ECONOMIC JUSTIFICATION OF INDUSTRIAL ROBOTS MANAGEMENT OVERVIEW

advertisement

ECONOMIC JUSTIFICATION

OF

INDUSTRIAL ROBOTS

MANAGEMENT OVERVIEW

I.

INTRODUCTION

II.

DISCUSSION OF KEY ISSUES IN

ROBOT APPLICATIONS

III. ANALYSIS TOOLS

IV.

SUMMARY

MAJOR DETERENTS TO

ROBOT APPLICATION INVESTIGATIONS

• WHERE TO BEGIN

• IDENTIFYING GOOD APPLICATIONS

• ESTABLISHING RESPONSIBILITIES

• SECONDARY TO MmING PRODUCTION

• MANPOWER

PURPOSE OF THE PRESENTATION

• ATTEMPT TO CLARIFY THE JUSTIFICATION

PROCESS

•

PROV! DE ANALYTICAL TOOLS TO ASSIST

ENGINEERS

• MAKE THE INITIAL INVESTIGATION FASTER

•

DEVELOP A METHODOLOGY FOR THE

INVESTIGATION

4

GOALS

• MORE EFFICIENT USE OF ENGINEERS

• CONSTRUCT TI-IE APPLICATION TO ACHIEVE

THE LOWEST MANUFACTURING COST

• PROVIDE INITIAL DIRECTION (GO/NO-GO)

• IDENTIFY THE BEST APPLICATIONS

5

f ROBOT APPLICATION?]

EQUIPMENT

CAPABILITIES

ROBOT CAPABILITIES

ECONOMICS

-_

CAP ITAL EXPEND nu RES

MACHINE TOOLS OR PROCESS

SAVINGS

PART ORIENTATION DEVICES

R. O. I.

SENSORS

RISK

MAINTENANCE

SPACE R£QU I REMENTS

PRODUCTIVITY

v

ALL OPERATIONS

... , y

ECONOMICS

. . . ,,.....v

CAPAS ILITIES

'

~

II

BEST APPLICATIONS

(~

TECHNICAL FEAS IB ILITY/ECONOM IC FEASIBILITY

RELATIONSHIP

Operations that are technically

teas ible

Ope rations that are econ om ica Ily

feasible

·

Operations that are both technically and economically feasible

ROBOT CAPABILITIES

ROBOTS CAN DO PRACTICALLY ANYTHING YOU WANT

THEM TO DO

ROBOTS CAN DO PRACTICALLY ANYTHING YOU WANT THEM

TO DO AND ARE WILLING TO PAY FOR

WHAT IS ECONOMIC JUSTIFICATION?

- CRITERIA FOR DECISIONS

- RELATIVE MEASURE

·~.INDUSTRY

TO INDUSTRY

• COMPANY TO COMPANY

• FACTORY TO FACTORY

- COMPARATIVE MEASURE

COSTS OF ROBOT SYSTEMS -

Included Items

•

ROBOT

•

FIXlURING AND ORIENTING DEVICES

•

INTERFACING SUPPLIES

•

TRAINING

• SPARE PARTS

•

TOOLING

• CONVEYORS AND RACKS

• MACHINE TOOL REVIS IONS

• SAFETY EQUIPMENT

•

INSTALLATION

•

TAXES

•

FREIGHT

•

DESIGN

•

LESS TAX CREDIT

SAVINGS AND EXPENSES IN NORMAL

ROBOT APPLICATIONS

SAVINGS

EXPENSES

Direct Labor

Maintenance Labor

* Part Redesigns

Farmout Reduction

Direct Material

Quality

'::

WIP

f.c

* Indirect Labor

Energy

Training

* Indirect Material

:~

EITHER WAY

Floor Space

M.E. Support

* Downtime

OSHA Compliance

INTANGIBLES

Scrap Reduction

* Safety

Resale of Old Equip.

