Systems Engineering at the Nanoscale

advertisement

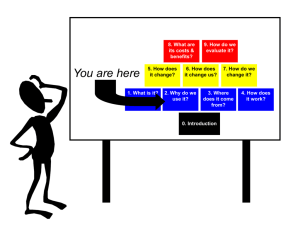

Systems Engineering at the Nanoscale Jennifer L. Sample and Harry K. Charles Jr. anotechnology has become ubiquitous in advanced technology and advanced product development. Nanotechnology exploits the properties of materials with at least one dimension at the nanoscale, typically in a novel and controllable way. As a result, nanotechnology has the ability to affect materials and structures as part of complex systems that can influence actions in the macroscopic world. This article explores nanotechnology and its emergence into systems engineering, highlighting attributes of the technology that may play a significant role in APL-developed systems of the future. INTRODUCTION A system is a composite of different elements that when brought together yield results that are not obtainable from the elements alone.1 The function of systems engineering is to guide the development of individual components into robust and efficient systems capable of autonomous operation as complex systems, where complex systems are defined as systems in which elements are diverse and have intricate relationships with each another. Nanotechnology refers to the creation of functional materials, devices, and systems via control of matter on the nanometer-length scale (nominally 1–100 nm) and exploitation of novel phenomena and properties (physical, chemical, biological) at that length scale. In general, nanotechnology begins with nanoscience: the study of material properties and their interactions at the nanoscale and how they can be exploited. 50 Once the properties of nanostructures are well characterized and can be reproducibly fabricated, those properties can be exploited as a technology. Two important concepts define a system: 1. The system has properties or attributes that cannot be associated with any of its components.2 2. The description of the system function is less complex than the functional descriptions of the system components. These concepts or properties are called emergent properties of the system.3 Emergence in the engineering disciplines is an expected outcome. Emergence can also occur in nanomaterial systems. For example, a microprocessor chip system can perform millions of arithmetical functions per second JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) under precise control of a software program. These mathematical functions are a straightforward manifestation of the input and output behavior of the software code. This description is much simpler than a description of the microprocessor chip states through which the chip would pass as the function is computed under the direction of the software code. Such component descriptions—regardless of the level considered, from individual quantum levels to gate or machine language functions—are much more complex than the description of the mathematical function itself. Microprocessors, however, are typically part of multiscale systems such as cellular phones and automotive sensors and similarly could be part of systems linking nanotechnology to society. This article will describe the development of nanotechnology for small systems or components at APL. Examples include physiologically responsive polymers, which release drugs only in response to a need-based physiological stimulus;4 nanoporous DNA sensors, which electrically detect DNA segments binding to a known segment;5 and biologically generated nanoscale cellulose composites, which provide strong transparent materials for structural or biomedical applications.6 All of these technologies are currently under development at APL. COMPLEX SYSTEMS Complex systems or complex adaptive systems have been studied extensively for almost 40 years.7 They trace their origins to the beginnings of chaos theory in 1890 by Jules Henri Poincaré8 (1854–1912), a professor of mathematics at the University of Paris from 1881 to 1912, and to the work in the 1960s of Edward Norton Lorenz9 (1917–2008), mathematician, meteorologist, and professor at Massachusetts Institute of Technology. To define a complex system we must consider the concept of upward predictability. Upward predictability implies that an analysis of interactions at the component level will yield a simple explanation of the phenomena observed at the system level. Systems that can be analyzed in this manner are upwardly predictable. Complex systems often are not upwardly predictable. The effects of interactions at the component level are correlated in complex ways to the phenomena occurring at the system level. This