IPS-E-IN-110(0)

FOREWORD

The Iranian Petroleum Standards (IPS) reflect the

views of the Iranian Ministry of Petroleum and

are intended for use in the oil and gas production

facilities,

oil

refineries,

chemical

and

petrochemical plants, gas handling and processing

installations and other such facilities.

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and

the local market availability. The options which

are not specified in the text of the standards are

itemized in data sheet/s, so that, the user can

select his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the user.

This addendum together with the relevant IPS

shall form the job specification for the specific

project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the relevant

technical committee and in case of approval will

be incorporated in the next revision of the

standard.

Standards and Research department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran.

Postal Code- 1585886851

Tel: 88810459-60 & 66153055

Fax: 88810462

Email: Standards@nioc.org

ﭘﻴﺶ ﮔﻔﺘﺎر

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ ﻧﻔﺖ

، واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﺋﻲ و ﭘﺘﺮوﺷﻴﻤﻲ، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ

.ﺷﺪه اﺳﺖ

ﺑﺮاﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

ﺑﻴﻦاﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﺋﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي

ﻫﻤﭽﻨﻴﻦ ﺑﺮاﺳﺎس ﺗﺠﺮﺑﻴﺎت ﺻﻨﻌﺖ ﻧﻔﺖ ﻛﺸﻮر.ﻣﺮﺟﻊ ﻣﻲﺑﺎﺷﺪ

ﻣﻮاردي،و ﻗﺎﺑﻠﻴﺖ ﺗﺄﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ ﺑﺮﺣﺴﺐ ﻧﻴﺎز

.ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ ﺷﺪه اﺳﺖ

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ آورده ﻧﺸﺪه

اﺳﺖ در داده ﺑﺮگ ﻫﺎ ﺑﺼﻮرت ﺷﻤﺎره ﮔﺬاري ﺷﺪه ﺑﺮاي اﺳﺘﻔﺎده

.ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را ﭘﻮﺷﺶ

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي ﺧﺎص.ﻧﺪﻫﻨﺪ

اﻳﻦ اﻟﺤﺎﻗﻴﻪ.آﻧﻬﺎ را ﺗﺄﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه و ﻳﺎ ﻛﺎر،ﻫﻤﺮاه ﺑﺎ اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.ﺧﺎص را ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ ﻗﺮار

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

66153055 و88810459 - 60 : ﺗﻠﻔﻦ

88810462 : دور ﻧﮕﺎر

Standards@nioc.org

:ﭘﺴﺖ اﻟﻜﺘﺮوﻧﻴﻚ

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

GENERAL DEFINITIONS:

Throughout this Standard

definitions shall apply.

the

following

COMPANY :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian Gas Company, National Petrochemical

Company and National Iranian Oil Refinery and

Distribution Company.

PURCHASER :

Means the "Company" where this standard is a

part of direct purchaser order by the "Company",

and the "Contractor" where this Standard is a part

of contract documents.

VENDOR AND SUPPLIER:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

CONTRACTOR:

Refers to the persons, firm or company whose

tender has been accepted by the company.

EXECUTOR :

Executor is the party, which carries out all or part

of construction and/or commissioning for the

project.

INSPECTOR :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

SHALL:

Is used where a provision is mandatory.

SHOULD:

Is used where a provision is advisory only.

WILL:

Is normally used in connection with the action by

the “Company” rather than by a contractor,

supplier or vendor.

MAY:

Is used where a provision is completely

discretionary.

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲ رود

: ﺷﺮﻛﺖ

ﻣﺜﻞ،ﺑﻪ ﻳﻜﻲ از ﺷﺮﻛﺖ ﻫﺎي اﺻﻠﻲ و ﻳﺎ واﺑﺴﺘﻪ ﺑﻪ وزارت ﻧﻔﺖ

ﺷﺮﻛﺖ ﻣﻠﻲ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان،ﺷﺮﻛﺖ ﻣﻠﻲ ﻧﻔﺖ اﻳﺮان

ﺻﻨﺎﻳﻊ ﭘﺘﺮوﺷﻴﻤﻲ و ﺷﺮﻛﺖ ﻣﻠﻲ ﭘﺎﻻﻳﺶ و ﭘﺨﺶ ﻓﺮآوردهﻫﺎي

.ﻧﻔﺘﻲ اﻃﻼق ﻣﻲﺷﻮد

:ﺧﺮﻳﺪار

ﻳﻌﻨﻲ "ﺷﺮﻛﺘﻲ" ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش

ﺧﺮﻳﺪ ﻣﺴﺘﻘﻴﻢ آن "ﺷﺮﻛﺖ" ﻣﻲﺑﺎﺷﺪ و ﻳﺎ "ﭘﻴﻤﺎﻧﻜﺎري" ﻛﻪ اﻳﻦ

.اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮارداد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺄﻣﻴﻦ ﻛﻨﻨﺪه

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻲﺷﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

.ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺄﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻲﺷﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش،ﺑﻪ ﺷﺨﺺ

.ﺑﺮاي ﻣﻨﺎﻗﺼﻪ ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

: ﻣﺠﺮي

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﻃﻼق ﻣﻲﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از ﻛﺎرﻫﺎي

.اﺟﺮاﺋﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

ﮔﺮوه ﻳﺎ ﻣﻮﺳﺴﻪاي اﻃﻼق/در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد

ﺳﺎﺧﺖ و ﻧﺼﺐ،ﻣﻲﺷﻮد ﻛﻪ ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ

.ﺗﺠﻬﻴﺰات ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

. اﺳﺘﻔﺎده ﻣﻲﺷﻮد،ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ

:ﺗﻮﺻﻴﻪ

. ﺑﻜﺎر ﻣﻲرود،ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

:ﺗﺮﺟﻴﺢ

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮاﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

. ﺑﻜﺎر ﻣﻲرود،ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري ﻣﻲﺑﺎﺷﺪ

IPS-E-IN-110(1)

ENGINEERING STANDARD

FOR

PRESSURE INSTRUMENTS

FIRST REVISION

JULY 2009

اﺳﺘـﺎﻧﺪارد ﻣﻬﻨـﺪﺳﻲ

ﺑـﺮاي

ادوات اﺑﺰار دﻗﻴﻖ اﻧﺪازه ﮔﻴﺮي ﻓﺸﺎر

وﻳﺮاﻳﺶ اول

1388 ﺗﻴﺮ

This Standard is the property of Iranian Ministry of

Petroleum. All rights are reserved to the owner. Neither

whole nor any part of this document maybe disclosed to any

third party, reproduced, stored in any retrieval system or

transmitted in any form or by any means without the prior

written consent of the Iranian Ministry of Petroleum.

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ ﺑﻪ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم ﻳﺎ ﺑﺨﺸﻲ،ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

، اﻧﺘﻘﺎل، ذﺧﻴﺮه ﺳﺎزي، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ ازﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ،از اﻳﻦ اﺳﺘﺎﻧﺪارد

.ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد

Jul. 2009/ 1388 ﺗﻴﺮ

CONTENT:

Page

No

IPS-E-IN-110(1)

:ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

1. SCOPE................................................................ 3

3 ..................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

2. REFERENCES .................................................. 3

3 ............................................................. ﻣﺮاﺟﻊ-2

3. TERMINOLOGIES .......................................... 5

5 ............................................................. واژﮔﺎن-3

3.1 DCS/FCS ..................................................... 5

5 ................................. ﺳﻴﺴﺘﻢ ﻛﻨﺘﺮل ﺗﻮزﻳﻌﻲ1-3

3.2 Field Bus...................................................... 5

5 ................................................... ﻓﻴﻠﺪ ﺑﺎس2-3

3.3 Proportional Band...................................... 5

5 .............................................. ﺑﺎﻧﺪ ﻣﺘﻨﺎﺳﺐ3-3

3.4 Reset Action ................................................ 5

5 .................................. ﻋﻤﻞ راه اﻧﺪازي ﻣﺠﺪد4-3

3.5 Reset Rate.................................................... 5

5 ................................. اﻧﺪازه راه اﻧﺪازي ﻣﺠﺪد5-3

3.6 Manometer .................................................. 6

6 ....................................... ﻓﺸﺎر ﺳﻨﺞ ﻣﺎﻧﻮﻣﺘﺮ6-3

3.7 Diaphragm Seal .......................................... 6

6 ................. ( ﺟﺪاﻛﻨﻨﺪه دﻳﺎﻓﺮاﮔﻢ )درﻳﭽﻪ ﺑﺴﺘﻦ7-3

3.8 Pulsation Dampener ................................... 6

6 ................................ ﺗﻌﺪﻳﻞ ﻛﻨﻨﺪه ارﺗﻌﺎﺷﺎت8-3

3.9 Siphon .......................................................... 6

6 ...................................................... ﺳﻴﻔﻮن9-3

3.10 Draft Gage................................................. 6

6 ...................... ﻧﺸﺎن دﻫﻨﺪه ﻛﺸﺶ ﺟﺮﻳﺎن ﻫﻮا10-3

4. UNITS................................................................. 6

6 ............................................................ واﺣﺪﻫﺎ-4

5. PRESSURE CONTROL LOOP DESIGN

CRITERIA ......................................................... 6

6 ..................... ﻣﻌﻴﺎر ﻫﺎي ﻃﺮاﺣﻲ ﺣﻠﻘﻪ ﻛﻨﺘﺮل ﻓﺸﺎر-5

5.1 Local Control Loops................................... 6

6 ....................................... ﺣﻠﻘﻪ ﻛﻨﺘﺮل ﻣﺤﻠﻲ1-5

5.2 Centralized Control Loops ........................ 7

7 .............................. ﺣﻠﻘﻪ ﻫﺎي ﻛﻨﺘﺮل ﻣﺘﻤﺮﻛﺰ2-5

6. PRESSURE GAGES DESIGN CRITERIA .... 8

8 ............................ ﻣﻌﻴﺎر ﻫﺎي ﻃﺮاﺣﻲ ﻓﺸﺎرﺳﻨﺞ ﻫﺎ-6

6.1 Application .................................................. 8

8 ....................................................... ﻛﺎرﺑﺮد1-6

6.2 Specification ................................................ 9

9 .................................................. ﻣﺸﺨﺼﺎت2-6

6.3 Installation Engineering............................. 11

11 ........................................... ﻣﻬﻨﺪﺳﻲ ﻧﺼﺐ3-6

1

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

7. PRESSURE SWITCHES.................................. 12

12 ................................................... ﻛﻠﻴﺪﻫﺎي ﻓﺸﺎر-7

8. PRESSURE TRANSMITTERS ....................... 14

14 ............................................ ﻓﺮﺳﺘﻨﺪه ﻫﺎي ﻓﺸﺎر-8

9. LOCAL PRESSURE CONTROLLERS ......... 15

15 .............................. ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﻣﺤﻠﻲ ﻓﺸﺎر-9

10. DATA SHEETS AND DRAWINGS .............. 15

15 ....................................... داده ﺑﺮگ ﻫﺎ و ﻧﻘﺸﻪ ﻫﺎ-10

10.1 General ...................................................... 15

15 ...................................................... ﻋﻤﻮﻣﻲ1-10

APPENDICES:

: ﭘﻴﻮﺳﺖ ﻫﺎ

APPENDIX A STANDARD DATA SHEET FORMS

ISA-TR20.00.01-2001 ................... 16

ﭘﻴﻮﺳﺖ اﻟﻒ ﻓــﺮﻣﻬﺎي داده ﺑﺮگ

16 .... ISA- TR20.00.01-2001اﺳﺘــﺎﻧﺪارد

2

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE

اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺗﺠﻬﻴﺰات اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر اراﺋﻪ دﻫﻨﺪه

ﻛﻪ ﺑﺎﻳﺪ در ﻃﺮاﺣﻲ،رﻫﻨﻤﻮدﻫﺎي ﻋﻤﻮﻣﻲ ﻣﻬﻨﺪﺳﻲ ﻣﻲ ﺑﺎﺷﺪ

ﻣﻬﻨﺪس.ﭘﺮوژه ﻫﺎ ﺑﻪ ﻋﻨﻮان ﺣﺪاﻗﻞ ﻧﻴﺎزﻫﺎ ﻣﻮرد ﺗﻮﺟﻪ ﻗﺮار ﮔﻴﺮد

ﻣﺴﺌﻮل ﻃﺮاﺣﻲ ﺑﺮ ﻣﺒﻨﺎي ﻗﻀﺎوت ﻣﻬﻨﺪﺳﻲ ﻫﺮ ﻧﻮع اﻟﺰاﻣﺎت

.اﺿﺎﻓﻲ ﻛﻪ ﺑﻪ ﻧﻈﺮ ﺿﺮوري ﻧﻤﻲ ﺑﺎﺷﺪ ﺑﺎﻳﺪ در ﻧﻈﺮ ﮔﻴﺮد

ﻣﺸﺨﺼﺎت،داﻣﻨﻪ ﻛﺎرﺑﺮد اﻳﻦ اﺳﺘﺎﻧﺪارد ﭘﻮﺷﺶ دادن ﺑﻪ ﻛﺎرﺑﺮد

، ﻛﻠﻴﺪﻫﺎ،ﻓﻨﻲ و ﻣﻌﻴﺎرﻫﺎي ﻣﻬﻨﺪﺳﻲ ﻧﺼﺐ ﺗﺠﻬﻴﺰات ﻓﺸﺎرﺳﻨﺞ

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻣﺤﻠﻲ و اﻧﺘﻘﺎل دﻫﻨﺪهﻫﺎي ﺳﻴﮕﻨﺎل ﻛﻪ ﺑﺮاي

اﻧﺪازه ﮔﻴﺮي و ﻛﻨﺘﺮل ﻓﺸﺎر ﻣﻲ ﺑﺎﺷﺪ در ﺻﻨﺎﻳﻊ ﻧﻔﺖ ﺑﻜﺎر ﺑﺮده

.ﻣﻲ ﺷﻮد

This Pressure Instrument Engineering Standard

recommends the general engineering practice to

be considered in the project design as a minimum.

The engineer in charge of design shall consider

any further requirement deemed to be necessary

by the engineering judgment.

The scope of this standard covers application,

specification, and installation engineering criteria

of gages, switches, local controller and

transmitters used for pressure measurement and

control in Petroleum Industries.

:1 ﻳﺎدآوري

Note 1:

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ1375 اﻳﻦ اﺳﺘﺎﻧﺪارد در آﺑﺎن ﻣﺎه ﺳﺎل

1 ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و ﻣﻮارد ﺗﺄﻳﻴﺪ ﺷﺪه ﺑﻪ ﻋﻨﻮان اﺻﻼﺣﻴﻪ ﺷﻤﺎره

. اﺑﻼغ ﮔﺮدﻳﺪ3 ﻃﻲ ﺑﺨﺸﻨﺎﻣﻪ ﺷﻤﺎره

This standard specification is reviewed and

updated by the relevant technical committee on

October 1997, as amendment No. 1 by circular

No. 3.

:2 ﻳﺎدآوري

Note 2:

ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه اﺳﺘﺎﻧﺪارد ﻓﻮق،اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺗﺎﻳﻴﺪ1388 ﻣﻲﺑﺎﺷﺪ ﻛﻪ در ﺗﻴﺮ ﺳﺎل

(0) از اﻳﻦ ﭘﺲ وﻳﺮاﻳﺶ.( اراﻳﻪ ﻣﻲﮔﺮدد1) و ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ

This bilingual standard is a revised version of the

standard specification by the relevant technical

committee on July 2009, which is issued as

revision (1). Revision (0) of the said standard

specification is withdrawn.

:3 ﻳﺎدآوري

Note 3:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

ﻣﺮاﺟﻊ-2

2. REFERENCES

Throughout this standard, the following dated and

undated standards/codes are referred to. These

referenced documents shall, to the extent

specified herein, form a part of this standard. For

dated references, the edition cited applies. The

applicability of changes in dated references that

occur after the cited date shall be mutually agreed

upon by the Company and the Vendor. For

undated references, the latest edition of the

referenced documents (including any supplements

and amendments) applies.

