Procedures for IUR Sampling Chapter 7

advertisement

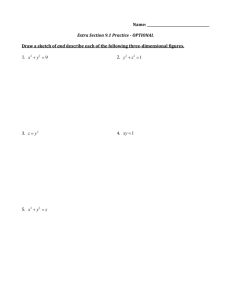

Chapter 7 Procedures for IUR Sampling Chapter 6 emphasized the requirement that sampling of a three-dimensional structure with points, lines or planes be isotropic, uniform and random (IUR). Accomplishing this is not easy, and much of the thrust of recent stereological development has been to explore sampling strategies that provide such results. It is useful to summarize here just what IUR means (without recapitulating the detailed discussion in Chapter 6). Point probes do not have to be isotropic, because the points themselves have no direction. It is sufficient to disperse a set of points through the structure with an equal probability of sampling all regions (e.g., not points that are concentrated near one end or near the surface), and which are randomly placed with respect to the structure. The idea of randomness is not always an easy one to test. If the structure itself has no regular spacings or repetitive structure, a regular grid of points can be used (and often is, for convenience in counting and for efficiency of sampling). But if the structure does have some regularity, then the use of a regular grid of points will produce a biased result. Figure 7.1 shows a cross section of a man-made fiber composite. While not perfectly regular in their arrangement, the fibers are clearly not randomly distributed in the microstructure. Attempting to measure the volume fraction of fibers with a grid of points would produce a biased result because that grid and the arrangement of the fibers would interfere to produce a result in which points systematically hit or missed the fibers. For an image such as this one a routine that placed points at random on the image would be required. Typically this is done by generating two uniform random numbers using a computer pseudo-random number generator (a mathematical routine seeded by the system clock; we will not consider the intricacies of such routines here). The two numbers are typically provided as decimal fractions between 0 and 1, and can conveniently be scaled to the dimensions of the image to locate points in X, Y coordinates. Such random sampling can be used for any structure of course, even one that has no regularities. But there is a more efficient procedure that produces equivalent results. It converges on the same answer as more and more points are sampled and converges more rapidly than the random sampling approach (Gundersen & Jensen, 1987). This is equivalent to saying that it has a better precision for a given amount of effort. The method (described in earlier chapters) is called structured random sampling, which at first seems to be an oxymoron. It can be applied to many types of sampling with points, lines and planes, but will be explained first as it applies to the point sampling of an image. 127 128 Chapter 7 Figure 7.1. Cross section image of a man-made fiber composite, with an approximately regular array of fibers. Volume Fraction To determine the volume fraction of a phase in a structure, assuming that the sampling plane is representative (we will see below how to deal with that requirement), the fundamental stereological relationship is VV = PP, or the volume fraction equals the point fraction. The precision of a counting measurement is a standard deviation equal to the square root of the number of events counted. For instance, if asked to estimate the number of cars per hour traveling along a highway we could count the cars and measure the time required for 100 cars to pass. The number of cars divided by the time T (expressed as a fraction of one hour) would give the desired answer. The standard deviation of the number counted is 10, so the relative standard precision would be 10/100 = 10%. By counting 1000 cars we could reduce —— the standard deviation to ÷1000 = 31.6, or a relative standard precision of 3.16%. Counting 10,000 cars would give a relative standard precision of 1%. Usually in a given experiment we know what precision is required or desired. Consider for the moment a desired precision of 10%. This requires counting 100 events as described above. For point counting, this means that there are 100 points in the grid or random distribution that hit the phase of interest. If the phase represents (e.g.) 25% of the structure, this would require placing 400 points onto the image to achieve 100 hits. However, there is one additional assumption hidden in this procedure: each of the points is required to be an independent sample of the structure. This means that the points should be separated from each other by enough distance that they do not repeat the same measurement, which is usually taken to mean that they do not lie closer together than a characteristic distance in the structure such as the mean intercept length. Procedures for IUR Sampling 129 Figure 7.2. An example of 200 random points. Note the presence of clusters of points that oversample some regions while large gaps exist elsewhere. However, random points generated by the procedure outlined above will not all conform to that assumption. As