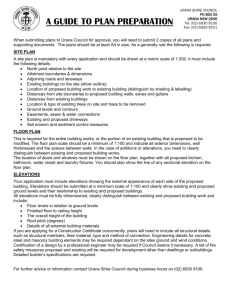

Requirements Strategy Stream IAQG General Assembly Napoli, Italia 11 April 2008

advertisement

Requirements Strategy Stream IAQG General Assembly Napoli, Italia 11 April 2008 Guy Dion - Requirements Strategy Stream Leader IAQG General Assembly Page 1 Team Membership Team leadership: – Team Leader Guy Dion – AAQG Leader Alan Daniels – APAQG Leader Masahiro Kawamoto – EAQG Leader Guy Dion – Facilitator Wayne Johnson Operating Management System Representative : John Addey Initiative Leaders: 9100 REQ-006 9110 REQ-007 9120 REQ-008 9115 REQ-009 9101 – REQ-001 – – – – GA - Naples – 11 April 2008 Guy Dion Jeff Wood Dale Gordon Michelle Pierce Hans Luijt Guy Dion - Requirements Strategy Stream Leader Page 2 Requirements Strategy Stream Mission & Future State Establish, Develop, and Maintain Industry Quality Requirements to improve product and process integrity Maintain Focus on Quality Management System (QMS) Standards – Improve the supplier performances and customer satisfaction, especially Product Quality & On-time Deliveries – Take into account the new requirements from aviation, space & defense – Stay abreast with emerging requirements (environmental requirements such as REACH) – Sustain and improve the audit process – Support QMS revision year 2008 Harmonization of Customer Requirements for suppliers Work with Relationship Growth Teams – Civil Authorities, Space, Defense & National Trade Associations, MRO (Maintenance, Repair and Overhaul Organizations) and Airlines GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 3 “ 9100 ” General QMS Standard Initiative Leader: Guy Dion IAQG General Assembly Page 4 9100 Standard - 2008 Revision Initiative Summary: Revise 9100 to incorporate ISO 9001-2008 changes Expand scope to include the Defense sector Analyze needs of stakeholders and add/revise requirements Comply with IAQG strategy IAQG General Assembly Page 5 9100: Revision Process IAQG Stakeholder Focals & 9100 Team Liaisons Stakeholder Certification/Registration Bodies Civil Aviation Authorities Defense / NATO Space OASIS Suppliers IAQG & Sector Companies IAQG Strategy Streams: – People Capability – Product and Supply Chain IAQG Focal 9100 Team Liaison Rick DOWNS Hans LUIJT Edward BAYNE Jack FLETCHER Roberto CIASCHI Hans LUIJT * Alan DANIELS Francisco LOSADA Roberto CIASCHI Hans LUIJT * Herbert MAIROSE Susan ARMSTRONG/ Larry WENG (co(co-chairs) Henry JOHANNSON Buddy CRESSIONNIE/ JeanJean-Louis DOULIERY * 9100 Team Sector Leaders Page 1 Data mining ) Stakeholders inputs Web survey MCRT Consolidation ) (Master Review Comments Template) Review process ) Accept / Reject / Proposals / Comments Nov. 2005 (Paris) 40 % accepted 9100 Design Specification Key considerations 9100 Objectives for the 9100 QMS Standard (IAQG Strategy) The 9100 standard shall : – constitute quality management system requirements that are not contractual in nature or contain product specific requirements, and that 1. Improve the suppliers performance and customer satisfaction, – enhance clarity of requirements or address stakeholder needs, needs, and that 2. Be the foundation of the requirements applicable to the whole especially : Quality of the products & On-time deliveries aerospace and defense industry – are auditable and define “what” what” not “how,” how,” and that 3. Be recognized by the authorities – are compatible for use by all stakeholder segments and by organizations of all types and sizes, and when 4. Be applicable to 10 000 suppliers in 35 countries, applied and adapted – the benefit of the proposed change/addition outweighs the impact of implementation to : primes, systems manufacturers, equipment manufacturers, sub-contractors, components manufacturers (mecanics, electronics, …) … Page 1 internal WG draft 7 August 2007 5. Allow a common interpretation of the 9100 standard by auditors, Orlando audited companies, at all levels 6. Take into account the new requirements from the aerospace and defense industry Page 1 GA - Naples – 11 April 2008 339 items MCRT Design Specification & IAQG Strategy > 9100 objectives Stakeholder requests for changes to ISO 9001 are out of scope Changes/additions to be considered