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﻳﻴﻦ ﻧﺎﻣﻪﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و

ﺗﺎ ﺣﺪي ﻛﻪ در، اﻳﻦ ﻣﺮاﺟﻊ.ﺑﺪون ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ،اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪاﻧﺪ

وﻳﺮاﻳﺶ ﮔﻔﺘﻪ، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.اﺳﺘﺎﻧﺪارد ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

ﺷﺪه ﻣﻼك ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ وﻳﺮاﻳﺶ در آﻧﻬﺎ

ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ اﺟﺮا،داده ﺷﺪه اﺳﺖ

آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ اﻧﻀﻤﺎم، در ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ.ﻣﻲﺑﺎﺷﺪ

.ﻛﻠﻴﻪ اﺻﻼﺣﺎت و ﭘﻴﻮﺳﺖﻫﺎي آن ﻣﻼك ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

ISA (THE INTERNATIONAL SOCIETY OF

AUTOMATION)

( )اﻧﺠﻤﻦ ﺑﻴﻦ اﻟﻤﻠﻠﻲ اﺗﻮﻣﺎﺳﻴﻮنISA

5.1

"Instrumentation Symbols and

Identification)" (1992)

5.4

"Instrument Loop Diagrams"

(1991)

3

" " ﻧﻤﺎد ﻫﺎ و ﺷﻨﺎﺳﺎﻳﻲ ادوات اﺑﺰار دﻗﻴﻖ

(1992)

5.1

(1991)" "ﻧﻤﻮدارﻫﺎي ﺣﻠﻘﻪ اﺑﺰار دﻗﻴﻖ

5.4

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

5.5

"Graphic Symbols for Process

Displays"(1985)

ﺗﺼﺎوﻳﺮ

"ﻧﻤﺎدﻫﺎي

(1985)"ﻓﺮآﻳﻨﺪي

5.5

20

"Specification

Forms

for

Process

Measurement

and

Control Instruments, Primary

Element

and

Control

Valves"(1981)

"ﻓﺮم ﻫﺎي ﻣﺸﺨﺼﺎت ﻓﻨﻲ ﺑﺮاي اﻧﺪازه

ﮔﻴﺮي ﻓﺮآﻳﻨﺪي و اﺑﺰار دﻗﻴﻖ ﻛﻨﺘﺮﻟﻲ

(1981)"ﻋﻨﺼﺮ اوﻟﻴﻪ و ﺷﻴﺮﻫﺎي ﻛﻨﺘﺮل

20

ﺗﺮﺳﻴﻤﻲ

"ﻓﺮم ﻫﺎي ﻣﺸﺨﺼﺎت ﻓﻨﻲ ﺑﺮاي اﻧﺪازهTR20.00.01

- ﮔﻴﺮي ﻓﺮآﻳﻨﺪي و اﺑﺰار دﻗﻴﻖ ﻛﻨﺘﺮﻟﻲ

(2001)" ﻣﻼﺣﻈﺎت ﻛﻠﻲ1 ﺑﺨﺶ

TR20.00.01 "Specification

Forms

for

Process

Measurement

and

Control

Instruments-Part 1

General Consideration"(2001)

ASME

ﺟﻬﺖ

( )اﻧﺠﻤﻦ ﻣﻬﻨﺪﺳﺎن ﻣﻜﺎﻧﻴﻚ آﻣﺮﻳﻜﺎASME

(AMERICAN

SOCIETY

OF

MECHANICAL ENGINEERS)

32.11

"Graphic Symbols for Process

Flow Diagrams"(1998)

"ﻧﻤﺎدﻫﺎي ﺗﺮﺳﻴﻤﻲ ﺑﺮاي ﻧﻤﻮدارﻫﺎي

(1998)"ﺟﺮﻳﺎن ﻓﺮآﻳﻨﺪي

32.11

B40.100

"Pressure Gauges & Gauge

Attachments"(2005)

(2005) ""ﻓﺸﺎر ﺳﻨﺞﻫﺎ و ﻣﺘﻌﻠﻘﺎت آن

B40.100

( ) ﻣﻮﺳﺴﻪ ﻧﻔﺖ آﻣﺮﻳﻜﺎAPI

API(AMERICAN PETROLEUM INSTITUTE)

RP 500

"Recommended Practice for

Electrical

Installation

at

Petroleum Facilities Classified

as Class 1 Division 1 and

Division 2"(2002)

"روﺷﻬﺎي ﺗﻮﺻﻴﻪ ﺷﺪه ﻛﺎرﺑﺮدي ﺑﺮاي

ﻧﺼﺐ ﺗﺠﻬﻴﺰات اﻟﻜﺘﺮﻳﻜﻲ در ﺗﺄﺳﻴﺴﺎت

و1 ﻧﺎﺣﻴﻪ1 ﻧﻔﺘﻲ ﺑﺎ رده ﺑﻨﺪي ﻛﻼس

(2002)"2 ﻧﺎﺣﻴﻪ

RP 551

"Process

Measurement

Instrumentation

– Sec.

4/Pressure"(1993)

"ﺗﺠﻬﻴﺰات اﺑﺰار دﻗﻴﻖ اﻧﺪازه ﮔﻴﺮي ﻓﺮآﻳﻨﺪ

(1993)" ﻓﺸﺎر4 ﺑﺨﺶ

ﻓﺸﺎرﺳﻨﺞ ﻫﺎي1 ﺑﺨﺶ- " ﻓﺸﺎر ﺳﻨﺞ ﻫﺎBS EN 837-1

(1996)" (ﺑﻮردن ﺗﻴﻮب )ﻧﺎﻳﻪ

BSEN 837-1 "Pressure Gages Part 1- Bourdon

Tubes Pressure Gages" (1996)

(NATIONAL ASSOCIATION

CORROSION ENGINEERS)

MR-0175

60079

OF

( ) اﻧﺠﻤﻦ ﻣﻠﻲ ﻣﻬﻨﺪﺳﻲ ﺧﻮردﮔﻲNACE

"Sulfide

Stress

Cracking

Resistant Metallic Materials for

Oilfield Equipment Item No.

21304"(1988)

IEC(INTERNATIONAL

TECHNICAL COMMISSION)

RP 551

( ) ﻣﻮﺳﺴﻪ اﺳﺘﺎﻧﺪاردﻫﺎي ﺑﺮﻳﺘﺎﻧﻴﺎBSI

BSI (BRITISH STANDARDS INSTITUTE)

NACE

RP 500

"ﻣﺼﺎﻟﺢ ﻓﻠﺰي ﻣﻘﺎوم در ﺑﺮاﺑﺮ ﺷﻜﻨﻨﺪﮔﻲ

ﺗﻨﺶ ﺳﻮﻟﻔﻴﺪي ﺑﺮاي ﺗﺠﻬﻴﺰات در ﺻﻨﻌﺖ

(1988) " 21304 ﻧﻔﺖ ﺑﻨﺪ ﺷﻤﺎره

ELECTRO

MR-0175

( ) ﻛﻤﻴﺴﻴﻮن ﺑﻴﻦ اﻟﻤﻠﻠﻲ اﻟﻜﺘﺮوﺗﻜﻨﻴﻚIEC

"Electrical

Apparatus

for

Explosive Gas Atmospheres "

(2000)

"وﺳﺎﻳﻞ ﺑﺮﻗﻲ ﺟﻬﺖ ﻣﺤﻴﻂ ﻫﺎي ﮔﺎزي

(2000)"ﻗﺎﺑﻞ اﻧﻔﺠﺎر

4

60079

Jul. 2009/ 1388 ﺗﻴﺮ

( ) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS (IRANIAN PETROLEUM STANDARDS)

IPS-M-IN-150

" Material and

Equipment

for Receiving Instruments"

IPS-E-GN-100

"Engineering Standard

Units"

IPS-E-IN-100

"Engineering Standards for

General Instrumentation"

IPS-E-IN-110(1)

" اﺳﺘﺎﻧﺪارد ﻛﺎﻻ و ﺗﺠﻬﻴﺰات ﺟﻬﺖIPS-M-IN-150

" (1996) ادوات اﺑﺰار دﻗﻴﻖ ﮔﻴﺮﻧﺪه ﻫﺎ

ﺟﻬﺖ

ﻣﻬﻨﺪﺳﻲ

"اﺳﺘﺎﻧﺪاردIPS-E-GN-100

(1993)"واﺣﺪﻫﺎ

" اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺟﻬﺖ ادواتIPS-E-IN-100

"(2005)اﺑﺰاردﻗﻴﻖ ﻋﻤﻮﻣﻲ

for

واژﮔﺎن-3

3. TERMINOLOGIES

ﺳﻴﺴﺘﻢ ﻛﻨﺘﺮل ﺗﻮزﻳﻌﻲ1-3

3.1 DCS/FCS

ﺳﻴﺴﺘﻤﻲ اﺳﺖ ﻛﻪ،(ﺳﻴﺴﺘﻢ ﻛﻨﺘﺮل ﻏﻴﺮ ﻣﺘﻤﺮﻛﺰ )ﺗﻮزﻳﻌﻲ

ﺑﺮﻧﺎﻣﻪ ﻧﺮم اﻓﺰار ﺑﻪ ﻗﻄﻌﺎت ﻣﻨﻄﻘﻲ ﺗﻔﻜﻴﻚ ﻣﻲ ﺷﻮﻧﺪ و ﻣﺴﺘﻘﻞ

ﺳﻴﺴﺘﻢ ﻓﻮق اﺟﺎزه ﻣﻲ دﻫﺪ.از ﺳﺨﺖ اﻓﺰار ﺳﻴﺴﺘﻢ ﻣﻲ ﺑﺎﺷﻨﺪ

ﻛﻪ ﺑﺮﻧﺎﻣﻪ ﻫﺎي ﻛﻮﭼﻚ ﻣﺘﻌﺪد ﺑﺮ روي رﻳﺰ ﭘﺮدازﻧﺪه واﺣﺪ و

اﻳﻦ ﺳﻴﺴﺘﻢ ﻣﺆﺛﺮ و.ﺑﺮاﺳﺎس ﺗﻘﺪم ﺑﺪون وﻗﻔﻪ اﺟﺮا ﺷﻮد

ﻗﺎﺑﻠﻴﺖ اﻃﻤﻴﻨﺎن ﺑﻴﺸﺘﺮ و ﭘﺎﺳﺦ،ﻛﺎرﺟﻬﺖ ﻧﮕﻬﺪاﺷﺖ ﺧﻮب

ﺳﺮﻳﻌﺘﺮ ﺑﺮاي ﺗﻔﻜﻴﻚ ﺳﻴﺴﺘﻤﻬﺎي ﻣﻨﻄﻘﻲ و دﺳﺘﻪ ﺑﻨﺪي

.ﻣﻲﺑﺎﺷﺪ

Distributive Control System is a system that breaks

down the software program into logical pieces,

independent of system hardware. It allows multiple

small programs to run on a single microprocessor in

a priority-structural manner. It is an efficient, better

maintained, a more reliable, and faster response for

a more logical system break down.

ﻓﻴﻠﺪ ﺑﺎس2-3

3.2 Field Bus

ارﺗﺒﺎط ﺑﻪ ﻫﻢ ﭘﻴﻮﺳﺘﻪ در ﻣﻴﺎن،ﻓﻴﻠﺪ ﺑﺎس ﻳﻚ ﺳﻴﺴﺘﻢ دوﻃﺮﻓﻪ

ﺳﻴﺴﺘﻢ.اﻧﺪازه ﮔﻴﺮي ﻫﻮﺷﻤﻨﺪ و دﺳﺘﮕﺎه ﻫﺎي ﻛﻨﺘﺮل ﻣﻲ ﺑﺎﺷﺪ

ﻓﻮق ﻳﻜﻲ از ﭼﻨﺪﻳﻦ ﺷﺒﻜﻪ ﻫﺎي ﻣﺤﻠﻲ ﻣﻲ ﺑﺎﺷﺪ ﻛﻪ ﺑﺮاي

ﻫﺪف از ﻓﻴﻠﺪ ﺑﺎس.اﺗﻮﻣﺎﺳﻴﻮن ﺻﻨﻌﺘﻲ اﺧﺘﺼﺎص داده ﺷﺪه اﺳﺖ

ﻛﺎﻫﺶ ﻣﻴﺎﻧﮕﻴﻦ ﻫﺰﻳﻨﻪ ﭼﺮﺧﻪ و ﺣﻴﺎت ﺧﻄﻮط ﺗﻮﻟﻴﺪ و ﻛﺎﻫﺶ

.ﻫﺰﻳﻨﻪ ﻫﺎي ﻛﻠﻲ ﻛﺎرﻓﺮﻣﺎ در ﺑﺮﻧﺎﻣﻪ رﻳﺰي و ﻧﺼﺐ ﻣﻲ ﺑﺎﺷﺪ

Field Bus is a two-way, multiple communication

links among intelligent measurement and control

devices. It is one of the several local area networks

dedicated for industrial automation. Field Bus is

mean of reduction in the life-cycle cost of

production line and the total cost of ownership in

planning and installation.

ﺑﺎﻧﺪ ﻣﺘﻨﺎﺳﺐ3-3

3.3 Proportional Band

ﺑﺎﻧﺪ ﻣﺘﻐﻴﺮ ﻛﻨﺘﺮل ﺷﺪه اﺳﺖ ﻛﻪ ﻣﺘﻨﺎﻇﺮ رﻧﺞ،ﺑﺎﻧﺪ ﻣﺘﻨﺎﺳﺐ

و ﻣﻌﻤﻮﻻً ﺑﺮ ﺣﺴﺐ،ﺣﺪاﻛﺜﺮ دﺳﺘﮕﺎه ﻛﻨﺘﺮل ﻧﻬﺎﻳﻲ ﻣﻲ ﺑﺎﺷﺪ

اﻳﻦ در ﺣﺎﻟﻲ،درﺻﺪ ﺷﺎﺧﺺ ﻣﺘﻐﻴﺮ ﻛﻨﺘﺮل ﺷﺪه ﺑﻴﺎن ﻣﻲ ﺷﻮد

.اﺳﺖ ﻛﻪ ﻛﻨﺘﺮل ﻛﻨﻨﺪه از ﻧﻮع ﻧﻤﺎﻳﺸﻲ ﻳﺎ ﻧﺸﺎن دﻫﻨﺪه ﺑﺎﺷﺪ

Proportion Band is the range of the controlled

variable, which corresponds to the full range of the

final control element, and usually is expressed in

percent of controlled-variable scale where the

controller is of the indicating variety.

ﻋﻤﻞ راه اﻧﺪازي ﻣﺠﺪد4-3

3.4 Reset Action

3.5 Reset Rate

ﺑﺮاي ﻛﺎﻫﺶ اﻧﺤﺮاف ﺑﺼﻮرت اﺗﻮﻣﺎﺗﻴﻚ در ﻛﻨﺘﺮل ﻛﻨﻨﺪهﻫﺎ از

در ﺣﺎﻟﺘﻲ ﻛﻪ ﺷﺮاﻳﻂ.ﻋﻤﻞ راهاﻧﺪازي ﻣﺠﺪد اﺳﺘﻔﺎده ﻣﻲ ﺷﻮد

ﻋﻤﻠﻴﺎﺗﻲ ﺑﻪ ﮔﻮﻧﻪ اي ﺑﺎﺷﺪ ﻛﻪ ﺣﺪاﻛﺜﺮ اﻧﺤﺮاف در ﻣﺤﺪوده

. ﺑﻪ ﻋﻤﻞ راه اﻧﺪازي ﻣﺠﺪد ﻧﻴﺎز ﻧﻤﻲ ﺑﺎﺷﺪ،ﺗﻠﺮاﻧﺲ ﻣﺠﺎز ﺑﺎﺷﺪ

اﻧﺪازه راه اﻧﺪازي ﻣﺠﺪد5-3

Reset Rate is the number of times per minute that

the proportional position action is repeated by the

reset action, and often expressed as repeats /

minutes.

