Guaranteed Energy Savings Program (GESP) via Energy Savings Company (ESCO)

advertisement

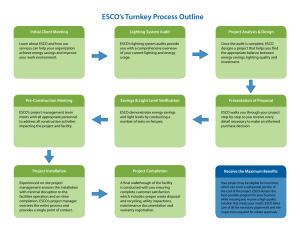

Guaranteed Energy Savings Program (GESP) via Energy Savings Company (ESCO) Basic Tenets • Minnesota Statute 16C.144 authorizes the use of a GESP Contract with an ESCO – ESCO analyzes operational cost savings via ECM’s (Energy Conversation Measures) – Savings are guaranteed – Funded by a Lease Purchase Agreement – Funding arranged by ESCO – Over a term of up to 15 years, maximum – MnSCU has developed with Dept of Commerce – Encouraged by State as alternative funding source Steps Taken To Date • • • • Commerce issued an RFQ (Request for Qualifications) (11) ESCO’s were pre-qualified to participate These ESCO’s signed a Master Contract SCSU developed and issued a Site-Specific RFP with the aid of the Minnesota Department of Commerce (MDOC) • SCSU received (9) RFP responses, reviewed, and invited three ESCO’s to interview, selected McKinstry • McKinstry signed a Work Order with SCSU • McKinstry is in the process of finalizing the ECM’s Review Committee • • • • • Peter Berger, MDOC Kent Dirks, MnSCU Ken Oas, MnSCU John Frischmann, SCSU Tim Norton, SCSU *Several other members of MnSCU and SCSU were involved in various stages of development and review. Financing • ESCO responsible to solicit and arrange thirdparty financing loan to fund ECM’s • Guaranteed Savings will exceed annual loan payments due • SCSU will pay lower utility bills plus new loan payments; total will not exceed current utility bills. Opportunities • Enhance student, faculty and staff participation, education and practice, in the area of sustainability and “green technology” • Reduce Greenhouse Gas Emissions • Potential use of renewable energy measures • Reduce energy, operational, and maintenance costs across system facility sites • Opportunity to address deferred maintenance needs through alternate funding sources The Basics • Projected total project (ECM) cost $12m to $16m • Projected annual savings $800k to $1m • Simple payback 12 to 15 years Energy Conservation Measures (ECM’s) • • • • • • • • • Cogeneration Microturbine Plants High- to Low-Pressure Steam Operations Stack Heat Recovery Reverse Osmosis Boiler Makeup Lighting Upgrades Digital Control Upgrades Water Conservation Measures Domestic Hot Water Improvement Building Envelope Improvements Energy Conservation Measures (ECM’s) • Solar PV/Solar Air Preheat • Green IT Measures • Condenser Coil Coating • V-Belt Drive Upgrades • Transformer Upgrades • Education Bldg. HVAC Upgrade • Vending Misers Projected Outcomes • Reduce 20% energy costs in academic buildings • Reduce by 24% CO2 emissions from utility energy • Improved learning environment comfort for staff and students • Career relevant experiential learning • Demonstration of environmental awareness and improvement Schedule • Complete ECM Preliminary Assessment September 2013 • Start Investment Grade Audit October 2013 • Complete Investment Grade Audit February 2014 • Presentation to Leadership Council February 2014 • Presentation to MnSCU Board of Trustees March 2014 • Construction Begins Spring 2014