shown in Figure 7.2, random distributions of points on an image inevitably produce some points that are quite close together. These are not all independent samples, and so the actual precision of the measurement is not as good would be predicted based on the number of points. The clustering of points produced by a random (Poisson) generation process is used in another context to study the degree to which features in images have tendencies toward clustering or self-avoidance. The standard deviation of the PP value obtained using random points will be greater (worse) than with a regular grid by a factor of e (2.718). Notice that this does not mean that the result obtained with such a random point array is biased or in error, just that it takes more work (more points have to be sampled) to obtain an equivalent measurement precision. The use of regular grids of points to count PP is widely used, of course. Grids of points are available as reticles to fit within microscope eyepieces, or applied to photographic prints as transparent overlays, or superimposed on images using computer displays. This is not so much a consequence of the greater measurement efficiency as a recognition of the ease of counting such points manually by having the eye track along a regular grid. The proper way to use such a grid while still obeying the requirements of random sampling according to the structured random sampling method is as follows: 130 Chapter 7 1. Determine, based on the desired level of precision and the estimated volume fraction of the target phase, the number of points to be sampled in the image. Note that in many real cases not all of the points will be sampled in a single image—there will be many fields and many section planes in order to meet the requirements of uniform sampling of the entire structure. There is also the restriction against using too many points on one image based on the requirement that the points must be separated far enough to be independent samples, meaning as noted above that multiple points do not fall into the same region of the structure. 2. The resulting number of points form a regular grid. Typically these grids are square so that the number of points is a perfect square (25, 49, 100, etc.) with fairly small numbers used for purely manual counting because larger numbers foster human counting errors. In the example shown in Figure 7.3, the grid is 5 ¥ 5 = 25 points. 3. Generate a pair of random numbers that define the X, Y coordinates for the placement of the first point of the grid within a square on the image. This will automatically place all of the other grid points at the same relative offset. 4. Perform the counting of PP. 5. For other fields of view, generate new random numbers for the offset and repeat steps 3 and 4, until enough fields of view, section planes, etc. have Figure 7.3. A 5 ¥ 5 grid placed on an image area. The upper left corner is displaced randomly within the red square to accomplish structured random sampling of the area. (For color representation see the attached CD-ROM.) Procedures for IUR Sampling 131 been examined to produce uniform sampling of the structure and enough points have been counted to produce the desired precision. This procedure is a straightforward application of structured random sampling. Several examples will be detailed below that extend the same method to other situations and types of probes. In all cases note that it is important to estimate beforehand the number of images (sections planes and fields of view) that must be examined in order to obtain the desired precision. This requires an estimate of the quantity being measured, in this example the volume fraction. Typically this parameter is known at least approximately from previous sampling of the structure, prior results on other similar specimens, or independent knowledge about the objects of interest. Sampling Planes The same procedure as detailed above can be applied to the selection of the sampling planes themselves. For example, consider the problem of determining the volume fraction of a phase within an irregular 3D object as shown in Figure 7.4. The measurement in this case must measure the volume of the object as a whole as well as that of the phase in order to obtain the volume fraction. If the phase is expected to be about 20% of the volume, and a measurement precision of 5% is desired, this means that about 400 points should hit the phase and hence 2000 points should hit the object. If the object is 5 inches long and about 3 inches in diameter, a rough estimate of its volume can be made by assuming a more-or-less ellipsoidal shape. The volume of an ellipsoid is about half (p/6 = 0.524) of the volume of the bounding box. This means that grid should have about 4000 points. A cubical grid spacing of 0.2 inches will produce a total of 15 ¥ 15 ¥ 25 = 5625 points, quite suitable for this measurement. This sampling grid can be achieved by sectioning the specimen every 0.2 inches and placing a grid with that spacing onto each section for counting. The placement of the grid uses the method described above. A similar method is used to