Less Common Stereological Measures Chapter 5

advertisement

Chapter 5

Less Common Stereological Measures

This chapter deals with manual stereological measurements that provide

access to geometric properties that are related to the curvature of the objects of

analysis. It begins with the concept of the spherical image of surfaces and its relation to the number and connectivity of the features the surfaces enclose. The probe

for this analysis is a plane that is visualized to sweep through the three dimensional

structure. This probe is implemented through the disector, or more generally by

serial sectioning. The concept of integral mean curvature is then developed with some

insight into the meaning of this rather abstract notion. Plane probes yield a feature

count in the plane which measures integral mean curvature. The same information

may be obtained in a more general way through the area tangent count. Polyhedral

features have edges and corners which contribute to the spherical image of the

feature and its integral mean curvature. The latter property provides access to the

mean dihedral angle at edges through a combination of counting measurements.

Three-Dimensional Features: Topological Properties and the Volume

Tangent Count

The topological properties, number NV and connectivity CV, provide rudimentary information about three dimensional feature sets. A fundamental property

of surfaces that is related to these topological properties derives from the concept

of the spherical image, W of the surface.

If a surface is smoothly curved, every point P on it has a tangent plane, as

shown in Figure 5.1a. (If the surface is not smoothly curved, i.e., has edges and

corners, then they also contribute to the spherical image.) A tangent plane at P also

has a vector, pointing outward from the surface, called the local surface normal.

This vector represents the local orientation of the patch of surface at P. This orientation can be mapped in longitude and colatitude as a point P¢ on the sphere of

orientation, as shown in Figure 5.1b. The point P¢ on the unit sphere is called the

spherical image of the point P on the surface. It represents the local direction of the

surface. For a small patch on a curved surface the collection of its normal directions map as a small patch on the unit sphere, as shown in Figure 5.1c,d. This is the

spherical image of the patch.

Now think about a convex surface (no bumps, dimples or saddles), as shown

in Figure 5.2a. The spherical images of the collection of normal directions for such

a surface cover the sphere of orientation exactly once. For every point that represents a direction on the sphere there is a point on the surface that has a normal

in that direction. No normal direction is represented more than once. Thus, the

79

80

Chapter 5

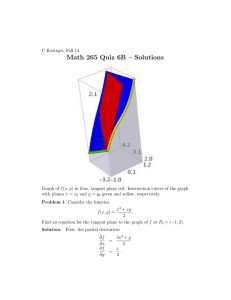

Figure 5.1. The spherical image of a point P on a surface (a) is a point P¢ on the unit

sphere (b). The spherical image of a patch of surface dS (c) is a patch dW on the unit

sphere (d). (For color representation see the attached CD-ROM.)

spherical image of any convex body covers the unit sphere exactly once, as shown

in Figure 5.2a, and may be evaluated as the area of the unit sphere, which is 4p

steradians1. This result is the same for every convex body, no matter what its shape

or size. The spherical image thus has the character of a topological property, at least

for convex bodies, i.e., it has a value that is independent of the metric properties of

the body. For a collection of N convex bodies, the spherical image is 4pN.

Particles with smooth bounding surfaces that are not convex, as shown in

Figure 5.2b and c, may have three different kinds of surface patches: convex,

concave, and saddle surface, as shown in the Figure. At any point on a convex patch

of surface, the tangent plane is outside the surface. At points on a concave patch,

the tangent plane is inside the surface. At any point on a saddle surface patch the

tangent plane lies partly inside the surface, partly outside. Saddle surface patches

(curved outward in one direction and inward in another like a potato chip) are

required to smoothly transition between convex and concave elements, or to surround holes in the particle, as in the inside of a doughnut, as shown in Figure 5.2c.

Patches of each kind of surface have their own collection of normal directions which

may be mapped on the unit sphere.

1

A steradian is a unit of solid angle represented by an area on the sphere of orientations analogous to the unit, radian, which applies to angles in a plane. The circle in a plane subtends

2p radians (the circumference of a circle with unit radius). The sphere in three dimensions

subtends a solid angle of 4p steradians.

Less Common Stereological Measure

81

Figure 5.2. Convex bodies (a) are composed of convex surface elements. Non-convex

(b,c) bodies have convex and saddle surfaces, and may also have concave surface

elements. Holes in multiply connected closed surfaces (d) contribute a net of -4p spherical image for each hole. (For color representation see the attached CD-ROM.)

It can be shown, and this appears remarkable at first sight, that if the parts

of area of the unit sphere that are covered by the convex and concave patch images

are counted as positive and the parts covered by saddle images are counted as negative, then the result, called the net spherical image,

W net = Wconvex + Wconcave - W saddle = 4p (1 - C )

(5.1)

where C is the connectivity of the particle. For simply connected features (no holes),

C = 0, and Wnet = 4p. This is a generalization of the result for convex bodies described

above. Where the shape departs from a simple convex closed surface, the extra

convex and concave spherical image is exactly balanced by the (negative) spherical

image of saddle surfaces on the feature, so that the unit sphere again is covered

(algebraically speaking) exactly once. If the feature has holes in it, every hole

requires a net of (-4p) steradians of saddle surface, which thus gives rise to equation (5.1). For a collection of N particles in a structure, with a collective connectivity of C, the net spherical image of the collection of features is

82

Chapter 5

W net = 4p ( N - C )

(5.2)

The difference (N - C) is called the Euler characteristic of the particles in

the structure.

The probe used to measure these properties is the sweeping tangent plane.

Figure 5.3 shows a set of particles in a specimen. Imagine that the plane shown at

the top of the figure is swept through the structure from top to bottom. Such a probe

can be realized in practice by confocal microscopy in which a plane of focus is translated through a transparent three dimensional specimen. For opaque specimens

where this is not possible, the sweeping plane probe may be visualized by producing a set of closely spaced plane sections (serial sections) through the structure and

examining the changes that occur between successive sections. The disector probe

(Sterio, 1984) is the minimum serial sectioning experiment, employing information

from two adjacent planes.