lack of upward predictability, coupled with emergence concepts, is the hallmark of a complex system. Complex systems can be engineered by humans or they can occur naturally. Representative humanengineered systems include many APL systems, including missile defense and spacecraft systems such as the Standard and Tomahawk missiles, the Midcourse Space Experiment (MSX, a DoD satellite), and the MErcury Surface, Space ENvironment, GEochemistry and Rang- JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) ing (MESSENGER) probe, a mission to the planet Mercury. Naturally occurring complex systems can range from biological entities to meteorological events. Virtually all important properties of engineered systems are emergent. The primary difference between engineered and naturally occurring systems is that in human-produced systems, the emergent properties are produced intentionally. Yet other real differences exist: humanengineered systems are often functionally fragile and do not hold up well in the environment in which they are used, whereas natural systems seem to be more robust, flexible, and adaptable. These differences are due in part to the top-down or hierarchical design approach3 used in human-engineered systems. At each level, performance goals are set and then subcomponents are added with the needed properties to achieve the performance at the next upward level. For each of the subcomponents, the same is done with sub-subcomponents and so on. In contrast, nature designs systems from the bottom up. Existing or modified components are put together with no known performance constraints or functionality goals in mind. The resultant system (assemblage) either survives in the environment or dies (trial and error and survival of the fittest). Nature’s designs are not always perfect, but surviving systems perform the required functions, and nature does not have to work against budget and schedule constraints. The description in this article of the latest developments in microelectronics and nanotechnology explores the application of natureemulating systems built by the self-assembly of fundamental components versus the top-down approach of conventional human-engineered systems. Both system types play important roles in all areas of science and engineering development. NANOTECHNOLOGY The properties of nanoscale materials differ from their macroscopic counterparts. One ubiquitous difference is higher surface area; nanostructures can have as much as 90% of the atoms at the surface (Fig. 1). This increased surface area leads to improved catalytic performance at the nanoscale for catalytic materials. It also leads to a maximization of relevant surface effects, such as capillary forces and electrostatic attraction, which can be exploited to assemble nanoparticles into functional, hierarchical arrays.10 Variance in optical properties with nanomaterial size and shape has been known for centuries in the use of gold and silver nanoparticles as pottery glazes and stainedglass pigments.11 Gold and silver exhibit size-dependent optical properties because they support a surface plasmon—a collective oscillation of free electrons in the material that can resonate, absorbing light in the visible spectrum. In recent decades, these materials have found 51­­­­ J. L. SAMPLE AND H. K. CHARLES JR. Macro 1 cm 1 mm 0.1 mm Micro Size scale 10 m 1 m 0.1 m Nano 10 nm 1 nm 0.1 nm 0 20 40 60 80 Atoms at the surface (%) 100 Figure 1. Nanoscale particles have a much larger percentage of atoms at the surface (76%) than macroscopic (millimetersized) particles, which have approximately 0% of atoms at the surface.11 extensive utility in sensing applications.12, 13 This surface plasmon gives rise in part to the surface-enhanced Raman scattering effect, which has been exploited by APL researchers to detect chemical or biological signatures of interest to APL sponsors.14, 15 Quantum confinement, or confinement of electrons in a material as a result of finite size (rather than bulk “infinite” size), leads to many interesting nanoscale effects. Semiconductors exhibit size-dependent optical properties as a result of quantum confinement. The term “quantum dot” is used in the context of referring to these materials, as they fluoresce at size-dependent wavelengths. These materials have been applied commercially as fluorescent biomarkers used for biomedical imaging, and they have been used at APL for sensing and tagging applications. There are many nanoscale devices that perform functions in response to stimuli or integrate the functionality of multiple counterparts to perform a function