Study of Mercury Oxidation by a Selective Catalytic Reduction

advertisement

Energy & Fuels 2007, 21, 145-156

145

Study of Mercury Oxidation by a Selective Catalytic Reduction

Catalyst in a Pilot-Scale Slipstream Reactor at a Utility Boiler

Burning Bituminous Coal†

Yan Cao,‡ Bobby Chen,‡ Jiang Wu,‡ Hong Cui,‡ John Smith,‡ Chi-Kuan Chen,§

Paul Chu,| and Wei-Ping Pan*,‡

Institute for Combustion Science and EnVironmental Technology (ICSET), Western Kentucky UniVersity

(WKU), Bowling Green, Kentucky 42101, Mingchi UniVersity of Technology, Taipei, Taiwan, and

Electric Power Research Institute (EPRI), Palo Alto, California 94304

ReceiVed May 30, 2006. ReVised Manuscript ReceiVed October 2, 2006

One of the cost-effective mercury control technologies in coal-fired power plants is the enhanced oxidation

of elemental mercury in selective catalytic reduction (SCR) followed by the capture of the oxidized mercury

in the wet scrubber. To better understand Hg oxidation chemistry within a SCR, the Institute for Combustion

Science and Environmental Technology at Western Kentucky University set up a pilot-scale SCR slipstream

facility at a selected utility boiler burning bituminous coal. The greatest benefit of this scaled-down SCR

slipstream test is the ability to investigate the effects of Hg oxidation in a SCR using actual flue gas with fly

ash included and to isolate and control specific flue-gas compositions with spike gas additions. The average

sulfur, chlorine, and mercury contents in the burned coal were 1.67% and 731 and 0.13 ppm, respectively.

CaO and Fe2O3 and loss on ignition of the fly ash, which are reported to possibly affect Hg speciation, are

approximately 1.65, 14.6, and 2.6% on average, respectively. The maximum concentrations of spike gases

were 500, 25, 2000, 50, and 15 ppm for HCl, Cl2, SO2, SO3, and HBr, respectively. Semicontinuous mercury

emission monitors were used to monitor the variation of mercury speciation at the inlet and outlet of the SCR

slipstream reactor, and the American Society for Testing and Materials certified Ontario hydro method was

used for data comparison and validation. This paper is the first in a series of two in which the validation of

the SCR slipstream test and Hg speciation variation in runs with or without SCR catalysts inside the SCR

slipstream reactor under special gas additions (HCl, Cl2, SO2, and SO3) are presented. Effects of HBr additions

on mercury speciation within the SCR will be presented in the second part of the series. Tests indicate that the

use of a catalyst in a SCR slipstream reactor can achieve greater than 90% NO reduction efficiency with a

NH3/NO ratio of about 1. There is no evidence to show that the reactor material affects mercury speciation.

Both SCR catalysts used in this study exhibited a catalytic effect on the elemental mercury oxidation but had

no apparent adsorption effect. SCR catalyst 2 seemed more sensitive to the operational temperature. The spike

gas tests indicated that HCl can promote Hg0 oxidation but not Cl2. The effect of Cl2 on mercury oxidation

may be inhibited by higher concentrations of SO2, NO, or H2O in real flue-gas atmospheres within the typical

SCR temperature range (300-350 °C). SO2 seemed to inhibit mercury oxidation; however, SO3 may have

some effect on the promotion of mercury oxidation in runs with or without SCR catalysts.

1. Introduction

Mercury (Hg) compounds released from human activities are

one of the most toxic pollutants to human health and the

ecosystem.1-2 Hg emissions from coal-fired power plants

contribute about 30% to the anthropogenic sources of mercury.

† Neither Western Kentucky University, the Electric Power Research

Institute, nor any person acting on behalf of either (A) makes any warrant

of representation, express or implied, with respect to the accuracy,

completeness, or usefulness of the information contained in this paper or

that the use of any information, apparatus, method, or process disclosed in

this paper may not infringe privately owned rights or (B) assumes any

liabilities with respect to the use of or for damages resulting from the use

of any information apparatus, method, or process disclosed in this paper.

Reference herein to any specific commercial product, process, or service

by trade name, trademark, manufacturer, or otherwise does not necessarily

state or reflect the endorsement of the Electric Power Research Institute.

* To whom correspondence should be addressed. E-mail:

wei-ping.pan@wku.edu.

‡ Western Kentucky University (WKU).

§ Mingchi University of Technology.

| Electric Power Research Institute (EPRI).

Coal contains naturally occurring mercury that varies with both

the coal rank and its origin. The United States Environmental

Protection Agency (U.S. EPA) announced the Clean Air

Mercury Rule (CAMR)3on Hg emission control from coal-fired

power generation on March 15, 2005, which requires the

reduction of Hg emissions from coal-fired utility boilers of

nearly 70% from 1999 levels by 2018. This will affect both

economic and environmental aspects of America, as well as

around the world. The U.S. EPA also announced the Clean Air

(1) Keating, M. H.; Mahaffey, K. R.; Schoeny, R.; Rice, G. E.; Bullock,

O. R.; Ambrose, R. B., Jr.; Swartout, J.; Nichols, J. W. Mercury Study

Report to Congress, EPA-452/R-97-003-010; Office of Air Quality

Planning and Standard and Office of Research Development, U.S. Environmental Protection Agency; Research Triangle Park, NC, 1997; Vol. 1-8.

(2) Brown, T. D.; Smith, D. N.; Hargis, R. A., Jr.; O’Dowd, W. J.

Mercury Measurement and Its Control: What We Know, Have Learned,

and Need To Further Investigate. J. Air Waste Manage. Assoc. 1999, 49,

628-640.

(3) U.S. Environmental Protection Agency. Clean Air Mercury Rules,

March, 2005; http://www.epa.gov/mercuryrule/index.htm. Available December, 2005.

10.1021/ef0602426 CCC: $37.00 © 2007 American Chemical Society

Published on Web 11/17/2006

146 Energy & Fuels, Vol. 21, No. 1, 2007

Interstate Rule (CAIR) that will place caps on the emissions of

sulfur dioxide (SO2) and nitrogen oxides (NOx) from coal-fired

power plants.4 CAIR calls for intensive investigation of mercury

emission control by the combined utilization of flue-gas

desulfurization (FGD) and selective catalytic reduction (SCR),

which were originally equipped for control of SO2 and NOx,

respectively.