The events of interest to the measurement of spherical image are the formation of tangents with the particle surfaces as the plane sweeps through the particles in the structure. Three kinds of tangent events may occur: at a convex surface

element (++); at a concave element (--), or at an element of saddle surface (+ -).

These three situations are pictured in Figure 5.3. These events are marked and

counted separately. The result is normalized by dividing by the volume swept

through by the sweeping probe. The spherical image per unit volume of each class

of surface in the structure is given by

WV ++ = 2pTV ++

WV - - = 2pTV - WV +- = 2pTV +-

(5.3)

Combining equations (5.1), (5.2) and (5.3) leads to a simple relation between

the Euler characteristic of a collection of particles and the volume tangent counts

NV - CV =

1

1

(WV ++ + WV -- - WV +- ) = (2pTV ++ + 2pTV -- - 2pTV +- )

4p

4p

(5.4)

which further simplifies to

1

NV - CV = TVnet (TV ++ + TV -- - TV +- )

2

(5.5)

For a collection of convex bodies CV = 0, as are TV - - and TV +-. Every particle has exactly two convex tangents, and counting tangents is evidently equivalent

to counting particles. More generally, for a collection of simply connected (not necessarily convex) particles, no matter what their shape, CV = 0, and the net tangent

count gives the number of particles in the structure. At the other extreme, for a fully

connected network (one particle) NV << CV, and the net tangent count (which will

be mostly saddle tangents) gives (minus) the connectivity. The case where both

number and connectivity are about the same order of magnitude is fortunately rare

in microstructures. In this case the separation of number and connectivity is a challenge. A sufficient volume of the sample must be examined, either in a confocal

microscope or by serial sections, to encompass many whole particles so that

a

b

Figure 5.3. The sweeping plane probe forms tangents with convex (++), concave

(- -) and saddle (+ -) surface elements. (For color representation see the attached CDROM.)

Probe population:

Sweeping plane in three dimensional space

This sample:

The specimen

Calibration:

None required

Event:

Plane forms tangents with convex, concave and saddle surface

Measurement:

Count each class of tangent formed

This count:

T++ = 16; T- - = 1; T+ - = 11

Relationship:

N - C = (1/2) Tnet = (1/2) (T++ + T- - - T+ -)

Geometric property:

N - C = (6 - 3) = (1/2) · (16 + 1 - 11) = 6/2 = 3

84

Chapter 5

a

Figure 5.4. The simple disector analysis measures the number density, NV, of convex

features in three dimensional space. (For color representation see the attached CDROM.)

Probe population:

Set of disector planes in three dimensional space

Calibration:

A0 = 64 mm2; h = 0.5 mm, V0 = 32 mm3

Event:

Feature in counted unbiased frame on the reference plane

does not appear on the look-up plane

Measurement:

Count these events

This count:

N=6

Relationship:

NV = N/V0

Geometric property:

NV = 6/32 mm3 = 0.19 mm-3 = 1.9 · 1011 per cm3

beginnings and ends of specific particles may be identified and counted to determine NV. This information may then be combined with the measurement of the

Euler characteristic to estimate the connectivity.

The disector is a minimum serial sectioning experiment composed of two

closely spaced planes. The distance between the planes, h, must be measured so that,

together with area of the field analyzed on the plane, the volume contained in the disector sample is known. The spacing h must be small enough so that tangent events that

occur in the volume between the planes can be inferred unambiguously. Usually this

means that the spacing must be a fraction (perhaps 1/4 or 1/5) of the size of the smallest features being analyzed. Figure 5.4 shows the two planes of the disector viewed

Less Common Stereological Measure

85

b

Figure 5.4. Continued

side by side for a simple structure composed of convex bodies. An unbiased

counting frame2 with area, A0, is delineated on the first plane, called the reference plane.

The second plane is called the look-up plane. Each feature on the reference plane is

viewed in conjunction with the corresponding region on the look up plane. If the particle still persists on the look-up plane it is not marked. If there is no particle section

observed in the region then it is inferred that the particle came to an end between the

planes. The particle is marked on the reference plane to indicate that a convex tangent

has occurred within the volume of the disector. Counting the marks is equivalent to

counting particle ends. Since in this simple case of convex particles each particle has

only one end, this is equivalent to counting particles. If N particle ends are counted,

then N/(h · A0) is an estimate of NV. If the disector is chosen to sample the population of disector volumes uniformly then this provides an unbiased estimate of NV.

2

A potential bias in counting particles in a plane probe frame arises because some particles

will intersect the boundary of the frame. Further, large particles are more likely to intersect

the frame boundary than small ones. The bias can be eliminated by assigning a count of 1/2

to particles that cross the frame. A more general strategy involving the concept of an unbiased frame is described in detail in a later section of this chapter.

86

Chapter 5

a

Figure 5.5. The sweeping tangent analysis analysis using the disector measures the

Euler characteristic of features in three dimensional space. The events are most easily

seen when the two images are overlaid (Figure 5.5c), and are marked with arrows (red

= T++, green = T- -, blue = T+ -). Note that features are not counted if any part of them

touches that touch the exclusion line in either image. (For color representation see the

attached CD-ROM.)

Probe population:

Set of disector planes in three dimensional space

Calibration:

A0 = (18 mm)2 = 324 mm2; h = 0.5 mm, V0 = 162 mm3

Event:

Features in counted unbiased frame on the each plane

indicate various tangent events in the volume

Measurement:

Count these events

This count:

T+ + = 3 (red)

T- - = 3 (green)

T+ - = 5 (blue)

Relationship:

NV - CV = 1/2 · (TV+ + + TV- - - TV+ -)

Geometric property:

NV - CV = 1/2 · (3 + 3 - 5)/162 mm3 = 0.0031 mm-3

= 3.1 · 109 cm-3

If the look-up and reference planes are now reversed, particles on the second

plane that do not appear on the first imply that a convex tangent has formed within

the volume of the disector. On the average, the number of counts in the second case

will be equal to that in the first, but this will not be true for individual disector fields.