or make a measurement. These are small, complex nanosystems. Three primary examples are nanowire sensors, biomimetic nanomaterial systems, and DNA “walkers” that 52 exploit the self-assembling material properties of DNA to enable a small “robot” to perform functions such as walking down a track.16 APL researchers have developed functional nanomaterials and devices to address critical challenges in homeland protection. For example, one project, the Nanoporous DNA Sensor, uses nanotechnology to achieve rapid, straightforward DNA matching. Nanoscale pores are functionalized with complementary DNA, and the size of the pores is small enough that DNA binding inside the pore will change impedance through the porous membrane in a detectable way. This technology is envisioned as an alternative to DNA microarray technology, providing the advantage of reduced sample preparation requirements, which will be useful in rapid screening scenarios. Another APL project uses electrodeposited bismuth nanowires to detect radiation. Incident gamma rays generate detectable electrical current in these materials. These bismuth nanowire arrays have the significant advantage of being less expensive to produce than the current technology, which involves large single-crystal semiconductor detectors. In addition to these sensor nanowire applications, metal nanotubes are being investigated at APL for high-energy-density thinfilm battery applications. These thin-film battery nanotubes are filled with battery chemicals, and they can be geometrically engineered to minimize battery inefficiencies such as diffusion-limited transport between anode and cathode.17 Researchers hoping to mimic the desirable functionalities of naturally occurring biological systems have created various nanomaterial systems. For example, the gecko lizard demonstrates the remarkable ability to defy gravity by scaling walls and walking on ceilings despite its relatively high mass (especially when compared with insects). Furthermore, this organism can scale surfaces of varying roughness in varying ambient environments such as low or high humidity. Research into the biological gecko foot and the structures of insects’ feet has revealed the presence of small hair-like structures whose sizes scale inversely with the creatures’ mass foot-to-pad area ratio, with the gecko’s foot hair structures consisting of flexible nanofiber-shaped hairs. Attempts to replicate these naturally occurring structures have integrated many types of lithography and materials, from microelectromechanical system (MEMS) foot hairs to highaspect-ratio polymer nanofiber structures created from a self-assembling polymer microsphere templated lithographic technique.18 At APL, researchers are mimicking nature to produce an “eye patch” for battlefield eye injuries. Biologically generated nanoscale cellulose fiber composites are being used to mimic the strong mechanical properties and simultaneously transparent optical properties of the natural cornea.19 The types of materials described above can be considered individual components of larger systems, rather JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) SYSTEMS ENGINEERING AT THE NANOSCALE than nanosystems themselves. Roco20 has classified nanotechnology into four generations: (i) nanomaterials fabrication, (ii) nanoscale phenomena exploitation, (iii) nanotechnology-based devices, and (iv) complex nanosystems. As a field, nanotechnology to date has certainly reached the third generation. The achievement of the fourth generation will likely challenge the field of systems engineering to accommodate these dynamic, reconfigurable nanosystems with properties that do not necessarily scale with size. INTERFACING NANOTECHNOLOGY WITH THE MACROSCOPIC WORLD At the time of this writing, several systems involving nanotechnology are under development for commercial use, including lab-on-a-chip (LOC) technology and hybrid nanoelectronics. LOC technology has received considerable attention in the last two decades21 as a promising, highly functioning diagnostic tool capable of providing fast diagnostic information to medical professionals and requiring minimally invasive sample collection. LOCs incorporate many types of technology at many scales, from sample collection (e.g., blood draw) to microfluidic chip-level sample processing (e.g., separation of cellular blood components from serum), to sensors for detecting biomarkers in the samples, to user interfaces. Thus LOCs incorporating nanosensors or other nanotechnology are an example of nanotechnology interfacing with the micro- and macroscales