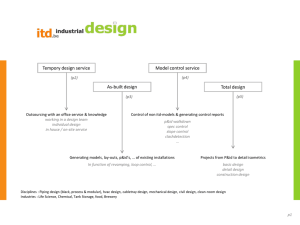

C IFE MEP Coordination in Building and Industrial Projects

advertisement