Figure 5.5 shows a more complex structure with particles that have concave

as well as convex boundary segments on a section. The presence of concave

b

c

Figure 5.5. Continued

88

Chapter 5

boundary elements on the plane probes results from sections through saddle surface

elements and/or concave elements in the three dimensional structure. The sweeping

plane probe is expected to form tangents of all three types of surfaces. A tangent

is formed with a convex surface element (T++) if an isolated particle on the reference

plane does not appear on the look-up plane, and also if an isolated particle on the

look-up plane does not appear on the reference plane. A tangent with a concave

surface element (T--) is indicated if a hole on the reference plane disappears on the

look-up plane, and also if a hole seen on the look-up plane disappears on the reference plane. If one feature on the reference plane becomes two on the look-up

plane, or two on the reference plane becomes one on the look-up plane, then a

tangent with an element of saddle surface (T+-) is inferred. The three classes of

tangent planes inferred from the disector sample in Figure 5.5 are indicated with

red (++), green (--) and blue (+-) markers. The analysis of the disector is presented

in the figure caption. The Euler characteristic estimated from this single observation is 0.0031 mm-3. If it is assumed that these particles are simply connected (CV =

0), the number of particles can be estimated to be 0.0031 mm-3. Relative amounts of

each of the three classes of spherical image may also be estimated from the tangent

counts by applying equations (5.3).

Three Dimensional Features: the Mean Caliper Diameter

The notion of the diameter has a straightforward meaning for a sphere. For

more general convex bodies, the “diameter” of a particle is different in different directions. Figure 5.6 illustrates the concept of the caliper diameter, D, of a convex

Figure 5.6. The mean caliper diameter, D, is the distance between parallel tangent

planes in any direction on a convex particle. This distance is sensed by plane probes

in three-dimensional space. (For color representation see the attached CD-ROM.)

Less Common Stereological Measure

89

particle. Choose a direction and visualize the sweeping plane probe moving along

that direction. The probe will form two tangents with the particle. The perpendicular distance between these two tangent planes is the caliper diameter of the particle

in that direction. This diameter has a value for each direction in the population of

orientations. If the value of the diameter is averaged over the hemisphere of orientation (the other hemisphere gives redundant information), the mean caliper diameter of the particle is obtained. This concept may be applied to convex bodies of any

shape. It provides one measure of the particle size of features in the structure.

An estimate of the mean caliper diameter may be obtained using a plane

probe through the three dimensional structure. Consider the subpopulation of plane

probes that all have the same normal direction. Individual planes in this subpopulation are located by their position along the direction vector. In order for a plane

probe to produce an intersection with a particle in the structure, its position must

lie between the planes that are tangent to the ends of the particle in that orientation. The event of interest is that the plane probe intersects the particle. This event

will produce a two dimensional feature, a section through the particle, observed on

the plane probe. The number of these events, i.e., the number of these two dimensional features that appear on the probe, is counted. The count is normalized by

dividing by the area of the probe sample to give NA, the number of features per unit

area of probe scanned. The governing stereological relationship is,

N A = NV D

(5.6)

The number of particles per unit volume can be estimated separately using

the disector probe as described in the last section. With this information, the mean

caliper diameter of particles in the structure can be evaluated from the expected

value of a feature count on plane probes. This result is limited to convex bodies, but

the shapes of the particles are not otherwise constrained. In order to obtain the

mean caliper of particles averaged over orientation it will be necessary to sample

the population of plane orientations in three dimensions. The difficulties in obtaining an unbiased sample of orientations of plane probes have already been discussed.

For a single orientation of plane probes, this count provides a measure of

the mean caliper diameter of particles in the direction perpendicular to the probe

planes. This result can be visualized as an application of equation (4.14) in Chapter

4, which is the stereological basis for measuring the length of lineal features in a

three dimensional structure. Visualize a subpopulation of parallel planes that share

some normal direction given by coordinates (q, f) on the orientation sphere. Replace

each convex particle with a stick that is the same length as the caliper diameter in

the direction perpendicular to those planes D(q, f). Then each particle section on

the plane probe may be visualized as resulting from an intersection of a plane probe

with one of these sticks. NA for the particle sections is the same as PA for the collection of sticks for this structure. The feature count thus measures the collective

length of these sticks, or more precisely, the collective lengths of the caliper diameters of the particles in the structure, in the direction that is perpendicular to the

plane probes.

N A (q , f ) = NV D (q , f )

(5.7)

90

Chapter 5

For a collection of particles that show a tendency to be elongated or flattened in a particular direction in space measurement of NA on planes with different orientations provides one measure of the anisotropy of the particle shapes.

Ratios of NA counts on planes oriented in different directions directly yield ratios

of the mean caliper diameters in those directions:

N A (q1 , f1 )

N D (q1 , f1 ) D (q1 , f1 )

= V

=

N A (q 2 , f2 )

NV D (q 2 , f2 ) D (q 2 , f2 )

(5.8)

Note that these caliper diameters are measured in the direction that is parallel to the normal to the plane probe.

Thus a feature count on a section, when combined with a disector measurement of NV gives access to the mean caliper diameter of convex particles, one convenient measure of particle “size”. If the particle shapes are anisotropically

arranged in space, then a feature count on an oriented plane probe provides a

measure of the mean particle diameter in the direction perpendicular to the probe.

Mean Surface Curvature and Its Integral

This section introduces curvature related geometric properties that are significantly more abstract than the straightforward geometric properties defined and

measured in previous sections. These hard-to-visualize properties are introduced

here because they have geometric meaning that is general for structures of arbitrary

geometry, and they can be measured (they are what is measured) by the feature count

when the features are not limited to being convex, as they were in the previous

section. For some special classes of features (plates or muralia, or rods or tubules)

these geometric properties have a meaning that can be visualized and put to conceptual use. For more general kinds of three dimensional features, although the

meaning is abstract, at the very least the measurement provides an additional

descriptor of the geometry of the system.

The central concept, the mean curvature at a point on a smooth surface, is

the geometric property of surfaces through which capillarity effects operate. If

surface energy or surface tension plays a role in the problem being investigated,

access to a measure of the mean curvature provides geometric information that has

direct thermodynamic meaning (DeHoff, 1993).

In order to present the concept of curvature at a point on a surface, it is first

useful to recall the concept of curvature of a plane curve in two dimensional space.