at the systems level. Much has been reported about the potential of nanostructure-based electronics, including devices consisting of supramolecular chemistry-based molecules connected to nanostructures as a new molecular electronics-based computing paradigm22 and devices that exploit the semiconductor properties combined with the small diameter and high aspect ratios of nanostructures such as carbon nanotubes (CNTs).23 Commercial nanoelectronic devices are available (e.g., Nantero, Inc., http:// www.nantero.com/). However, manufacturability issues remain a challenge for integrating some nanoelectronic materials with current CMOS technology. Specifically, it remains challenging to control the electronic structure of CNTs during the growth process, often requiring the separation of semiconducting tubes from metallic tubes or the time-intensive wiring of only the semiconducting tubes (after identification) in place. In addition, many nanostructure growth procedures require high temperatures (600–1000°C) or gases not typically compatible with conventional CMOS technology. Because the CMOS device infrastructure is enormous, these nanodevices have not made it into the mainstream and thus are an example of a nanotechnology challenge with respect to integration into a larger system. JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) To incorporate nanoelectronic materials into mainstream device technology, the nanoelectronic materials must be integrated into hybrid devices by using conventional integrated circuit processes. This process is very challenging with CNTs, as a result of their varied electronic properties, but may not be as prohibitive with graphene. Graphene consists of a single sheet of graphite, and it can be deposited at lower temperatures onto silicon or transferred mechanically.24 APL researchers are working with graphene for several projects. In addition to manufacturing challenges associated with nanotechnology, the nanotechnology itself may require additional considerations in the systems engineering process. Nanomaterials, because of their very small size, are much more susceptible to thermal fluctuations and to weak, reversible forces than are their macroscopic counterparts. These susceptibilities can be exploited to create materials and devices by using self-assembly. Selfassembly is a process that nanomaterials undergo through which weak, reversible forces such as van der Waals attractions, capillary forces, electrostatic interactions, and hydrophobic/hydrophilic interactions are exploited to assemble larger structures from nanoscale counterparts. Self-assembled monolayers (SAMs) are an example of an early studied self-assembling system in which molecules spontaneously form monolayers onto substrates for which they have an affinity, e.g., sulfur-containing thiol molecules onto gold. With the invention and maturity of atomic imaging techniques such as scanning tunneling microscopy, these selfassembled monolayers were used initially to study the positional bonding and thermal migration of molecules on surfaces. Soon thereafter, however, it was discovered that these films could also be used to passivate nanoparticles, thus preventing their aggregation, or could be exploited to introduce new functionalities to material surfaces.25 Beyond SAMs, self-assembly has been exploited to create nanoparticle-based colorimetric DNA sensors, precisely shaped microstructures from the folding of components engineered to self-assemble,26 complex structures made out of DNA (which readily selfassembles to strands with corresponding base pairs), and metalized DNA grids with nanoscale dimensions.27 Because a strand of DNA will automatically form a helical structure with its corresponding base pair-matched counterpart, computer scientists and materials scientists have been able to exploit this material for its innate self-assembling properties rather than for its biological function. In fact, it is possible to simply order the desired strands so that one must only design the proper sequence to create imaginable structures. DNA “smiley-face” structures have been formed in this way, by engineering small crossing strands to force a long strand to fold in programmed ways into the desired structure. 