8/1/2011 Contents Routine Ultrasound Equipment Tests for Quality Assurance

8/1/2011

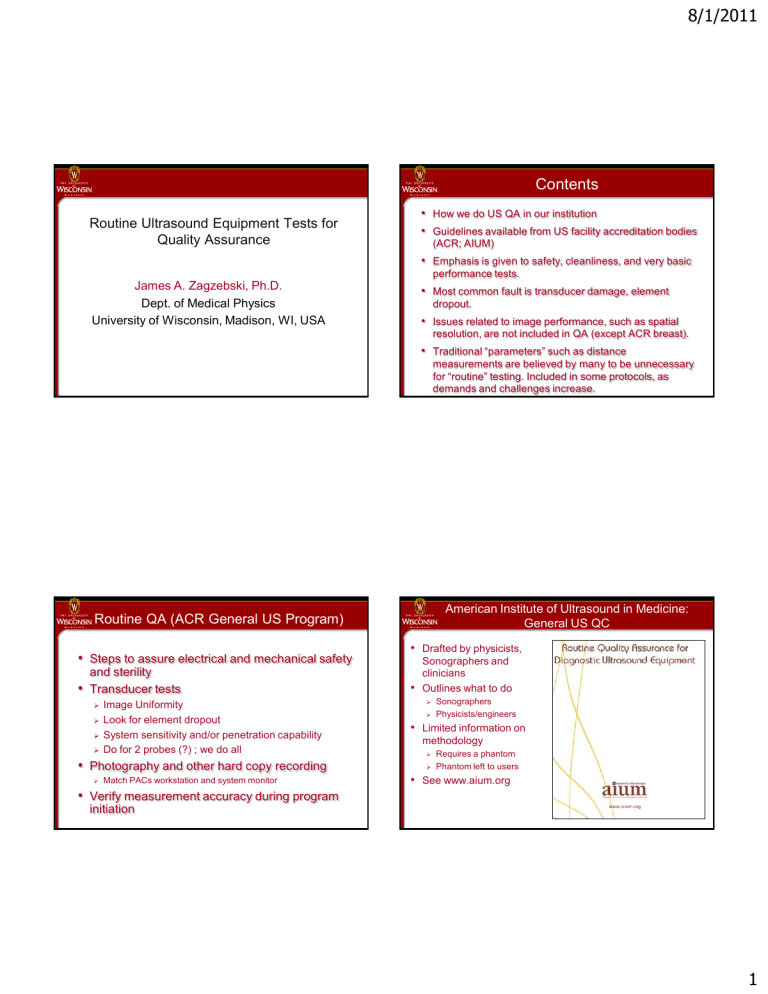

Routine Ultrasound Equipment Tests for

Quality Assurance

James A. Zagzebski, Ph.D.

Dept. of Medical Physics

University of Wisconsin, Madison, WI, USA

Contents

•

How we do US QA in our institution

•

Guidelines available from US facility accreditation bodies

(ACR; AIUM)

•

Emphasis is given to safety, cleanliness, and very basic performance tests.

•

Most common fault is transducer damage, element dropout.

•

Issues related to image performance, such as spatial resolution, are not included in QA (except ACR breast).

• Traditional “parameters” such as distance measurements are believed by many to be unnecessary for “routine” testing. Included in some protocols, as demands and challenges increase.

Routine QA (ACR General US Program)

•

Steps to assure electrical and mechanical safety and sterility

•

Transducer tests

Image Uniformity

Look for element dropout

System sensitivity and/or penetration capability

Do for 2 probes (?) ; we do all

•

Photography and other hard copy recording

Match PACs workstation and system monitor

•

Verify measurement accuracy during program initiation

American Institute of Ultrasound in Medicine:

General US QC

•

Drafted by physicists,

Sonographers and clinicians

•

Outlines what to do

Sonographers

Physicists/engineers

•

Limited information on methodology

Requires a phantom

Phantom left to users

•

See www.aium.org

1

American Institute of Ultrasound in Medicine: General

Sonography (physicist, engineer)

•

Cables OK, air filters clean, mechanical and electrical inspection

•

Transducer Uniformity

Phantom

Electronic probe tester

•

Sensitivity, Maximum depth of visualization into a phantom

•

Distance measurement accuracy

•

Target detection and imaging

Focal targets such as simulated cysts or low contrast objects

Choice of phantoms left to users

•

Image display fidelity

•

Minimum frequency: annual for physicists/engineer tests

Routine QA: Cleanliness, safety

Transducer Inspection

Delaminations

Frayed cables

Proper cleaning

Console

Air filters

Viewing monitor, keyboard clean

Lights, indicators

Wheels, wheel locks

Proper cleaning

8/1/2011

Currently used materials:

Water-based gels

Advantages:

Speed of sound = 1540 m/s

Attenuation proportional to frequency

Backscatter

Disadvantages:

Subject to desiccation (?)