اﻧﺪازه راه اﻧﺪازي ﻣﺠﺪد ﺗﻌﺪاد ﺷﻤﺮدن در دﻗﻴﻘﻪ اﺳﺖ ﻛﻪ

وﺿﻌﻴﺖ ﺑﺎﻧﺪ ﻣﺘﻨﺎﺳﺐ و ﺗﻜﺮار ﻋﻤﻞ ﺳﺮﻋﺖ راه اﻧﺪازي ﻣﺠﺪد

.ﻣﻲﺑﺎﺷﺪ و ﻣﻌﻤﻮﻻً ﺑﺮ ﺣﺴﺐ ﺗﻜﺮار در دﻗﻴﻘﻪ ﻧﺸﺎن داده ﻣﻲ ﺷﻮد

Reset Action is used in controllers to reduce the

offset automatically. Where operating conditions are

such that the maximum offset is within the

permissible tolerance, reset action is not needed.

5

)IPS-E-IN-110(1

ﺗﻴﺮ Jul. 2009/ 1388

6-3ﻓﺸﺎر ﺳﻨﺞ ﻣﺎﻧﻮﻣﺘﺮ

3.6 Manometer

ﻓﺸﺎرﺳﻨﺞ ﻣﺎﻧﻮﻣﺘﺮ ﻳﻚ وﺳﻴﻠﻪ اﺑﺰار دﻗﻴﻖ ﻣﻲ ﺑﺎﺷﺪ ﻛﻪ ﺑﺮاي

اﻧﺪازه ﮔﻴﺮي ﻓﺸﺎر ﮔﺎز ﻳﺎ ﻣﺎﻳﻊ ﺑﻪ ﻛﺎر ﻣﻲ رود .ﺳﺎده ﺗﺮﻳﻦ ﺷﻜﻞ

ﻣﺎﻧﻮﻣﺘﺮ ﺗﺮﻛﻴﺒﻲ از ﺗﻴﻮب ﺑﺼﻮرت Uﻛﻪ ﺷﺎﻣﻞ ﻣﺎﻳﻊ )آب ،روﻏﻦ

ﻳﺎ ﺟﻴﻮه( ﻣﻲ ﺑﺎﺷﺪ ،ﻛﻪ ﻳﻚ ﺷﺎﺧﻪ آن ﺑﻪ ﻇﺮﻓﻲ ﻛﻪ ﻓﺸﺎر آن

اﻧﺪازه ﮔﻴﺮي ﻣﻲ ﺷﻮد ﻣﺘﺼﻞ اﺳﺖ ،و ﺷﺎﺧﻪ دﻳﮕﺮ آن ﻳﺎ ﺑﻪ

اﺗﻤﺴﻔﺮ وﺻﻞ ﻣﻲ ﺷﻮد ﻳﺎ ﺑﺴﺘﻪ ﻣﻲ ﺑﺎﺷﺪ ،در ﻏﻴﺮ اﻳﻨﺼﻮرت ﺑﻪ

ﻣﻜﺎﻧﻴﺰم ﺛﺒﺖ ﻛﻨﻨﺪه وﺻﻞ ﺷﺪه اﺳﺖ.

Manometer is an instrument used to measure the

pressure of gas or liquid. The simplest form consists

of a U-tube containing a liquid (water, oil, or

mercury), one limb being connected to enclosure

whose pressure is to be measured, while the other

limb is either open to the atmosphere or is closed or

otherwise connected to a registering or recording

mechanism.

7-3ﺟﺪاﻛﻨﻨﺪه دﻳﺎﻓﺮاﮔﻢ )درﻳﭽﻪ ﺑﺴﺘﻦ(

3.7 Diaphragm Seal

ﺟﺪاﻛﻨﻨﺪه دﻳﺎﻓﺮاﮔﻤﻲ اﻟﻤﺎﻧﻲ ﻣﻲ ﺑﺎﺷﺪﻛﻪ ﺑﺮاي ﺳﻴﺎﻻت ﻓﺮآﻳﻨﺪي

ﺧﻮرﻧﺪه و ﻓﺎﺳﺪ ﻛﻨﻨﺪه و ﺑﺮاي ﺣﺬف ﭘﺎﻛﺴﺎزي و ﺑﻌﻀﻲ از

روشﻫﺎي ردﻳﺎﺑﻲ ﺑﻪ ﻛﺎر ﻣﻲ روﻧﺪ .ﺟﺪاﻛﻨﻨﺪه دﻳﺎﻓﺮاﮔﻤﻲ ﺑﻄﻮر

ﻣﺴﺘﻘﻴﻢ ﺑﻪ اﻟﻤﺎن ﻓﺸﺎر وﺻﻞ ﻣﻲ ﺷﻮد و داراي ﻳﻚ ﺷﻴﺮ

اﻃﻤﻴﻨﺎن ﻣﻲ ﺑﺎﺷﺪ ﻛﻪ ﻗﺴﻤﺖ ﭘﺎﻳﻴﻦ آن ﻗﺎﺑﻞ ﺑﺮداﺷﺘﻦ اﺳﺖ.

داﺧﻞ ﺟﺪاﻛﻨﻨﺪه دﻳﺎﻓﺮاﮔﻤﻲ ﺑﺎ ﻣﺎﻳﻌﺎت ﺧﻨﺜﻲ ﭘﺮ ﻣﻲ ﺷﻮد.

Diaphragm Seal is an element used for in corrosive

process fluids, and for elimination of purging and

any type of tracing. It is directly connected to the

pressure element, and has bleeders with removable

bottom section. The element is filled with inert

liquid.

8-3ﺗﻌﺪﻳﻞ ﻛﻨﻨﺪه ارﺗﻌﺎﺷﺎت

3.8 Pulsation Dampener

ﺗﻌﺪﻳﻞ ﻛﻨﻨﺪه ﻫﺎي ارﺗﻌﺎﺷﺎت ﺟﻬﺖ ﺗﻌﺪﻳﻞ اﺛﺮات ﭘﺎﻛﺴﺎزي

ﭘﻤﭗﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ و ﻛﻤﭙﺮﺳﻮرﻫﺎ ﺑﻪ ﻛﺎر ﻣﻲ روﻧﺪ و

ﻣﻌﻤﻮﻻً ﻗﺎﺑﻞ ﺗﻨﻈﻴﻢ ﻣﻲ ﺑﺎﺷﻨﺪ.

Pulsation Dampeners are to dampen purging effects

of reciprocating Pumps, or compressors, and usually

are adjustable.

9-3ﺳﻴﻔﻮن

3.9 Siphon

ﺳﻴﻔﻮن ﻳﻚ اﻟﻤﺎﻧﻲ اﺳﺖ ﻛﻪ اﮔﺮ ﮔﺮﻣﺎي ﺑﺨﺎر ﻓﺮآﻳﻨﺪ ﻳﺎ آب از

104درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد ﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ از آن اﺳﺘﻔﺎده ﻣﻲﺷﻮد.

Siphon is an element used where heat of process

steam or water is over 104ºC.

10-3ﻧﺸﺎن دﻫﻨﺪه ﻛﺸﺶ ﺟﺮﻳﺎن ﻫﻮا

3.10 Draft Gage

ﺑﺮاي ﻧﻤﺎﻳﺶ ﻛﺸﺶ ﺟﺮﻳﺎن ﻫﻮا در دﻳﮓ ﺑﺨﺎر ﻛﻮره ﻫﺎ ﺑﺮ ﺣﺴﺐ

اﻳﻨﭻ آب ،از ﻓﺸﺎر ﺳﻨﺞ ﺣﺴﺎس ﻧﺴﺒﺖ ﺑﻪ ﺧﻼء اﺳﺘﻔﺎده ﻣﻲﺷﻮد.

Draft Gage is a sensitive vacuum gage for

indicating, in inches of water, the draught in a boiler

furnace.

-4واﺣﺪﻫﺎ

4. UNITS

اﻳﻦ اﺳﺘﺎﻧﺪارد ،ﺑﺮﻣﺒﻨﺎي ﻧﻈﺎم ﺑﻴﻦ اﻟﻤﻠﻠﻲ واﺣﺪﻫﺎ ) ،(SIﻣﻨﻄﺒﻖ

ﺑﺎ اﺳﺘﺎﻧﺪارد IPS-E-GN-100ﻣﻲﺑﺎﺷﺪ ،ﻣﮕﺮ آﻧﻜﻪ در ﻣﺘﻦ

اﺳﺘﺎﻧﺪارد ﺑﻪ واﺣﺪ دﻳﮕﺮي اﺷﺎره ﺷﺪه ﺑﺎﺷﺪ.

International System of Units (SI) in accordance

with IPS-E-GN-100 shall be used.

-5ﻣﻌﻴﺎر ﻫﺎي ﻃﺮاﺣﻲ ﺣﻠﻘﻪ ﻛﻨﺘﺮل ﻓﺸﺎر

5. PRESSURE CONTROL LOOP DESIGN

CRITERIA

5.1 Local Control Loops

5.1.1 In the following circumstances, preference is

given to the utilization of local pneumatic control

loops.

- When, there is no set-point adjustment or

indication requirement.

1-5ﺣﻠﻘﻪ ﻛﻨﺘﺮل ﻣﺤﻠﻲ

1-1-5در ﻣﻮارد زﻳﺮ ،اﺳﺘﻔﺎده از ﺣﻠﻘﻪ ﻛﻨﺘﺮل ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ

ﺗﺮﺟﻴﺢ داده ﻣﻲ ﺷﻮد.

در ﺣﺎﻟﺘﻲ ﻛﻪ ﻧﻴﺎزي ﺑﻪ ﻧﻤﺎﻳﺶ ﻳﺎ ﻧﻘﻄﻪ ﺗﻨﻈﻴﻢ ﻣﺮﺟﻊﻧﺒﺎﺷﺪ.

در ﻛﺎرﺧﺎﻧﺠﺎت ﺧﻴﻠﻲ ﻛﻮﭼﻚ ﺑﺎ ﺗﻌﺪاد ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎيﻛﻢ و در ﺣﺎﻟﺘﻲ ﻛﻪ ﻛﻨﺘﺮل ﻣﺮﻛﺰي ﺗﻮﺟﻴﻪ ﻧﺪارد.

- In very small plants with few controllers where

central control is not justified.

6

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

در ﺣﺎﻟﺘﻲ ﻛﻪ ﻫﻮاي اﺑﺰار دﻗﻴﻖ ﻳﺎ، در ﻛﺎرﺑﺮد ﻫﺎي راه دورﻣﻨﺒﻊ اﻧﺮژي دﻳﮕﺮي ﺑﺠﺰ ﮔﺎز ﻃﺒﻴﻌﻲ ﺗﺤﺖ ﻓﺸﺎر در دﺳﺘﺮس

.ﻧﺒﺎﺷﺪ

در ﻣﻮاردي ﻛﻪ دﺧﺎﻟﺖ ﻣﻜﺮر اﭘﺮاﺗﻮر در ﺣﻠﻘﻪ ﺑﺴﺘﻪ ﻣﻮردﻟﺰوم و ﺗﻮﺟﻴﻪ ﻧﻤﻲ ﺑﺎﺷﺪ و ﻧﻴﺰ در ﺣﺎﻟﺘﻲ ﻛﻪ ﻓﺎﺻﻠﻪ ﻧﻘﻄﻪ

ﻛﻨﺘﺮل ﺷﻮﻧﺪه ﺗﺎ اﺗﺎق ﻛﻨﺘﺮل ﻣﺮﻛﺰي ﺑﻴﺶ از ﺣﺪ ﻗﺎﺑﻞ ﻗﺒﻮل

.ﺑﺎﺷﺪ

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﻣﺤﻠﻲ ﻓﺸﺎر ﺑﺎﻳﺪ از ﻧﻮع ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ ﺑﺎﺷﻨﺪ و

ﺧﻄﻮط ﻓﺮآﻳﻨﺪي ﺑﺎﻳﺪ ﻣﺴﺘﻘﻴﻤﺎً ﺑﻪ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻣﺘﺼﻞ ﺷﻮﻧﺪ

.()ﻓﺮﺳﺘﻨﺪه ﻧﺒﺎﻳﺪ ﺑﻪ ﻛﺎر ﮔﺮﻓﺘﻪ ﺷﻮد

- In remote applications, where there is no

instrument air or energy source available

except pressurized natural gas.

- Where, frequent intervention of operator in

the loop is not necessary or recommended and

where the distance of control point to the

central control station is beyond the acceptable

limit.

The local pressure controllers shall be of

pneumatic type and the impulse line shall be

connected directly to the controller (no

transmitter shall be employed).

5.1.1.1 Pneumatic controller may be approved

with company approval.

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ ﻣﻲ ﺗﻮاﻧﺪ ﺑﻪ ﺗﺄﻳﻴﺪ1-1-1-5

5.1.2 The process variable measurement point

shall be as near as possible to the manipulation

point to minimize the transfer lag and dead time.

ﻓﺎﺻﻠﻪ ﺑﻴﻦ ﻧﻘﻄﻪ اﻧﺪازه ﮔﻴﺮي ﻣﺘﻐﻴﺮ ﻓﺮآﻳﻨﺪي ﺑﺎﻳﺪ در2-1-5

.ﺷﺮﻛﺖ ﺑﺮﺳﺪ

ﺣﺪ اﻣﻜﺎن ﺑﻪ ﻣﺤﻞ اﻋﻤﺎل ﺳﻴﮕﻨﺎل ﻛﻨﺘﺮﻟﻲ ﻧﺰدﻳﻚ ﺑﺎﺷﺪ ﺗﺎ و

.ﺗﺄﺧﻴﺮ در اﻧﺘﻘﺎل و زﻣﺎن ﻣﺮده ﻛﻤﻴﻨﻪ ﮔﺮدد

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﻧﺼﺐ ﺷﺪه در ﻣﺤﻞ و ﺗﺎﺑﻠﻮﻫﺎي3-1-5

5.1.3 Field mounted controllers and control

panels must be located in an area that is safe and

convenient for the operators and maintenance

technicians.

ﻛﻨﺘﺮل ﺑﺎﻳﺪ در ﻣﺤﻠﻲ ﻗﺮار ﮔﻴﺮﻧﺪ ﻛﻪ ﻣﻼﺣﻈﺎت اﻳﻤﻨﻲ در آن

رﻋﺎﻳﺖ ﺷﺪه ﺑﺎﺷﺪ و ﻧﻴﺰ ﻣﻨﺎﺳﺐ ﺑﺮاي اﭘﺮاﺗﻮرﻫﺎ و ﺗﻜﻨﺴﻴﻦ ﻫﺎي

.ﺗﻌﻤﻴﺮ و ﻧﮕﻬﺪاري ﺑﺎﺷﺪ

ﺣﻠﻘﻪ ﻫﺎي ﻛﻨﺘﺮل ﻣﺘﻤﺮﻛﺰ2-5

5.2 Centralized Control Loops

ﺑﺎﻻ ﻣﺸﺨﺺ ﺷﺪه1-5 ﺑﻪ ﻏﻴﺮ از ﻣﻮاردي ﻛﻪ در ﺑﻨﺪ1-2-5

5.2.1 In general pressure control loop

applications, centralized control shall be

implemented and for other services than what

specified in 5.1 here above.

در ﺣﺎﻟﺖ ﻋﻤﻮﻣﻲ ﻛﻨﺘﺮل ﻣﺘﻤﺮﻛﺰ ﺑﺎﻳﺪ ﺑﺮاي ﻛﺎرﺑﺮد،اﺳﺖ

.ﺣﻠﻘﻪ ﻫﺎي ﻛﻨﺘﺮل ﻓﺸﺎر اﺟﺮا ﺷﻮد

5.2.2 The centralized controllers shall be

specified as analog electronic, digital loop, or

shared display DCS (FieldBus). Pneumatic

systems may be employed in special

circumstances with the Company’s prior

approval.

، ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﻤﺮﻛﺰ ﺑﺎﻳﺪ ﺑﺼﻮرت آﻧﺎﻟﻮگ2-2-5

5.2.3 Controllers may be specified as indicating,

Manual/Auto and Remote set point type, as

required in specific application.

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎ ﺑﺮﺣﺴﺐ ﻛﺎرﺑﺮدﻫﺎي ﻣﺸﺨﺺ3-2-5

اﺗﻮﻣﺎﺗﻴﻚ و ﺑﺎ ﻗﺎﺑﻠﻴﺖ/ ﻣﻲ ﺗﻮاﻧﻨﺪ ﻫﻤﺮاه ﻧﺸﺎن دﻫﻨﺪه دﺳﺘﻲ

.ﻧﻘﻄﻪ ﺗﻨﻈﻴﻢ از راه دور ﻣﻌﻴﻦ ﺷﻮﻧﺪ

5.2.4 Control modes shall normally be adjustable

proportional band with automatic reset (PI).

، ﺣﺎﻟﺖ ﻫﺎي ﻛﻨﺘﺮل ﻣﻌﻤﻮﻻً ﺑﺎﻳﺪ ﺗﻨﺎﺳﺒﻲ ﺗﻨﻈﻴﻢ ﭘﺬﻳﺮ4-2-5

5.2.5 Suppressed ranges can be used on

applicable controllers to obtain maximum

accuracy and control.

ﺑﻪ ﻣﻨﻈﻮر دﺳﺘﻴﺎﺑﻲ ﺑﻪ ﺑﻴﺸﺘﺮﻳﻦ دﻗﺖ و ﻛﻨﺘﺮل در5-2-5

ﻣﻤﻜﻦ. ﻓﻴﻠﺪ ﺑﺎس ﻣﺸﺨﺺ ﺷﻮﻧﺪ/ دﻳﺠﻴﺘﺎل ﻳﺎ ﻛﻨﺘﺮل ﺗﻮزﻳﻌﻲ

اﺳﺖ در ﻣﻮارد ﺧﺎص ﺑﺎ ﺗﺄﻳﻴﺪ ﻗﺒﻠﻲ ﻛﺎرﻓﺮﻣﺎ ﺳﻴﺴﺘﻢ ﻫﺎي

.ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ ﺑﻜﺎرﮔﺮﻓﺘﻪ ﺷﻮد

.( ﺑﺎﺷﺪPI)ﺑﺎ اﻧﺘﮕﺮال ﮔﻴﺮ ﺧﻮدﻛﺎر

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎ ﻣﻴﺘﻮان از داﻣﻨﻪ ﻫﺎي ﻣﺤﺪود ﺷﺪه اﺳﺘﻔﺎده

.ﻧﻤﻮد

7

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

ﻣﻌﻴﺎر ﻫﺎي ﻃﺮاﺣﻲ ﻓﺸﺎرﺳﻨﺞ ﻫﺎ-6

6. PRESSURE GAGES DESIGN CRITERIA

ﻛﺎرﺑﺮد1-6

6.1 Application

In the following paragraphs the recommended

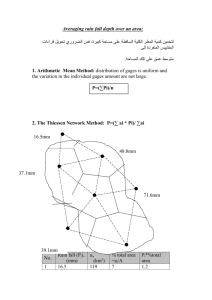

design criteria of pressure gages will be

presented, but not limited to.

در ﺑﻨﺪﻫﺎي ذﻳﻞ ﻣﻌﻴﺎر ﻫﺎي ﻃﺮاﺣﻲ ﺑﺮاي ﻓﺸﺎرﺳﻨﺞ ﻫﺎ اراﺋﻪ

.ﻣﻲﺷﻮدﻛﻪ اﻳﻦ ﻣﻌﻴﺎرﻫﺎ ﻣﺤﺪود ﺑﻪ ﻣﻮارد زﻳﺮ ﻧﻤﻲ ﺑﺎﺷﺪ

6.1.1 Pressure gages shall be considered for all

pressure vessels, either working under vacuum or

pressure service conditions.

ﻓﺸﺎر ﺳﻨﺞ ﺑﺎﻳﺪ، ﺑﺮاي ﻫﻤﻪ ﻇﺮوف ﺗﺤﺖ ﻓﺸﺎر ﻳﺎ ﺧﻼء1-1-6

6.1.2 Headers and manifolds shall be provided

with suitable pressure gages (liquids, gases and

steam applications).

ﻟﻮﻟﻪ ﻫﺎي اﺻﻠﻲ و ﭼﻨﺪ راﻫﻪ ﻫﺎ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﻓﺸﺎر2-1-6

6.1.3 Hand valves used for pressure control

applications shall be equipped with pressure

gages on upstream and/or down-stream piping of

the valve.

ﺷﻴﺮﻫﺎي دﺳﺘﻲ ﻛﻪ ﺑﺮاي ﻛﻨﺘﺮل ﻓﺸﺎر اﺳﺘﻔﺎده3-1-6

6.1.4 Self-operated pressure regulating valves

shall be equipped with a pressure gage on the

down-stream piping.

ﺷﻴﺮﻫﺎي ﺧﻮد ﺗﻨﻈﻴﻢ ﻛﻨﻨﺪه ﻓﺸﺎر ﺑﺎﻳﺪ روي ﻟﻮﻟﻪ ﻫﺎي4-1-6

6.1.5 All gas compressors shall be provided with

a pressure gage on the suction and discharge

piping.

در روي ﻟﻮﻟﻪ ﻫﺎي، ﺑﺮاي ﻛﻠﻴﻪ ﻛﻤﭙﺮﺳﻮرﻫﺎي ﮔﺎز5-1-6

6.1.6 A pressure gage shall be provided on

discharge piping of all gas and air compressors.

روي ﻛﻠﻴﻪ ﻟﻮﻟﻪ ﻫﺎي ﺧﺮوﺟﻲ ﻛﻤﭙﺮﺳﻮرﻫﺎي ﻫﻮا و ﮔﺎز6-1-6

6.1.7 All pumps shall be provided with pressure

gages on suction and discharge piping, as near as

possible to the pump skid.

روي ﻛﻠﻴﻪ ﻟﻮﻟﻪ ﻫﺎي ورودي و ﺧﺮوﺟﻲ ﭘﻤﭗ ﻫﺎ ﺑﺎﻳﺪ7-1-6

6.1.8 A pressure gage shall be considered for

steam inlet piping of all ejector pumps.

ﺑﺮ روي ﻟﻮﻟﻪ ورودي ﺑﺨﺎر ﻛﻠﻴﻪ ﭘﻤﭗ ﻫﺎي ﺧﺎرج8-1-6

6.1.9 Safety relief valves shall be provided with a

pressure gage near the relieving point.

در ورودي ﻧﺰدﻳﻚ ﻣﺤﻞ ﻧﺼﺐ ﺷﻴﺮﻫﺎي ﺗﺨﻠﻴﻪ اﻳﻤﻨﻲ9-1-6

6.1.10 Well-head pipelines shall be provided with

a pressure gage adjacent to production facility.

ﺧﻄﻮط ﻟﻮﻟﻪ ﻫﺎي ﺳﺮﭼﺎﻫﻲ در ﻧﺰدﻳﻜﻲ ﺗﺄﺳﻴﺴﺎت10-1-6

6.1.11 Pipelines entering or leaving the

compressor or pump stations shall be provided

with suitable gages adjacent and inside the fence

of the station.

ﺧﻄﻮط ﻟﻮﻟﻪ ﻫﺎي ورودي ﺑﻪ اﻳﺴﺘﮕﺎه ﻫﺎي ﺗﻘﻮﻳﺖ ﻓﺸﺎر11-1-6

.در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد

. ﮔﺎز و ﺑﺨﺎر( ﺑﺎﺷﻨﺪ،ﺳﻨﺞ ﻫﺎي ﻣﻨﺎﺳﺐ )ﺟﻬﺖ ﻛﺎرﺑﺮدﻫﺎي ﻣﺎﻳﻊ

ﻣﻲﺷﻮﻧﺪ ﺑﺎﻳﺪ در روي ﻟﻮﻟﻪ ﻫﺎي ﺑﺎﻻ دﺳﺖ و ﻳﺎ ﭘﺎﻳﻴﻦ دﺳﺖ

. ﻣﺠﻬﺰ ﺑﻪ ﻓﺸﺎرﺳﻨﺞ ﺑﺎﺷﻨﺪ،ﺷﻴﺮ

.ﭘﺎﻳﻴﻦ دﺳﺖ ﻣﺠﻬﺰ ﺑﻪ ﻓﺸﺎرﺳﻨﺞ ﺑﺎﺷﻨﺪ

.ورودي و ﺧﺮوﺟﻲ ﺑﺎﻳﺪ ﻓﺸﺎرﺳﻨﺞ ﺗﻌﺒﻴﻪ ﺷﻮد

.ﺑﺎﻳﺪ ﻓﺸﺎرﺳﻨﺞ ﻧﺼﺐ ﺷﻮد

ﻓﺸﺎرﺳﻨﺞ ﻧﺼﺐ ﺷﻮد و اﻳﻦ ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺗﺎ ﺣﺪ اﻣﻜﺎن ﺑﺎﻳﺪ

.ﻧﺰدﻳﻚ ﺗﺮﻳﻦ ﻧﻘﻄﻪ ﺑﻪ ﺟﺎﻳﮕﺎه ﭘﻤﭗ ﺑﺎﺷﻨﺪ

.( ﻓﺸﺎرﺳﻨﺞ ﺑﺎﻳﺪ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮدEjector) ﻛﻨﻨﺪه

.ﺑﺎﻳﺪ ﻓﺸﺎرﺳﻨﺞ ﻧﺼﺐ ﺷﻮد

.ﺗﻮﻟﻴﺪ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﻓﺸﺎرﺳﻨﺞ ﺑﺎﺷﻨﺪ

ﻓﺸﺎرﺳﻨﺞ ﺑﺎﻳﺪ،ﻳﺎ ﺧﺮوﺟﻲ از آن ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﻓﺸﺎرﺳﻨﺞ ﺑﺎﺷﻨﺪ

.ﻧﺰدﻳﻚ و داﺧﻞ ﻣﺤﺪوده اﻳﺴﺘﮕﺎه ﺑﺎﺷﺪ

6.1.12 Blind pneumatic or electronic transmitters

shall be supplemented with a pressure gage

connected directly to the process line.

ﻓﺮﺳﺘﻨﺪه ﻫﺎي ﺑﺪون ﻧﺸﺎن دﻫﻨﺪه ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ ﻳﺎ12-1-6

6.1.13 In the following cases, pressure transmitter

with receiving indicator shall be used instead of

pressure gage.

ﺑﺮاي ﺣﺎﻻت زﻳﺮ ﺑﺠﺎي ﻓﺸﺎرﺳﻨﺞ ﺑﺎﻳﺪ از ﻓﺮﺳﺘﻨﺪه و13-1-6

اﻟﻜﺘﺮوﻧﻴﻜﻲ ﺑﺎﻳﺪ داراي ﻓﺸﺎرﺳﻨﺞ ﺑﺎ اﺗﺼﺎل ﻣﺴﺘﻘﻴﻢ ﺑﻪ ﺧﻂ

.ﻓﺮآﻳﻨﺪي ﺑﺎﺷﺪ

.درﻳﺎف ﻛﻨﻨﺪه ﻓﺸﺎر ﻛﻪ ﻣﺠﻬﺰ ﻧﻤﺎﻳﺶ دﻫﻨﺪه ﺑﺎﺷﺪ اﺳﺘﻔﺎده ﺷﻮد

8

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

- To prevent hazardous hydrocarbons or any

other material entering the control room

through piping.

ﺑﻪ ﻣﻨﻈﻮر ﺟﻠﻮﮔﻴﺮي از ورود ﻫﻴﺪروﻛﺮﺑﻦ ﻫﺎي ﺧﻄﺮﻧﺎك ﻳﺎ.ﻫﺮ ﻧﻮع ﻣﺎده دﻳﮕﺮ از ﻃﺮﻳﻖ ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﻪ اﺗﺎق ﻛﻨﺘﺮل

- Where long tubing of pressure gage causes

problems or difficulties, i.e. where solid

particles present in the process fluid may cause

plugging difficulties or where difference in

elevation could result in a liquid head

problem.

ﺑﻪ ﻣﻨﻈﻮر ﺟﻠﻮﮔﻴﺮي از اﻳﺠﺎد ﻣﺸﻜﻞ در اﺛﺮ ﻃﻮﻻﻧﻲ ﺑﻮدن وﺟﻮد ذرات: ﺑﻪ ﻋﻨﻮان ﻣﺜﺎل،ﻣﺴﻴﺮ ﻟﻮﻟﻪ ﻛﺸﻲ ﻓﺸﺎرﺳﻨﺞ

ﺟﺎﻣﺪ در ﺳﻴﺎل ﻓﺮآﻳﻨﺪي ﻛﻪ ﺑﺎﻋﺚ ﺑﺴﺘﻪ ﺷﺪن ﻣﺴﻴﺮ

ﻣﻲﺷﻮد ﻳﺎ اﺧﺘﻼف ارﺗﻔﺎع ﻛﻪ ﺑﺎﻋﺚ اﻳﺠﺎد ﻓﺸﺎر اﺳﺘﺎﺗﻴﻜﻲ

.ﺳﻴﺎل ﻣﻲ ﮔﺮدد

زﻣﺎﻧﻲ ﻛﻪ ﻳﺦ زدﮔﻲ ﻳﺎ ﺟﺎﻣﺪ ﺷﺪن ﺳﻴﺎل در درﺟﻪﺣﺮارتﻫﺎي ﭘﺎﻳﻴﻦ ﻛﻪ ﻧﻴﺎز ﺑﻪ ﻋﺎﻳﻖ و ﮔﺮم ﻛﺮدن ﻣﺴﻴﺮ

.ﻟﻮﻟﻪﻛﺸﻲ ﻧﺸﺎن دﻫﻨﺪه ﻓﺸﺎر را ﺑﻪ دﻧﺒﺎل دارد

- When the fluid involved would freeze or

solidify at low temperature, and therefore gage

tubing requires insulation and heating.

6.1.14 Pressure gages shall be considered on

piping locations for maintenance purposes in

accordance with piping standard or as requested

by piping engineer.

ﻣﻄﺎﺑﻖ ﺑﺎ اﺳﺘﺎﻧﺪارد ﻟﻮﻟﻪ ﻛﺸﻲ ﻳﺎ ﺑﻪ درﺧﻮاﺳﺖ14-1-6

6.1.15 Pressure gages shall be considered on

piping locations for increased operational safety

in accordance with process engineering

requirements.

ﻣﻄﺎﺑﻖ ﺑﺎ ﻧﻴﺎز ﻫﺎي ﻣﻬﻨﺪﺳﻲ ﻓﺮآﻳﻨﺪ و ﺑﻪ ﻣﻨﻈﻮر15-1-6

6.1.16 Glass tube manometer may be specified

where required for low pressure or absolute

pressure measurement, where design pressure is

under 200 m.barg and the fluid encountered is not

dangerous.

ﻣﻴﻠﻲ ﺑﺎر200 در ﻣﻮاردي ﻛﻪ ﻓﺸﺎر ﻃﺮاﺣﻲ ﻛﻤﺘﺮ از16-1-6

6.1.17 For general local measurement of pressure,

bourdon tube type indicating pressure gages shall

be used.

17-1-6

ﻋﻤﻮﻣﺎ ﺑﺮاي اﻧﺪاز ﮔﻴﺮي ﻣﺤﻠﻲ ﻓﺸﺎر از ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺑﺎ

ً

6.1.18 Measuring element shall be generally

selected to be of bourdon tube type. Bellows or

diaphragm type pressure gages may be specified

for very low pressure applications exceptionally.