position the planes: A single random number can be used to determine the position of the first plane within the first 0.2 inches of the specimen, and then all of the other planes are regularly spaced with respect to this first one. In this way structured random sampling is extended to all three dimensions. This represents a fairly large number of points and a high sampling density; most stereological experiments use much lower sampling density and achieve lower precision on each specimen, but average over many specimens. In the example of Figure 7.4, a lower sampling density has been used for clarity. The planes are spaced 1/2 inch apart and the grids have a 1/2 inch spacing, producing a total of 360 points, of which about 180 can be expected to fall within the object and hence about 36 within the phase of interest. This corresponds to a standard deviation due to counting statistics of ±6, or a relative precision of 6/36 = 17%. In many cases the sections of the specimen are obtained with a microtome, in which case the procedure is to take every Nth section from the series to obtain the desired spacing, starting with a randomized initial section. Likewise, if the 132 Chapter 7 a b Figure 7.4. A representative irregular object (potato) to be sampled as discussed in the text, and one section to be used for counting with a portion of the grid superimposed. (For color representation see the attached CD-ROM.) examination procedure is to use M fields of view on each section, the procedure is to create a grid of field positions which is offset by a random location on each section. The procedure can also be extended to sampling specimens within a population in the same way. Isotropic Planes Unlike point probes, lines and planes have a direction and so it is also necessary to make their orientation isotropic within the structure. This is much more Procedures for IUR Sampling 133 difficult to accomplish (and may be very important, as few natural structures are themselves isotropic). Line probes are used to sample surfaces and volumes, either by counting the intersections of the line probes with surfaces or measuring the intercept length with the volumes. Because counting is a much easier and hence preferred technique, and the precision of counting experiments can be predicted as discussed above, most modern stereological experiments emphasize counting of intercepts and so we discuss here the use of line probes for that purpose. Lines cannot in general be passed through structures without first cutting planes on which to draw the lines. If all of the planes were cut as in the preceding experiment as a series of parallel sections, it would not be possible to draw lines in any direction except those included in the planes. Hence the most commonly used and efficient method of cutting parallel plane sections through a specimen cannot be used when line probes are to be employed for surface area measurement. It is instructive to consider first the procedures for placing an IUR set of planes through an object. This is required when the measurement probe is a plane, for instance when measuring the size and shape of plane intersections with features or counting the intersections of the plane with features in the volume. Plane probes are primarily used for counting the number of intersections per unit area with linear structures such as fibers, which are rarely isotropic in space, in order to measure the total length of the linear structures. IUR planes can also be used for drawing line probes through structures, although we will see later that there is an easier way to accomplish this when the purpose is simply to count intersections of the lines with surfaces. In order for sampling to be uniform, it will still be necessary to obtain a series of sections that cover the extent of the feature. There is a tendency in visualizing the orientation of section planes to deal with those that pass through the geometric center of the object being sectioned, which of course does not provide uniform sampling of the extremities. Since many real structures are not only anisotropic but also have gradients, the need for uniform sampling is very important. Using a series of section planes (distributed as discussed above using the principles of structured random sampling) naturally limits the sampled planes to a single orientation, because once cut they cannot be reassembled to permit sampling again in another orientation. This usually means that multiple specimens must be used to obtain many different sampling orientations, which in turn requires that specimens within a population must have some definable or discernible axis of orientation of their own that can be used as a basis for selecting orientations. In biological systems, which is the primary field of application of these techniques, this is usually straightforward. For materials or geological specimens there are also natural axes (typically perpendicular to deposited planes or parallel to a cooling gradient or deformation direction) but these may be more difficult to ascertain before sectioning. In any case, assuming that there is some natural