Depreciation Costs

* Better Management Control

"'

* Inflation

* Less Hu man Problems

* Step In The Right Direction For Future

* Capacity ,

* Maintaining State of the Art

* Meeting Product Demand

*

ITEMS THAT ARE NOT NORMALLY INCLUDED ON AFE/DCF

UNLESS SPECIFICALLY IDENTIFIABLE

r'T1

x

(/)

-c

MAINTENANCE

D. L + F. B.

z

(/)

TRAINING

WIP

DOWNTIME

QUALITY & SCRAP

I~

I~

FLOOR SPACE

<

ltn

•

OSHA

I~

DIRECT MATERIAL

I~

RESALE OLD EQUIP.

I tn

r'T1

r'T1

(/)

)>

<

-z

C)

(/)

-c

Vl

r'T1

-~

L - - - -- -- -- --

- -

-

·-·-·- - -

ASSUMPTIONS IN ROBOT ANALYSIS

• AN OPERATOR WILL BE ASSIGNED TO

THE OPERATION

• IT IS PREFERABLE THAT THE OPERATION

REMAIN ON INCENTIVE

• THE OPERATOR SHOULD BE GIVEN 130%

INCENTIVE OPPORTUNITY

• SAFETY DEVICES WILL BE SUFFICIENT TO

ALLOW THE OPERATOR AND ROBOT TO

WORK IN THE SAME CELL

ROBOT WORK ELEMENT DISTRIBUTION

GRAPHIC DIS PLAY

(SINGLE ROBOT SYSTEM)

l________________~Jo

ALL WORK PERFORMED BY THE OPERATOR

f77/fi_llCAR

I

Ia

I.::

OPTIMAL WORK DISTRIBUTION

I

CYCLE TIME

f7/7~R

Ia

I

j

ACTUAL WORK

ASSIGNMENT

CYCLE TIME----+]

V/ffl/_ITJTIZ//Tfl/ll/1R

. . . _I_lo

I-<----

CYCLE T I M E - - - - - 1

W/7/////ZJR

LOST POTENTIAL

MAXIMUM

ROBOT WORK

Optimal Division of Total Standard

Minutes (at l 15 Avg. P&F Factor)

K-factor

8

:

7

z

T7

- - ---- -- - _ _[___j___~J..:I_;__~--l----i---+---ll~-l-----1--JL'-+--,Z,__-1·~-,~~~

.J

·77

17

------1-----'-----+----+--------ir--+---+---+---t----'------Y-¥---------l-----1----+----+---+----+---+--f---7,,___~7

