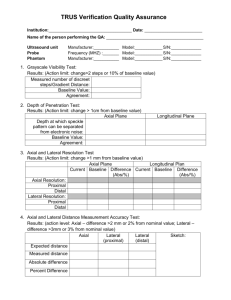

B Real-time -mode ultrasound quality control test procedures

advertisement