are those that: Started in April 2005 (Amsterdam) Guy Dion - Requirements Strategy Stream Leader Oct. 2006 (Sevilla) Apr. 2007 (Melbourne) AAQG : Sept. 18 & 19 (Los Angeles) EAQG : Oct 2 & 3 (Paris) 7-8, 12 Oct 2007 (Orlando) Page 6 9100: Revision Process Issue of a “9100 coordination draft” 9 Nov. 2007 on the basis of: − Changes proposals reviewed − Design specification − IAQG Strategy − 9100 objectives Request for stakeholders comments due by 30 January 2008 GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 7 9100: Revision Process Review of the comments on the “9100 coordination draft” in each sector ) (under the coordination of each 9100 sector leader) Consolidation ) AAQG APAQG EAQG separate review meetings (due date 21/02/2008) IAQG sectors, CAAs, CBs, Defense & Space comments New MCRT (Master Comments Review Template) Accept / Reject / Review and Rewrite disposition process ) 9100 Planning for deployment Formal support material & Ballot preparation of the Formal Sector Ballot May 2008 182 items Full Team 4, 5, 7 April 2008 (Naples) Issue planned : May 2008 Limit date for comments : August 2008 9100 Publication: November 2008 GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 8 9100 – Main proposed changes Product quality and on-time delivery performance ¾ Added requirement for “product conformity” and “on-time delivery” to be measured, and appropriate actions taken if planned results are not achieved ) benefits: Linkage between the QMS and organization performance, In line with the IAQG strategy Formal monitoring of customer satisfaction data ¾ Added the requirement to monitor data and to develop improvement plans that address deficiencies ) benefits: To promote continuous improvement of the product and customer satisfaction, Address the ICOP requests GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader ion9 AdditPage s 9100 – Main proposed changes Added to 7.1 – Planning of Product Realization 7.1.1 Project Management ¾ New requirement for planning and managing product realization in a structured and controlled way 7.1.2 Risk Management ¾ New requirement of implementation of a risk management process applicable to the projects & products : responsibility, criteria, mitigation & acceptance 7.1.3 Configuration Management ¾ Moved from clause 4.3 to clause 7.1 + more details on the different activities to be covered 7.1.4 Control of Work Transfer ¾ Moved from clause 7.5 (Production) to clause 7.1 + must have a process to plan and control the transfer activities ) benefits: Pro-active approach for management of these activities tio10ns GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader AddiPage 9100 – Main proposed changes Expanded “key characteristics” to “special requirements” and “critical items”: ) “Special requirements” (previously in the CD draft : “essential requirements”) ¾ which have high risks to being achieved, hence ¾ requiring their inclusion in the risk management process. ) “Critical items” including “key characteristics” (previously in the CD draft :“essential items”) ¾ which have significant effect on the product realization and use of the product, hence ¾ requiring specific actions to assure they are adequately managed. ) benefits: To provide focus on important items GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader tio11ns AddiPage 9100 – Main proposed changes General QMS requirements ¾ Organization’s Quality Management System shall address customers and applicable statutory and regulatory QMS requirements ation c i f i r a l C (instead only QMS documentation) Use of recognized certifications ¾ For suppliers selection and evaluation ¾ As one component of an organization’s supplier control process Addition GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 12 9100 – Main proposed changes Update the requirement for controlling suppliers ¾ Approval status and scope (i.e., approved, conditional, disapproved), ¾ Authority for decision, change and controlled use of suppliers ¾ Requirements to be flowed down the supply chain ation c i f i r a l C 7.5.1.1 Production process verification “FAI” ¾ Formal requirement to validate the production processes, documentation and tooling + repeat the process when necessary (engineering or manufacturing processes changes). ¾ Moved from 8.2.4.2 (measurement) to 7.5.1.1 (production) ation c i f i r a l C GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 13 9100: Deployment Support Material Press Release on the 9100 main changes (on release of 9100) FAQs (Frequent Asked Questions) (on release of 9100) – Implement a visible 9100 FAQs link from IAQG website – Develop FAQs and responses (to be reviewed in Yokohama – Oct. 2008) Overall 9100 training material planned to be developed – that can be used by companies highlighting changes (on release of 9100, draft planned July 2008) Coordination actions planned on the other IAQG standards / documents impacted by 9100 changes – with initiative leaders of IAQG published / in-work standards (e.g. 9101, 9102, 9103, SCMH,…) GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 14 “ 9110 ” Maintenance QMS Standard Initiative Leader: Jeff Wood IAQG General Assembly Page 15 9110 Standard – 2009 Revision Initiative Summary: Revise and align with the next revision of IAQG 9100 Review scope and identify stakeholder needs IAQG General Assembly Page 16 9110: Progress Status 9110 draft: – Draft in development; will be updated to reflect ISO 9001/9100 proposed revisions/updates – 9110 coordination draft planned for IAQG coordination (June 2008) • 60 days for IAQG comment/feedback • Team disposition comments • Incorporate content into 9110 ballot draft after 9100 publication GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 17 9110: Related Concerns/Issues Concerns/Issues: – Industry impacted by redundant audit activity (e.g., Airlines, CASE, Customers, Authorities) – Limited industry recognition of 9110 certification; to date only 153 organizations are certified – Repair stations are mainly organized to address the regulations, they may not have a mature quality management system • few performance indicators, • no improvement process, … GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 18 9110: Strategy Actions : – Promotion by the IAQG members of the 9110 certification in the ICOP scheme (for their repair stations and the repair station of their suppliers) – To add a dedicated team in the “Relationship Growth Strategy” to address the maintenance issues of redundant audit activities (Team will incorporate Airlines, MRO, OEM and Authorities participation) GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 19 “ 9120 ” Distributor QMS Standard Initiative Leader: Dale Gordon IAQG General Assembly Page 20 9120 Standard - 2009 Revision Initiative Summary: Revise 9120 to incorporate ISO 9001:2008 changes Revise 9120 to incorporate 9100:2008 changes Analyze needs of 9120 stakeholders and add/revise requirements IAQG General Assembly Page 21 9120: Progress Status Writing Sub-Team meeting 28 February 2008 - Florida – Second 9120 draft prepared Naples 9120 meeting: – Full Team review of second 9120 draft – Coordination draft comments reviewed and reconciled – Reviewed new ISO 9001 schedule (TC176 changed their estimated release date from 2Q 2009 to 4Q 2008) – Kept 9120 schedule to release in January 2009 GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 22 “ 9115 ” Software QMS Standard Initiative Leader: Michelle Pierce IAQG General Assembly Page 23 9115 Standard – Software QMS Initiative Summary: – To establish software quality management requirements for the Aviation, Space and Defense industry for deliverable embedded or loadable software products – To harmonize the content of AS9006 with the content of ISO 12207:2007 and other applicable standards, retaining the 9100 framework IAQG General Assembly Page 24 9115: Progress Status Orlando Review Draft from Orlando For: consistency flow duplications text placement Review Relevant Standards For missing requirements AP APAQG QG October 2007: Complete 12207 Integration EAQG EA AAQG AQ G AAQG March 2008: Integration of Sector Comments Naples Cleanup June 2008: Initial Draft released for Comments Planned Publication : Oct. 2009 IAQG General Assembly Page 25 9115: Utilization ¾ 9115 is used as a supplement to 9100 and explains the 9100 requirements, where necessary, for software