻲ

ﻫﻴﺪروﻟﻴﻜﻲ

□ OIL RELAY

ﻣﺪار روﻏﻨﻲ

NEMA CLASS / SPEED MIN. MAX.

OTHER:

WHEEL:

TYPE

WHEEL DIA: MAX /RATED

ﺣﺪاﻗﻞ/ﺳﺮﻋﺖ ﺣﺪاﻛﺜﺮ/ ﻛﻼسNEMA

ﺳﺎﻳﺮ

:ﭼﺮخ

ﻧﻮع

ﻃﺮاﺣﻲ/ ﺣﺪاﻛﺜﺮ:ﻗﻄﺮ ﭼﺮخ

□

□

mm

mm

19

Jul. 2009/ 1388 ﻣﺮداد

IPS-E-PM-110(2)

IRANIAN PETROLEUM STANDARDS

A4-QUOTATION ANALYSIS REPORT TABLE FOR

GENERAL PURPOSE STEAM TURBINE

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

ﺟﺪول ﮔﺰارش ﺗﺤﻠﻴﻠﻲ اﺳﺘﻌﻼم ﺑﺮاي-4-اﻟﻒ

ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻣﺼﺎرف ﻋﻤﻮﻣﻲ

MAX. WHEEL. TIP SPEED

ﺳﺮﻋﺖ ﺣﺪاﻛﺜﺮ ﻟﺒﻪ ﭼﺮخ

OTHERS:

m/s

:ﺳﺎﻳﺮ

BEARING & LUBRICATION SYSTEM

ﻳﺎﺗﺎﻗﺎن و رواﻧﻜﺎري

LUBRICATION SYSTEM’S STANDARD

اﺳﺘﺎﻧﺪارد ﺳﺎﻣﺎﻧﻪ رواﻧﻜﺎري

□ IPS

□ MAUFACTURER

MAGNETIC

BEARING TYPE:

:ﻧﻮع ﻳﺎﺗﺎﻗﺎن

□

□ HYD.DYNAMIC

SLEEVE

TILT-PAD

ﻫﻴﺪرودﻳﻨﺎﻣﻴﻚ

AXIAL. THRUST LOAD

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

□

YES

□ NO

□ N/A

ﻣﻐﻨﺎﻃﻴﺴﻲ

□

ﻟﺰﺟﺖ

ﻟﻘﻤﻪاي

ﻧﻴﺮوي ﺑﺎر ﻣﺤﻮري

THRUST COLLAR

دﻳﺴﻚ ﻣﺘﺤﻤﻞ ﻧﻴﺮوي ﻣﺤﻮري

BEARING TEMP. DEVICES

اﺑﺰار اﻧﺪازه ﮔﻴﺮي دﻣﺎي ﻳﺎﺗﺎﻗﺎن

□ INTEGRAL

□REPLACEABLE

ﻗﺎﺑﻞ ﺟﺎﻳﮕﺰﻳﻨﻲ

□THERMOCOUPLE

□ RTD

ﺗﺮﻣﻮﻛﻮﭘﻞ

NO.PER BRG ( RADIAL/ THRUST)

ﻣﺤﻮري/ﺗﻌﺪاد ﺑﻪ ازاي ﻫﺮ ﻳﺎﺗﺎﻗﺎن ﺷﻌﺎﻋﻲ

OTHERS:

:ﺳﺎﻳﺮ

DESCRIPTION (Spec.)

DATA

ﻣﺸﺨﺼﺎت

دادهﻫﺎ

BASEPLATE:

VENDOR′S PROPOSAL

ﭘﻴﺸﻨﻬﺎد ﻓﺮوﺷﻨﺪه

A

B

C

ﺻﻔﺤﻪ ﭘﺎﻳﻪ

TYPE:

:ﻧﻮع

WITH AIR VENT HOLES

ﻣﻨﺎﻓﺬ ﺗﺨﻠﻴﻪ ﻫﻮا

DRAIN CONNECTION

اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت

OTHERS:

:ﺳﺎﻳﺮ

DRIVEN:

:ﻣﺘﺤﺮك

MAUFACTURER

□ COMMON □ STEEL FABR. □ HEAVY- DUTY

ﻣﻌﻤﻮﻟﻲ

ﻓﻮﻻدي

□ REQUIRED

□ REQUIRED

ﻣﺼﺎرف ﺳﻨﮕﻴﻦ

□ NOT REQUIRED

□ NOT REQUIRED

□

□

□

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□

□

□

YES

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□

□

□

YES

YES

YES

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□

□

□

YES

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

□

□

□

YES

YES

YES

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

YES

□ NO

□ NO

□ NO

□ N/A

□ N/A

□ N/A

YES

YES

YES

ﺳﺎزﻧﺪه

TYPE/ MODEL

ﻣﺪل/ﻧﻮع

ROTATION SPEED:

ﺳﺮﻋﺖ ﭼﺮﺧﺶ

OTHERS:

:ﺳﺎﻳﺮ

GEAR UNIT:

ﺟﻌﺒﻪ دﻧﺪه

MAUFACTURER

ﺳﺎزﻧﺪه

ROTATION SPEED:

:اﻓﺰاﻳﻨﺪه ﻳﺎ ﻛﺎﻫﻨﺪه ﺳﺮﻋﺖ

TYPE/ MODEL

ﻣﺪل/ﻧﻮع

GEAR RATIO

ﻧﺴﺒﺖ دﻧﺪه

OTHERS

ﺳﺎﻳﺮ

CONTROL:

:ﻛﻨﺘﺮل

CONTROL SYSTEM

ﺳﺎﻣﺎﻧﻪ ﻛﻨﺘﺮل

□ELECTRONIC □PLC □DCS □OTHERS -------□ REQUIRED

□ REQUIRED

□ NOT REQUIRED

□ NOT REQUIRED

□

□

□