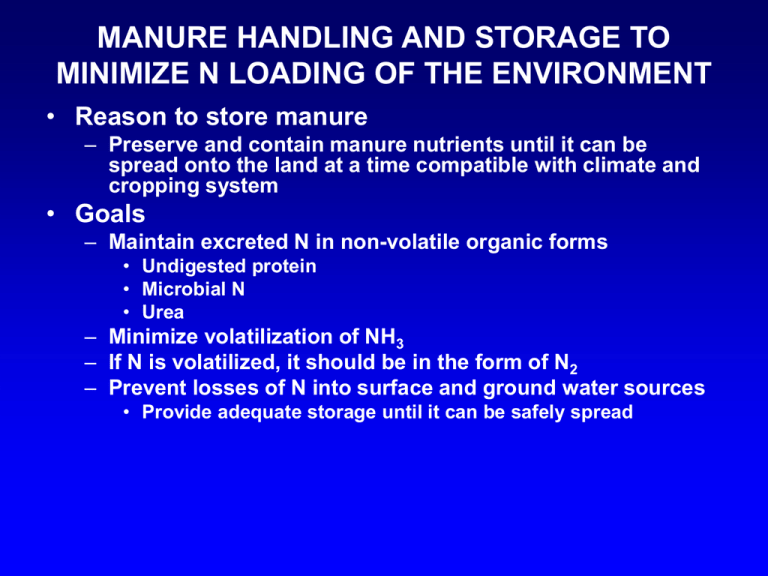

MANURE HANDLING AND STORAGE TO MINIMIZE N LOADING OF THE ENVIRONMENT Goals

advertisement

MANURE HANDLING AND STORAGE TO MINIMIZE N LOADING OF THE ENVIRONMENT • Reason to store manure – Preserve and contain manure nutrients until it can be spread onto the land at a time compatible with climate and cropping system • Goals – Maintain excreted N in non-volatile organic forms • Undigested protein • Microbial N • Urea – Minimize volatilization of NH3 – If N is volatilized, it should be in the form of N2 – Prevent losses of N into surface and ground water sources • Provide adequate storage until it can be safely spread N TRANSFORMATIONS IN LIVESTOCK PRODUCTION AND MANURE STORAGE FACILITIES Manure N Anerobic microbial degradation (slow) C skeletons H 2S VOCs Fecal N (20-40% of N) Microbial N NH4+ Urine N (60-80% of N) Microbial O urease (rapid) H2N C NH2 + H+ + H2O 2NH4+ Slow aerobic Anerobic NH3 pH (volatile) 2HCO3• In poultry •Urinary N is secreted as uric acid with the feces NO2 N2 • NH3 volatilization increased by: – Increasing rumen pH • Increased by increased HCO3 and NH3 – Increasing moisture – Increasing temperature • From outside of confinement buildings – Greater ventilation – Concentrations of NH3 greater inside confinement buildings in cold weather • From outside lots – Greater surface area METHODS TO LIMIT AMMONIA VOLATILIZATION FROM MANURE • Dietary approaches – Reduce N excretion – Feed acidic Ca and P sources to decrease manure pH • Examples – Calcium chloride – Phosphoric acid • Limitations – Unpalatable – May cause ulcers in mouth – Feed Yucca extract • May inhibit microbial urease • Technological approaches – Frequent removal of manure from facilities • Ne feedlot – One-time cleaning, 68% N loss by volatilization – Monthly cleaning, 55.5% N loss by volatilization – Increase carbon in manure • Increases C:N ratio to increase microbial growth • Approaches – Feed more fiber – Use more bedding – Separate liquid and solids • Separates urea in urine from urease in feces • Methods – Gravity (Inclined floors, sedimentation pits) – Mechanical (Screens, centrifuges, presses) • Separated solids – Land applied – Composted • Liquids – Need further processing – Urease inhibitors • N-(n-butyl) thiophosphoric triamide (NBPT) • Must be applied weekly to feedlot surface • Currently not cost effective • Solid COMMON MANURE STORAGE – Systems • Poultry – Litter • Swine and Dairy – Separated solids – Bedded manure • Beef – Scraped – Facilities • Concrete pad with sides • Settling basins – Advantages • Low volume • Low odor • Moderate nutrient retention – Disadvantages • More labor • Must prevent precipitation run-off BEEF FEEDLOT WITH SETTLING BASIN – Composting • Treatment to stabilize N • Requirements – Appropriate C:N ratio Optimum Manures Dairy cow Beef cow Beef feedlot Swine Poultry Horse C:N >30:1 10:1 10:1 13:1 7-8:1 7-9:1 19:1 – Temperature » 140o F » Requires frequent turning – Moisture level » 40-60% – Adequate porosity » Particles should be > 1 inch » Straw a better source than paper – pH » 5.5 – 7.5 • Slurry – For livestock and poultry confinements – Facilities • Pit under slatted floor – Needs access ports for pumping and agitation at 40 foot intervals – Ventilation is necessary – Manure is either applied directly or after storage • Fabricated storage tank – Manure is either scraped or pumped into structure – Easily covered • Earthen basin – Provides a large volume at low cost – Soil materials must seal basin – Vegetation must be maintained on berms – Advantages • Less volume than liquid storage • Possible to cover to reduce volatilization • High nutrient retention, if covered – Disadvantages • Higher odor than solids • Toxic gases – H2S SLURRY SYSTEMS • Covers to limit NH3 and odor release • Floating covers – Natural » Crust floating on top of manure – Artificial organic » Straw, chopped corn stalks, wood shavings – Artificial » Polystyrene foam, air-filled clay balls, geotextile – Effectiveness » Provides a barrier between liquid manure and the atmosphere » Provides aerobic media to all microbes