53­­­­ J. L. SAMPLE AND H. K. CHARLES JR. 54 Tim e Level/scale When the DNA structure also performs a complex function, this structure becomes a system. (Months–years) Self-assembly has also been Environment 4 exploited on a wide variety of (system) APL projects, most recently for self-healing paint applications and drug delivery. The self-healing (Days–months) Environment 3 paint has been created by APL (subsystem) researchers for naval applications. The paint contains essentially miniature metal “paint” cans, (Hours–days) Environment 2 which actually contain uncured (devices/components) polymer that cures upon contact with air. The process of scratching the paint breaks open these Environment 1 “cans” and releases the polymer, (Minutes–hours) (self-organization) and the polymer flows to fill up the scratch and then cures. The Complexity emulsification of the paint into (nearly) identical microscopic Figure 2. Schematic representation of emergence and increasing complexity of nanotechdroplets is a wet chemical self- nology building blocks as they evolve into more complex structures or systems. assembly process. Self-assembly is being exploited to create physioframework for the implementation of working complex logically responsive polymers, which release a drug only systems at micro- and nanoscales. These same principles in response to a physiological stimulus. Binding of the also help the integration of micro- and nanosystems into allergen or antibody of interest causes a conformational the building blocks of larger-scale engineered systems. change in the polymer, which releases the drug. Also Figure 2 illustrates the emergence and the evolution of at APL, chemiluminescent solid lipid nanoparticles the complexity of systems as the size of the system’s comhave been created by using self-assembly, and these are positional entities increases and the entities’ environbeing explored as a fluorescent or colorimetric assay for ments change. Timescales of development also increase inflammatory markers in the skin that may be indica28 with increasing system complexity and the expected tive of disease, such as peroxides in skin cancer. emergence behavior. Self-assembly is of interest when nanotechnology is Scale (or size) is a key element in all microelectronicbeing considered for use as a component of a greater and nanotechnology-based systems. Not only has shrinksystem. Because self-assembly is a naturally dynamic ing size improved the performance of electronic devices process that exploits forces that in many cases are of a (integrated circuits), but it has also reduced particle size magnitude similar to the thermal energy of the system, (diameter, surface area-to-volume ratio) in all matecare must be taken to understand and account for the rial systems and has allowed significant breakthroughs dynamic nature of the nanotechnology being used when in many fields. Today these breakthroughs range from engineering the system. Nanomaterials and related materials and medical breakthroughs to devices that devices may be more dynamic than micro- or macroemulate nature. devices with similar functions. For this reason, strategies Just as the invention of the planar process and the such as redundancy or capability-based design (rather integrated circuit attributed to Kilby29, 30 and Noyce31, 32 than requirements-based design) might be necessary in more than 50 years ago were seminal moments in the the systems engineering process. microelectronic industry, the discovery of the CNT by Iijima33, 34 in 1991 and the preceding development of the atomic force microscope by Binnig, Quate, and Gerber35 SYSTEMS ENGINEERING APPLICATION TO in 1986 were defining moments in nanotechnology. The SMALL, COMPLEX SYSTEMS atomic force microscope has allowed engineers and sciSuccessfully managing the issues surrounding emerentists to view atoms. This ability to “see” has led to gence, system complexity, and the top-down vs. bottomvarious investigations and the ability to manipulate up design philosophy is a key factor in determining the individual atoms. viability of microelectronic- and nanotechnology-based The issue of scale and the possibility of manipuproducts. Systems engineering principles provide the lating the structure of materials on an atomic basis JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) SYSTEMS ENGINEERING AT THE NANOSCALE While nanotechnology applications and funding are increasing, there is growing concern about the health risks associated with nanoparticles and nanomaterials. These concerns spring from lack of knowledge about certain factors that are necessary for predicting human health risks. Such factors include the types of exposure and particle entrance into the body, movement of particles from the entry site (translocation), and interaction of the material with the body’s biological systems. Once exposed, the health risks are related to the level and time of exposure, the material’s