Document 14268070

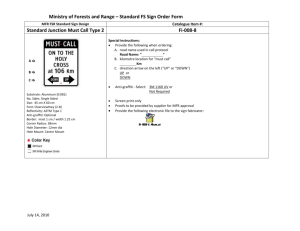

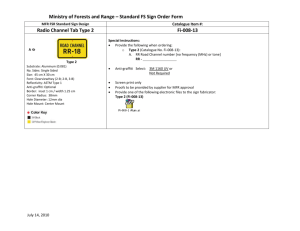

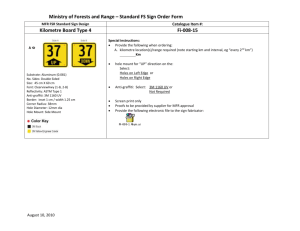

advertisement