N IGHT VISION

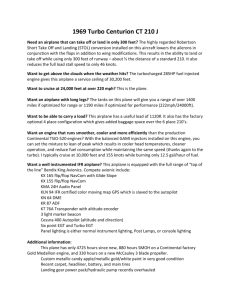

advertisement