Hg compounds from coal combustion sources mainly consist

of particle-bound mercury [Hg(P)], gaseous elemental mercury

(Hg0), and gaseous oxidized mercury (Hg2+). Most of the Hg

in coal evaporates during the combustion process as Hg0 in the

coal-fired utility boiler. In the downstream cooling within the

utility boiler, the oxidation of Hg0 to Hg2+, which is mainly a

result of HgCl2, is thermodynamically favored. Because of an

ash affinity and water solubility, HgCl2 is much easier to be

controlled than Hg0 with conventional air pollution control

devices (APCDs), such as electrostatic precipitators (ESPs) and

fabric filters (FFs) for particle emission control and FGD wet

scrubbers for SOx emission control.1,5-6SCR, the most preferable

and cost-effective technology for nitrogen oxides (NOx) emission

control, is shown to have an enhanced impact on catalytic

oxidation of Hg0 by chlorine species in flue gas.7-10 Thus, the

combination of SCR together with ESP or FF and FGD in a

coal-fired power plant may logically be the most economic

means for simultaneous control of SOx, NOx, and mercury

emissions.

Data on Hg transformation and capture are available in the

U.S. EPA’s Information Collection Request (ICR) Hg emission

database and other sources regarding the potential effects of

SCR.6,11 Tests in several coal-fired utility boilers, with a wet

scrubber and a SCR included, showed a significantly higher

Hg capture than those boilers with a wet scrubber but without

a SCR (about 88% with SCR versus about 45% without SCR).

However, a comparison of tests in pulverized-coal boiler units,

using a spray dryer absorber (SDA) with a FF, showed no

discernible difference in Hg capture with or without the use of

a SCR. Tests also indicated that a coal-fired utility boiler,

(4) http://www.epa.gov/mercuryrule/basic.htm. Available in December,

2005.

(5) Cao, Y.; Duan, Y. F.; Kellie, K; Li, L. C.; Xu, W. B.; Riley, J. T.;

Pan, W. P. Impact of Coal Chlorine on Mercury Speciation and Emission

from a 100-MW Utility Boiler with Cold-Side Electrostatic Precipitators

and Low-NOx Burners. Energy Fuels 2005, 19, 842-854.

(6) Kilgroe, J. D.; Sedman, C. B.; Srivastava, R. K.; Ryan, J. V.; Lee,

C. W.; Thorneloe, S. A. Control of Mercury Emission from Coal-Fired

Electric Utility Boilers. Interim Report, number EPA-600/R-01-109; U.S.

Environmental Protection Agency, Washington, D.C., December, 2001.

(7) Laudal, D. L.; Thompson, J. S.; Wocken, C. A. Selective Catalytic

Reduction Mercury Field Sampling Project, EPA-600/R-04-147; Office of

Research and Development, U.S. Environmental Protection Agency,

Washington, D.C., 2004.

(8) Lee, C. W.; Srivastava, R. K.; Ghorshi, S. B.; Karwowski, J.;

Hastings, T. W.; Hirschi, J. Pilot-Scale Study of the Effects of Selective

Catalytic Reduction Catalyst on Mercury Speciation in Illinois and Powder

River Basin Coal Combustion Flue Gas. J. Air Waste Manage. Assoc. 2004,

54, 1560-1566.

(9) Spitznogle, G.; McDonald, K.; Lin, C.; Vesanen, A.; Toole, A.;

Duellman, D. Oxidation of Mercury across a Slipstream Reactor Equipped

with Various Catalyst Formulations. In Proceedings of the 8th Electric

Utilities Environmental Conference, Tucson, AZ, 2005; paper number A96.

(10) Lee, S. J.; Lee, C. W.; Serre, S. D.; Zhao, Y.; Karwowski, J.;

Hastings, T. W. Study of Mercury Oxidation by SCR Catalyst in an

Entrained-Flow Reactor under Simulated PRB Conditions. In Proceedings

of the V Air Quality Conference, Washington, D.C., September 18-21,

2005.

(11) Chu, P.; Laudal, D; Brickett, L; Lee, C. W. Power Plant Evaluation

of the Effect of SCR Technology on Mercury. Presented at the Department

of Energy-Electric Power Research InstitutesU.S. Environmental Pretection

AgencysAir and Waste Management Association Combined Power Pant

Air Pollutant Control Symposium; The Mega Symposium, Washington,

D.C., May 19-22, 2003; paper number 106.

Cao et al.

equipped with a SCR and a cold-side ESP (CS-ESP), showed

increased Hg capture when bituminous coals were burned but

not when a powder river basin (PRB) coal with a lower chlorine

content was burned. The use of NH3 to assist in NOx reduction

in the SCR seems to have no effect on Hg speciation variation.

Lab- and pilot-scale SCR tests with simulated flue-gas conditions can isolate factors affecting Hg oxidation.12-14 However,

they cannot duplicate all of the conditions present in the flue

gas from the full-scale utility boilers, such as adsorption of Hg

on the SCR catalyst and the relation of the HCl concentration

and Hg oxidation rates in the flue gas. Therefore, efforts have

been made to set up a pilot-scale slipstream SCR facility at a

working utility boiler, which can simulate real flue-gas conditions as well as flexibly control test conditions.15-17 It is found

that coal rank, chlorine content, temperature, and space velocity

were major factors affecting Hg oxidation.

Several questions have arisen regarding the use of SCR to

enhance mercury oxidation. First, what chlorine species in the

flue gas can participate in Hg0 oxidation on a SCR catalyst (such

as HCl or Cl2)? Second, what is the contribution of the Deacon

reaction within a typical SCR catalyst temperature range? Third,

what species in the flue gas can enhance or inhibit mercury

oxidation within typical SCR conditions (flue-gas chemistry such

as SO2, SO3, NOx, NH3, and other active species additions)?

Fourth, what is the effect of catalyst geometry and formulation,

which may affect mass transfer and reaction kinetics of the SCR

catalyst? This paper is the first in a series, which attempts to

answer several questions mentioned above regarding the catalytic nature of SCR catalysts on mercury oxidation. Tests were

conducted to disseminate the complicated factors in a SCR

slipstream reactor with a real flue-gas atmosphere and individual

spiking gas additions. The second in this series will present

the effects of the HBr addition on Hg speciation and adsorption.