Figure 5.7 shows a curve in the xy plane. To define the curvature at a point P place

two other points, A and B, on the curve. Construct a circle through these three

points. This circle has a center, O, and a radius r. Now let A and B approach P. The

point O moves and the radius changes. In the limit as A and B arrive at P, the center

approaches the center of curvature for the point P, and the radius becomes the

radius of curvature. This limiting circle, which just kisses the curve, is called the

osculating circle. The curvature of the curve at P is the reciprocal of this radius. It

can also be shown that the curvature is the rate of rotation of the tangent to the

curve as the point P moves along the arc length, s:

Less Common Stereological Measure

91

Figure 5.7. Curvature at a point P on a curve in two dimensional space is the reciprocal of the radius of a circle that “passes through three adjacent points” on the curve

at P.

k=

1 dq

=

r ds

(5.9)

This two dimensional concept is the basis for defining the curvature at a point

on a surface in three dimensional space.

Figure 5.8a shows a smooth surface. Focus on the point P on this surface.

There is a tangent plane at P, and a local surface normal, perpendicular to that

plane. Imagine a plane that contains this normal direction and intersects this surface

at P. The intersection of this “normal plane” with the surface is a plane curve that

passes through P. The radius of curvature, r, and the curvature, k, of that curve

may be defined at P using the concepts developed in the previous paragraph.

Next visualize another normal plane that makes some arbitrary angle with

the first plane. The curve of intersection of this plane with the surface also has a

value of curvature at P. If the piece of surface is a piece of a sphere, these two curvatures will be the same. However, for an arbitrarily shaped surface, the curvature

values on two different normal planes will be different. As the normal plane is

rotated, the curvature of the intersecting curve at P changes smoothly. As the

normal plane is rotated through half a circle, there will be some direction for which

the curvature has a maximum value, and another direction for which its value is a

minimum. In differential geometry, which deals with the geometry of entities in

the vicinity of a point on the entity, it is shown that the directions for which the

maximum and minimum values occur are 90° apart. These two directions in

the tangent plane are called the principle directions. The curvatures in these two

directions, k1 and k2, are called the principle normal curvatures at the point P,

92

Chapter 5

Figure 5.8. Curvature at a point P on a surface is reported by two principle normal curvatures k1 and k2 measured on two orthogonal normal planes through P. Of all the possible planes through P that contain the normal direction (a), the two with the minimum

and maximum radii (b) give the principle normal curvatures.

corresponding to radii r1 and r2. In differential geometry it is shown that these two

curvature values completely describe the local geometry near a point on a smooth

surface. The local configuration for an element of surface around a point P is shown

in Figure 5.8b.

For a spherical surface with radius R, k1 = k2 = 1/R at every point on the

surface. For a right circular cylinder of radius r, the maximum curvature occurs on

a plane perpendicular to the axis: k1 = 1/r. The minimum curvature occurs on a plane

containing the cylinder axis, which intersects the surface in a straight line so that

k2 = 0. The values of k1 = 1/r and k2 = 0 are the same at all points on the cylindrical surface. For smooth surfaces with arbitrary geometry, k1 and k2 vary smoothly

from point to point and have some distribution of values over the surface area.

For a surface that encloses a three dimensional volume, i.e., for a closed

surface, these curvatures may be assigned a sign. If the curvature vector points

toward the inside of the surface it is defined to be positive; if it points outward, it

is negative. The possible combinations of signs of the curvature give rise to the three

classes of surface elements described earlier in this chapter:

Convex surface (++)—if both curvatures point inward and are thus positive;

Concave surface (- -)—if both point outward and are thus negative;

Saddle surface (+-)—if one points inward and the other points outward.

These three classes of surfaces were illustrated in Figure 5.2. In general, if

a surface has any departure from a simple convex shape, extra convex lumps, or

Less Common Stereological Measure

93

concave dimples, it must possess patches of saddle surface that connect these

smoothly. At the boundaries of saddle surface one of the curvatures changes sign

(passes from {+-} to {++}, or from {+-} to {--}), so that one of the principle curvatures passes through zero. Such points occur only along the lines bounding saddle

patches (or on the surface of a cylinder), and are called parabolic points.

Two combinations of the principle normal curvatures find widespread application in geometry, topology, physics and stereology:

1

The mean curvature, defined by H = –2 (k1 + k2), the algebraic average of the

two curvatures, and

The Gaussian curvature, defined by K = k1 · k2.

Both have a value at each point on a surface and thus vary smoothly over

the surface.

The mean curvature, H, is important for two distinct reasons. Capillarity

effects play a crucial role in the formation and performance of most microstructures. These effects arise from the physical action of curved surfaces on their surroundings. The geometric property of the surfaces that determines the nature of

these capillarity phenomena is shown in thermodynamics to be the local mean curvature, H. Thus an important component of the behavior of surfaces involves the

local mean curvature, its distribution and its average value over the surfaces

involved.

The second compelling reason for interest in this geometric property has to

do with its integrated value for the collection of surfaces in a microstructure, called

the integral mean curvature. This property has a single value for a closed surface. It

may also be evaluated for a collection of surfaces that make up a microstructure.

Visualization of its meaning is elusive. Consider an element (a small patch) of

surface with incremental area dS; suppose H is the value of mean curvature at that

element. Compute the product HdS for the element. Then add these values together

for all of the surface elements that bound the particle. The resulting quantity,

defined mathematically by

M ∫ Ú Ú HdS

(5.10)

S

has units of length. H has units of length-1 and dS has units of length2. (The double

integral signs ÚÚ signifies that the local incremental value HdS is summed over the

whole area of the surface, S.) This abstract geometric property has geometric

meaning that can be visualized for particular classes of three dimensional features.

As a simple example, apply the concept to a spherical particle of radius R.