requirements. ¾ When utilized, 9115 must be used in conjunction with 9100 (9100 text not reproduced in 9115) ¾ If contractually flowed down, then organization will monitor compliance to the standard (no certification, 2nd party audit) GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 26 “ 9101 ” Audit Process Standard (9111, 9121) Initiative Leader: Hans Luijt IAQG General Assembly Page 27 9101: Audit Process Standard Initiative Summary: Amend 9101 Assessment standard in order to enhance its clarity and compatibility with process based management QMS ISO 9001, and IAQG 9100 Standard update to be published end of 2008. IAQG General Assembly Page 28 9101: Progress Status New ISO 17021-2 Assessment Standard published as draft: contains new detailed material that was in the original 9101 update scope First draft 9101 distributed for internal WG discussion: 17 December 2007 Permission obtained to use ISO Audit Practices Group (APG) material Strong relation with new 9104-1 (activities just launched) GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 29 9101: Main changes ¾ No scoring ¾ For the first certification an initial on site audit is requested in 2 stages : 9 Check ‘on site’ of the QMS documentation and determination of the scope, request of customers feedback/complaints, focus on availability of performance information and continual improvement, 9 Full on site audit. ¾ For all the audits the CBs must review and take into account the customers feedback (through OASIS) and customer satisfaction ¾ New checklist contains specific aerospace situations (documents, records, procedures, etc) to look for during on-site audits ¾ Improved link with Product quality, On Time Delivery and processes: 9 Using actual product example during system audit 9 Use product quality and OTD performance measurement to focus audit on under performing processes ¾ More focus on determining effectiveness in addition to determining compliance GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 30 9101: Main change benefits 9 Scoring is not used at all and elimination will save a lot of time 9 Focus will more on performance improvement instead of compliance monitoring 9 More emphasis on aerospace specific issues, and less on completing a questionnaire 9 Better link with product quality and OTD performance Note: the text of the present (and future) 9100 has the potential to focus more on performance and effectiveness, the present 9101 only focuses on general compliance GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 31 9100 / 9101 Implementation – Transition phase Publications – 9100 : Nov. 2008 – 9101 : Dec. 2008 CBs – Have 6 months for preparing the training material (until 01/07/2009) – Transition period : 24 months from the 01/07/2009 ¾ 12 months for the auditors training ¾ 12 months to perform the certification (possible during a surveillance audit) Organizations already certified – Ready Ö can start on 01/07/2009 – Can move from the old to the new 9100 during a surveillance audit, ) current 9100 valid until 01/07/2011 Organizations not yet certified (new contracts) – New 9100 / 9101 mandatory on 01/07/2010 GA - Naples – 11 April 2008 Guy Dion - Requirements Strategy Stream Leader Page 32 QMS Requirements Supply Chain Management Handbook Sales,Master Contract Design Scheduling Requirt. & and & Flow down Developt. Sequencing People Capability Strategy Stream 9102 FAI GA - Naples – 11 April 2008 Supplier Order Capacity sourcing planning & Managt & selection scheduling logistic & approval 9103 Key Charact. . 9107 DDA Operational Non conf, Manufact. managt and corrective Customer and product preventive Support inspection validation actions 9114 Direct ship. 9131 Non conf. 91XX …….. Best practices SUPPY CHAIN Strategy Stream 9101 Audit Process (IAQG 103) REQUIREMENTS Strategy Stream 9120 (Distributors) 9110 (Maintenance) 9100 (General) Maintenance of standards issued by IAQG Oversight of Certification Scheme 9104-2 (surveillance) 9104-3 (auditors) 9104-1 (organization) ICOP : Certification Scheme Other Party Managt System Document Relationships People Capability documents : dictionary… Guy Dion - Requirements Strategy Stream Leader Page 33