to degrade odor compounds » Limitations Straw will only last from 2 weeks to 6 months • Liquid systems – Anerobic lagoons • • • • Most common liquid system Usually treats liquid fraction separated from solids Requires warm temperatures for microbial activity Advantages – Large storage volume – Can use conventional pumping equipment • Disadvantages – – – – – Very high NH3 volatilization Requires appropriate soil materials to seal lagoon Requires solids separation Manure additions must be slow and uniform High odor in spring when microbial activity increases under Midwest conditions – Requires periodic sludge removal – Alternate treatments to limit NH3 loss from liquid systems • Aeration – Converts NH3 to NO3 – Requirements » Second lagoon with aerator Surface pump Compressed air Aerobic biofilters » One lagoon with 2 compartments Aerobic top and Anerobic bottom – Disadvantages » Expense » Limited effectiveness » Production of NOx gases • Methane production – – – – – Enclosed anerobic fermentation Can supply energy for farm or for sale Requires additional structure for storage of effluent Good N retention if additional storage is covered Expense • Constructed wetlands – For processing liquid fraction after solids separation » N trapped in plants growing in or on wetland – Types » Surface Most common » Subsurface Water treatment in a gravel bed Works better in winter than surface wetland May plug » Reciprocating Recurrently fill and empty Causes aerobic and anerobic zones N LOSSES FROM DIFFERENT MANURE HANDLING AND STORAGE SYSTEMS Daily scrape and haul from barn Open lot Pile (Cattle/Swine) Pile (Poultry) Compost Deep pit (Poultry) Litter Pit under floor (Swine) Tank above ground top loaded Tank above ground bottom loaded Tank above ground with cover Holding basin Anerobic lagoon w/ no cover Constructed wetlands N loss, % 20-35 40-70 10-40 5-15 20- 50 25-50 25-50 15-30 20-35 5-10 2-30 20-40 70-80 15 N retention, % 65-80 30-60 60-90 85-95 50-80 50-75 50-75 70-85 65-80 90-95 70-98 60-80 15-30 85 FACTORS AFFECTING SIZE OF MANURE STORAGE • Volume of manure and wastewater produced – Include wash water, run-off from open lots and feed storage, and water for flushing • Limitations for spreading – Amounts of land available for spreading – Crop nutrient requirements • Length of storage period – Climatic limitations – Length of application windows – Needs • A minimum of 6 months storage • Equipment capabilities • Discharge regulations – All beef and dairy CAFOs • No discharge except for a 25-year, 24-hour storm – All new or renewed swine, poultry, and veal CAFOs • No discharge except for a 100-year, 24-hour storm MANURE APPLICATION TO MINIMIZE N LOADING • Considerations – Manure N concentration • Needs laboratory analysis to adjust for factors like diet, volatilization, water dilution, and bedding • If developing a CNMP, need to consider total N production Manure N (lb N/lb animal wt/yr) Swine Nursery Growing Finishing Sows and litter Sow gestation Gilts Boars Beef 450-750 lb High energy finish Cows Dairy 50 lb milk/d 70 lb milk/d 100 lb milk/d Dry Heifer Layers Broilers Turkeys .22 .15 .15 .17 .07 .088 .055 .11 .11 .12 .18 .22 .27 .11 .11 .30 .40 .27 – Availability of N to plants (PAN) • PAN = Organic N x mineralization rate + NH4-N x volatilization factor + NO3-N • Mineralization rate of organic N – Generally slow – Increases with: » Lower soil moisture » Increased soil temperature » Increased soil pH » Nutrients for soil microbes – Average rates Soil moisture < 18% > 18% % OM-N available 35 25 • Volatilization of NH3 – Very rapid with surface application – Rate dependent on: » Application method Lower with injection or incorporation » Temperature Greater from surface applied at higher temperature » Plant uptake Losses lower when plants actively growing – Average factors Application method % NH4-N available Injected or side-dressed during growing 100 season Injected or incorporated in spring 65 (Reduce by 12% for each day delay in incorporation) All other conditions 0 • Plant Available Nitrogen (PAN) – After storage loss Storage type Proportion of manure