2. Experimental Section

2.1. Site Description and Configuration. The SCR slipstream

reactor was installed at a selected coal-fired power station parallel

to the economizer with an inlet flue-gas temperature of about 300350 °C to ensure “real world” flue gas was introduced into the

SCR slipstream reactor. The greatest benefit of the smaller pilot(12) Lee, C. W.; Srivastava, R. K.; Ghorishi, S. B.; Hastings, T. W.;

Stevens, F. M. Study of Speciation of Mercury under Sumulated SCR NOx

Emission Control Conditions. Presented at the Department of EnergyElectric Power Plant Research InstitutesU.S. Environmental Protection

AgencysAir and Waste Management Association Combined Power Plant

Air Pollution Control Symposium; The Mega Symposium, Washington,

D.C., May 19-22, 2003.

(13) Hocquel, M. The Behaviour and Fate of Mercury in Coal-Fired

Power Plants with Downstream Air Pollution Control Devises. Forschr.Ber. VDI Verlag: Dusseldorf, Germany, 2004.

(14) Richard, C; Machalek, T; Miller, S.; Dene, C.; Chang, R. Effect of

NOx Control Processes on Mercury Speciation in Flue Gas. Presented at

the Air Quality III Meeting, Washington, D.C., September 10-13, 2002.

(15) Laudal, D. L.; Pavish, J. H.; Chu, P. Pilot-Scale Evaluation of the

Impact of Selective Catalyst Reduction for NOx on Mercury Speciation.

Presented at the Air and Waste Management Association, 94th Annual

Conference, Orlando, FL, June 24-28, 2001.

(16) Macharlek, T.; Ramavajjala, M.; Richardson, D. C.; Goeckner, B.;

Anderson, H.; Morris, E. Pilot Evaluation Flue Gas Mercury Reaction across

an SCR Unit. Presented at the Department of Energy-Electric Power Plant

Research InstitutesU.S. Environmental Protection AgencysAir and Waste

Management Association Combined Power Plant Air Pollution Control

Symposium; The Mega Symposium, Washington, D.C., May 19-22, 2003.

(17) Spitznogle, G.; Senior, C. Strategies for Maximizing Mercury

Oxidation across SCR Catalysts in Coal-Fired Power Plants. Presented at

the Department of Energy-Electric Power Plant Research InstitutesU.S.

Environmental Protection AgencysAir and Waste Management Association

Combined Power Plant Air Pollution Control Symposium; The Mega

Symposium, Washington, D.C., September 18-21, 2005.

Hg Oxidation by a SCR Catalyst

Energy & Fuels, Vol. 21, No. 1, 2007 147

Figure 1. Schematic of the SCR slipstream reactor.

scale SCR slipstream tests is that it provided the ability to control

variables and isolate specific factors under actual flue-gas conditions. The typical operating parameters for the selected boiler are

as follows: load capacity, 200 MWe; boiler type, B&W, front wall

fired with three rows of burners, with a total of nine burners;

particulate control type, CS-ESP; SO2 control, none; NOx control

type, low-NOx burners; and coal, bituminous coal with medium

sulfur and high chlorine contents.

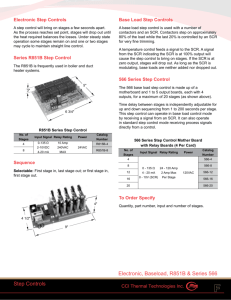

2.2. SCR Slipstream Reactor System. A pilot-scale slipstream

SCR reactor has been designed to simulate the “full-scale”

applications of a SCR system, as shown in Figure 1. The site setup

picture is shown in Figure 2. The SCR reactor was designed and

manufactured in a concentric configuration with an inside pass for

SCR catalyst loading, where the main stream of flue gas passes

through, and an outside pass, where the bypassed flue gas passes

through. The flue gas, which is extracted from the well-insulated

intake pipe before the SCR slipstream reactor, is split into two

streams, whose ratio is controlled by manual flashboard valves to

adjust the slot area of the outside flue-gas pass. The bypassed flue

gas functions as a “strengthened” heat insulation because of its

higher temperature, which minimizes the heat transfer rate by

decreasing the temperature difference between the introduced main

stream of flue gas and the bypassed flue-gas stream. Thus, this

slipstream reactor was well-insulated, so that the temperature drop

across the SCR slipstream reactor was below 20 °C. The area of

the inside pass was 0.152 × 0.152 m, and the outside pass was a

0.01 m slot around the inside square. The total height of the reactor

was 6.6 m. The pilot-scale SCR had a two-layer catalyst to simulate

the variation of the residence time for gas-solid contact. Each

catalyst chamber was 1 m in height. The specific locations of the

sampling ports were in relation to the locations of the catalysts.

There were three sampling ports located at the inlet, middle, and

outlet of each SCR catalyst bed. The “inlet” refers to the location

before the first catalyst layer; the “middle” refers to the location

between the first and second catalyst layers; and the “outlet” is at

the outlet of the second catalyst layer. The Hg samples were taken

at the inlet and outlet of the SCR slipstream reactor using

semicontinuous mercury emission monitors (SCEMs) and all three

locations using the Ontario hydro method (OHM) to gain a better

understanding of Hg conversion mechanisms.

148 Energy & Fuels, Vol. 21, No. 1, 2007

Cao et al.

Figure 2. Actual setup on site of the SCR slipstream reactor system.

To prevent the fly ash from depositing on the SCR catalysts, an

ash blower using compressed air was designed and installed. The

ash-blower control allowed each catalyst layer to have the ash

purged with high-velocity compressed air independently. Along with

the ash blower, their ports have also been adapted to allow for

pressure differential monitoring using a manometer. The overall

ash-blowing cycle time was determined by the length of time it

took for the pressure differential to reach the upper limit. Generally,

the first catalyst layer had a blow cycle of 5 s, blowing at 30 min

intervals, while the second catalyst layer had a blow cycle of 8 s,

blowing at 30 min intervals. With the aid of cross-catalyst

differential pressure monitoring, the ash buildup was monitored,

and when the predetermined upper pressure level was reached, the

ash-blowing sequence was activated to blow the ash, thereby

bringing the pressure differential back to normal levels.