axis, one approach is to define a different axis orientation for sampling each member of the population using a scheme that distributes the orientations randomly and uniformly in three dimensions to achieve isotropic sampling. This is not so easy to do for an arbitrary number 134 Chapter 7 of orientations. We have already seen the efficiency of the structured random sampling approach, so a method based on random tumbling of the specimen is not desired. Visualization of the problem may be assisted by realizing that each direction can be mapped as a point onto a half-sphere of orientations. Is there an arrangement of such points so that they are regularly and equally spaced over the surface of the sphere? The arrangements which are exactly equal and regular correspond to the surface normals of the regular polyhedra, of which there are only five (Figure 7.5): the tetrahedron with four triangular faces, cube with size square faces, octahedron with eight triangular faces, dodecahedron with twelve pentagonal faces, and icosahedron with twenty triangular faces. Taking just the faces whose normal directions point into the upper half of the sphere of orientations, the number of orientations is half of the number of faces (except for the tetrahedron). For instance, the dodecahedron has 12 faces but they provide only six sampling orientations. If one of these solids corresponds to the desired number of orientations to be used for sampling, a useful strategy would be to embed each entire object to be sectioned into such a structure, the number of such objects corresponding to the number of faces (e.g., six organs from a population placed into six dodecahedra). This would place the natural axis at some random orientation, which would however fall within the area of one of the faces. Identify this face, and select a unique and different face for each of the polyhedra. Figure 7.6 shows the normal directions for the dodecahedron. Use the surface normal of the selected face as a sectioning axis for that object, using the usual procedure as presented above to determine the number of sections to be used and the location of fields of view within each section. This procedure is fairly easy to implement but is appropriate only when there are multiple objects representing a population which is to be measured. When a single object must be sampled isotropically with planes, an equivalent procedure is to first subdivide the object into portions, for example cutting it into six (for the dodecahedron) or ten (for the icosahedron) parts. Then each part can be embedded into the regular polyhedron and sectioned as described above. The danger in this approach is that orientations of structure within the object may vary from place to place, and since the sampling orientation also varies this can result in measurement bias. Correcting such bias requires performing the procedure on several specimens with different orientations selected for each portion. In this case, it is just as efficient to use the first approach with sectioning of each specimen in one orientation. If it is not required that the specimen be uniformly sampled at each orientation, then another sampling method can be employed to obtain section planes that Figure 7.5. The five platonic solids (regular polyhedra). Procedures for IUR Sampling 135 Figure 7.6. Orientation vectors for the dodecahedron, plotted on the sphere of orientation. (For color representation see the attached CD-ROM.) are isotropic. First cut a so-called “vertical” section that includes the specimen’s natural axis (or some identifiable direction) and is uniformly random with respect to orientation, as shown in Figure 7.7. Then cut a surface perpendicular to this surface but at an angle that is not uniformly random but is instead sine-weighted. Sine weighting is accomplished by generating a uniform random number in the range -1 . . . 1 and then calculating the angle whose sine has that value = Arc Sin (Random). This angle varies from -90 to +90 degrees and represents the angle from Figure 7.7. Vertical sections cut to include the vertical axis of a specimen. Each section includes the vertical direction (arrow) and is rotated randomly to a different azimuthal angle. (For color representation see the attached CD-ROM.) 136 Chapter 7 Figure 7.8. The “Orientator”. Place a horizontal cut surface (perpendicular to the assigned vertical direction in a specimen) along the 0–0 line with a vertical cut (parallel to the vertical direction and uniformly random with respect to rotation) face down on the diagram. Generate a random number from 0–99 to select a cutting direction as shown. Repeating this procedure produces planes that are isotropic (uniformly sample orientations). (For color representation see the attached CD-ROM.) vertical. It is also easy to implement this procedure by creating a grid of radial lines that are not uniformly spaced but instead have the appropriate sine weighting, and then to select one using a uniform random number from 0 to 99 (Figure 7.8). This procedure is called the Orientator (Mattfeldt, quoted in Gundersen et al., 1988). Figure 7.9 shows