-7 --7

i

r

~

z

7

I

7

7

--7----+----- --

-f------+--~

~~~--c~'

7_ ; -----.>--

7

.......

0

..c

0

a:::

6

0

.......

.&

C'C

u

5 1-1-..7

___ ,. ___ --+- ----- --l-------'--+------l---1~

'--vhl7

'--7-V7.-~

0

<(

0

.......

Vl

Q.)

.......

::J

c:

:E

"E

C'C

zy_-;,

~-- - . -~-- - --=-----~ -___ --=4---------l----'---7-'~'-~77,__-~,1--'-1'---~7 ,-7 7 --//,. -- .

-1 if 7_-f- 7_~?-7

7

T7

--r--• 7_,,__..,,__

. ---- -- ---- - - - - ,- - 1 - - -'--

- --- - - - ---+

- ~ -- --~-=-

:i---:

7 :7

7

~y

7

7

'77

77

7'.7 - - ' - - - - + - - - .7

7

-7'7jZ7

v;?- ___ ]_____==+_c _-_ ~~

__

___l_

L ____ _

~----- - --

7

-7~~7 7~ -Y/----L---l--__J_----'J:--~1---'·- - - i -------

7-7 -7 -7

------- . -- --'----

7

7

7

Z-f-• 7 /

7

---- - -

"'C

c:

JS

V>

K FACTOR=

'

Robot Time

Operator Standard Time

:I

Total Standard Minutes to Apportion

Between the Operator and Robot

- -

---

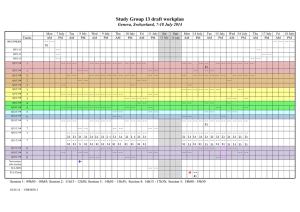

ROBOT ANALYSIS -- U.S. FACTORIES

TOTAL ANNUAL HOURS VS. JUSTIFIABLE CAPITAL EXPENDITURE

(@ % DIRECT LABOR REDUCTION AND % MACHINE UTILIZATION)

13

MORE THAN ONE

ROBOT REQUIRED

(100% MACHINE UTILIZATION)

11

10

9

=

8

TOT

INCf -t--=--b~f-!~;?1~7-f--.~A---:?l,,_-~~-+~'7-+-~7'£--_;_1----l-----i--~:..+---t

(XK)

TE-:---- -+------+---+------+--------

---+-------! ·-----~-- ···-·-

- - - - - - -· --- - · - - -

2 -t-tt-t+.H-~:;.t:;~~+--7"'-~---!---+----J..--+-----1-------+--...;.-----+

--+--+----+----4--~--._

- - - 4 - - -··- - _ __.____._----+---- - -···. -i' -----·-··i

---~- ·- - ·'

+----+----+---!--

1

'

--+-----+---+------<-----·-+ -- ·- -

- : - - ---i-----i

- -- ·- --- --t ----··---- ·---~-- ----- ·-t

-t~/f.~T.n.sfL--.~--+---+----ir----+---+--+--_;,_·

_ __,__ _ _+ _ __., _ _t----·:~-+-------1'I

__...__ __,__ _.. . .___ _~-~:: __:_=t----- --~- :~~--~~ ~ =--~~ :~-~~~-:-:· .~ -~~:.~ -~ -=~-~=-~· ·i

: ::1~: :-: -i o : -~-its=-::·-i o=: l7s= = 2 o: :ib : : z~o: : z7s :: 30o :: 32s ·: JSO

_ _....., ---- ---·---,--·-'---·;-+··--·-- -- - ··· -- -1··------- ···----·--··--···-------- .. - - ~ --· - - ... - - .. ... - --- -- !

--1--~--+--+---t-~~=:::-=-:-:::-t--~=-:-::--:+-:---~~---·-- - ----+

-----t- ---- -- --~-- 1

- ·--,·. ,JUSIIFIAB E ·CAPITAL { _) :··: -; : ·: -:- ~ - ~ : : ·-:-·: ~ : : : ~ : : : : : : :: : .: 1

·

---~:-:-::·· ~ -~-~ ·:!~- :--:· =~ -=~ : :.~ t~~ -~~ ~ ::: j::::

- - + · - - -MACH+NE LOADING - - ·- - :..._ --- -- - -- · - · · · : : : '. ! : : : : . : : : : : : : : : 4 . : : : : : · : : J

.APB.If .l9 0 ..

---1--· --- - .. - .

I

•• ---

-·-

-

-i -··- ··l .. - . ~ . - .. j . .. . '. . .. .

. . .

I

.

I

ROBOT ANALYSIS -- U.S. FACTORIES

TOTAL ANNUAL HOURS VS. JUSTIFIABLE CAPITAL EXPENDITURE

(@ % DIRECT LABOR REDUCTION AND % MACHINE UTILIZATION)

13

MORE THAN ONE

ROBOT REQUIRED

(100% MACHINE UTILIZATION)

12

11

10

9

8

TOT

ANN INC'/

HRS

(XK)

6

5

4

3

1

0

--'---+-- ---··

·--- · ·--

-

· -- · - - . - .. ............ . ..... - - - -....,-- ·· -

~-

-

----

•··· · --- ··

.... · ····- -- -

···- ····- -

~ --· ··-··- ---- -

• • • ·-

t

• ...•

.

!

'

- - - - - - --

.

~=~=:~~:~ =~= ~=~~·l : :·~· : ·=~~=t--=~ A ~rij~y-~-:·:~: · :· : ~-· :I :~ :•

-------4- -- -

- ·- · ··-·--· - "t-··- ..- - - ---·.

•

- ·-