To ensure the control and even distribution of spike-gas injection,

three static mixers were built and installed at different locations in

the SCR slipstream reactor. The first static mixer was located one

duct diameter below the spiking gas injection ports to ensure

homogeneous distribution of spiking gas before reaching the first

catalyst layer. The second and third static mixers were installed at

the bottom of each catalyst layer to ensure homogeneous concentrations of Hg and other gases after the flue gas exited each catalyst

layer.

The precise control of spiking gas addition was achieved through

the construction of a multiport mass-flow controller that had the

capability of being set to inject a predetermined amount of gas from

one to four attached cylinders including SO2, HCl, Cl2, and NH3.

SO3 or HBr addition solution injection equipment with a predetermined concentration of H2SO4 or HBr solutions, respectively.

The solutions vaporized to generate SO3 or HBr spiking gases inside the SCR reactor with the desired spiking concentration. All

injection ports for spiking gases were set up below the first Hg

sampling port, which left the “inlet” sampling port unaffected. The

injection of NH3 was separated from other spiking gas lines to

ensure operational safety. Considering the actual injection ratio of

NH3 in a commercial SCR facility, the ratio of NH3 injection was

set at NH3/NO ) 1-1.1. Because of the low-NOx burner used, the

NOx level was about 250 ppm during tests. To simulate the flue

gas of various types of coal ranks, the maximum addition rates of

HCl, Cl2, SO2, SO3, and HBr spiking gases were 500, 25, 2000,

50, and 15 ppm, respectively. The incremental steps for spiking

gas addition were dependent upon the actual response of mercury

speciation variation, as indicated in Table 1. On the basis of the

chlorine (Cl) and sulfur (S) contents, mass balance, and spiking

gas concentrations, the total flue-gas compositions of SO2, SO3,

HCl, and Cl2 were calculated and are listed in Table 1. All gas

concentrations were corrected to 3% O2 and a dry basis. SO3 and

Cl2 concentrations in the raw flue gas were calculated on the basis

of an assumption of 1% coal sulfur content and 5% coal Cl content.

The catalyst average temperature was 305 °C.

2.3. SCR Catalysts. Commercial monolith (Honeycomb) SCR

catalysts were provided by two vendors. Catalyst 1 had an 8.4 mm

pitch, and the square cross-section had an array of 18 × 18 channels.

Catalyst 2 had an approximately 7.5 mm pitch, and the square crosssection had an array of 20 × 20 channels. Each catalyst section

was 1 m in length; therefore, the total length of the catalyst chamber

was 2 m. The SCR catalysts were designed to be operated at a

space velocity of 1800 h-1, which is the actual space velocity used

on full-scale coal-fired SCR reactors.18

2.4. Coal and Ash Analysis. Bituminous coal was burned during

SCR slipstream tests. The coal sample was collected at the coal

transport line after the coal pulverizer. The ash sample was collected

from the front-row hopper because it captured the majority of fly

ash in the flue gas. The key proximate and elemental analysis of

the coal samples is shown in Table 1. Hg in all solid samples was

analyzed using a LECO AMA-254 [American Society for Testing

and Materials (ASTM) method D 6722]. The variation of Hg, Cl,

and S contents during the tests were 0.10-0.15 and 354-1186 ppm

and 1.30-2.17%, respectively, with averages of 0.11 and 854 ppm

and 1.3% during runs with the SCR catalyst, 1.4% and 946 and

0.13 ppm during runs with SCR catalyst 1, and 1.9% and 549 and

0.14 ppm during runs with SCR catalyst 2. Analytical data for fly

ash taken from the ESP hopper are shown in Table 2. Loss on

ignition (LOI) and Cl and S contents in the ash samples were

determined using ASTM methods D 5142, D 5373, and D 5016,

respectively. It was found that the LOI content of the fly ash was

lower at about 2.6%, which indicated a good combustion performance during testing, even for the boiler equipped with the lowNOx burner. Only a small portion of sulfur and chlorine was

(18) Laudal, D. L.; Thompson, J. S.; Pavlish, J. H.; Brickett, L.; Chu,

P.; Srivastava, R. K.; Lee, C. W.; Kilgore, J. Mercury Speciation at Power

Plants Using SCR and SNCR Control Technologies. EM February 22, 2003.

Hg Oxidation by a SCR Catalyst

Energy & Fuels, Vol. 21, No. 1, 2007 149

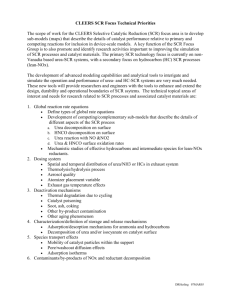

Table 1. SCR Slipstream Test Conditions and Coal Properties

catalyst information

additives

catalyst

type

space

velocity

(h-1)

catalyst

temperature

(°C)

HCl addition

none

1837

317

Cl2 addition

none

1850

SO2 addition

none

HCl addition

total flue-gas concentration

dry, 3% O2

coal analyses

Cl

(ppm)

dry

Hg

(ppm)

dry

S

(%)

dry

NO

(ppm)

HCl

(ppm)

0

1270

0.1

1.56

290

101

301

501

601

302

0

647

0.12

1.3

280

1890

304

0

647

0.12

1.3

280

1

1935

293

0

1186

0.13

1.39

231

HCl addition

1

1870

313

1.02

1186

0.13

1.39

231

Cl2 addition

1

1885

303

0

963

0.13

1.34

274

SO2 addition

1

1875

302

0

685

0.12

1.48

293

SO3 addition

1

1870

313

0

710

0.15

1.42

168

NH3/NOx

ratio

HCl addition

2

1920

293

1.03

571

0.12

1.89

282

HCl addition

2

1880

305

0

842

0.15

1.76

234

HCl addition

2

1865

310

1.07

842

0.15

1.76

243

SO2 addition

Cl2 addition

2

2

1865

1935

310

293

0

0

396

571

0.15

0.12

2.17

1.89

242

2

1850

302

1.02

354

0.16

1.95

215

SO3 addition

2

1883

304

0

423

0.14

1.89

232

SO3 addition

2

1875

310

1.01

396

0.15

2.17

258

SO2

(ppm)

SO3

(ppm)

3

8

13

28

1037

2037

3037

95

295

595

95

595

4

9

14

24

1181

1681

2181

3181

6

56

46

146

246

446

546

67

167

267

467

500

67

167

267

467

567

1731

2481

3231

3731

246

SO2 addition

captured by fly ash in the duct. Over 95% of the sulfur and chlorine

in the coal remained in the gas phase. The major and minor element

data from the X-ray fluorescence analysis (ASTM method D 4326)

of ashes prepared from the coal samples during the test period are

also shown in Table 2. A total of 13 oxides were selected for

determination, including CaO, Fe2O3, TiO2, and MnO, which were

reported to possibly affect Hg transformation. The higher Fe2O3

content at 14.6% and a lower CaO content at about 1.65% in the

Cl2

(ppm)

2

7

12

22

27

1556

2056

2306

3056

3556

8

28

43

58

9

29

59

ash of the tested coal could be attributed to the active function of

the fly ash on Hg speciation.