در ﺣﺎﻟﺖ ﻛﻠﻲ اﻟﻤﺎن اﻧﺪازه ﮔﻴﺮي ﺑﺎﻳﺪ از ﻧﻮع ﻟﻮﻟﻪ18-1-6

6.1.19 Oil filled type pressure gages shall be

specified for vibration services, such as;

compressor, or other rotating machines.

ﺑﺮاي ﻛﺎرﺑﺮدﻫﺎﻳﻲ ﻛﻪ ﻫﻤﺮاه ﺑﺎ ﻟﻐﺰش ﻣﻲ ﺑﺎﺷﺪ ﻣﺎﻧﻨﺪ19-1-6

ﻣﻬﻨﺪس ﻣﺮﺑﻮﻃﻪ ﺑﻪ ﺟﻬﺖ ﻣﻮارد ﺗﻌﻤﻴﺮاﺗﻲ ﺑﺎﻳﺪ در روي ﻟﻮﻟﻪ ﻫﺎ

.ﻓﺸﺎر ﺳﻨﺞ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد

ﻓﺸﺎرﺳﻨﺞ ﻫﺎ در ﻣﻜﺎﻧﻬﺎﻳﻲ از ﻟﻮﻟﻪ ﻫﺎي، اﻓﺰاﻳﺶ اﻳﻤﻨﻲ ﻋﻤﻠﻴﺎت

.ﻣﻮرد ﻧﻈﺮ ﺑﺎﻳﺪ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد

ﮔﻴﺞ و ﺳﻴﺎل ﻓﺮآﻳﻨﺪي ﺧﻄﺮﻧﺎك ﻧﺒﺎﺷﺪ ﻣﻲ ﺗﻮان از ﻓﺸﺎرﺳﻨﺞ

ﺗﻴﻮب )ﻧﺎﻳﻪ( ﺷﻴﺸﻪ اي ﺑﺮاي اﻧﺪازه ﮔﻴﺮي ﻓﺸﺎر ﭘﺎﻳﻴﻦ ﻳﺎ ﻣﻄﻠﻖ

.اﺳﺘﻔﺎده ﻛﺮد

.( ﺑﺎﻳﺪ اﺳﺘﻔﺎده ﻛﺮدBourdon) ﻟﻮﻟﻪ ﺑﻮردون

ﺑﺮاي ﻓﺸﺎرﻫﺎي ﺧﻴﻠﻲ ﭘﺎﻳﻴﻦ اﺳﺘﺜﻨﺎً از.ﺑﻮردون اﻧﺘﺨﺎب ﺷﻮد

( ﻳﺎ دﻳﺎﻓﺮاﮔﻤﻲ ﻣﻴﺘﻮانBellows) ﻓﺸﺎرﺳﻨﺞ ﻫﺎي اﻧﻮاع ﻓﺎﻧﻮﺳﻲ

.اﺳﺘﻔﺎده ﻛﺮد

ﻛﻤﭙﺮﺳﻮر ﻳﺎ ﺳﺎﻳﺮ ﻣﺎﺷﻴﻦ ﻫﺎي دوار ﺑﺎﻳﺪ از ﻓﺸﺎرﺳﻨﺞ ﻫﺎﺋﻲ ﻛﻪ

.ﺑﺎ روﻏﻦ ﭘﺮ ﺷﺪه اﻧﺪ اﺳﺘﻔﺎده ﻛﺮد

ﺑﺮاي ﺳﺮوﻳﺲ ﻫﺎي ﺑﺨﺎر و ﺳﻴﺎﻻت ﻓﺮآﻳﻨﺪي ﺑﺎ دﻣﺎي20-1-6

6.1.20 Siphons shall be designed for all services

containing steam with temperature higher than

100°C or liquid with temperature above 100°C.

Gage siphons shall be of coiled type preferably.

. درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد ﺑﺎﻳﺪ از ﺳﻴﻔﻮن اﺳﺘﻔﺎده ﻛﺮد100 ﺑﺎﻻﺗﺮ از

.( ﺑﺎﺷﺪCoiled) ﺳﻴﻔﻮن ﺗﺮﺟﻴﺤﺎً ﺑﺎﻳﺪ از ﻧﻮع ﻣﺎرﭘﻴﭻ

ﻣﺸﺨﺼﺎت2-6

6.2 Specification

The following clauses define recommended

practice for specifying pressure gages.

ﺑﻨﺪﻫﺎي زﻳﺮ روش ﻫﺎي ﺗﻮﺻﻴﻪ ﺷﺪه ﺑﺮاي اﻧﺘﺨﺎب ﻓﺸﺎرﺳﻨﺞ ﻫﺎ

.را ﺑﻴﺎن ﻣﻲ ﻛﻨﺪ

6.2.1 Range of the gage shall be specified in a

داﻣﻨﻪ ﻓﺸﺎرﺳﻨﺞ ﺑﺎﻳﺪ ﻃﻮري ﻣﺸﺨﺺ ﮔﺮدد ﻛﻪ ﻋﻘﺮﺑﻪ1-2-6

9

Jul. 2009/ 1388 ﺗﻴﺮ

manner that the pointer operate in the middle

third of the scale at normal service condition and

that the maximum working pressure (relief valve

setting) does not exceed the range.

IPS-E-IN-110(1)

در ﺷﺮاﻳﻂ ﻋﺎدي ﻋﻤﻠﻴﺎﺗﻲ در ﻳﻚ ﺳﻮم ﻣﻴﺎﻧﻲ ﻣﻘﻴﺎس ﻗﺮار ﺑﮕﻴﺮد

و ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻛﺎرﻛﺮد )ﺑﺎ در ﻧﻈﺮ ﮔﺮﻓﺘﻦ ﻧﻘﻄﻪ ﺗﻨﻈﻴﻢ ﺷﻴﺮ

.اﻳﻤﻨﻲ(ﻧﺒﺎﻳﺪ از داﻣﻨﻪ ﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ

6.2.2 Dial size shall be preferably specified as 63

/100/ 150 mm. for all standard gages.

ﺑﺮاي ﻫﻤﻪ ﻓﺸﺎرﺳﻨﺞ ﻫﺎي اﺳﺘﺎﻧﺪارد اﻧﺪازه ﺻﻔﺤﻪ2-2-6

6.2.3 Bourdon-tube pressure gages shall be

specified for the ranges from 1 bar up to 1000

bar.

ﺑﺎر از ﻧﺸﺎن دﻫﻨﺪه1000 ﺗﺎ1 ﺑﺮاي ﻣﺤﺪوده ﻫﺎﻳﻲ از3-2-6

6.2.4 Diaphragm element pressure gages shall be

specified for measuring pressures bellow 1 bar.

ﺑﺮاي اﻧﺪازه ﮔﻴﺮي ﻓﺸﺎر ﻛﻤﺘﺮ از ﻳﻚ ﺑﺎر از ﻓﺸﺎرﺳﻨﺞ4-2-6

6.2.5 Sensing element of gages used in oil, gas,

water and steam services shall be specified with

stainless steel bourdon tube.

اﻟﻤﺎن ﺣﺴﺎﺳﻪ ﻣﺮﺑﻮط ﺑﻪ ﻧﺸﺎن دﻫﻨﺪه ﻫﺎ ﻛﻪ ﺑﺮاي5-2-6

. ﻣﻴﻠﻴﻤﺘﺮ ﺗﻌﻴﻴﻦ ﮔﺮدد150/100/63 ﻣﺪرج ﺗﺮﺟﻴﺤﺎً ﺑﺎﻳﺪ

.ﻓﺸﺎر ﻧﻮع ﻟﻮﻟﻪ ﺑﻮردون اﺳﺘﻔﺎده ﺷﻮد

.ﻧﻮع اﻟﻤﺎن دﻳﺎﻓﺮاﮔﻤﻲ ﺑﺎﻳﺪ اﺳﺘﻔﺎده ﻛﺮد

آب و ﺑﺨﺎر ﺑﻜﺎر ﻣﻲ روﻧﺪ ﺑﺎﻳﺪ ﻟﻮﻟﻪ، ﮔﺎز،ﺳﺮوﻳﺲ ﻫﺎي ﻧﻔﺖ

.ﺑﻮردون از ﺟﻨﺲ ﻓﻮﻻد ﺿﺪ زﻧﮓ ﺑﺎﺷﺪ

،ﺑﺮاي ﺳﺮوﻳﺲ ﻫﻮا ﻣﻲ ﺗﻮان از اﻟﻤﺎن ﻫﺎي از ﺟﻨﺲ ﺑﺮﻧﺞ

. ﻓﺴﻔﺮ ﺑﺮﻧﺰ اﺳﺘﻔﺎده ﻛﺮد، ﻣﺲ- ﺑﺮﻳﻠﻴﻮم

ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﻛﻠﻴﻪ ﻓﺸﺎرﺳﻨﺞ ﻫﺎﻳﻲ ﻛﻪ ﺑﺮاي ﻳﻚ واﺣﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﻣﻄﺎﺑﻖ ﺑﺎ ﺳﺮوﻳﺲ ﻧﻔﺖ،ﺻﻨﻌﺘﻲ ﺑﻜﺎر ﻣﻲ رود

ﻣﮕﺮ اﻳﻨﻜﻪ ﺗﻌﺪاد ﻗﺎﺑﻞ ﺗﻮﺟﻬﻲ ﺑﺮاي ﺳﺮوﻳﺲ ﻫﻮا،و ﮔﺎز ﺑﺎﺷﺪ

ﻓﺸﺎر ﺳﻨﺞ ﻫﺎ ﺑﺮاي ﺳﺮوﻳﺲ ﻫﺎي ﺗﺮش.ﻣﻮرد ﻧﻴﺎز ﺑﺎﺷﺪ

Brass, Beryllium -copper and phosphor bronze

elements can be used on air services.

It is recommended that all pressure gages used in

a single plant to be specified for oil and gas

service, unless substantial numbers are required

for air service only. Pressure gages on sour

service shall be of Monel-400 or Hastalloy C

according to NACE MR-01 75.

ﻣﻄﺎﺑﻖHastalloy C ﻳﺎMonel-400 )اﺳﻴﺪي( ﺑﺎﻳﺪ ازﺟﻨﺲ

. ﺑﺎﺷﺪNACE MR-01 75 ﺑﺎ اﺳﺘﺎﻧﺪارد

ﺑﺮاي ﺳﻴﺎﻻت ﻓﺮآﻳﻨﺪي داراي ﺧﻮرﻧﺪﮔﻲ ﻳﺎ در ﺷﺮاﻳﻂ6-2-6

6.2.6 Diaphragm seals shall be specified for

corrosive process fluids, or in freezing climates or

process fluids that will clog the pressure element.

These gages shall also be specified with capillary

bleeder.

ﻳﺎ ﺳﻴﺎﻻت ﻛﻪ ﺑﺎﻋﺚ ﮔﺮﻓﺘﮕﻲ و ﻣﺴﺪود،آب و ﻫﻮاي ﻳﺨﺒﻨﺪان

ﺷﺪن اﻟﻤﺎن اﻧﺪازه ﮔﻴﺮي ﻓﺸﺎر ﻣﻲ ﺷﻮﻧﺪ از آب ﺑﻨﺪ دﻳﺎﻓﺮاﮔﻤﻲ

اﻳﻦ ﻧﻮع از ﻧﺸﺎن دﻫﻨﺪه ﺑﺎﻳﺪ در ﻟﻮﻟﻪ ﻣﻮﺋﻴﻦ.ﺑﺎﻳﺪ اﺳﺘﻔﺎده ﮔﺮدد

.روان ﻣﺸﺨﺺ ﺷﻮد

6.2.7 Accuracy of the gage shall be better than 0.6

percent of scale span as per part .6, Table 1 BS

EN 837-1.

درﺻﺪ ﮔﺴﺘﺮه ﻣﻘﻴﺎس0/6 دﻗﺖ ﻓﺸﺎرﺳﻨﺞ ﺑﺎﻳﺪ ﺑﻬﺘﺮ از7-2-6

6.2.8 At locations where pressure instruments will

be compensated for static head, the tag shall be

specified to be clearly marked accordingly (by

manufacturer).

در ﻣﻜﺎن ﻫﺎﻳﻲ ﻛﻪ در اﺑﺰار دﻗﻴﻖ ﻓﺸﺎري ﺗﺼﺤﻴﺢ8-2-6

6.2.9 Draft gages in stack, shall be diaphragm

type.

ﻧﺸﺎن دﻫﻨﺪه ﻫﺎي ﻛﺸﺶ ﺟﺮﻳﺎن ﻫﻮا در دودﻛﺶ ﺑﺎﻳﺪ9-2-6

6.2.10 Pressure gages shall not have suppressed

ranges.

ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﻧﺒﺎﻳﺪ داراي داﻣﻨﻪ ﻣﺤﺪوده ﺷﺪن10-2-6

6.2.11 Bellows shall be SS-316, copper nickelmagnesium alloy or other materials of appropriate

mechanical and corrosion resistance.

آﻟﻴﺎژ، SS-316 ﺟﻨﺲ ﻓﺎﻧﻮس ﺑﺎﻳﺪ از ﻓﻮﻻد ﺿﺪ زﻧﮓ11-2-6

. ﺑﺎﺷﺪBS EN 837-1 ﺟﺪول ﻳﻚ، 6 ﻣﻄﺎﺑﻖ ﺑﺨﺶ

ﺑﺎﻳﺪ روي ﺑﺮﭼﺴﺐ ﻧﺸﺎن دﻫﻨﺪه ﺑﻄﻮر،ارﺗﻔﺎع اﻧﺠﺎم ﻣﻲ ﺷﻮد

.(واﺿﺢ اﻳﻦ ﻣﻮرد ﻣﺸﺨﺺ ﺷﻮد )ﺗﻮﺳﻂ ﺳﺎزﻧﺪه

.از ﻧﻮع دﻳﺎﻓﺮاﮔﻢ ﺑﺎﺷﺪ

.( ﺑﺎﺷﺪsuppressed)

ﻣﻨﻴﺰﻳﻢ ﻳﺎ از ﻣﻮاد دﻳﮕﺮ ﺑﺎ ﻣﻘﺎوﻣﺖ ﻣﻜﺎﻧﻴﻜﻲ و ﺿﺪ- ﻣﺲ ﻧﻴﻜﻞ

.ﺧﻮرﻧﺪﮔﻲ ﻣﻨﺎﺳﺐ ﺑﺎﺷﻨﺪ

10

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

6.2.12 Diaphragm sealed gages shall not be

specified for services above 200°C for direct

application.

درﺟﻪ200 ﺑﺮاي ﺳﺮوﻳﺲ ﻫﺎي ﺑﺎ درﺟﻪ ﺣﺮارت ﺑﺎﻻي12-2-6

6.2.13 Pressure gage ranges shall be considered in

accordance with BS EN 837-1.

ﻣﺤﺪودﻳﺖ ﻫﺎي ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ اﺳﺘﺎﻧﺪارد13-2-6

6.2.14 General purpose bourdon tube-type

pressure gages should be specified where only

indication of pressure is required.

، در ﺣﺎﻟﺘﻲ ﻛﻪ ﻓﻘﻂ ﻧﻤﺎﻳﺶ ﻓﺸﺎر ﻣﺪ ﻧﻈﺮ ﺑﺎﺷﺪ14-2-6

ﺳﺎﻧﺘﻴﮕﺮاد اﺗﺼﺎل ﻣﺴﺘﻘﻴﻢ ﺑﻪ ﻟﻮﻟﻪ ﻓﺮآﻳﻨﺪي ﻧﺒﺎﻳﺪ از ﻧﺸﺎن دﻫﻨﺪه

.ﻧﻮع آب ﺑﻨﺪ دﻳﺎﻓﺮاﮔﻤﻲ اﺳﺘﻔﺎده ﻛﺮد

. ﺑﺎﺷﺪBS EN 837-1

ﺗﺮﺟﻴﺤﺎً از ﻓﺸﺎرﺳﻨﺞ ﻫﻤﻪ ﻛﺎره ﻧﻮع ﻟﻮﻟﻪ ﺑﻮردون )ﻧﺎﻳﻪ( اﺳﺘﻔﺎده

.ﺷﻮد

ﺑﺮاي ﺗﺠﻬﻴﺰاﺗﻲ ﻛﻪ در ﺷﺮاﻳﻂ ﻧﺮﻣﺎل ﻋﻤﻠﻴﺎﺗﻲ ﺑﺎﻻي15-2-6

6.2.15 On equipment normally operating at

pressure above atmospheric, but before plant

operation may expose to vacuum because of air

removal, a combined pressure/vacuum range may

be specified.

