T AILWHEEL AIRPLANES

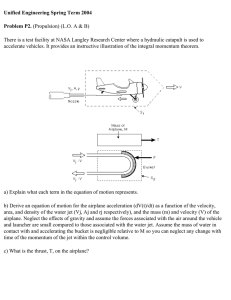

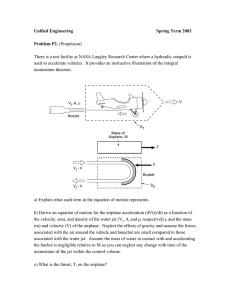

advertisement