2.5. Instrumentation. The variation of the Hg concentration was

monitored continuously by SCEMs at two locations (inlet and

outlet) and by OHM at three locations in the SCR slipstream reactor.

OHM measurements (ASTM method 6784-02) for each of the

sampling locations were applied to confirm the SCEM sampling

results at a period of validation of SCR slipstream tests. Only one

150 Energy & Fuels, Vol. 21, No. 1, 2007

Cao et al.

Table 2. Analysis Data on Ash Properties

sample name

tests without

SCR catalysts

tests with

SCR catalysts

ash

ash

sulfur

(%)

chlorine

(ppm)

mercury

(ppm)

LOI

(%)

0.11

100

0.10

2.57

Na2O

(%)

MgO

(%)

Al2O3

(%)

SiO2

(%)

CaO

(%)

K2O

(%)

SO3

(%)

P2O5

(%)

BaO

(%)

SrO

(%)

Fe2O3

(%)

MnO

(%)

TiO2

(%)

1.705

2.348

1.935

0.583

0.152

0.130

17.508

0.023

1.140

0.004

0.895

18.142

38.272

sulfur

(%)

chlorine

(ppm)

mercury

(ppm)

LOI

(%)

0.13

Na2O

(%)

177

MgO

(%)

0.12

Al2O3

(%)

2.73

SiO2

(%)

CaO

(%)

K2O

(%)

SO3

(%)

P2O5

(%)

BaO

(%)

SrO

(%)

Fe2O3

(%)

MnO

(%)

TiO2

(%)

13.811

32.609

1.608

1.902

1.350

0.574

0.120

0.088

11.688

0.030

0.962

0.041

0.807

modification was made to the SCEMs, by which the higher

temperature inertial probe (300-350 °C) was applied to minimize

the gas-phase sampling bias. A detailed description of the two Hg

test methods and QA/QC procedures can be found in the references.5,19

3. Results and Discussion

3.1. Validation of the SCR Slipstream Test. Before any

investigation tests on the variation of Hg speciation in the SCR

slipstream reactor, several issues had to be addressed, including

the reduction performance of NOx addition, effects of the reactor

material on mercury speciation, and the effect of the SCR

catalyst on mercury adsorption.

3.1.1. NOx Reduction by NH3 Addition in the SCR

Slipstream Reactor. The reduction performance of the SCR

slipstream reactor was evaluated by monitoring the NO concentration at the inlet and outlet locations of the SCR slipstream

reactor. Because of the low-NOx burner installed in the test unit,

NO concentrations at the inlet were found to be about 280300 ppm during the SCR slipstream validation tests. The NO

concentration at the outlet location was almost the same as that

at the inlet location with the same O2 concentration. After the

NH3 addition started with a molar ratio of NO/NH3 at about 1,

the NO concentration decreased gradually and finally went down

below 20 ppm, as shown in Figure 3A for catalyst 1 and Figure

3B for catalyst 2. Both catalysts in the SCR slipstream reactor

worked properly as expected with above 95% NO reduction.

3.1.2. Effect of the Empty Bed of the Slipstream Reactor

Material on the Oxidation of Hg0. With the exception of

Teflon and glass, all other materials may affect mercury

speciation. Thus, the construction material of the SCR slipstream

reactor, which was stainless-steel, could have affected the

mercury speciation under typical SCR temperatures. Hence, the

reactor blank tests by OHM were made at three locations: inlet,

middle, and outlet. Results are presented in Figure 4, where

the y axis represents the variation of mercury oxidation by an

incremental percentage relative to the inlet value based on the

equation shown in eq 1.

reactor materials on mercury speciation at this high temperature.

The small increase in mercury oxidation that occurred in the

SCR slipstream reactor could possibly be attributed to oxidation

effects of in-flight fly ash within the typical SCR temperature

range, which is thermodynamically favored.

3.1.3. Effect of the SCR Catalyst on the Total Vapor-Phase

of Mercury [Hg(VT)]. To evaluate the possible adsorption of

mercury on the SCR catalyst, the total vapor-phase mercury

concentration was monitored by the SCEM system and OHM

tests at the inlet and outlet of the SCR slipstream reactor with

SCR catalysts 1 and 2 test runs. Although the total vapor-phase

of mercury varied with coal properties and the boiler load, a

good agreement between the experimental results of the total

Hg(VT) by SCEM and OHM and the predicted Hg(VT) in the

flue gas, which was calculated on the basis of the conversion

of the total Hg in coal into the flue gas, was reached. Test results

additional oxidation of Hg0 )

100{1 - [Hg0/Hg(VT)]mid or out/[Hg0/Hg(VT)in]} (1)

Blank tests indicated that the percentage of variation of the

mercury oxidation was within 5% as the flue gas crossed the

empty SCR slipstream reactor between sampling ports. There

seemed to be no evidence to show significant effects of SCR

(19) Kellie, S.; Cao, Y.; Duan, Y. D.; Li, L. C.; Chu, P.; Mehta, A.;

Carty, R.; Riley, J. T.; Pan, W. P. Factors Affecting Mercury Speciation in

a 100-MW Coal-Fired Boiler with Low-NOx Burners. Energy Fuels 2005,

19, 800-806.

Figure 3. (A) NO reduction performance of the SCR slipstream reactor

for catalyst 1. (B) NO reduction performance of the SCR slipstream

reactor for catalyst 2.