وﻟﻲ ﻗﺒﻞ از ﻋﻤﻠﻴﺎﺗﻲ ﺷﺪن واﺣﺪ،ﻓﺸﺎر اﺗﻤﺴﻔﺮ ﻛﺎر ﻣﻲ ﻛﻨﻨﺪ

در اﻳﻦ ﺣﺎﻟﺖ،اﻣﻜﺎن اﻳﺠﺎد ﺧﻼء ﺑﺨﺎﻃﺮ ﺗﺨﻠﻴﻪ ﻫﻮا وﺟﻮد دارد

داﻣﻨﻪ ﺗﺮﻛﻴﺒﻲ ﻓﺸﺎر و ﺧﻼء را ﻣﻲ ﺗﻮان ﺑﺮاي ﻓﺸﺎرﺳﻨﺞ در ﻧﻈﺮ

.ﮔﺮﻓﺖ

ﻣﻬﻨﺪﺳﻲ ﻧﺼﺐ3-6

6.3 Installation Engineering

These clauses are practical recommendations to

be considered in pressure instrument installation,

engineering and design.

ﻃﺮاﺣﻲ و ﻧﺼﺐ،ﺗﻮﺻﻴﻪ ﻫﺎي ﻛﺎرﺑﺮدي زﻳﺮ ﻛﻪ ﺑﺎﻳﺪ در ﻣﻬﻨﺪﺳﻲ

6.3.1 Gages up to and including 150 mm. dial size

may be supported by their own connections.

ﻣﻴﻠﻴﻤﺘﺮ ﻣﻲﺗﻮاﻧﻨﺪ150 ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺗﺎ ﺻﻔﺤﻪ ﻣﺪرج1-3-6

6.3.2 Vent valves shall be arranged with suitable

drain lines to ensure safe and non-hazardous

operation.

ﺑﺮاي، ﺑﻪ ﻣﻨﻈﻮر ﺗﻀﻤﻴﻦ ﻋﻤﻠﻴﺎت اﻳﻤﻦ ﺑﺪون ﺧﻄﺮ2-3-6

6.3.3 All gages used in process applications shall

be provided with a stop valve, at the pressure

source. This valve shall not be less than 1 inch.

Consideration shall be given to the use of

approved ball valves where temperature condition

permit. Exception will be permitted in the

following cases:

ﻛﻠﻴﻪ ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺑﺎ ﻛﺎرﺑﺮد ﻓﺮآﻳﻨﺪي ﺑﺎﻳﺪ در ﻗﺴﻤﺖ3-3-6

.اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر ﻣﻮرد ﺗﻮﺟﻪ ﻗﺮار ﮔﻴﺮد

.ﺗﻮﺳﻂ اﺗﺼﺎﻻت ﺧﻮد ﻧﮕﻪ داﺷﺘﻪ ﺷﻮﻧﺪ

( ﻣﻨﺎﺳﺐ ﺗﻌﺒﻴﻪDrain) ﺷﻴﺮﻫﺎي ﺗﺨﻠﻴﻪ ﺑﺎﻳﺪ ﺧﻄﻮط آﺑﮕﺬر

.ﺷﻮد

اﻧﺪازه اﻳﻦ ﺷﻴﺮ.ﻣﻨﺒﻊ ﻓﺸﺎر داراي ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه ﺑﺎﺷﻨﺪ

در ﻣﻮاردي ﻛﻪ ﺷﺮاﻳﻂ دﻣﺎ اﺟﺎزه.ﻧﺒﺎﻳﺪ از ﻳﻚ اﻳﻨﭻ ﻛﻤﺘﺮ ﺑﺎﺷﺪ

در ﺷﺮاﻳﻂ زﻳﺮ.دﻫﺪ ﺑﺎﻳﺪ اﺳﺘﻔﺎده از ﺷﻴﺮ ﺗﻮﭘﻲ را در ﻧﻈﺮ ﮔﺮﻓﺖ

: اﺳﺘﺜﻨﺎء ﻣﺠﺎز ﺧﻮاﻫﺪ ﺑﻮد

a) The pump or equipment physical size

necessitates a smaller size stop valve.

Anyhow, in no circumstances, the size of the

valve shall be considered less than half inch

unless specific approval is obtained from the

Company.

اﻟﻒ( ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ اﻧﺪازه ﻓﻴﺰﻳﻜﻲ ﭘﻤﭗ ﻳﺎ ﺗﺠﻬﻴﺰ ﻣﻲ ﺗﻮان ﺷﻴﺮ

b) When a gage is located at a distance of 2.5

m. or more from its pressure connection, an

additional block valve in conjunction with a

vent valve shall be considered adjacent to the

gage.

ﻣﺘﺮ ﻳﺎ ﺑﻴﺸﺘﺮ از2/5 ب( در ﺣﺎﻟﺘﻴﻜﻪ ﻓﺸﺎرﺳﻨﺞ در ﻓﺎﺻﻠﻪ

وﻟﻲ در ﻫﺮ.ﻣﺴﺪود ﻛﻨﻨﺪه را ﺑﺎ اﻧﺪازه ﻛﻮﭼﻜﺘﺮ اﻧﺘﺨﺎب ﻛﺮد

ﺗﺤﺖ ﻫﻴﭻ ﺷﺮاﻳﻄﻲ اﻧﺪازه ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه،ﺣﺎل ﻧﺒﺎﻳﺪ

اﻳﻨﭻ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد ﻣﮕﺮ اﻳﻨﻜﻪ ﺗﺄﻳﻴﺪﻳﻪ0/5 ﻛﻤﺘﺮ از

.ﻣﺨﺼﻮص از ﻛﺎرﻓﺮﻣﺎ درﻳﺎﻓﺖ ﮔﺮدد

ﻳﻚ ﺷﻴﺮ،ﻣﺤﻞ اﺗﺼﺎل ﺑﻪ ﻟﻮﻟﻪ ﻓﺮآﻳﻨﺪي ﻗﺮار داﺷﺘﻪ ﺑﺎﺷﺪ

( ﺑﺎﻳﺪ درvent) ﻣﺴﺪود ﻛﻨﻨﺪه اﺿﺎﻓﻲ ﻫﻤﺮاه ﺷﻴﺮ ﺗﺨﻠﻴﻪ

.ﻧﺰدﻳﻚ ﺑﻪ اﻧﺪازه ﮔﻴﺮ در ﻧﻈﺮ ﮔﺮﻓﺖ

6.3.4 In all cases, the gage pressure source stop

valve shall comply with piping standards. No

other fittings between the stop valve and process

pressure are permitted.

ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ، در ﻫﻤﻪ ﺷﺮاﻳﻂ4-3-6

ﻫﻴﭻ اﺗﺼﺎل دﻳﮕﺮي ﺑﻴﻦ ﺷﻴﺮ ﻣﺴﺪود.اﺳﺘﺎﻧﺪارد ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﺎﺷﺪ

.ﻛﻨﻨﺪه ﻓﺸﺎر ﻓﺮآﻳﻨﺪ ﻣﺠﺎز ﺑﻪ اﺳﺘﻔﺎده ﻧﻤﻲ ﺑﺎﺷﺪ

11

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

6.3.5 Snubbers or adjustable pulsation dampeners

shall be specified for fitting to all pressure gages

that are subject to pulsation. Where blockage of

the snubber may occur due to solids, a suitable

globe valve may be used to snub the impulse.

Liquid filled pressure gages are an acceptable

alternative to snubbers.

ﻣﺤﺪودﻛﻨﻨﺪه ﻳﺎ ﺿﺮﺑﻪ ﮔﻴﺮ ﻗﺎﺑﻞ ﺗﻨﻈﻴﻢ ﺑﺮاي ﻛﻠﻴﻪ5-3-6

6.3.6 Installation of indicating pressure gages

shall conform with the Company Standard

Drawings.

ﻧﺼﺐ ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺑﺎﻳﺪ ﻣﻨﻄﺒﻖ ﺑﺎ ﻧﻘﺸﻪ ﻫﺎي اﺳﺘﺎﻧﺪارد6-3-6

6.3.7 Surface mounted gages shall have back

mounting cases with bottom process connection.

ﻓﺸﺎرﺳﻨﺞ ﻫﺎﻳﻲ ﻛﻪ ﺑﺮ روي ﺳﻄﺢ ﻧﺼﺐ ﺷﺪه اﻧﺪ ﺑﺎﻳﺪ7-3-6

ﻓﺸﺎرﺳﻨﺞ ﻫﺎﻳﻲ ﻛﻪ در ﻣﻌﺮض ﻧﻮﺳﺎن ﻣﻲ ﺑﺎﺷﻨﺪ ﺑﺎﻳﺪ ﻣﺸﺨﺺ

در ﺷﺮاﻳﻄﻲ ﻛﻪ اﻣﻜﺎن ﮔﺮﻓﺘﮕﻲ ﻣﺤﺪودﻛﻨﻨﺪه ﻧﺎﺷﻲ از.ﮔﺮدد

ﻣﻮاد ﺟﺎﻣﺪ وﻗﻮع داﺷﺘﻪ ﺑﺎﺷﺪ ﺟﻬﺖ ﻣﺤﺪود ﻛﺮدن ﺿﺮﺑﻪ ﻣﻤﻜﻦ

ﻓﺸﺎرﺳﻨﺞ.( اﺳﺘﻔﺎده ﺷﻮدGlobe valve) اﺳﺖ از ﺷﻴﺮ ﻛﺮوي

ﭘﺮ ﺷﺪه از روﻏﻦ ﺟﺎﻳﮕﺰﻳﻦ ﻗﺎﺑﻞ ﻗﺒﻮل ﺑﺮاي ﻣﺤﺪودﻛﻨﻨﺪه

.ﻣﻲﺑﺎﺷﺪ

.ﻛﺎرﻓﺮﻣﺎ ﺑﺎﺷﺪ

داراي ﻳﻚ ﻧﮕﻬﺪارﻧﺪه از ﭘﺸﺖ ﺑﻮده و از ﻗﺴﻤﺖ ﭘﺎﻳﻴﻦ ﺑﻪ ﻓﺮآﻳﻨﺪ

.اﺗﺼﺎل داﺷﺘﻪ ﺑﺎﺷﻨﺪ

6.3.8 Panel mounted receiver gages shall have

flush mounting cases with rear signal connection,

where the signal connection shall be screwed ¼"

NPT/API standard male thread.

ﺳﻨﺠﻪ ﻫﺎي ﮔﻴﺮﻧﺪه اﻃﻼﻋﺎت ﺑﺎﻳﺪ روي ﺗﺎﺑﻠﻮ ﻫﻢ ﺳﻄﺢ8-3-6

6.3.9 Pressure gages mounted above the take-off

connection shall be protected from hot

condensable vapors (with higher than 100°C) by

means of a coiled siphon installation.

، ﻓﺸﺎرﺳﻨﺞ ﻫﺎﺋﻲ ﻛﻪ ﺑﺎﻻﺗﺮ از اﻧﺸﻌﺎب ﻧﺼﺐ ﻣﻲ ﺷﻮﻧﺪ9-3-6

6.3.10 pressure instruments on gas and vapor

service should be mounted above the pressure

tapping wherever possible. The tapping shall be

located on the top or side of the equipment.

اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر ﺑﺮ روي ﺳﺮوﻳﺲ ﻫﺎي ﮔﺎز و ﺑﺨﺎر ﺑﺎﻳﺪ10-3-6

اﺗﺼﺎل ﺳﻴﮕﻨﺎل ﺑﺎﻳﺪ.ﻧﺼﺐ و اﺗﺼﺎل ﺳﻴﮕﻨﺎل از ﭘﺸﺖ ﺑﺎﺷﺪ

. اﻳﻨﭻ روي ﭘﻴﭻ و رزوه اي ﺑﺎﺷﺪ0/25 NPT/API اﺳﺘﺎﻧﺪارد

ﺑﺎﻳﺪ ﺑﻪ وﺳﻴﻠﻪ ﺳﻴﻔﻮن ﻣﺎرﭘﻴﭻ درﻣﻘﺎﺑﻞ ﺑﺨﺎرات ﻣﺎﻳﻊ ﺷﻮﻧﺪه داغ

. درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد( ﻣﺤﺎﻓﻈﺖ ﮔﺮدﻧﺪ100 )ﺑﺎ دﻣﺎي ﺑﺎﻻﺗﺮ از

.ﺗﺎ آﻧﺠﺎﻳﻲ ﻛﻪ اﻣﻜﺎن دارد ﺑﺎﻻﺗﺮ از ﻧﻘﻄﻪ اﺗﺼﺎل ﻧﺼﺐ ﮔﺮدﻧﺪ

.ﻧﻘﻄﻪ اﺗﺼﺎل ﺑﺎﻳﺪ از ﺑﺎﻻ ﻳﺎ ﭘﻬﻠﻮي ﺗﺠﻬﻴﺰ ﺑﺎﺷﺪ

6.3.11 Pressure instruments installed on a

hydrocarbon service where an accumulation of

condensate is possible, shall be mounted above

the pressure tapping.

در ﺳﺮوﻳﺲ ﻫﺎي ﻫﻴﺪروﻛﺮﺑﻦ ﻛﻪ اﻣﻜﺎن ﺗﺠﻤﻊ ﺑﺨﺎرات11-3-6

6.3.12 Pressure instruments on LPG service shall

be fitted with an excess flow check valve,

downstream of a block valve, to prevent

excessive flow in the event of fracture of the

measuring element.

اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر ﺑﺎﻳﺪ ﻫﻤﺮاهLPG ﺑﺮاي ﺳﺮوﻳﺲ ﻫﺎي12-3-6

اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر ﺑﺎﻳﺪ ﺑﺎﻻي اﻧﺸﻌﺎب ﻓﺸﺎر،ﻣﺎﻳﻊ ﺷﺪه وﺟﻮد دارد

.ﻗﺮار ﮔﻴﺮد

ﺑﺎ ﺷﻴﺮ ﻳﻚ ﻃﺮﻓﻪ ﻗﻄﻊ ﺟﺮﻳﺎن اﺿﺎﻓﻲ ﺑﺎﺷﻨﺪ ﻛﻪ در ﭘﺎﻳﻴﻦ دﺳﺖ

ﻫﺪف از اﻳﻦ ﺷﻴﺮ ﺟﻠﻮﮔﻴﺮي از.ﺷﻴﺮ ﺟﺪاﻛﻨﻨﺪه ﻧﺼﺐ ﻣﻲ ﺷﻮد

ﺟﺮﻳﺎن اﺿﺎﻓﻲ ﻓﺮآﻳﻨﺪ ﻫﻨﮕﺎم ﺷﻜﺴﺘﻦ ﻋﻨﺼﺮ اﻧﺪازه ﮔﻴﺮي

.ﻣﻲﺑﺎﺷﺪ

ﺑﺮاي ﻧﺼﺐ ﻓﺸﺎرﺳﻨﺞ ﻫﺎ ﺑﺮ روي ﻣﺨﺎزن ﺑﺎﻳﺪ از ﻓﻠﻨﺞ13-3-6

6.3.13 Gages for use on vessels shall be flange

mounted type .The flange shall be 1½" class 300

minimum.