I

- --

. . ··- .

'

'·------·-· ···-

! .

. · - - - ~ - ---·+·

: ~- : -~ j ~ ~=

.. -· -- -

. -- - · -

::_ :-.: : :. ~=-==·

· · ·· -·· ·-1 ····- --

.APB.ILI .19.80

.. . . j . .. - ..

Optimal Division of Total Standard

Minutes (at l 15 Avg. P&F Factor)

K-factor

___·:J:ii1-.:.: ____:

~ : J . : =~ -=..:: -==i-·-~-----J--i---+---+--+--+--+----t:r----11---,---;----.--.jlQi"i"-

.

_g_ .

:Z =-7------i

· 7=-l=--------L

· -- -___...._

~ 1 ' c1. ..l ,__i]",;2 ...i.J"'.

1'1..!d. _I

- --=·--.

. .:. ·----L-----+--+---+---i---t---+---o--r---rY.

'7

JZ7

=--=-----1----'

.. -

-- - ---------------+-----+---+---i----1--..-----t---I.,_

.L _· ___,..f

.L

L

L

- - -·-· -- -- -- -----1--f----l--+---+---+----+-o

L-f'-~f-

i

•: ~

.....,

0

-·-

0

6

.c

.L

.L.

:-.:.::: .:._~::.:...--------+-----.------r---t----r--·'--,7---v-

- ::--_:· :-::::__ ~ :: _-_-____-----1---+-_-_-_--t_-_-_::-__:::-_::::-_::::-_::::-~_::::-_::::_::::.L7Z=7

7

L

_,_.L_ _ _ _._ ____ - · -

·L

IL

_L-

L

77

-

-- -y.g

.....05

_..

. ._

.

L

L

. /1 _

___ _

- t - - -- i

'

..f ::::-7'

17~-=±

:..Z--+x ._-_-:=::-/.!·· ,----Y --------!.L:-==L:::j-- - -==1-==-==

-::-__-::-.·. _---=-~-=:.....;. . ;--------::-_::=:::::~::~:::::::~:__,../...-./....,:a,_.

7.-..,~-7-~

-~-

~

~--.z.-:L

_.-_7_.r-~-t

,--:

.. __ .,...._

~

-- ---t-;---~--~-i~?

!

·

±

_

' _-· :;

. -._-:::::.:.::j ___ · -·· --+----'------t-~----t--f_z-=:r-v~

e::::

-:?----· - ~-~-- ·· ·

0

.....,

.....,

Q)

ro

u

0

.J.. .

----

· - ---- · - -- -

. ---· ___ _,__

.. . - .. .. - - - -- --l

. - · - - -- -' --

-'] 7 / z.L.. .,,L ./- . ~ - ----+--- -- - +------ ·- LL

-z z L - L - . ?~

----j ---.-- --r 7_ 7_ Z Z

.,L____L__----1--------'--t------t- -

.

r

_,-L_--v 7

z z

-- 1 - · -· -

- --t ·-

..I...

zl____,,£_

- --· --

~-:

-

-- -L -· - -- --

Z

lL

L.

_j _:::_:: __

~-~-~~~-~-~~.i---~-~-~-+---+--~--t----- ~---- -- -

------+--___,....

' #-L--1.L. Y. .L 7

.. . . .

-- - c

.LL 1.+-.L~L'--F-L+.--rz.'d:___z...,l:'-:__-t-----1---__.;...--t---t--:----i--t---t--t, ~_::::.::::--t

_ _i____,;i

:.1_- - - -

~ :=~~~-=--=-1~ /ij#/~¥

------ -W.U~.L ·

-1 ___:

·

K FACTOR I=

Robot Time

Operator Standard Time

~ ;-=~~:-+--:-.Ji'-.-+---'-+-~~1---------····

~!

~- - - - - =1

'

:~--_ a-: -: _·. j. .-_:-=_:_=,_--=--=--~~~~=--=~~-+:r=====:=!::=====:+======:t======:t=====:::;:t=======;======:=f=-~==-,+=-=---=-- - -:-'1"~-~·-=-:--~-·~-~j·---~-~-~-:

:-.-:_ __

::

±

--

-

-~--+-~--f-..;..-t---+--+---1----i---+----t------t--------:

_j_

---- - -

~=4·

----

- -~--i---+-_,r-~l--'--1---+------i ----.---< - --., -- -··-' ~

--- ·1 -

----,-

- - . :I

-

-·

- ·-- -~ ---· - - --·--·-

.....

~-===-=t.J.===.it====!~==-=1l-il=,::==t::=.:::::tR::=·=+==-=1'=il:Gf===.::t:r==::J1_~~==.=!r==~it4F=-_,.

--- ---j:!:jt~r--_-

Total Standard Minutes to Apportion

Between the Operator and Robot

ROBOT ANALYSIS -- U.S. FACTORIES

TOTAL ANNUAL HOURS VS. JUSTIFIABLE CAPITAL EXPENDITURE

(@ % DIRECT LABOR REDUCTION AND % MACHINE UTILIZATION)

5

I/

""'

1

A__

V.LL LLZ

3

ZL~ZL

. .Li ,

-1,4+-;/1- LLL_

I

=

fll!TL 'LL.

y :z

z

:I

,

_,,y -

~

;

I

L-

~

-

.

ZL

I

.,,,,.

l -

~_:' ,,, ·~J~L

_;_

,'

T

/

T•

..:.

'

I

~'

/

J1.

'

• .

:J.\_ Dfil'K..._

_;_J_