Hg Oxidation by a SCR Catalyst

Energy & Fuels, Vol. 21, No. 1, 2007 151

Figure 4. Variation of the mercury speciation across the empty bed of the SCR slipstream reactor (runs 1, 2, and 3).

are shown in parts A and B of Figure 5 for SCR catalysts 1 and

2, respectively. There is no evidence to relate mercury adsorption

to the SCR catalysts, at least for catalysts tested in this study at

a temperature around 300 °C. However, Lee et al. have

examined data from a small-scale SCR reactor under simulated

flue-gas conditions and have found that there may possibly be

some adsorption of Hg0 on the catalyst for certain measurements.12 We noted that the work of Lee et al. is done under

conditions to simulate the flue gas of PRB coal, which is lower

in chlorine content. Actually, a reasonable assumption may be

that a dynamic situation could be established on the SCR catalyst

surface. First, Hg0 is attracted and trapped because of active

sites on the SCR catalyst surface, then Hg0 reacts with adsorbed

chlorine species or other oxidizing species to form Hg2+, and

finally, Hg2+ will be liberated from the surface of the SCR

catalyst because there has been no report of mercury adsorption

on any material under such a high temperature. Another reason

for no Hg adsorption on the SCR catalyst may be associated

with the deposition of ash, which covers some of the Hg

adsorption sites. The different findings on the adsorption of

elemental mercury on the surface of catalysts between different

sources may be due to the individual experimental conditions

(catalyst, flue-gas compositions, and fly-ash deposit) or measurements.

3.2. Effects of Spiking Gases on Hg Oxidation with or

without the SCR Catalyst. Hg oxidation in the SCR may occur

because of two processes, including homogeneous oxidation,

which occurs in the gas phase, and heterogeneous oxidation,

which occurs at the interface between the solid and gas on a

solid surface. In the SCR slipstream reactor during runs without

the SCR catalyst, the possible oxidation mechanism was

homogeneous oxidation and also heterogeneous oxidation by

the interaction with “in-flight” fly ash, which was different from

solid-gas contact mode in the fixed bed when fly ash deposited

on the sampling probe. After runs with the SCR catalyst, the

additional Hg0 oxidation compared to the runs without the SCR

catalyst should be solely a result of Hg0 oxidation from the

catalytic effect of the SCR catalyst. Gas compositions in the

flue gas, such as HCl, Cl2, SO2, SO3, and NH3, may be the

oxidizing or reducing agents to impact Hg0 oxidation chemistry

in the Hg transformation process. The SCR catalyst may

promote the oxidation of the Hg0 in the flue gas with the

participation of the active agents mentioned above. The addition

of the individual spiking gases into the SCR slipstream reactor

during runs with or without the SCR catalyst could possibly

provide the information on the reaction mechanism of the

heterogeneous catalytic oxidation of Hg0.

For tests of spiking gas additions during both runs with and

without SCR catalysts, results are presented as the variation of

Hg0 oxidation across the SCR reactor versus the total concentrations of individual flue-gas species, as shown in Figures 6-9.

Considering the constant Hg(VT) during runs with SCR

catalysts, the variation of Hg0 oxidation across the SCR reactor

is represented by eq 2,

percent Hg0 oxidation ) 100[Hg0in - Hg0out]/[Hg0in] (2)

which is the incremental percentage variation between the Hg0

concentration at the SCR reactor inlet (Hg0in) and the Hg0

concentration at the SCR reactor outlet (Hg0out).

3.2.1. Effects of HCl and Cl2 on Mercury Oxidation during

Runs with or without SCR Catalysts. HCl and Cl2 are the

two most important species with regard to mercury oxidation

because of the fact that the main oxidized mercury species in

coal-fired flue gas is Hg(Cl)2. The effects of the spike gases

HCl and Cl2 on Hg0 oxidation during runs with or without SCR

catalysts are shown in Figures 6 and 7. With the SCR catalyst,

HCl addition could further promote the oxidation of Hg0 even

with the coal chlorine content at 1270 ppm in the present study.

During tests without the SCR catalyst in the reactor, the

percentage of Hg0 oxidation increased by 3, 6.5, 19.4, and

27.9%, with increasing HCl addition concentrations of 100, 200,

400, and 500 ppm (total chlorine concentration of approximately

200, 400, 500, and 600 ppm in the flue gas), respectively.

During runs with SCR catalyst 1, the percentage of Hg0

oxidation increased greatly to above 60% compared to the same

conditions during runs without the SCR catalyst, which indicates

that SCR catalyst 1 is an active catalyst for Hg0 oxidation.

152 Energy & Fuels, Vol. 21, No. 1, 2007

Cao et al.

Figure 5. (A) Investigation of mercury adsorption on SCR catalyst 1 by SCEM and OHM. (B) Investigation of mercury adsorption on SCR

catalyst 2 by SCEM and OHM.

Uncertainty existed on how to evaluate the effects of temperature

and NH3 addition on Hg0 oxidation because of the simultaneous

variation of these two parameters during tests in this study.

During two tests with SCR catalyst 1, the percentage of Hg0

oxidation remained almost constant with a variation of just

5-10% at different HCl addition levels and there was no

apparent improvement upon mercury oxidation with HCl

additions.

During runs with SCR catalyst 2, the percentage of Hg0

oxidation was shown to increase greatly by gradually increasing

HCl addition by 0, 200, 400, and 500 ppm (total HCl

concentrations of 100, 300, 500, and 600 ppm in the flue gas),

as shown in Figure 6. However, the curves become flat with an

increasing of HCl addition concentrations. When HCl addition

was 400 ppm, the additional oxidation of Hg0 was approximately

25% relative to those runs without the SCR catalyst. Thus, SCR

catalyst 2 was also shown to have a catalytic effect on Hg0

oxidation. From Figure 6, the addition of NH3 did not have

any impact on the Hg0 oxidation process for SCR catalyst 2.

However, results indicated that temperature impacted Hg0

oxidation greatly for SCR catalyst 2 when a comparison was

made between two cases with a temperature difference of 20

°C at a similar NH3 addition ratio (NH3/NO ∼ 1). The higher

curve in Figure 6 (NH3/NO ) 1.03) corresponds to a temperature of 293 °C, while the lower curve in Figure 6 (NH3/NO )

1.07) corresponds to a temperature of 310 °C. The shapes of

these two curves are similar, but the magnitude of the mercury

oxidation was considerably different between the two curves.

The difference between these two curves could be associated

with the temperature differences. Models of mercury oxidation

across SCR catalysts and other sets of slipstream data have

shown higher Hg oxidation at lower temperatures.20

The present study confirms that NOx reduction by NH3 and

Hg0 oxidation by chlorine species simultaneously occur on the

surface of SCR catalyst 1; however, they are competitively

(20) Senior, C. L. Oxidation of Mercury across Selective Catalyst

Reduction Catalysts in Coal-Fired Power Plant. J. Air Waste Manage. Assoc.