toxicity, persistence of the material in the body, and the body’s susceptibility to the biologFigure 3. Size scales and development regimes for small, complex systems. Listed on the ical effects. Experimental studies right are examples of well-known objects in each of the size regimes. in animals and with cell cultures have shown that the toxicity of ultrafine or nanoparticles is greater than the toxicity of were first discussed by Richard Feynman in 1959 in the same amount (mass) of larger particles of the same his famous lecture, “There’s Plenty of Room at the chemical composition.38 Bottom.”36 The “bottom” is now labeled nanotechInhalation is the most common route for exposing the nology, a phrase coined by K. E. Drexler,37 who was body to airborne particles. The deposition of nanoparattempting to describe advanced capabilities based on ticles in the respiratory tract is determined primarily by molecular assemblers. The word “nanotechnology” is the particles’ size and shape (aerodynamics) rather than now used to describe or label a diverse array of entiby their composition. Nanoparticles, being so small, are ties and activities, all involving some aspect at the not readily exhaled like their larger counterparts; thus nanoscale. Clearly these materials, with dimensions they can build up at faster rates in the respiratory tract of less than 100 nm, encompass a variety of entities and lungs. More research is needed on the effects of including integrated circuit components, nanocrystals, nanoparticle inhalation on health. and CNTs. Figure 3 illustrates various size scales and Ingestion is another way nanoparticles can enter the gives examples of well-known objects in each of the body. Unless special precautions are taken, the accidensize regimes. tal transfer of materials from hand to mouth is common in handling of most substances. Similarly, ingestion could occur by swallowing mucous that contains parNANOMATERIALS AND HEALTH AND ticles inhaled through the respiratory tract. The effects ENVIRONMENTAL SAFETY of ingestion of nanoparticles are unknown. Nanotechnology has become ubiquitous in our sociRecent reports indicate that nanoparticles can penety. Areas of application are diverse, from medicine to etrate the skin. They penetrate by a standard diffusion electronics. In electronics, nanoparticles have been process and tend to collect in the epidermal and dermal incorporated into adhesives and coatings as well as layers. Potential harmful effects of these nanoparticle interconnecting materials. Nanotubes and nanowires accumulations in the body’s outer covering are again are used as sensors, are incorporated in improved elecunknown. However, studies of cells have shown that trical and thermal conductors, and are starting to make CNTs can enter cells and cause release of cytokines, appearances as active devices for space applications. which cause inflammation, produce oxidative stress, More than 50,000 publications on nanotechnology and decrease culture viability—thus indicating potenideas came out in 2008; 13 nations produced more than tial occupational hazards. One study (based on animal 1,000 publications each, and an additional 32 nations models) estimated that a 20-day exposure to single-wall had nanotechnology publication numbers ranging from CNTs at the Occupational Safety and Health Adminis100 to 1,000. tration (OSHA) permissible exposure limit posed a high JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) 55­­­­ J. L. SAMPLE AND H. K. CHARLES JR. risk of development of lung lesions. Given the potential risks, workers should take every precaution to avoid inhalation, ingestion, and contact of skin with nanotubes and particles. FUTURE Many issues must be explored before nanosystems can be realized and integrated into society. As the potential for large-scale integration is considered, for example, the following issues will be relevant: • System design tools: new tools may be required • Material suppliers and their consistency: standardization of nanomaterials may be needed • Reliability: smaller scaling may lead to higher failure rates • Architecture: redundancy may counter effects of smaller scaling • Circuit manufacturing technology • Circuit architectures • Toxicity • Public fear/marketing • Cost • Profit margin • Unforeseen risks Organizations exist to address most of these issues, from organizations devoted to raising awareness of the benefits, dangers, and possibilities for responsible use of advanced nanotechnology39 to organizations tracking nanotechnology-based consumer products, their toxicity, and their geographical manufacture.40 Nanoelectronic architectures have prompted extensive research, as self-assembling components may lead to cheaper manufacture but higher defect densities. Such self-assembling components could be incorporated into the designs by using architectural redundancy or software algorithms (as discussed in the conference proceedings at http://www.nanoarch.org). All these factors may enable or inhibit the integration of nanosystems into mainstream application, regardless of their inherent promise. REFERENCES AND NOTES 1International Council of Systems Engineering (INCOSE), A Consensus of the INCOSE Fellows, http://www.incose.org/practice/ fellowsconsensus.aspx (2 Oct 2006). 