. اﺳﺘﻔﺎده ﮔﺮدد300 اﻳﻨﭻ و رده1/5 ﺑﺎ اﻧﺪازه ﺣﺪاﻗﻞ

ﻛﻠﻴﺪﻫﺎي ﻓﺸﺎر-7

7. PRESSURE SWITCHES

ﺗﻮﺻﻴﻪ ﻫﺎي ذﻳﻞ در راﺑﻄﻪ ﺑﺎ ﻣﻬﻨﺪﺳﻲ و ﻣﺸﺨﺼﺎت ﻓﻨﻲ

ﻛﻠﻴﺪﻫﺎي ﻓﺸﺎر ﺑﺮاي ﻛﺎرﺑﺮدﻫﺎي ﻫﺸﺪار و ﺣﻔﺎﻇﺖ ﺑﺎﻳﺪ در ﻧﻈﺮ

.ﮔﺮﻓﺘﻪ ﺷﻮﻧﺪ

The following recommendations shall be

considered in engineering and specifying the

pressure switches in annunciating and logic

protection applications.

12

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

اﺗﺼﺎل ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر ﺑﻪ ﺧﻄﻮط ﻓﺮآﻳﻨﺪ ﻣﻌﻤﻮﻻً ﺑﻪ ﺻﻮرت1-7

7.1 Connection of the pressure switch shall

normally be ½" NPT to the process and ¼" NPT

connection for pneumatic switch output signal.

اﻳﻨﭻ ﻣﻲ ﺑﺎﺷﺪ و ﺑﺮاي ﺳﻴﮕﻨﺎل ﺧﺮوﺟﻲ ﻛﻠﻴﺪ0/5 NPT

. اﻳﻨﭻ اﺳﺘﻔﺎده ﻣﻲ ﺷﻮد0/25 NPTﭘﻨﻴﻮﻣﺎﺗﻴﻚ از اﺗﺼﺎل

7.2 Housing of the pressure switches shall meet

the required climatic condition and electrical

classification of the plant.

ﺑﺪﻧﻪ ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ ﺷﺮاﻳﻂ آب و ﻫﻮاﻳﻲ2-7

7.3 Alarm annunciator pressure switches shall be

specified as single pole double throw (SPDT)

type. The normally closed (NC) contact shall be

utilized for normal operating condition in a

manner that the abnormal condition opens the

circuit.

ﻛﻠﻴﺪ ﻫﺎي ﻫﺸﺪاردﻫﻨﺪه ﻓﺸﺎر ﺑﺎﻳﺪ از ﻧﻮع ﺗﻚ ﭘﻞ دوﻃﺮﻓﻪ3-7

7.4 The pressure switches may be specified as

double pole double throw (DPDT) type switches.

DPDT ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر ﻣﻲ ﺗﻮاﻧﻨﺪ از ﻧﻮع دوﭘﻞ دوﻃﺮﻓﻪ4-7

7.5 Interlock and shut-down pressure switches

may be specified either normally open or

normally closed for normal operating conditions

depending on type and reliability of power

source, and also on fail-safe requirements.

ﻛﻠﻴﺪﻫﺎي ﻓﺸﺎر ﻛﻪ ﺑﺮاي ﻋﻤﻠﻴﺎت ﺗﻮﻗﻒ ﻛﺎﻣﻞ واﻳﻨﺘﺮﻻك5-7

.ﻣﻨﻄﻘﻪ و ﻃﺒﻘﻪ ﺑﻨﺪي اﻟﻜﺘﺮﻳﻜﻲ واﺣﺪ ﺑﺎﺷﺪ

( ﺑﺮاي ﺷﺮاﻳﻂNC) ﺑﺎﺷﻨﺪ ﻛﻨﺘﺎﻛﺖ ﻣﻌﻤﻮﻻ ﺑﺴﺘﻪSPDT

ﺑﻪ ﻃﻮرﻳﻜﻪ در ﺣﺎﻟﺖ ﻏﻴﺮ.ﻋﻤﻠﻴﺎﺗﻲ ﻧﺮﻣﺎل ﺑﺎﻳﺪ اﺳﺘﻔﺎده ﺷﻮد

.ﻧﺮﻣﺎل ﺑﺎﻋﺚ ﺑﺎز ﺷﺪن ﻣﺪار ﮔﺮدد

.ﻧﻴﺰ ﻣﺸﺨﺺ ﺷﻮﻧﺪ

ﺑﻜﺎر ﻣﻲ روﻧﺪ ﻣﻴﺘﻮاﻧﻨﺪ در ﺣﺎﻟﺖ ﻧﺮﻣﺎل ﺑﺎز ﻳﺎ ﻧﺮﻣﺎل ﺑﺴﺘﻪ ﺑﺮاي

ﺑﺴﺘﻪ ﺑﻪ ﻧﻮع و ﻗﺎﺑﻠﻴﺖ،ﺷﺮاﻳﻂ ﻋﻤﻠﻴﺎﺗﻲ ﻣﻌﻤﻮﻟﻲ اﺳﺘﻔﺎده ﺷﻮﻧﺪ

.اﻋﺘﻤﺎد ﻣﻨﺒﻊ ﺗﻐﺬﻳﻪ و ﻫﻤﭽﻨﻴﻦ اﻟﺰاﻣﺎت ﻗﻄﻊ اﻳﻤﻦ ﻣﻲ ﺑﺎﺷﺪ

7.6 Integral switches provided in recording and

controlling instruments shall not be used for

interlocking purposes.

ﺑﺮاي ﻣﻘﺎﺻﺪ اﻳﻨﺘﺮﻻك از ﻛﻠﻴﺪ ﻫﺎﻳﻲ ﻛﻪ روي ﺛﺒﺖ ﻛﻨﻨﺪه و6-7

7.7 Alarms and logic system elements are

preferable to be actuated from separate primary

switches rather than single associated switch, or

transmitter switching signal.

ﻋﻨﺎﺻﺮ ﻫﺸﺪار دﻫﻨﺪه و ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﻣﻨﻄﻘﻲ ﺗﺮﺟﻴﺤﺎً از7-7

7.8 Pressure switch measuring element may be;

bourdon tube, bellows or diaphragm type

depending upon the service and pressure

encountered. The measuring element in process

service shall be hardened type 316 stainless steel.

ﻋﻨﺼﺮ اﻧﺪازه ﮔﻴﺮي ﻛﻠﻴﺪﻫﺎي ﻓﺸﺎر ﻣﻲ ﺗﻮاﻧﻨﺪ از ﻧﻮع8-7

.ﻳﺎ ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﺗﻌﺒﻴﻪ ﺷﺪه اﻧﺪ ﻧﻤﻲ ﺗﻮان اﺳﺘﻔﺎده ﻛﺮد

ﻛﻠﻴﺪ ﻫﺎي ﺟﺪاﮔﺎﻧﻪ اي ﺑﺎﻳﺪ ﺗﺤﺮﻳﻚ ﺷﻮﻧﺪ و ﻧﻤﻲ ﺗﻮان از ﻳﻚ

ﻛﻠﻴﺪ ﺑﺮاي دو ﻣﻨﻈﻮر ﻣﺘﻔﺎوت ﻳﺎ ﺳﻴﮕﻨﺎل ﻛﻠﻴﺪ ﻧﺎﺷﻲ از اﻧﺘﻘﺎل

.دﻫﻨﺪه اﺳﺘﻔﺎده ﻛﺮد

ﺑﻮردن ﺗﻴﻮپ و ﻓﺎﻧﻮس ﻳﺎ دﻳﺎﻓﺮاﮔﻢ ﺑﺎﺷﺪ ﻛﻪ در اﻳﻦ ﻣﻮرد ﺑﺴﺘﮕﻲ

ﻋﻨﺼﺮ اﻧﺪازه ﮔﻴﺮي در.ﺑﻪ ﻧﻮع ﺳﺮوﻳﺲ ﻓﺮآﻳﻨﺪي و ﻓﺸﺎر دارد

ﺳﺨﺖ316 ﺳﺮوﻳﺲ ﻓﺮآﻳﻨﺪي ﺑﺎﻳﺪ از ﺟﻨﺲ ﻓﻮﻻد ﺿﺪ زﻧﮓ

.ﺷﺪه ﺑﺎﺷﺪ

7.9 The mercury type pressure switches shall only

be used in environments free from vibration, and

in applications which they can be installed in a

leveled position.

از ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر از ﻧﻮع ﺟﻴﻮه اي ﻓﻘﻂ در ﻣﺤﻴﻂ ﻫﺎي9-7

7.10 The pressure switches may be selected of

adjustable range, or fixed range as applicable.

ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر ﻣﻲ ﺗﻮاﻧﻨﺪ ﺑﺎ داﻣﻨﻪ، ﺑﺴﺘﻪ ﺑﻪ ﻧﻮع ﻛﺎرﺑﺮد10-7

7.11 Irrespective of the pressure setting, the

pressure switch shall be capable to withstand 1.3

times of the maximum service pressure.

ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر ﺑﺎﻳﺪ، ﺻﺮف ﻧﻈﺮ از ﻧﻘﻄﻪ ﺗﻨﻈﻴﻢ ﻓﺸﺎر11-7

7.12 Electrical entry shall be internally threaded

type, and suitable for pg-13.5 conduits or M20

ورودي ﻛﺎﺑﻞ ﻛﻠﻴﺪ ﻫﺎي ﻓﺸﺎر ﺑﺎﻳﺪ از داﺧﻞ رزوه ﺷﺪه12-7

ﺑﺪون ارﺗﻌﺎش و در ﻛﺎرﺑﺮد ﻫﺎﻳﻲ ﻛﻪ ﻣﺤﻞ ﻧﺼﺐ آن ﻛﺎﻣﻼً ﺗﺮاز

.ﺑﺎﺷﺪ ﻣﻲ ﺗﻮان اﺳﺘﻔﺎده ﻛﺮد

.ﻗﺎﺑﻞ ﺗﻨﻈﻴﻢ ﻳﺎ داﻣﻨﻪ ﺛﺎﺑﺖ اﻧﺘﺨﺎب ﮔﺮدﻧﺪ

.ﺑﺮاﺑﺮ ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ را داﺷﺘﻪ ﺑﺎﺷﻨﺪ1/3ﺗﻮاﻧﺎﻳﻲ ﺗﺤﻤﻞ

ﻳﺎ وروردي ﮔﻠﻨﺪPg-13.5 ﻣﺘﻨﺎﺳﺐ ﺑﺎ ﻟﻮﻟﻪ ﻛﺎﻧﺪوﺋﻴﺖ،ﺑﺎﺷﺪ

13

Jul. 2009/ 1388 ﺗﻴﺮ

gland entrance.

IPS-E-IN-110(1)

. M20

ﻓﺮﺳﺘﻨﺪه ﻫﺎي ﻓﺸﺎر-8

8. PRESSURE TRANSMITTERS

8.1 Conventional electronic transmitters normally

shall be specified for conventional or DCS

control systems with 4-20 mA output signal.

ﻓﺮﺳﺘﻨﺪه ﻫﺎي اﻟﻜﺘﺮوﻧﻴﻜﻲ ﻣﺘﺪاول ﺑﺮاي ﺳﻴﺴﺘﻢ ﻫﺎي1-8

8.2 Intelligent digital transmitters shall be used

for remote or inaccessible applications to utilize

their self calibration capability, or for DCS

system when digital output signal is used in a

manner to match the communication system of

the DCS.

ﻓﺮﺳﺘﻨﺪه ﻫﺎي دﻳﺠﻴﺘﺎل ﻫﻮﺷﻤﻨﺪ ﺑﻪ ﻣﻨﻈﻮر اﺳﺘﻔﺎده از2-8

ﻣﻴﻠﻲ آﻣﭙﺮ20 ﺗﺎ4 ﺑﺎ ﺳﻴﮕﻨﺎل ﺧﺮوﺟﻲDCS ﻛﻨﺘﺮل ﻣﻌﻤﻮﻟﻲ ﻳﺎ

.ﺑﺎﻳﺪ ﻣﺸﺨﺺ ﺷﻮد

ﻗﺎﺑﻠﻴﺖ ﺗﻨﻈﻴﻢ از راه دور ﻳﺎ ﻏﻴﺮ ﻗﺎﺑﻞ دﺳﺘﺮس ﺑﺎﻳﺪ اﺳﺘﻔﺎده ﻛﺮد

درﺣﺎﻟﻴﻜﻪ از ﺳﻴﮕﻨﺎل دﻳﺠﻴﺘﺎل ﺧﺮوﺟﻲDCS ﻳﺎ از ﺳﻴﺴﺘﻢ

. اﺳﺘﻔﺎده ﮔﺮددDCS ﺑﺮاي ﺗﻄﺒﻴﻖ ﺳﻴﺴﺘﻢ ارﺗﺒﺎط

8.3 Application of pneumatic transmitters in

pneumatic loops shall be considered according to

the requirements aforementioned in item 5.

ﻛﺎرﺑﺮد اﻧﺘﻘﺎل ﻓﺮﺳﺘﻨﺪه ﻫﺎي ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ در ﺣﻠﻘﻪ ﻫﺎي3-8

8.4 Pressure range of transmitters shall be

selected so that, normal operating pressure will be

within 50% and 85% of calibrated range.

ﻣﺤﺪوده ﻓﺸﺎر ﻓﺮﺳﺘﻨﺪه ﺑﺎﻳﺪ ﻃﻮري اﻧﺘﺨﺎب ﺷﻮد ﻛﻪ ﻓﺸﺎر4-8

8.5 Pressure instruments measuring elements may

be; bourdon tube, spiral, helical, bellows or

diaphragm type, depending upon the service and

pressure. The measuring element shall be type

316 stainless steel, unless process fluid requires

application of other materials, which in such

cases, selection shall be made according to NACE

MR-0175. Diaphragm seal elements may be

provided in order to eliminate steam tracing,

purging, winterizing and corrosion except for

vacuum services.

ﻋﻨﺼﺮ اﻧﺪازه ﮔﻴﺮي ﻓﺸﺎر، ﺑﺴﺘﻪ ﺑﻪ ﻧﻮع ﺳﺮوﻳﺲ و ﻓﺸﺎر5-8

5 ﺑﺴﺘﻪ ﭘﻨﻴﻮﻣﺎﺗﻴﻚ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ اﻟﺰاﻣﺎت ذﻛﺮ ﺷﺪه در ﺑﻨﺪ

.ﺑﺎﺷﺪ

درﺻﺪ ﻣﺤﺪوده80 درﺻﺪ و50 ﻧﺮﻣﺎل ﻋﻤﻠﻴﺎﺗﻲ ﺑﻴﻦ

.ﻛﺎﻟﻴﺒﺮاﺳﻴﻮن ﺑﺎﺷﺪ

ﻓﺎﻧﻮس ﻳﺎ، ﺑﻴﻀﻮي، ﻣﺎرﭘﻴﭻ،ﻣﻲﺗﻮاﻧﺪ از ﻧﻮع ﻟﻮﻟﻪ ﺑﻮردون

ﻋﻨﺼﺮ اﻧﺪازه ﮔﻴﺮي ﺑﺎﻳﺪ از ﺟﻨﺲ ﻓﻮﻻد ﺿﺪ.دﻳﺎﻓﺮاﮔﻤﻲ ﺑﺎﺷﺪ

ﻣﮕﺮ در ﻛﺎرﺑﺮد ﻫﺎﻳﻲ ﻛﻪ ﺳﻴﺎل ﻓﺮآﻳﻨﺪي اﻟﺰام، ﺑﺎﺷﺪ316 زﻧﮓ

ﻛﻪ در آن ﺻﻮرت،اﺳﺘﻔﺎده از ﻣﺎده دﻳﮕﺮي را داﺷﺘﻪ ﺑﺎﺷﺪ

اﻧﺘﺨــــﺎب ﻋﻨﺼﺮ اﻧﺪازه ﮔﻴﺮي ﺑـــﺎﻳﺪ ﻣﻄﺎﺑـﻖ ﺑﺎ اﺳﺘــــﺎﻧﺪارد

ﺻﻔﺤﻪ ﻣﺠﺰا ﻛﻨﻨﺪه ﻣﻲ ﺗﻮاﻧﺪ. ﺑﺎﺷﺪNACE-MR-0175

ﺳﺮﻣﺎ زدﮔﻲ و ﺧﻮردﮔﻲ ﺑﺠﺰ، ﻫﻮادﻫﻲ،ﺟﻬﺖ ﺣﺬف ﮔﺮم ﻛﻨﻨﺪه

.در ﺳﺮوﻳﺲ ﺧﻼ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﻴﺮد

8.6 Instruments shall be specified to have overrange protection equal to 1.3 times of maximum

operating pressure to which they may be exposed.

