The Problem of Substandard Medicines in Developing Countries

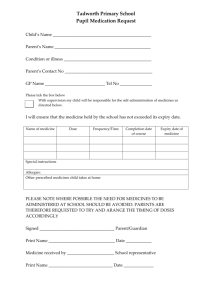

advertisement