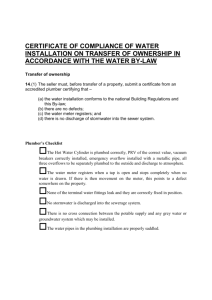

Natural Gas Installation Standards Handbook

advertisement