the process applied to the object from Figure 7.4. It produces section planes that are isotropically uniform. Of course, this produces only a single section that passes through the object, and so does not provide spatially uniform sampling. Isotropic Line Probes Fortunately, there are few stereological procedures that require IUR planes as the sampling probes. IUR lines are much easier to generate. If the generated planes in the specimen were themselves IUR then drawing lines on them that were also IUR would produce line probes having an IUR distribution in 3D space. Such a grid of lines would be produced for example by drawing a set of parallel lines with an appropriate spacing, shifting them by a random fraction of that spacing, and rotating them to an angle given by a uniform random number between 0 and 180 Procedures for IUR Sampling 137 a b Figure 7.9. Implementation of the orientator: a) cutting a vertical section; b) cutting the examination plane using the sine-weighted grid. (For color representation see the attached CD-ROM.) degrees. The structured random sampling approach lends itself directly to the positioning of the lines in this way. Note that a grid of radial lines with uniform angular spacing drawn from the center of the field of view or of the specimen does not satisfy the IUR requirement because it is not uniform across the area—more of the lines sample positions near the center than at the periphery. Given the difficulty of drawing the IUR planes in the first place, another easier approach is generally used. It relies on the idea of a vertical section (Baddeley et al., 1986), the same as mentioned above. This is a plane that includes some natural axis of the specimen or some readily identifiable direction within it. It does not matter whether this orientation is actually “vertical” in a geocentric sense, and the name comes from the fact that the placement of images of the vertical section plane for viewing and measurement often positions this direction in the vertical orientation. 138 Chapter 7 Figure 7.10. A series of planes cut parallel to one vertical section. (For color representation see the attached CD-ROM.) A vertical section plane can be cut through a specimen parallel to the vertical direction without necessarily passing through the center of the specimen. In fact, while most diagrams and illustrations of vertical sectioning tend to draw the plane as passing through the center, for IUR sampling it is of course important that this restriction not be present. A series of parallel vertical section planes (Figure 7.10) with one uniformly random rotation angle about the vertical axis can be cut using the same principles of uniform random sampling discussed above by calculating an appropriate plane spacing and a random offset of a fraction of that spacing. The uniform random sampling must then also be performed by cutting a similar set of section planes on additional specimens (or portions of the same specimen) at angles offset from the first chosen angle. On all of the vertical section planes cut at different rotational angles, directions near the vertical direction are sampled. Plotted onto a sphere of directions (as shown in Figures 7.11 and 7.12), it can be seen that these lines cluster near the north pole of the figure while directions at low latitudes near the equator are sparsely sampled. The compensation for this is to use the same sine-weighting as discussed above. By generating lines with an angle from the vertical calculated as Arc Sine (R) where R is a uniform random number between -1 and +1, the directions are spread uniformly over the latitudes on the sphere (Figure 7.12). This approach fits well with structured random sampling because the number of angles in the horizontal (uniform) direction, the vertical (sine-weighted) Procedures for IUR Sampling 139 Figure 7.11. Radial lines drawn on a vertical section; top) uniformly distributed every 15 degrees (these lines are not isotropic in 3D space); bottom) the same number of lines drawn with sine-weighting, which does produce lines isotropic in 3D space. direction, the number of lines and their spacing can all be calculated based on the required precision. However, it requires more horizontal orientations and hence more vertical section cuts than a modified procedure that uses cycloids rather than straight lines. This obviously does not apply to experiments in which intercept lengths are to be measured, but is quite appropriate for the counting of intersections between the line probes (the cycloids) and surfaces within the structure. Cycloids are the correct mathematical curve for this application because they have exactly the same sine weighting as used to generate the straight lines in the method above. A cycloid is the path followed by a point on the rim of a rolling circle, and can be generated using the mathematical procedure shown in Figure 7.13. The curve has only a small fraction of line with vertical orientation and considerably greater extent that is near horizontal, and exactly compensates for the vertical bias in the vertical section planes. Distributing a series