Must be kept in containers

Requires scanning window

Currently used TM materials:

•

Solid, non-water-based materials (urethane)

•

Advantages:

Not subject to desiccation

No need for scanning window; possibility for soft, deformable scanning window

Produce tissue-like backscatter

Disadvantages:

C= 1430-1450 m/s

Attenuation not proportional to frequency (~f 1.6

)

Surface easily damaged if not cleaned regularly to remove gels

2

Maximum Depth of Visualization

•

Considered by many as a good overall check of the integrity of the system

•

FOV at 18 cm (or set to match the phantom)

•

Output power (MI) at max

•

Transmit focus at deepest settings

•

Gains, TGC for visualization to the maximum distance possible

Maximum Depth of Visualization

How far can you see the speckle pattern in the material?

8/1/2011

Objective Maximum Depth of Visualization

• Gibson, Dudley, Griffith, “A computerized Quality Control System for

Bmode Ultrasound,” Ultrasound Med Biol 27 :1697-1711, 2001.

•

Shi, Al-Sadah, Mackie, Zagzebski, Signal to Noise Ratio Estimates on Ultrasound Depth of Penetration (abstract only), Medical Physics

30 : 11367, 2003.

•

Gorny, Tradup, Bernatz, Stekel, and Hangiandreou , “Evaluation of an Automated Depth of Penetration Measurement ofr the Purpose of

23: S76, 2004.

•

Compute mean pixel value vs depth for phantom (signal) and for noise only (noise)

•

Depth where signal/noise = 1.5 =DOP

Routine QA: Image Uniformity

Considered to be the most important and useful test!

Ideally:

No evidence of element dropout

No vertical

„shadows‟

3

Uniformity

Turn off spatial compounding, speckle reduction

Use 1 tx focus

Search for

“shadows” emanating from transducer

Common in new and old probes!

Checking uniformity for curvilinear transducers

•

Solution 1: rock transducer from side to side

•

Solution 2: Use a liquid TM material

•

Solution 3: Use newer phantoms with special curved windows

8/1/2011

Difficulties with Uniformity (coupling)

•

Solution 1: rock transducer from side to side

Need Proper Technique to Detect Element Dropout

Transducer with severe element dropout scanned using compound imaging

4

Need Proper Technique to Detect Element Dropout

Transducer with severe element dropout

Disable spatial compounding

Use single, shallow transmit focus

Difficulties with Uniformity

•

Visualizing 1-2 element dropouts

•

Use persistence; translate transducer.

8/1/2011

Difficulties with Uniformity

•

Visualizing 1-2 element dropouts

•

Record Image loops while translating the transducer;

•

Compress a 100 frame loop into 1 image (averages speckle) - Project of the AAPM

1 image

Ultrasonix SonixTouch

Enables masking off individual elements

Elements 95 and 96 masked

Difficulties with Uniformity

•

Visualizing 1-2 element dropouts

•

Record Image loops while translating the transducer;

•

Compress a 100 frame loop into 1 image (averages speckle)

•

Computer analysis

Average image

Ultrasonix SonixTouch

Enables masking off individual elements

Elements 95 and 96 masked

5

Gray Scale Photography, Workstation Fidelity

•

Important for monitor on machine to be set up properly to view all echo levels available and entire gray bar pattern.

Set up during acceptance testing

Take steps to avoid the “meat hook” effect (mark or inscribe contrast and brightness controls)

•

Workstation monitors and/or hardcopy devices should be matched to the machine monitor.

AAPM,August, 2011

Check hardcopy, workstation displays.

Are all gray bar transitions visible?

8/1/2011

SMPTE or Other Gray Scale Test Pattern

•

Available on some scanners

•

0% to 100% gray bar pattern

•

Squares for detecting geometric distortion

•

Are all gray transitions visible?

Result of a recent test of system monitor

•

After seeing the test result, the sonographer mentioned that images being sent for accreditation tended to be washed out, cysts seemed to be filled in.