2005, 56, 23-31.

Hg Oxidation by a SCR Catalyst

Energy & Fuels, Vol. 21, No. 1, 2007 153

Figure 6. Variation of the mercury oxidation with HCl addition by SCEM for two catalysts.

Figure 7. Variation of the mercury oxidation with Cl2 addition by SCEM for two catalysts.

adsorbed on the active sites on the surface of the SCR catalyst,

while NOx reduction by NH3 is apparently predominant. Both

factors of temperature and NH3 addition impact the Hg0 oxidation by controlling process kinetics. Observed curves of the Hg0

oxidation process become flat for both SCR catalysts in this

study. This may indicate the impact of the NOx reduction reaction by NH3 on Hg oxidation by their competitive nature (HCl

and NH3) on active sites of surfaces of SCR catalysts, which

result in the independence of HCl addition concentrations on

Hg0 oxidation when HCl continuously increases to certain levels.

Observed Hg0 oxidation varied greatly between SCR catalysts

1 and 2. Differences in catalyst pitch and formulation might

have been responsible for the differences in performance

between these two SCR catalysts. Mercury oxidation by HCl

across SCR catalyst 2 appeared to be affected by both temperature and HCl concentrations, while SCR catalyst 1 seemed

virtually unaffected by the variation of both temperature and

HCl concentrations. Recently, models for mercury oxidation

across SCR catalysts have been developed to include the effects

of mass transfer and surface chemistry kinetics simultaneously.10-22 The catalyst formula was the key parameter that impacted surface chemistry kinetics across the temperatures used,

and the catalyst geometry was the key parameter that impacted

mass transfer. Thus, the design of a certain SCR catalyst directly

impacts the performance of the SCR catalyst on Hg0 oxidation

through relative influences of the mass transfer rate and chemical

(21) Niksa, S.; Fujiwara, N. A Predictive Mechanism for Mercury

Oxidation on Selective Catalytic Reduction Catalysts under Coal-Derived

Flue Gas. J. Air Waste Manage. Assoc. 2005, 55, 1866-1875.

(22) Edwards, J. R.; Srivastava, R. K.; Kilgroe, J. D. A Study of GasPhase Mercury Speciation Using Detailed Chemical Kinetics. J. Air Waste

Manage. Assoc. 2001, 5, 69-87.

154 Energy & Fuels, Vol. 21, No. 1, 2007

Cao et al.

Figure 8. Variation of the mercury oxidation with SO2 addition for two catalysts.

reaction kinetics. SCR catalyst 1 could possibly be improved

by enhancing its mass transfer through geometry design, and

SCR catalyst 2 could be improved by modification of its

formulation of active sites.

The variation of the percentage of oxidation of Hg0 by the

addition of Cl2 into the SCR slipstream reactor was much

different when compared to that by the addition of HCl, as

shown in Figure 7. The addition of Cl2, with a maximum

addition concentration of 25 ppm, results in little variation of

the percentage of oxidation of Hg0 in this study, which was

within (5% under testing conditions during runs with or without

the SCR catalyst and thus cannot be regarded to be significant.

In comparison with HCl, which is the main chlorine species in

the flue gas, Cl2 seemed to have little impact on mercury

speciation under current experimental conditions. The difference

in performance between the two SCR catalysts in terms of the

percentage of oxidation of Hg0 under the same Cl2 addition

concentration should be attributed to the difference in catalyst

pitch or formulation, as mentioned previously. Previous work

on mercury oxidation has suggested that chlorine compounds

are intensively involved in mercury oxidation within the typical

SCR temperature range. This study clearly demonstrated that

HCl and not Cl2 is the chlorine compound that affects mercury

oxidation.

3.2.2. Effects of SO2 and SO3 on Mercury Oxidation

during Runs with or without SCR Catalysts. The effects of

SO2 addition on the variation of Hg0 oxidation is shown in

Figure 8. Although the results show a little scatter, it seemed

that the percentage of oxidation of Hg0 followed a decreasing

trend as the SO2 addition concentration increased. The incremental percentage of oxidation of Hg0 under the condition of

2000 ppm SO2 addition relative to the zero addition levels in

the SCR slipstream reactor was found to be approximately 25

and 5% lower for SCR catalysts 1 and 2, respectively.

However, Figure 9 indicates that the percentage of oxidation

of Hg0 followed an increasing trend when SO3 addition increased

to its maximum addition concentration of 50 ppm. The larger

extent of the incremental percentage of oxidation of Hg0 by

SO3 addition during runs with the SCR catalyst, compared to

those runs without the SCR catalyst, may indicate the possible

promoting effect of the SCR catalyst on Hg0 oxidation by SO3

addition. Two exceptions occurred at 20 ppm SO3 addition

during runs without the SCR catalyst and with SCR catalyst 2.

This may be attributed to the measurement errors or the variation

of the boiler performance occurring when tests were conducted.

The incremental percentage of oxidation of Hg0 with the addition

of 50 ppm SO3 in the SCR slipstream reactor for both SCR

catalysts was found to be approximately 20% higher relative to

the zero addition levels. Just as with the previous findings, a

higher percentage of oxidation of Hg0 for SCR catalyst 1

compared with that of SCR catalyst 2 under the same SO2 or

SO3 addition concentration should be attributed to the difference

in catalyst pitch and formula.

3.2.3. Mechanisms Discussion. This study clearly demonstrated that it was HCl and not Cl2 that promoted Hg0 oxidation

within a typical SCR temperature range in the flue-gas

atmospheres. SO3 also had some positive impact on Hg0 oxidation. These oxidation mechanisms involving SCR catalysts

can be promoted to a large extent through HCl and to a lesser

extent through SO3. SO2 may inhibit Hg0 oxidation, even

reducing Hg2+ to Hg0.

However, combining the results of investigations on Hg0

oxidation mechanisms in the present study and previous

studies5,6,22 leads to several questions. First, the Deacon reaction,

which is shown in eq 3,22

2HCl + 1/2O2 ) Cl2 + H2O

(3)

will be favored below 600 °C in the reverse direction to generate

HCl by dissipating Cl2, as shown in eq 4.