2Maier, M. W., and Rechtin, E., The Art of Systems Architecting, 2nd Ed., CRC Press, London (2000). 3Abbott, R., “Putting Complex Systems to Work,” Complexity 13(2), 30–49 (2007). 4Brown, E. N., White, S. R., and Sottos, N. R., “Fatigue Crack Propagation in Microcapsule-Toughened Epoxy,” J. Mater. Sci. 41(19), 6266–6273 (2006). 56 5Huergo, J., and Buckley, M., “Johns Hopkins Applied Physics Laboratory Names Inventions of the Year: Nanoporous Nucleic Acid Sensor,” APL Press Release, http://www.jhuapl.edu/newscenter/ pressreleases/2007/070417.asp (17 Apr 2007). 6Sain, M., and Oksman, K. (eds.), “Introduction to Cellulose Nanocomposites,” Chap. 1, ACS Symposium Series 938: Cellulose Nanocomposites: Processing, Characterization, and Properties, American Chemical Society, Washington, DC, pp. 2–8 (2006). 7Holland, J. H., Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence, MIT Press, Cambridge, MA (1992). 8Poincaré, J. H., “Sur le Probléme des Trios Corps et les Equations de la Dynamique,” Acta Math. 13(1), 1–270 (1890). 9Lorenz, E. N., “Deterministic Nonperiodic Flow,” J. Atmos. Sci. 29(2), 130–141 (1963). 10Kalsin, A. M., Fialkowski, M., Paszewski, M., Smoukov, S. K., Bishop, K. J. M., and Grzybowski, B. A., “Electrostatic Self-Assembly of Binary Nanoparticle Crystals with a Diamond-Like Lattice,” Science 312(5772), 420–424 (2006). 11Chang, K., “Tiny Is Beautiful: Translating ‘Nano’ Into Practical,” NY Times, 22 Feb 2005. 12Slocik, J. M., Zabinski, J. S. Jr., Phillips, D. M., and Naik, R. R., “Colorimetric Response of Peptide-Functionalized Gold Nanoparticles to Metal Ions,” Small 4(5), 548–551 (2008). 13Haick, H., “Chemical Sensors Based on Molecularly Modified Metallic Nanoparticles,” J. Phys. D: Appl. Phys. 40(23), 7173–7186 (2007). 14Papadakis, S. J., Miragliotta, J. A., Gu, Z., and Gracias, D. H., “Scanning Surface-Enhanced Raman Spectroscopy of Silver Nanowires,” in Plasmonics: Metallic Nanostructures and Their Optical Properties III, M. I. Stockman (ed.), Proc. of SPIE, Vol. 5927, SPIE, Bellingham, WA, pp. 337–344 (2005). 15Sample, J. L., Papadakis, S. J., Fitch, M. J., and Miragliotta, J. A., “Microfabricated Substrates for Spectroscopy and Separation,” in Imaging, Manipulation, and Analysis of Biomolecules and Cells: Fundamentals and Applications III, D. V. Nicolau, J. Enderlein, R. C. Leif, D. L. Farkas, and R. Raghavachari (eds.), Proc. of SPIE, Vol. 5699, SPIE, Bellingham, WA, pp. 531–538 (2005). 16Shin, J.-S., and Pierce, N. A., “A Synthetic DNA Walker for Molecular Transport,” J. Am. Chem. Soc. 126(35), 10834–10835 (2004). 17Srinivasan, R., Baird, L., and Deacon, R., “Metal Nanotubes and Their Applications in Micro Power Sources,” ECS Trans. 16(26), 73 (2009). 18Kustandi, T. S., Samper, V. D., Yi, D. K., Ng, W. S., Neuzil, P., and Sun, W., “Self-Assembled Nanoparticles Based Fabrication of Gecko Foot-Hair-Inspired Polymer Nanofibers,” Adv. Function. Mat. 17(13), 2211–2218 (2007). 19Mulreany, D. G., Chae, J. J., Guo, Q., Espinoza, F. A., Strehin, I., et al., “Collagen Vitrigels with Chondroitin-Sulfate Adhesive for Repair of Full-Thickness Corneal/Scleral Injury,” in Proc. 27th Army Science Conf., Orlando, FL, paper KP-08 (2010). 20Roco, M. C., “Nanoscale Science and Engineering: Unifying and Transforming Tools,” AIChE J. 50(5), 890–897 (2004). 21de Micheli, G., Leblebici, Y., Gijs, M., and Vörös, J. (eds.), Nanosystems Design and Technology, Springer, Berlin (2009). 22Flood, A. H., Stoddart, J. F., Steuerman, D. W., and Heath, J. R., “Whence Molecular Electronics?” Science 306(5704), 2055–2056 (2004). 23Avouris, P., Chen, Z., and Perebeinos, V., “Carbon-Based Electronics,” Nat. Nanotechnol. 2(10), 605–615 (2007). 24Geim, A. K., and Novoselov, K. S., “The Rise of Graphene,” Nat. Mat. 6(3), 183–191 (2007). 25Love, J. C., Estroff, L. A., Kriebel, J. K., Nuzzo, R. G., and Whitesides, G. M., “Self-Assembled Monolayers of Thiolates on Metals as a Form of Nanotechnology,” Chem. Rev. 105(4), 1103–1170 (2005). 