of cycloidal arcs (in all four possible orientations obtained by reflection) across the vertical section and shifting the grid of these lines according to the usual structured random sampling guidelines produces isotropic uniform random sampling in three dimensions. Note that the grid of cycloids (Figure 7.14) is not square, but wider than it is high; the shifting using random offsets must displace the grid by a random fraction of the grid 140 Chapter 7 a b Figure 7.12. Direction vectors in space mapped as points on a half-sphere of orientations: a) uniformly distributed angles at every 15 degrees along each vertical section corresponding to Figure 7.11a; the vectors are close together near the north pole. b) sine-weighted angles along the same vertical section corresponding to Figure 7.11b; the same number of directions are now uniformly distributed. (For color representation see the attached CD-ROM.) size in each direction. As usual, the size of the grid must be such that in few cases will more than one line intersect the same element of structure. In many examples of this technique the statement is made that as few as three sets of planes at angles of 60 degrees are sufficient for many purposes. Obviously, this premise can be tested in any particular experiment by sampling at higher density and seeing whether the results are affected. For projected images through transparent volumes, it is possible to generate IUR surfaces using cycloids. As described in detail in Chapter 14 on finite section Procedures for IUR Sampling 141 Figure 7.13. A cycloidal arc and the procedure for drawing it. The are has a width of p, a height of 2 and a length of 4 (twice its height). thickness, a set of cycloidal lines drawn on the projected image represent surfaces through the volume. Choosing a vertical direction (which can be arbitrary) for the volume and rotating it about that axis while collecting projected images causes the same bias in favor of directions near the vertical axis as that produced by vertical sectioning. Elements of area of these surfaces have orientations that compensate for the bias so that isotropic sampling of the structure is obtained. As shown in the Figure 7.14. A grid of cycloidal arcs. Placed on vertical sections (the vertical direction in the specimen is vertical on the figure), the lines isotropically sample directions in 3D space. 142 Chapter 7 examples in that chapter, the result is an ability to obtain isotropic uniform random sampling of intersections of linear features to measure NA, from which LV can be calculated. Volume Probes—The Disector One of the first developments in the so-called “new” stereology that emphasizes design of probes and sampling strategies rather than “classical” methods such as unfolding of size distributions based on shape is the Disector (Sterio, 1984). The disector requires comparing two parallel section planes to detect features that are present in one but not the other. But while it is implemented using section planes, it is actually a volume probe (the volume between the planes). Since volumes have no orientation isotropy is not an issue, although requirements for uniform random sampling remain (and can be satisfied using the same methods described above). The initial and still primary use of the disector is to determine the number of objects per unit volume. Point, line and plane probes cannot accomplish this without bias because they are more likely to intersect large features than small ones. As noted in the first chapter, the number of objects present in a region is a topological property, and cannot be determined by probes of lower dimension than the volume. The disector provides a surprisingly simple and direct way to count objects that is unbiased by feature size and shape. It relies on the fact that features can be counted by finding some unique characteristic that occurs only (and always) once per feature. In this case that characteristic is taken to be the topmost point (in some arbitrary direction considered to be “up”) of each feature. For illustration, consider counting people in a room. For most of them the topmost point would be the top of the head, but in some cases it might be the tip of an raised hand, or the nose (someone lying on his back on the floor). Regardless of what the point is, there is only one. Counting those points gives the number of people. Of course, in this example the procedure must be able to look throughout the volume of the room. When three-dimensional imaging is used, as discussed in Chapter 15, this is the method actually used. The disector provides an efficient method using just sets of two parallel planes. The disector can be implemented either with physical sectioning (e.g., microtoming) to produce two thin sections, or by sequential viewing of two polished surfaces of an opaque material, or by optical sectioning of a transparent volume using confocal microscopy. In all cases the spacing between the two sections must be known, which can be difficult particularly in the case of microtomed sections. For polished opaque materials one method for accomplishing this is to