3M VHB Tapes Permanently Adhere Different Substrates, Offering a Proven

advertisement

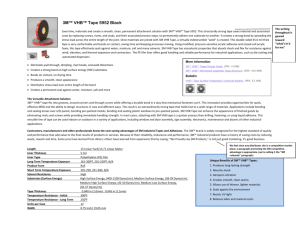

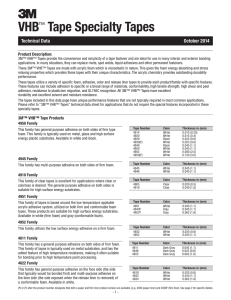

3M™ VHB™ Tapes Permanently Adhere Different Substrates, Offering a Proven Alternative to Mechanical Fasteners 3M™ VHB™ Tapes permanently adhere to metal, plastic and glass surfaces commonly found in a variety of vehicle applications. It is fast, easy-to-use and reliable to replace screws, rivets, welds and other mechanical fasteners. Why 3M™ VHB™ Tapes? Vehicle engineers are tasked with assembling complex designs using weight-saving materials, such as aluminum, composites, and thermoset polymers, as well as traditional materials like steel and rubber. 3M™ VHB™ Tapes are ideal for creating a virtually indestructible bond between dissimilar materials, including those subject to static and dynamic loads, shocks, and impacts. These tapes also feature a closed cell construction that offers excellent waterproofing capabilities, accommodates material expansion and contraction, and prevents galvanic corrosion. Smooth Appearance and Design Flexibility Mechanical fasteners join materials at singular points, deforming the smoothness of the surface and marring it with rivets and screws. 3M™ VHB™ Tapes spread the stress load across the entire length of the joint, creating a smooth appearance while conforming to irregularities of rigid substrates and maintaining high internal strength. The tapes can be precision die-cut to fit any shape, size, or profile, maximizing design flexibility while minimizing assembly time. Materials Partner Spotlight Fabrico uses 3M™ VHB™ Tapes for vehicle and transportation manufacturing applications. These tapes have a remarkably high holding power that offers proven strength, reliability, durability, and quality that out-performs many other fastening and assembly methods. With several decades of use, 3M™ VHB™ Tapes continually prove to be the far superior choice for one or more steps in the assembly, mounting, fastening, and sealing process. 3M™ VHB™ Tape 3M™ VHB™ Tapes offer unlimited design and application possibilities for manufacturers who want to streamline their assembly and enhance the look of their specialty vehicles by eliminating rivets, bolts, screws, and welds. Selecting the Right Converter Quality Control Fabrico offers their design engineering expertise to help customers determine the specific requirements, select the best materials and adhesives, and choose the Very High Bond Tape that works best for their application. With a fully equipped test lab, Fabrico ensures that customer materials meet designed-in specs before they leave the factory floor, often eliminating the need to test materials on the customer end. Fabrico uses its laboratory to test adhesion, tensile, and dielectric strengths, as well as coat weight, resistance, capacitance, and voltage measurements. Fabrico’s test and measurement equipment is calibrated annually per the ISO standard. With the proper combination of those factors, VHB Tapes offer unlimited design and application possibilities and dramatically increase joint strength as compared to metal fasteners. With Fabrico’s extensive experience and converting capabilities, VHB Tapes can be slit, die-cut, rewound, or stacked. Additionally, Fabrico can laminate narrow and wide width materials with carefully selected liner materials to provide optimum release characteristics required for the VHB Tape adhesive backing. Factors to be considered for protective tape applications: • Instant bonding and cure time • Shock and impact absorption • Stress distribution • Expansion and contraction • Waterproofing • Conformability • Adherence of dissimilar materials • Visual appearance • Design flexibility and assembly efficiency With more than 30 years of materials experience, Fabrico engineers understand the impact a material selection can have on the overall manufacturing process, therefore, material systems are designed to optimize production efficiency and improve overall cost-effectiveness. Headquarters 4175 Royal Drive, Suite 800 • Kennesaw, GA 30144 Phone: 844-FABRICO • Fax: 678-202-2702 Toll Free: 800-351-8273 • E-mail: info@fabrico.com About Fabrico Fabrico is the market leader in design and manufacturing services for flexible materials. Fabrico has developed a track record of solving unique challenges and providing sound customer solutions. The company offers a wide range of custom fabrication services including product engineering, material sourcing, prototyping, converting, laminating, complex printing, custom die-cutting, rotary die-cutting, water jet cutting, laser cutting, assembly, and performance packaging. Fabrico’s Advanced Assembly capabilities apply design-formanufacturing principles to complex, high-value projects in demanding markets that include electrical/electronics, medical, military/aerospace, power generation, renewable energy, and transportation. Fabrico is located in Kennesaw, GA, USA and is a division of EIS. More information is available at www.fabrico.com or by calling (800)-351-8273. Fabrico is a trademark of EIS, Inc. www.fabrico.com Fabrico is a trademark of EIS, Inc. 3M and VHB are trademarks of 3M Company