The principle curvatures are both equal to (1/R), and have the same value at every

point on the sphere. Thus, for every point on a sphere the mean curvature is simply

1/R:

H=

1Ê1 1ˆ 1Ê 1 1ˆ 1

+

=

+

=

2 Ë r1 r2 ¯ 2 Ë R R ¯ R

Put this value into the definition of M:

(5.11)

94

Chapter 5

1

1

1

1

dS = Ú Ú dS = Ssphere = 4pR 2 = 4pR

R

R

R

R

S

S

M sphere = Ú Ú HdS = Ú Ú

S

(5.12)

This result generalizes through the Minkowski formula; for general convex

bodies,

Mconvex = 2pD

(5.13)

where D is the mean caliper diameter defined in the previous section.

We have seen that for a collection of convex bodies the feature count on a

plane probe, NA, reports the product of the number density and the mean caliper

diameter. For non-convex bodies, i.e., for the general case, a generalization of the

feature count reports the integral mean curvature, M. In the discussions up to now,

the classes of features considered produced sections that are free of holes on the

plane probe. However, in the general case of arbitrarily shaped particles in three

dimensional space, some plane probes will produce features with holes in them. In

this most general kind of structure, the feature count generalizes to the Euler characteristic of the particle sections, which is defined to be the number of particles

minus the number of holes (N - C). It is useful to think of this as a count of the

net number of closed loops bounding particles in the structure, where loops enclosing particles are counted as positive and those enclosing holes are negative. The fundamental stereological relationship is

NA

net

= NA - CA =

1

MV

2p

(5.14)

where MV is the integral mean curvature of the surfaces bounding the particles

in the three dimensional structure divided by the volume of the structure. Thus,

no matter how complex the features in three dimensions are, the net feature count

on a plane probe provides an unbiased estimate of this abstract property, the

integral mean curvature. It is the three dimensional property that the feature count

measures.

Applying Minkowski’s formula for convex bodies, equation (5.13), to equation (5.14):

NA

convex

=

1

1

1

MVconvex =

NV MVconvex =

NV 2pD = NV D

2p

2p

2p

(5.15)

recovers equation (5.6), now seen to be a special case of equation (5.14).

Figure 5.9 reproduces the microstructure in the left side of the disector in

Figure 5.4 so that a feature count may be made and illustrated. In this case, the

value of the mean curvature MV estimated to be 4.45 mm/mm3 can be used to estimate the mean caliper diameter. The value of NV obtained from the disector analysis in Figure 5.4 is 0.19 mm-3. Apply the Minkowski formula, equation (5.13), to

compute:

D=

MV

4.45

=

= 3.72 mm

2pNV 2 ◊ p ◊ 0.19

(5.16)

Less Common Stereological Measure

95

Figure 5.9. A feature count measures the integral mean curvature, MV, of the bounding surfaces in three dimensional space. (For color representation see the attached CDROM.)

Probe population:

Planes in three dimensional space

This sample:

The unbiased frame in the field

Calibration:

L0 = 6.9 mm; A0 = (6.9 mm)2 = 47.9 mm2

Event:

Feature lies “within” the unbiased frame

Measurement:

Count the features

This count:

N = 34

Relationship:

·NAÒ = (1/2p) · MV

Normalized count:

NA = 34 counts/47.9 mm2 = 0.71 counts/mm2

Geometric property:

MV = (2p) · 0.71 = 4.45 mm/mm3

Figure 5.10 reproduces the microstructure on the left side of the disector in

Figure 5.5. A net area loop count estimates the integral mean curvature for this

structure of general geometry.

The integral mean curvature is a key geometric property of a collection of

plate shaped particles, or, more generally muralia, i.e., “thick surfaces”, features that

are small in one dimension and extensive in the other two, as shown in Figure 5.11a.

For such features it can be shown that M measures the length of the perimeter of

the edge of the the plate or muralia, L (DeHoff, 1977):

96

Chapter 5

Figure 5.10. Net feature count for non-convex features in the area measures the integral mean curvature, MV, of the surfaces bounding the features in the three dimensional

microstructure. (For color representation see the attached CD-ROM.)

Probe population:

Planes in three dimensional space

This sample:

The unbiased frame in the field

Calibration:

L0 = 17.7 mm; A0 = (17.7 mm)2 = 313 mm2

Event:

Feature (particle or hole) lies “within” the unbiased frame

Measurement:

Count the features

This count:

8 particles; 2 holes

Relationship:

·NAÒnet = ·NAÒ+ - ·NAÒ- = (1/2p) · MV

Normalized count:

NAnet = 8 - 2 counts/313 mm2 = 0.019 counts/mm2

Geometric property:

MV = (2p) · 0.019 = 0.120 mm/mm3

M muralia =

p

L

2

(5.16)

At the other extreme of feature shapes, the integral mean curvature reports

visualizable information for rod or more generally for tubule features. A feature satisfies the definition of a tubule if it is small in two of its dimensions and extensive

in the third, as shown in Figure 5.11b. For this class of features,

Less Common Stereological Measure

97

Figure 5.11. Muralia are “thick surfaces; a flat muralium is a plate. Tubules are “thick

space curves”; a straight tubule is a rod.

Mtubules = pL

(5.17)

where L is the length of the tubule.

Figure 5.12 shows a plane probe section through a microstructure consisting of muralia. The vast majority of sections will appear as curved strips in the

microstructure. Orientations and positions of the probe that produce fat sections

are not very likely. For muralia equation (5.16) yields,

NA

muralia

=

1

LVmuralia

4

(5.18)

where LVmuralia is the total perimeter of plates or length of edges of muralia in unit

volume of structure. If it is assumed that Figure 5.12 is an unbiased sample of the

population of positions and orientations of plane probes in the structure, the feature

count, NA = 0.074 (1/mm2) gives, for the total length of feature edges in the three

dimensional structure = 0.295 (mm/mm3).

Most sections through tubules are small and equiaxed, as shown in Figure

5.13. Orientations and positions which produce a very long section only occur for

planes that are nearly parallel to the local axis of the tubule, and are close to it in

position. Such sections will be relatively rare, particularly if the radius is small. From

equation (5.17) the expected value of the feature count gives

NA

tubules

=

1

LVtubules

2

(5.19)

where LVtubules is the collective length of the rods or tubules in unit volume. For the

example shown in Figure 5.13, NA = 0.29 (1/mm2) which estimates a total tubule

length of 0.58 (mm/mm3).