place hardness indentations (which have a known shape, typically either spherical, conical or pyramidal) in the surface and measure the change in size with polishing, from which the depth of polishing can be determined. These hardness indentations also help to align the two images. Similar fiducial marks can be used for the microtomed sections. Optical sectioning is generally the easiest method (when applicable) because spacing can be measured directly and image alignment is not required. Procedures for IUR Sampling 143 The key to the disector is to have the two parallel images be close enough together (small spacing between them) that the structure between them is relatively simple. No entire feature of interest can be small enough to hide in that volume, and as we will see no branching of networks can have branch lengths smaller than that distance. It must be possible to infer what happens in the volume by comparing the two images. Only a small number of basic topological events can be allowed to occur, which can be detected by comparing the images: 1. A feature may continue from one plane to the other with no topological events (the size of the intersection can change, but this is not a topological change). 2. A feature may end or begin between the planes, appearing in one but not the other. 3. A feature may branch so that it appears as a single intersection in one plane and as two (or more) in the other. 4. Voids and indentations within a feature may also continue, begin or end, or branch. Figure 7.15 shows a diagram illustrating several of these possibilities. The critical assumption is made that familiarity with the structures will enable identification by a human to detect features in the two sections that are matched. For automatic analysis the planes must be spaced closely enough together that feature overlaps can be used to identify feature matches. Features of type 6 (in the figure) are considered to be continuations of the same object with no topological events occurring. Events of type 3 and 4 represent the start or end of a feature (depending on which of the two planes is taken to be the floor and which the ceiling). Events Figure 7.15. Diagram of the disector (cases illustrated are discussed in the text). (For color representation see the attached CD-ROM.) 144 Chapter 7 of type 1 and 2 represent simple branching. The type 5 event reveals the bottom of an internal void. If the spacing between the planes is small so that no complex or uninterpretable events can occur in the volume between them, then in real images most objects will continue through the two planes (type 6) and these non-events are ignored. For counting features, events of type 3 and 4 are of interest. The number of these events divided by two since we are now counting both beginnings and endings of features, and divided by the volume between the planes (the area of the images times their spacing) gives the number of features per unit volume directly. As noted above, this value is unbiased since feature size or shape does not affect the count (Mayhew & Gundersen, 1996). The method is only simple for convex objects. When features may branch, or are long and slender so that they may cross and re-cross through the sampled volume, it becomes necessary to keep track of all of the parts of the feature so that it is only counted once. Since the images are finite in area, attention must be given to the problems that the edges of the image introduce. As shown in Figure 7.16, this is accomplished by defining “exclusion edges” and a guard region around the active counting area so that features are ignored if they extend across the exclusion edge (Gundersen et al., 1988). Of course, as noted above it is necessary to follow features that branch or extend laterally to detect any crossing of the exclusion edges (this is why the exclusion edges are extended as shown by the arrows in the figure). The requirement for a small spacing between planes to eliminate confusion about connectivity means that only a few topological events are detected, so that a large area or many fields of view are required to obtain enough counts for useful statistical precision. Figure 7.16. Guard frame and exclusion lines for the disector. Only the red features are considered. (For color representation see the attached CD-ROM.) Procedures for IUR Sampling 145 Networks As noted above, the disector can be used to count the number per unit volume (NV) when the objects are convex, or at least relatively compact and well separated. Objects that are long, twisted, branched and intertwined create difficulties in identifying the multiple sections that occur as part of the same object. On the other hand, the disector is also very useful for dealing with an extended network such as the pore structure in a ceramic, blood vessels or neurons in the body, etc. The topological property of interest for these structures is the connectivity or genus of the network. This is a measure of how branched the structure is, or more specifically of the number of connections (per unit volume) or paths that are present between locations. Topological