، ﺑﺮاي ﺣﻔﺎﻇﺖ ﻓﺮﺳﺘﻨﺪه در ﺑﺮاﺑﺮ ﻓﺸﺎر ﻫﺎي اﺿﺎﻓﻲ6-8

8.7 Electronic pressure transmitter may be

specified as; smart force balance electronic, strain

gage, capacitance or piezo electric type. Priority

will be given to the system with better

maintainability and reliability.

ﻓﺮﺳﺘﻨﺪه ﻓﺸﺎر اﻟﻜﺘﺮوﻧﻴﻜﻲ ﻣﻲ ﺗﻮاﻧﺪ از ﻧﻮع ﻫﻮﺷﻤﻨﺪ7-8

8.8 Pressure instrument shall be located so that

the head of the liquid between the instrument and

the lowest point of measurement does not exceed

the ratio span of the instrument.

ﻣﺤﻞ ﻗﺮارﮔﺮﻓﺘﻦ ادوات اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر ﺑﺎﻳﺪ ﻃﻮري ﺑﺎﺷﺪ8-8

ﺑﺮاﺑﺮ ﺣﺪاﻛﺜﺮ1/3 ﻣﺤﺪوده ﺣﻔﺎﻇﺘﻲ اﻧﺘﻘﺎل دﻫﻨﺪه ﺑﺎﻳﺪ ﺑﺮاﺑﺮ

.ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ ﺑﺎﺷﺪ ﻛﻪ ﺑﻪ دﺳﺘﮕﺎه اﻋﻤﺎل ﻣﻲ ﺷﻮد

ﺧﺎزﻧﻲ ﻳﺎ ﻓﻴﺰو، اﻧﺪازه ﮔﻴﺮ ﻛﺸﺶ،(DP Cell) ﺗﻌﺎدل ﻧﻴﺮو

اوﻟﻮﻳﺖ اﻧﺘﺨﺎب ﺑﺎﻳﺴﺘﻲ ﻛﻪ داراي ﻗﺎﺑﻠﻴﺘﻬﺎي.اﻟﻜﺘﺮﻳﻚ ﺑﺎﺷﺪ

.ﺗﻌﻤﻴﺮاﺗﻲ و اﻃﻤﻴﻨﺎن ﺑﻴﺸﺘﺮ ﻣﻲ ﺑﺎﺷﺪ

ﻛﻪ ﻓﺸﺎر اﺳﺘﺎﺗﻴﻚ ﻣﺎﻳﻊ ﺑﻴﻦ ﺗﺠﻬﻴﺰ اﺑﺰار دﻗﻴﻖ و ﭘﺎﺋﻴﻦ ﺗﺮﻳﻦ

.ﻧﻘﻄﻪ اﻧﺪازه ﮔﻴﺮي ﺑﻴﺸﺘﺮ از ﮔﺴﺘﺮه ﺗﺠﻬﻴﺰ ﻧﺒﺎﺷﺪ

ﻓﺮﺳﺘﻨﺪه ﻫﺎي اﺧﺘﻼف ﻓﺸﺎر ﺑﺮاي ﻧﻤﺎﻳﺶ ﮔﺮﻓﺘﮕﻲ ﻓﻴﻠﺘﺮﻫﺎ9-8

8.9 Differential pressure transmitters shall be

used in applications such as indication of filter

blockage, control of separator performance, etc.

ﻳﺎ ﻛﻨﺘﺮل ﻋﻤﻠﻜﺮد ﻇﺮوف ﺟﺪاﮔﺎﻧﻪ و ﻏﻴﺮه ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار

.ﻣﻲﮔﻴﺮد

14

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻫﺎي ﻣﺤﻠﻲ ﻓﺸﺎر-9

9. LOCAL PRESSURE CONTROLLERS

ﻛﻨﺘﺮل ﻛﻨﻨﺪهﻫﺎي ﻣﺤﻠﻲ ﻓﺸﺎر ﭘﻨﻴﻮﻣﺎﺗﻴﻜﻲ از ﻧﻮع ﻧﻤﺎﻳﺸﮕﺮ1-9

9.1 Local pneumatic pressure controllers of

indicating type or blind type may be used for

applications where transmission to remote

receivers is not required. The controller shall be

considered with weatherproof case or housing,

suitable for free-stand mounting. Convenient

control point setting shall be provided in the

controller. In case of blind controllers, a pressure

gage shall be supplied to indicate the process

pressure.

ﻳﺎ ﺑﺪون ﻧﻤﺎﻳﺸﮕﺮ در ﻣﻮاردي ﻛﻪ اﻧﺘﻘﺎل ﺳﻴﮕﻨﺎل ﺑﻪ ﮔﻴﺮﻧﺪه ﻏﻴﺮ

ﻛﻨﺘﺮﻟﺮ ﺑﺎﻳﺪ ﺑﺎ.ﻣﺤﻠﻲ ﻣﺪ ﻧﻈﺮ ﻧﺒﺎﺷﺪ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮد

ﺑﺪﻧﻪ ﻣﻘﺎوم در ﺑﺮاﺑﺮ ﻫﻮا و ﺷﺮاﻳﻂ ﻣﺤﻴﻂ و ﻣﻨﺎﺳﺐ ﺑﺮاي ﻧﺼﺐ

ﺗﻨﻈﻴﻢ ﻧﻘﻄﻪ ﻛﻨﺘﺮل ﻣﻨﺎﺳﺐ ﺑﺎﻳﺪ ﺑﺮاي ﻛﻨﺘﺮﻟﺮ در.روي ﭘﺎﻳﻪ ﺑﺎﺷﺪ

در ﺣﺎﻟﻲ ﻛﻪ از ﻛﻨﺘﺮﻟﺮ ﺑﺪون ﻧﻤﺎﻳﺸﮕﺮ اﺳﺘﻔﺎده.ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد

از ﻳﻚ ﻓﺸﺎرﺳﻨﺞ ﺟﻬﺖ ﻧﻤﺎﻳﺶ و ﻧﺸﺎن دادن ﻓﺸﺎر،ﻣﻲ ﺷﻮد

.ﻓﺮآﻳﻨﺪ ﺑﺎﻳﺪ اﺳﺘﻔﺎده ﺷﻮد

ﺗﻨﻈﻴﻢ ﻛﻨﻨﺪه ﻓﺸﺎر ﺧﻮد ﻋﻤﻠﮕﺮ ﻛﻪ ﺑﻪ ﻃﻮر ﻣﺴﺘﻘﻴﻢ ﻧﺼﺐ2-9

9.2 Direct connected self-actuated pressure

regulators may be used for air and utility services

where a deviation of ten percent from the control

point can be tolerated.

، ﻣﻲ ﺗﻮاﻧﻨﺪ ﺑﺮاي ﺳﺮوﻳﺲ ﻫﺎي ﺟﺎﻧﺒﻲ ﺑﻜﺎر روﻧﺪ،ﻣﻲ ﺷﻮﻧﺪ

. درﺻﺪ را ﺗﺤﻤﻞ ﻧﻤﺎﻳﺪ10 ﻣﺸﺮوط ﺑﻪ اﻳﻨﻜﻪ اﻧﺤﺮاف

داده ﺑﺮگ ﻫﺎ و ﻧﻘﺸﻪ ﻫﺎ-10

10. DATA SHEETS AND DRAWINGS

ﻋﻤﻮﻣﻲ1-10

10.1 General

اﺳﺘﺎﻧﺪارد

10.1.1 P & ID drawings shall be prepared using

ISA 5.1 (R1992) symbols and notations. For

Graphic Symbols & Process Flow Diagram see

ASME Y32.11

ﺑﺎ

ﻣﻄﺎﺑﻖ

ﺑﺎﻳﺪ

P&ID

ﻧﻘﺸﻪ

1-1-10

ﺑﺮاي ﻧﺸﺎنﻫﺎي. "ﻧﺸﺎن و ﻧﻤﺎد" ﺗﻬﻴﻪ ﮔﺮددISA 5.1(R1992)

رﺟﻮعASME Y32.11 ﮔﺮاﻓﻴﻜﻲ و دﻳﺎﮔﺮام ﺟﺮﻳﺎن ﻓﺮآﻳﻨﺪ ﺑﻪ

.ﺷﻮد

10.1.2 Generally, the drawing requirements shall

be fully in accordance with general instrument

engineering requirement stated in IPS-E-IN-100.

در ﺣﺎﻟﺖ ﻛﻠﻲ اﻟﺰاﻣﺎت ﻧﻘﺸﻪ ﺑﺎﻳﺪ ﻛﺎﻣﻼ ﻣﻄﺎﺑﻖ ﺑﺎ2-1-10

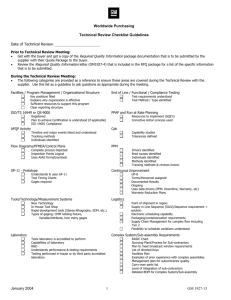

10.1.3 The pressure instruments data sheets shall

be based on ISA-TR20. forms. The attached data

sheets are recommended to be used for design

purpose. In case that the company’s consultant

engineers prefer to use their own standard data

sheets, then all information required on the

attached data sheets shall be included in theirs as

well.

داده ﺑﺮگ ادوات اﺑﺰار دﻗﻴﻖ ﻓﺸﺎر ﺑﺎﻳﺪ ﺑﺮ ﻣﺒﻨﺎي ﻓﺮم3-1-10

ﺑﻴﺎنIPS-E-IN-100 ﻧﻴﺎزﻫﺎي ﻣﻬﻨﺪﺳﻲ اﺑﺰار دﻗﻴﻖ ﻛﻪ در

.ﺷﺪه اﺳﺖ ﺑﺎﺷﺪ

داده ﺑﺮگﻫﺎي ﺿﻤﻴﻤﻪ ﺑﺮاي اﻫﺪاف ﻃﺮاﺣﻲ. ﺑﺎﺷﺪISA-TR20.

در ﻣﻮاردي ﻛﻪ ﺷﺮﻛﺖ ﻫﺎي ﻣﻬﻨﺪﺳﻴﻦ ﻣﺸﺎور.ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد

ﺗﺮﺟﻴﺢ ﻣﻲ دﻫﻨﺪ ﻛﻪ از داده ﺑﺮگ اﺳﺘﺎﻧﺪارد ﺧﻮدﺷﺎن اﺳﺘﻔﺎده

ﺗﻤﺎم اﻃﻼﻋﺎت ﻣﻮرد ﻧﻴﺎز در داده ﺑﺮگ ﻫﺎي ﺿﻤﻴﻤﻪ ﺑﺎﻳﺪ،ﻛﻨﻨﺪ

.در داده ﺑﺮگﻫﺎي ﻣﻬﻨﺪﺳﻴﻦ ﻣﺸﺎور ﮔﻨﺠﺎﻧﺪه ﺷﻮد

10.1.4 In case that the forms presented for

pressure instruments contain information about

controller/recorders or instruments covered under

other titles, they only apply to local type

instruments.

در ﻣﻮاردﻳﻜﻪ ﻓﺮم ﻫﺎي اراﺋﻪ ﺷﺪه ﺑﺮاي ادوات اﺑﺰار4-1-10

ﺛﺒﺖ ﻛﻨﻨﺪه ﻳﺎ اﺑﺰار،دﻗﻴﻖ ﻓﺸﺎر ﺷﺎﻣﻞ اﻃﻼﻋﺎﺗﻲ در ﻣﻮرد ﻛﻨﺘﺮﻟﺮ

دﻗﻴﻘﻲ ﺑﺎﺷﺪ ﻛﻪ ﺗﺤﺖ ﻋﻨﻮان دﻳﮕﺮي ﭘﻮﺷﺶ داده ﺷﺪه اﺳﺖ

.ﻓﺮﻣﻬﺎ ﻓﻘﻂ ﺑﺮاي اﺑﺰار دﻗﻴﻖ ﻣﺤﻠﻲ ﺑﺎﻳﺪ ﺑﻜﺎر روﻧﺪ

15

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

APPENDICES

ﭘﻴﻮﺳﺖ ﻫﺎ

APPENDIX A STANDARD DATA SHEET

FORMS ISA-TR20.00.01-2001

ﻓــﺮﻣﻬﺎي داده ﺑﺮگ اﺳﺘــﺎﻧﺪارد-ﭘﻴﻮﺳﺖ اﻟﻒ

ISA- TR20.00.01-2001

داده ﺑﺮگ ﻫﺎي ﻓﺮﺳﺘﻨﺪه ﻓﺸﺎر ﺑﺎ آب ﺑﻨﺪ1-اﻟﻒ

A.1 Pressure Transmitter with Diaphragm

Seal Data Sheets

دﻳﺎﻓﺮاﮔﻤﻲ

داده ﺑﺮگ ﻫﺎي ﻓﺮﺳﺘﻨﺪه ﻓﺸﺎرﺳﻨﺞ2-اﻟﻒ

A.2 Pressure Transmitter Data Sheets

A.3 Differential Pressure Gauge Data Sheets

داده ﺑﺮگ ﻫﺎي ﺳﻨﺠﻪ اﺧﺘﻼف ﻓﺸﺎر3 -اﻟﻒ

A.4 Differential Pressure Switch Data Sheets

داده ﺑﺮگ ﻫﺎي ﻛﻠﻴﺪ اﺧﺘﻼف ﻓﺸﺎر4-اﻟﻒ

16

Jul. 2009/ 1388 ﺗﻴﺮ

IPS-E-IN-110(1)

A.1 Pressure Transmitter with Diaphragm Seal Data Sheets

17

)IPS-E-IN-110(1

ﺗﻴﺮ Jul. 2009/ 1388

اﻟﻒ 1-داده ﺑﺮگ ﻫﺎي ﻓﺮﺳﺘﻨﺪه ﻓﺸﺎر ﺑﺎ آب ﺑﻨﺪ دﻳﺎﻓﺮاﮔﻤﻲ

18

Jul. 2009/ 1388 ﺗﻴﺮ

A.2 Pressure Transmitter Data Sheets

19

IPS-E-IN-110(1)

)IPS-E-IN-110(1

ﺗﻴﺮ Jul. 2009/ 1388

اﻟﻒ 2-داده ﺑﺮگ ﻫﺎي ﻓﺮﺳﺘﻨﺪه ﻓﺸﺎرﺳﻨﺞ

20

Jul. 2009/ 1388 ﺗﻴﺮ

A.3 Differential Pressure Gauge Data Sheets

21

IPS-E-IN-110(1)

)IPS-E-IN-110(1

ﺗﻴﺮ Jul. 2009/ 1388

اﻟﻒ 3 -داده ﺑﺮگ ﻫﺎي ﺳﻨﺠﻪ اﺧﺘﻼف ﻓﺸﺎر

22

Jul. 2009/ 1388 ﺗﻴﺮ

A.4 Differential Pressure Switch Data Sheets

23

IPS-E-IN-110(1)

)IPS-E-IN-110(1

ﺗﻴﺮ Jul. 2009/ 1388

اﻟﻒ 4-داده ﺑﺮگ ﻫﺎي ﻛﻠﻴﺪ اﺧﺘﻼف ﻓﺸﺎر

24