98

Chapter 5

Figure 5.12. A feature count on a section through muralia measures the integral mean

curvature, MV, or the muralia surfaces in three dimensional space. In this case, MV is

simply related to the totallength of edges of the muralia, LVmuralia (For color representation see the attached CD-ROM.)

Probe population:

Planes in three dimensional space

This sample:

Area within the unbiased frame

Calibration:

A0 = 122 mm2

Event:

Feature lies “within” the unbiased frame

Measurement:

Count the features

This count:

N=9

Relationship:

·NAÒ = (1/2p) · MVmuralia = 1/4 LVmuralia

Normalized count:

NA = 9 counts/122 mm2 = 0.074 counts/mm2

Geometric property:

LVmuralia = 4 NA = 4 · 0.074 = 0.295 mm/mm3

A plane probe intersects particles in three dimensional space to produce a

collection of two dimensional features on the sectioning plane. The number of such

features, normalized by dividing by the area of the probe, is proportional to the integral mean curvature of the surfaces bounding the three dimensional particles in the

structure divided by the volume of the specimen (equation 5.14). Integral mean curvature has simple geometric meaning for convex bodies, for which it reports the

mean caliper diameter, platelets or muralia, for which it reports the total length of

edge, and tubules, for which it reports the total tubule length. These results assume

the set of plane probes in the sample are drawn uniformly from the population of

Less Common Stereological Measure

99

Figure 5.13. A feature count is used to estimate MV, the integral mean curvature. For

tubules MV is proportional to the LVtubules length of the tubules. (For color representation

see the attached CD-ROM.)

Probe population:

Planes in three dimensional space

This sample:

Area within the unbiased frame

Calibration:

L0 = 6.9 mm; A0 = (6.9 mm)2 = 47.9 mm2

Event:

Feature lies “within” the unbiased frame

Measurement:

Count the features

This count:

N = 14

Relationship:

·NAÒ = (1/2p) · MVtubules = 1/2 LVtubules

Normalized count:

NA = 14 counts/47.9 mm2 = 0.29 counts/mm2

Geometric property:

MVtubules = 2pNA = 1.84 mm/mm3

LVmuralia= 2 · NA = 0.58 mm/mm3

positions and orientations of plane probes in three dimensional space. Oriented

plane probes give information about these lengths in the direction that is perpendicular to the probes.

The Sweeping Line Probe in Two Dimensions

Figure 5.14 shows a feature in two dimensional space. Any point P on the

boundary has a tangent direction and, perpendicular to the tangent and pointing

100

Chapter 5

a

b

Figure 5.14. The circular image of a convex feature in a plane is equivalent to the unit

circle. Every point on the feature periphery has a normal direction that corresponds to

one point on the circle, as shown by the colored vectors in Figure 14a. A segment dS

on the feature maps to a segment of arc dq on the circle. A non-convex feature has

regions of negative curvature as shown in Figure 14b. The angular range which these

cover (shown in green) exactly cancels the extra positive curvature (shown in blue and

orange), again leaving a net circular image of 2p. (For color representation see the

attached CD-ROM.)

Less Common Stereological Measure

101

outward, a normal direction. Mapping these directions onto a unit circle creates the

circular image of the points, and a small arc of the boundary ds has a small range

of normal directions that map as a segment of arc on the unit circle, dq, as shown

in Figure 5.14a. The circular image of a convex feature maps point for point on the

unit circle exactly once. Thus, no matter what the shape of the particle boundary,

so long as it is convex, its circular image is exactly 2p radians, the circumference of

the unit circle.

If the boundary shape departs from convex, as shown in Figure 5.14b, then

part of it will consist of convex arc segments and part will be made up of concave

arc segments. Mapping the rotations of the boundary normal on the unit circle as

the point P moves aroung the perimeter of the particle will produce ranges of

overlap as shown in Figure 5.14d. However, if concave segments are defined to contribute a negative circular image, then the net rotation of the normal vector around

the perimeter remains exactly 2p radians because the point chosen to begin and end

the map is the same point. Thus, like the spherical image of a surface discussed

earlier, the circular image of the boundary of a two dimensional feature also has

the character of a topological property. It is equal to 2p radians, no matter what is

the size and shape of the particle enclosed by the boundary.

In a two dimensional structure particles of the b phase are said to be “multiply connected” if they have holes in them. The connectivity of a two dimensional

particle, C, is equal to the number of holes in the particle. The boundary of each

of these holes, no matter what their size or shape, contributes a net circular image

of (-2p) because overall, a hole contributes a net of 2p of concave arc. Thus, the

net circular image of a two dimensional particle with C holes in it is

q net = q + - q - = 2p (1 - C )

(5.20)

For a collection of N features with a total of C holes in them,

q net = 2p ( N - C )

(5.21)

The difference in the topological properties (N - C) is called the Euler characteristic of the two dimensional collection of particles. These concepts for a two

dimensional structure mirror those presented earlier for the spherical image and the

topological properties of three dimensional closed surfaces.

It was shown earlier that a volume tangent count, based on a sweeping plane

probe through a three dimensional structure, measured the spherical image of the

surface bounding particles in the volume. An analogous probe and measurement

applies to the boundaries of two dimensional features in two dimensions. Figure

5.15 illustrates the concept of the sweeping line probe in two dimensions. The line

in the figure is swept across the field. In the process the moving line forms tangents

with elements of the ab boundary. Tangents formed with elements of the boundary that are convex (T+) with respect to the b phase and elements that are concave

(T-) may be marked separately and subsequently counted. Dividing these counts by

the area of the field included in the count gives the area tangent count. This is the

two dimensional analogue of the volume tangent count described in a previous

section.

102

Chapter 5

Figure 5.15. An area tangent count is used to estimate the Euler characteristic and

integral mean curvature. A horizontal line is swept down across the image and the locations of tangents with convex and concave boundaries are counted. (For color representation see the attached CD-ROM.)