26Cho, J. H., and Gracias, D. H., “Self-Assembly of Lithographically Patterned Nanoparticles,” Nanoletters 9(12), 4049–4052 (2009). 27Yan, H., Park, S. H., Finkelstein, G., Reif, J. H., and LaBean, T. H., “DNA-Templated Self-Assembly of Protein Arrays and Highly Conductive Nanowires,” Science 301(5641), 1882–1884 (2003). 28Breidenich, J., Patrone, J., Kelly, L., Benkoski, J., Le, H., and Sample, J., “Chemiluminescent Solid Lipid Nanoparticles (SLN) and Interactions with Intact Skin,” in Biosensing II, M. Razeghi and H. Mohseni (eds.), Proc. of SPIE, Vol. 7397, SPIE, Bellingham, WA, pp. 73970L-1– 73970L-10 (2009). JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) SYSTEMS ENGINEERING AT THE NANOSCALE 29Kilby, J. S., “Invention of the Integrated Circuit,” IEEE Trans. Electron. Devices 23(7), 648–654 (1976). 30Jack St. Clair Kilby (1923–2005), an engineer and inventor with Texas Instruments, who received the Nobel Prize in Physics in 2000. 31Berlin, L., The Man Behind the Microchip: Robert Noyce and the Invention of Silicon Valley, Oxford University Press, New York (2005). 32Robert Norton Noyce (1927–1990) was a cofounder of Fairchild Semiconductor in 1957 and Intel in 1968 and is credited by many as the inventor (along with Kilby) of the integrated circuit. 33Iijima, S., “Helical Microtubules of Graphite Carbon,” Nature 354(6348), 56–58 (1991). 34There is still some controversy over who invented (grew) the first nanotube. While widely attributed to Iijima, some still feel that Radushkevich working in Russia in the early 1950s was the true inventor. The invention of the single-wall CNT, however, is well known, and credit for its invention is jointly shared by Iijima and Ichibashi from Japan and an IBM California team led by Bethune. 35Binnig, G., Quate, C. F., and Gerber, C., “Atomic Force Microscope,” Phys. Rev. Lett. 56(9), 930–933 (1986). 36Feynman, R. P., “There’s Plenty of Room at the Bottom,” Eng. Sci. 23, 22–36 (1960). 37Drexler, K. E., Nanosystems: Molecular Machinery, Manufacturing, and Computation, John Wiley & Sons, New York (1992). 38Oberdörster, G., Oberdörster, E., Oberdörster, J., “Nanotechnology: An Emergency Discipline Evolving from Studies of Ultrafine Particles,” Environ. Health Persp. 113(7), 823–835 (2005). 39Hart Research Associates, Nanotechnology, Synthetic Biology, & Public Opinion: A Report of Findings Based on a National Survey Among Adults, Hart Research Associates, Washington, DC, http://www. nanotechproject.org/process/assets/files/8286/nano_synbio.pdf (2009). 40Since its establishment in 2005, the Project on Emerging Nanotechnologies has generated an ongoing inventory of nanotechnologybased consumer products currently on the market (http://www. nanotechproject.org/inventories/consumer/). The Authors Jennifer L. Sample supervises a section working on materials and nanostructures for primarily aerospace applications, including coatings, power management, self-healing materials, bionanomaterials, soft materials, and stimulus-responsive materials. Dr. Sample also is an experienced principal investigator, project manager, and physical chemist, studying and applying nanomaterials to homeland defense and space exploration applications, specifically engineered multifunctional materials, polymer nanocomposJennifer L. Harry K. ites, refractory nanomaterials, and nanoscale bioconjugation and tagging. Sample Charles Jr. She has experience in sensor systems and materials-based thermal management. Harry K. Charles Jr. has an extensive background in the development and packaging of miniaturized electronic, electro-optic, and electromechanical devices, assemblies, and systems for use in a wide variety of stringent environments, including space, underwater, avionic, and biomedical environments. His experience includes the design, modeling, and analysis of semiconductor and precision material structures, including transistors, integrated circuits, optoelectronic devices, MEMS, and novel sensors. An authority on electronic packaging, Dr. Charles is recognized internationally for his work in interconnection, wirebond testing, thin- and thick-film circuitry, multichip modules, and ultrathin and flexible circuitry. He is a Principal Staff Engineer in the Research and Exploratory Development Department. For further information on the work reported here, contact Jennifer Sample. Her e-mail address is jennifer.sample@jhuapl.edu. The Johns Hopkins APL Technical Digest can be accessed electronically at www.jhuapl.edu/techdigest. JOHNS HOPKINS APL TECHNICAL DIGEST, VOLUME 31, NUMBER 1 (© 2012) 57­­­­