•

Sonographers were

“over-gaining” the machine to compensate for the poor monitor performance.

Pacs

Workstation

Logiq 9

Monitor

(simulation)

6

Distance Measurement Accuracy: Vertical

Actual 2.5

Measure 2.46

error 1.5%

Acceptable

Distance Measurement Accuracy: Horizontal

Actual 1.0

Measure 1.01

error <1%

Acceptable

8/1/2011

Routine QA (ACR General US Program)

•

Distance Measurement

Accuracy tests

Necessary?

(“Scanner is a transducer tied to a computer.”)

May be important for specific uses

• Images reregistered from 3-D data sets

• Workstation measurements

• Radiation seed implants

Acquisition Plane

(Normal 2-D view)

Reconstructed Elevational Plane

4-year Experience with a clinical ultrasound quality control program Hangiandreou et al, Mayo Clinic, Rochester, Minnesota,

•

About 50 scanners (47-55 over the 4 year period; most Siemens and a few Philips)

•

About 300 transducers (267-322 over the 4 year period)

•

Quarterly assessments of:

Depth of penetration

Distance measurement accuracy

Transducer uniformity (element dropout)

Mechanical integrity

7

8/1/2011

4-year Experience with a clinical ultrasound quality control program,

(Ultrasound Med Biol 37, 1350-1357, 2011)

Hangiandreou et al, Mayo Clinic, Rochester, MN

Minnesota, USA

Evaluation

Method

# of detected

“failures”

% of detected

“failures”

47 25.1

Mechanical

Integrity

Image uniformity

Distance

Accuracy

DOP

(penetration)

124

0

3

66.3

0.0

1.6

Clinical

Problems

TOTAL

13

187

7.0

100.

4-year Experience with a clinical ultrasound quality control program,

(Ultrasound Med Biol 37, 1350-1357, 2011)

Hangiandreou et al, Mayo Clinic, Rochester, MN , USA

Evaluation

Method

Mechanical

Integrity

Image uniformity

Distance

Accuracy

DOP

(penetration)

Clinical

Problems

TOTAL

# of detected

“failures”

47

124

0

3

13

187

% of detected

“failures”

25.1

Recommendation

Quarterly

66.3

0.0

1.6

7.0

100.

Quarterly

Annually

Annually, (if done with software)

Sonographer‟s daily inspections

Image of a phantom is useful for qualitative comparisons!

(DOP or Distance Measureent)

Image of a phantom is useful!

Conventional Spatial Compounding

Images obtained during routine Breast QC testing, 3/2010

Conventional Spatial Compounding

Images obtained 1 month later, after a software change;

8

Potentially Useful Aids

Use Stored Presets

Sonographers can set up

FOV

Focus

Gain

Compound off, etc

Generate a backup

updates often wipe out old presets

Summary

•

Setting up, maintaining an equipment QA program is straight forward

•

The ACR listed procedures are a useful, basic QA program

Directed by physicist or lab personnel

Integrated effort including lab and technical staff

Requires a Phantom

Closely correlates with AIUM list of factors needing to be tested

• Transducer uniformity is a frequent fault in today‟s scanning machines. I recommend testing ALL transducers.

•

Computational methods can be developed for objective tests

8/1/2011

References

• Goodsitt et al, “Real-time B-mode ultrasound quality control test procedures”, Medical Physics 1998; 25:1385-1406.

• J Zagzebski, “US quality assurance with phantoms.” In Categorical

Course in Diagnostic Radiology Physics: CT and US Cross-Sectional

Imaging, Edited by L. Goldman and B. Fowlkes, 2000, Oak Brook, IL:

Radiological Society of North America, pp. 159-170.

• J Zagzebski and J Kofler, “Ultrasound Equipment Quality Assurance,” in Quality Management in the Imaging Sciences, ed. By J Papp, 2002,

St. Louis, Mosby, pp. 207-215.

•

QA Manual for Gray Scale Ultrasound Scanners, 1995, American

Institute of Ultrasound in Medicine, Laurel, MA.

• D Groth et al, “Cathode ray tube quality control and acceptance program: initial results for clinical PACS displays, Radiographics

2001, 21: 719.

•

Hangiandreou, Stekel, Tradup, Gorny, and King, Four-Year experience with a clinical ultrasound quality control program, UMB

2011, 37: 1350-57.

9