Cl2 + H2O ) 2HCl + 1/2O2

(4)

If Cl2 has no effect on Hg0 oxidation, as indicated in this study,

at least the increasing of the HCl concentration by Cl2 addition

should show some impact on Hg0 oxidation. Second, previous

studies attributed the active chlorine compound for Hg0 oxidation to Cl2 because of the possible “Cl” pool maintained by Cl2

through eq 5,

Hg Oxidation by a SCR Catalyst

Energy & Fuels, Vol. 21, No. 1, 2007 155

Figure 9. Variation of the mercury oxidation with SO3 addition for two catalysts.

HgCl + Cl2 ) HgCl2 + Cl

(5)

which is in conflict with the conclusion of this study. Third,

the active species in the SCR catalyst generally contains V2O5,

which can convert SO2 to SO3. Thus, the addition of SO2 into

the SCR reactor should result in increasing the SO3 concentration in the flue gas, which should further enhance Hg0 oxidation

by producing SO3 as indicated in this study. However, this

reasonable assumption is not in agreement with evidence that

the possible Hg0 reduction occurred after the addition of the

higher concentration of SO2 in the present study.

The prevailing mechanisms5,6,22 for Hg0 oxidation validate

the important effects or contributions of chlorine compounds

(HCl, Cl2, and Cl) and possible interferences of sulfur chemistry

in the flue gas. It should be pointed out that the reaction

illustrated by eq 6

Hg + Cl ) HgCl

(6)

is the initial step of the Hg0 oxidation process because of its

fast rate in reaction kinetics, if Cl2 is available in the flue gas.

The slower reactions, represented by eqs 5, 7,

Hg + Cl2 ) HgCl2

(7)

2Hg + 4HCl + O2 ) 2HgCl2 + 2H2O

(8)

and 8,

dominate the overall Hg oxidation kinetics mainly through Cl2.

Cl2 provides the important Hg0 oxidation species of Cl and

maintains the pool of this active agent. Furthermore, Cl2 is a

much stronger oxidizing agent over HCl because of the

difference of their valence electron configurations, which will

result in the difference of affinity for Hg0. However, several

investigators indicated possible depletion of Cl2 within the

temperature range of 200-700 °C by flue-gas compositions such

as SO2, NO, and H2O.6,23-25 The reaction routines for depletion

(23) Agarwal, H.; Stenger, H. G.; Wu, S.; Fan, Z. Effects of H2O, SO2,

and NO on Homogeneous Hg Oxidation by Cl2. Energy Fuels 2006, 20,

1068-1075.

of Cl2 in the coal-fired flue gas are shown in eqs 4, 9,

SO2 + Cl2 ) SO2Cl2

(9)

2NO + Cl2 ) 2NOCl

(10)

and eq 10.

Thus, the reaction routine in eq 8, which is presented as the

global reaction, and possible reaction steps in eqs 11

Hg + HCl ) HCl + H

(11)

HgCl + HCl ) HgCl2 + H

(12)

and 12,

may dominate Hg0 oxidation through HCl within the temperature

range of the typical SCR operation range (300-350 °C), as

confirmed by the present study. SCR also may catalyze Hg0

mainly by this reaction through HCl.

SO2 was regarded as an inhibitor for Hg0 oxidation, as

indicated in the previous studies and this study. With the SCR

catalyst, SO3 was generally produced because of the active site

of V2O5 available for conversion of SO2 to SO3, through eq

13.

SO2 + 1/2O2 ) SO3 (with the SCR catalyst)

(13)

Thus, the inhibition by SO2 and promotion by SO3 on Hg0

oxidation may be balanced somehow when SO2 is added into

the SCR reactor. In summary, this study provides some clues

of different reaction routes for Hg0 oxidation in the real coalfired flue-gas atmosphere within the typical SCR temperature

range. For the present study, the reactions represented in eqs

(24) Laudal, D. L.; Brown, T. D.; Nott, B. R. Fuel Process. Technol.

2000, 65-66, 157-165.

(25) Albert, A. P.; Evan, J. G.; Andrew, K.; Richard, A. H.; William, J.

O.; Henry, W. P. A Kinetic Approach to the Catalytic Oxidation of Mercury

in Flue Gas. Energy Fuels 2006, 20, 1941-1945.

156 Energy & Fuels, Vol. 21, No. 1, 2007

8-10 are believed to be responsible for Hg0 oxidation within

the typical SCR temperature range in real coal-fired flue gas.

4. Conclusion

A SCR slipstream reactor was set up to simulate the scaleddown “real world” circumstance of SCR catalysts for investigation of Hg oxidation at a selected coal-fired utility boiler burning

a bituminous coal. This system has observed above 90% of NO

reduction performance with selected SCR catalysts and NH3

addition. A modified high-temperature inertial probe provided

the measurement accuracy for monitoring mercury speciation

by the SCEM. Both SCR catalysts used in this study showed

catalytic effects on Hg0 oxidation. The different performance

of SCR catalysts on Hg0 oxidation may be attributed to their

different characterization of chemical formulation and manufacture geometry, which are related to the mass transfer rate

and chemical reaction kinetics. SCR catalyst 2 seemed sensitive

to operational temperature with regard to Hg0 oxidation, but

SCR catalyst 1 did not. Hg0 oxidation by SCR catalyst 1 may

be improved by enhancing its mass transfer through geometry

Cao et al.

design, and SCR catalyst 2 may be improved by modification

of its formulation of active sites.

Tests by additions of gaseous acidic spike gases indicated

that it is HCl and not Cl2 that is the major source of chlorine

that dominates the Hg0 oxidation process within the typical SCR

temperature range (300-350 °C) in a real flue-gas atmosphere.

Cl2 may be depleted by flue-gas compositions, such as SO2,

NO, and H2O, and thus cannot impact Hg oxidation in the

present study with real flue-gas atmospheres. This study also

demonstrated that SO2 has an inhibiting effect on Hg0 oxidation;

however, SO3 can promote mercury oxidation. The developed

mechanisms for Hg0 oxidation within the typical SCR temperature range are in agreement with pre-existing Hg0 oxidation

mechanisms.

Acknowledgment. This paper was prepared by the Western

Kentucky University Research Group with support, in part, by

grants made possible by the Electric Power Research Institute (EPRI

project number EP-P13792/C6821).

EF0602426