Probe population:

Sweeping line in two dimensional space

This sample:

Area within the frame

Calibration:

L0 = 20 mm; A0 = (20 mm)2 = 400 mm2

Event:

Line forms tangents with convex and concave boundaries

Measurement:

Count each class of tangent formed

This count:

T+ = 45 (red)

T- = 19 (green)

Relationship:

NA - CA = (1/2) · (T+ - T-) = (1/2p) · MV

Normalized count:

NA - CA = (1/2) · (45 - 19) /400 mm2 = 0.0325 counts/mm2

Geometric property:

MV = 0.204 mm/mm3

The area tangent count applied to boundary elements of a collection of features measures the circular image of those features:

q A+ = pTA+ ;

q A- = pTAq Anet = p (TA+ - TA- ) = pTAnet

(5.22)

Combine this result with equation (5.21) to show that the Euler characteristic of a collection of two dimensional features with holes is simply related to the

net area tangent count:

Less Common Stereological Measure

1

1

N A - C A = TAnet = (TA+ - TA- )

2

2

103

(5.23)

For a collection of convex features CA = 0 (there are no holes) and TA- = 0,

so that NA = 1/2 · TA+; the result that every particle has two tangents is self evident

in this case. If the features are simply connected, i.e., have no holes, then every

bounding loop has two terminal convex tangents and, for each concave tangent there

is a balancing extra convex tangent. The net tangent count still gives two per particle. If there are holes, equation 5.23 gives the Euler characteristic of the collection

of features.

If the two dimensional structure in this discussion results from probing a

three dimensional microstructure with a plane then the expected value of the Euler

characteristic on the section is an estimator of the integral mean curvature of the

corresponding collection of ab surfaces in the volume, according to equation (5.14).

Thus, the net tangent count provides an unbiased estimate of the integral mean curvature:

TA net = 2 N A

net

=

1

MV

p

(5.24)

It may appear that the tangent count merely provides the same information

that a feature and hole count could provide, since in a two dimensional structure

the features are visible in the field and can be separately marked and counted. The

tangent count would appear to give redundant information. However, there are

some valid arguments for considering replacing the feature count with the tangent

count:

1. Tangents occur at a point; a point is either inside the boundary of the field,

or outside it. Bias due to particles intersecting the boundary of the field is

not a factor in the tangent count;

2. In some structures, e.g., lamellar structures, or structures in which both

phases occupy about the same area fraction, features of, say, the b phase may

wander in and out of the boundary of the field several times so that it is not

possible to make the feature count.

3. In a three phase structure (a + b + e) part of the boundary of b particles is

ab boundary, and part may be be boundary. In this case it is possible make

separate area tangent counts of these two kinds of interface and assess the

circular image (and the integral mean curvature) of each.

4. If the boundary on a section has vertices, separate application of the tangent

count to smooth segments versus vertices provides a measure of the dihedral

angle at edges in the three dimensional structure the section samples. This is

described in more detail in an example below.

5. Since separate counts are obtained for convex and concave elements of

boundary the circular images of convex and concave arc in the plane probe

structure may be separately estimated. While this information does not have

104

Chapter 5

Figure 5.16. An edge is formed by two surfaces meeting to form a space curve. The

angle between the surface normals at a point P on an edge, c, is called the dihedral angle.

(For color representation see the attached CD-ROM.)

a simple relation to the geometry of the parent three dimensional microstructure (DeHoff, 1978) it may be useful information in some applications.

Thus, the net tangent provides an unbiased estimator of MV in all of its

applications.

Edges in Three Dimensional Microstructures

Because microstructures are space filling, triple line structures, such as those

described in the qualitative microstructural state discussion in Chapter 3, are

common. A triple line results when three “cells”, some or all of which may be the

same phase, are incident in three dimensional space. Three surfaces also meet at a

triple line, namely the three pairwise incidences of the cells involved. From the viewpoint of any particular cell, the triple lines it touches are edges of that polyhedral

shaped body. More generally an edge is a geometric feature which results from the

intersection of two surfaces that bound a feature to form a space curve, as shown

in Figure 5.16. In addition to the properties of space curves (length, curvature and

torsion) an element of edge has a dihedral angle. The two surfaces that meet at an

element of edge each have a local normal vector. The dihedral angle, c in Figure

5.16, is the angle of rotation between these two surface normals.3 In general this

angle varies from point to point along the edge.

3

Like surfaces, edges may be convex (ridge with a maximum); concave (valley with a minimum)

or saddle (ridge with a minimum or valley with a maximum) in character. Valley edges by

definition have a negative value of c.

Less Common Stereological Measure

105

The dihedral angle also plays an important role in the physical behavior

of structures in which surface tension plays a role. In the thermodynamics of surfaces that meet at triple lines it is shown that the dihedral angles at the three

edges are determined by the relative surface energies of the three surfaces that

meet there. For example, the tendency of one phase to spread over a surface

between two other phases, i.e., to “wet” the surface, is measured by this dihedral

angle. This property plays an important role in soldering, adhesion, liquid phase

penetration, welding, powder processing and the shape distribution of phases at

interfaces.

An element of length of an edge may be thought of as a limiting case of an

element of surface for which one of the radii of curvature goes to zero, i.e., sharpens to an angle. With this point of view it can be shown that for a polyhedral particle the edges make their own contribution to the integral mean curvature of the

boundary of a particle:

Medges =

1

c ◊ dL

2 ÚL

(5.24)

where the integration is over the length of edge in the structure. To lend

some credence to this assertion that this property is in fact the contribution to M

due to edges it may be shown that this result may be used in conjunction with

Minkowski’s formula for convex bodies, equation (5.13), to compute the mean

caliper diameter of polyhedral shapes. Consider the cube with edge length e shown

in Figure 5.17a. The dihedral angle at all points on the twelve edges is p/2. The total

length of edge is 12e. The surfaces (faces) all have zero curvature, so that the contribution of the surfaces to M is zero. Combine equation 5.24 with the Minkowski

formula:

Mcube = M faces + Medges = 0 +

Dcube =

3

e

2

p

1p

L = 12 e = 3pe = 2pDcube

22

4

(5.25)

This is the same result that is obtained by evaluating the caliper diameter of

a cube as a function of orientation and averaging over orientation.