N available after storage Feedlot .60 Manure pack under roof .70 Bedded swine .50 Liquid/slurry, covered .90 Liquid/slurry, uncovered .75 Storage pit under slats .85 Poultry manure on shavings .70 Compost .70 Anerobic lagoon .20 • After application ___________Application method______________ Soil incorporation Broadcast Irrigation Proportion of manure N available after application Scraped manure Livestock Poultry litter Liquid slurry Dairy or Beef Swine Layers Anerobic lagoon Dairy or Beef Swine Layer .6 .6 .5 .5 - .7 .7 .7 .5 .4 .5 .4 .3 .4 .8 .9 .9 .5 .5 .5 .5 .5 .5 • Total PAN = Total N x ( PAN after storage x PAN after application) – Examples • PAN of Feedlot manure applied with incorporation – PAN = Total N produced x (.6 x .6) = Total N produced x .36 • PAN of Swine pit manure applied with incorporation – PAN = Total N produced x (.85 x .7) = Total N produced x .595 • PAN of Anerobic lagoon manure applied with irrigation – PAN = Total N produced x (.2 x .5) = Total N produced x .10 – Other N sources • N-fixation by legume plants – Supplies enough N to meet legume plant needs for growing year – N-fixed by legume plants for following year Soybeans Alfalfa lb plant available N/acre/year 30-45 50-125 • N fertilizer – Rates should be calculated as the difference between plant N needs and PAN from manure and legumes – Crop N needs • Nutrients should be applied to achieve Realistic Yield Expectations of the crop – The ‘Agronomic rate’ • Realistic yield expectations – Factors » Soil fertility » Soil management » Climate » Plant populations » Pest control » Variety » Grazing (60-75% of PAN reqt. for hay) – Estimates » Average of 3 highest years of last 5 » Can use county soil survey – Plant N requirement for yield N removal in harvested crop, wet basis Crop Corn Grain Stover (Baled) Soybeans Grain Stover (Baled) Alfalfa (Baled) Bromegrass (Baled) Reed canarygrass (Baled) Switchgrass (Baled) Alfalfa haylage Corn silage Efficiency of N use, __%__ N required for crop .81 lb/bu 17.80 lb/ton 83 100 .97 lb/bu 17.80 lb/ton 3.54 lb/bu 13.60 lb/ton 46.10 lb/ton 39.20 lb/ton 28.00 lb/ton 21.80 lb/ton 25.90 lb/ton 9.00 lb/ton 166 100 200 100 100 100 200 100 2.13 lb/bu 13.60 lb/ton 23.05 lb/ton 39.20 lb/ton 28.00 lb/ton 21.80 lb/ton 12.95 lb/ton 9.00 lb/ton – Calculating manure application rate based on N • Plant available N = Realistic yield expectation x Crop N reqt. needs • Manure application = Plant available N reqt / PAN conc in manure rate Example: Say: Corn yield = 180 bu/acre PAN needed, lb/acre = 180 bu/acre x .97 lb N/bu = 174.6 lb PAN/acre Say: Swine lagoon manure containing 50 lb PAN/1000 gal which will be injected Manure applied, gal/ac = 174.6 lb PAN/ac / 50 lb N/1000 gal = 3,492 gal/ac USING CROPS TO ‘MINE’ MANURE N • Some CAFOs look at harvested crop as method to remove manure N from operation • Potential amounts of N removed Crop RYE Corn grain 180 bu Corn stover (Baled) 4 ton Soybeans 55 bu Alfalfa (Baled) 5 ton Bromegrass (Baled) 4 ton Reed canarygrass 5 ton (Baled) Corn silage 20 ton N removed/unit .81 lb/bu 17.80 lb/ton 3.54 lb/bu 46.10 lb/ton 39.20 lb/ton 28.00 lb/ton 9.00 lb/ton lb total N removed/acre 146 71 195 230 156 140 180 • Considerations – To mine N, crop must either be sold or used in the diet to reduce purchase of protein supplements on farm – Grazing is effective at recycling N • Therefore, grazing is ineffective for mining nutrients – If N is applied at the agronomic rate, Phosphorus will accumulate • N rate is 2 to 3 times greater than the P rate CONSIDERATIONS IN MANURE APPLICATION • Application rate • Method Surface application Greater N volatilization Greater potential for N loss in run-off Nutrients further from crop roots Injection or incorporation Less N volatilization Less run-off potential Nutrients near roots • Site – In Iowa, manure application can not occur within 200 feet of a surface water source if no vegetative buffer – In Iowa, manure application may occur up to 50 ft if vegetative buffer and manure is incorporated • Timing – Manure should be applied shortly before nutrients will be used for growth • 30 days