properties such as number of objects and connectivity of pore networks require volume probes. The use of full three-dimensional imaging (Chapter 15) offers one approach to this, but the disector offers another that is elegant and efficient. It will be useful first to digress slightly and revisit some aspects of topology and genus, and define some terms and quantities, which were introduced more comprehensively in earlier chapters. Points on the surfaces of objects in three-dimensional space have normal vectors (perpendicular to the local tangent plane) that identify their orientation. Each such vector can be represented by a point on the surface of a sphere, which is called the “spherical image” of the point. A patch or region on the curved surface of the object corresponds to a patch of orientations on the sphere. For the surface of a convex, closed object every direction on the sphere corresponds to one (and only one) point somewhere on the surface of the object. Since the spherical image of the convex surface exactly covers (or is mapped onto) the unit sphere, its spherical image value is 4p (the area of the unit sphere), independent of any details about the shape of the body. The spherical image is an important topological property since it has a value that is independent of size and shape. For bodies that are not totally convex we must recall the idea of negative spherical image introduced in Chapter 5. This is the projection of points on saddle surfaces (Figure 7.17), which have two principle radii of curvature with different signs. With this convention, the total spherical image of any simply-connected closed surface is 4p (and the total spherical image of N objects would be 4Np). If the body has a hole through it (for instance a donut or torus, Figure 7.18), the surface around the hole is saddle surface and covers the sphere exactly once, and the surface on the outside is convex and also covers the sphere once, so the new spherical image of a donut is 0. The hole in the donut changes the topological quantity called the genus of the object. It becomes possible to make one cut through the object without disconnecting it into separate parts. Every hole introduced into the object adds a spherical image of -4p, so the general result is that the spherical image of an object is related to the genus or connectivity by the relationship Spherical Image = 4p · (1 - C). The total spherical image of a set of N objects with a total connectivity of C would be 4p · (N - C). We are usually primarily interested in the two extreme cases when C = 0 (a set of separate, simply connected objects which need not be 146 Chapter 7 a b c Figure 7.17. Convex, concave and saddle curvatures of surface elements. (For color representation see the attached CD-ROM.) Procedures for IUR Sampling 147 Figure 7.18. A torus; the green shaded area is saddle surface with a negative spherical image, the red surface is convex with a positive spherical image. (For color representation see the attached CD-ROM.) convex but have no holes) or N = 1 (a single extended network whose genus we wish to determine). Imagine a plane sweeping through the volume of the structure and note the occurrences when the plane is momentarily tangent to the surface. There can be three different kinds of tangent events as illustrated in Chapter 5 (DeHoff, 1987; Zhao & MacDonald, 1993; Roberts et al., 1997): 1. The plane may be tangent to a locally convex surface (both radii of curvature point inside the object). This is called a T++ event and the total number of them per unit volume is denoted TV++. 2. The plane may be tangent to a locally concave surface (both radii of curvature point outside the object). This is called a T -- event and the total number of them per unit volume is denoted TV--. 3. The plane may be tangent to a local patch of saddle surface (the two radii of curvature lie on opposite sides of the plane). This is called a T +- event and the total number of them per unit volume is denoted TV+-. The disector can be used to count these tangent events. The appearance of features in the two planes allows us to infer that a tangent event of one type or another occurred in the volume between the planes. Referring back to the diagram in Figure 7.15, types 1 and 2 correspond to T +- events, types 3 and 4 to T++ events, and type 5 to a T -- event. The total number of counts per unit volume (the product of the area of the image and the spacing between the planes) can be obtained by counting. The sum of these tangent counts (TV++ + TV-- - TV+-) is called the net tangent count TV, and the total spherical image of the structure is just 2p · TV. Consequently the difference between the number of features present N and the connectivity or number of holes C is just N - C = TV/2. For a network structure with N = 1, this 148 Chapter 7 gives the connectivity of the structure directly. Because topological properties and the volume probe used cannot be anisotropic, orientation considerations do not arise in using the disector (but of course averaging of samples to obtain uniform representation of the structure is still necessary).