Similar analysis of other shapes provides an efficient way to calculate D averaged over orientation. This is generally far easier than the modelling approach using

Monte-Carlo sampling introduced in Chapter 11, but the latter method can also

produce the distribution of intercept lengths or areas which are needed to unfold

particle size distributions.

Figure 5.17b shows a cylinder with radius r and length l. In this case there

are contributions to M from both the curved surface and the edges. On the curved

face of the cylinder the curvature in the axial direction is zero, and the mean curvature everywhere has the value (1/2r). The dihedral angle at every point on the

edges is p/2. Evaluate M for a cylinder:

106

Chapter 5

Figure 5.17. The integral mean curvature for features with edges contains a contribution from edges. For the cube (or any flat faced polyhedron), all of the integral mean

curvature resides at the edges. A feature with curved faces and edges has both

contributions. (For color representation see the attached CD-ROM.)

Mcyl = M faces + Medges = Ú Ú H ◊ dS +

S

1

H ◊ dL

2 ÚL

1

1 p

1

p

2prl + 2 ◊ 2pr

= Ú Ú dS + Ú dL =

2r

2L2

2r

4

S

(5.26)

Mcyl = pl + p 2 r = 2pDcyl

1

p

Dcyl - l + r

2

2

Again, this is the same result that is obtained if D is computed as a function

of orientation and averaged over the hemisphere. Note that for the limiting cases of

p

1

a plate (r >> l), D = –2 r, while for a rod (l >> r), D = –2 l.

Edges can also be treated as a limiting case of a curved surface in the sense

that the integral mean curvature of an edge can be measured by the tangent count,

equation (5.23):

TA

=

edges

1

11

c ◊ dL

MVedges =

p

p 2 LÚV

(5.27)

where c is the dihedral angle measured at any point along the edge. An average dihedral angle may be defined,

c =

Ú c ◊ dL

LV

Ú

dL

=

2 MVedges

LV

(5.28)

LV

MVedges can be measured with the tangent count at edges, using equation

(5.27), and LV can be measured by counting points of intersection of the edge line

Less Common Stereological Measure

107

Figure 5.18. The mean dihedral angle at edges, ·cÒ on the b (colored) phase of this

structure can be measured with a triple point count combined with a tangent count. (For

color representation see the attached CD-ROM.)

Probe population:

Planes in three dimensional space and sweeping line probes

in two dimensions

Calibration:

L0 = 14.7 mm; A0 = (14.7 mm)2 = 215 mm2

Event:

Plane intersects aab triple line;

Sweeping line forms tangent at aab triple line

Measurement:

Count the triple points; count the tangents

This count:

49 triple points, 32 tangents

Relationship:

·cÒ = p TA/PA

Normalized count:

PA = 45 counts/215 mm2 = 0.23 counts/mm2

TA = 32 counts/215 mm2 = 0.15 counts/mm2

Geometric property:

·cÒ = p · 0.15/0.23 = 2.05 radians = 117 degrees

with the plane probe. Thus, the average dihedral angle for any specific type of edge

can be estimated from the ratio

c =

2p ◊ TAedges pTAedges

=

2 PA

PA

(5.29)

Figure 5.18 shows a two phase structure with aab triple lines. A sweeping

line probe is visualized to move from the top to the bottom of the field. Tangents

with the aab edge are marked and counted. The total number of aab triple points

108

Chapter 5

is also counted. With the usual assumptions about the sample plane, these properties are normalized and used to estimate MVedge and LVaab. These computations are

indicated in the caption to Figure 5.18. The ratio is then used to estimate the average

dihedral angle on aab edges of the b particles. The result, 2.05 radians or 117

degrees, is the average value of the angle between the surface normals at the edge.

This result may be used, for example, in the assessment of the relative surface energies of the ab and aa interfaces in this system.

Summary

The disector probe is required to obtain information about the topological

properties, number (NV) and connectivity (CV) of surfaces bounding three dimensional features. This is achieved by comparing the structures on a reference plane

and a look-up plane in order to infer the occurrence of tangents with the surfaces

formed by a plane that is visualized to sweep the volume between the planes of the

disector. Counts of the three kinds of tangents measure the spherical image of

convex, concave and saddle surfaces in the structure. The Euler characteristic,

(NV - CV), may be estimated from these tangent counts in the disector probe

NV - CV

1

1

TVnet = [TV++ + TV-- - TV+- ]

2

2

For most structures the connectivity is small in comparison with the number

of disconnected parts of the structure, and the disector probe provides the primary

strategy for estimating number density in microstructures.

If the three dimensional particles are convex, then a feature count on a plane

probe estimates the product of the number density and mean caliper diameter:

NV = NV D

Feature counts on oriented plane probes measure the caliper diameter in the

direction of the plane probe normal.

N A (q , f ) = NV D (q , f )

For more general structures, the (net) feature count (or equivalently, the

net area tangent count) reports the integral mean curvature of the surface in the

structure:

NA

net

= NA - CA =

1

1

1

TAnet = TA+ - TA- =

M

2

2

2p

Particles of arbitrary shape in the three dimensional structure may, for some

positions and orientations of a plane probe, produce sections with holes in them.

In this general case, the feature count is interpreted as the number of features in the

section minus the number of holes. This net number of features can also be determined from the area tangent count, which visualizes a line that sweeps across the

field of view and forms tangents with convex and concave elements of the boundaries of particle sections. In the general case, either of these counts reports the value

Less Common Stereological Measure

109

of integral of the mean surface curvature of the boundaries of particles in the three

dimensional microstructure. For convex bodies, M is proportional to the mean

caliper diameter. For muralia (plates) it reports the length of perimeter of the features in three dimensions. For tubules (rods), M reports their total length in the

volume.

If the features in the three dimensional collection of particles have edges,

then these edges contribute to the integral mean curvature of the boundaries of the

particles so that

MVtotal = MVsurfaces + MVedges = Ú

1

Ú H ◊ dS + 2 Ú c ◊ dL

SV

LV

where c is the dihedral angle between the surface normals at the each point on the

edge. This result may be used to estimate the average dihedral angle along a collection of edges in the structure.

c =

pTAedges

PA