~~~~~ ~' ~ -~nt;w_

·-.~~ . _:_

···· ······

, -~-

-

~----L~ -~ _:s~~-, -- ~~~-~1Po

~ s-u

~a-===rts-~-==2~o ~=~ts~~~~2~0 : : 215 ~--: _3 Jo-- :-=-=3~s

::_:~~o

+: l

l : :

---------------r-----------i

-,--,---ii--------,------'-+-~~----1_____._----;-----,-__. _: +: ,--i.Jt]S'*'IFIAB.,.E · CAP~ TAL-----{ ICK> - ----+----7----1 ---+--- - - __. ----- .. ----- --~ ------- - -----'

'

-

.

I

.

'

I

I

'!

'

~-----; ~~ --t---------1 ---------- - --f ----- --- ----

;

_ _ ,l_ _ _,_ _ _ _,_~~H- NE l.~1~=-0~ I-+=-¥~- - -· 2=-~- ~ ~:~=~- -

::-< -::==~r~-== ~~-

~-~~-~:~-r-~~==~

~-~- ---~-=-~-' -'"+1~- -~~ ']7~±-.-._·'-~ ~-~ :_: -~ -~ - - -:~ ; -~ -=_ :_- :: ~li :. ~ -:

----'--+·- - ---

--~---+---F ,

---'- ----j

~

,

_ _ __: _ _

· : - - _, --;.-.:. __l___--+--'----'-__;___ -A~SEMBL"'7

----'--'---- -- -- - -- - - ·_:_____:_____:__---:---h ----<-----i t __"_L_: ____; --~ - - -- ; ; - ; ~~____:__J _ __:_ ____:__ - - -- ~~---------- - ------- -------\---- - ----

~ ~ ~ ~ {~.: i ~-:--+--~~-:; -+~1~-WEiJoi~t\i~ PA~iNo : ~ :_: : -:~J;==~~~=- =-~: =~t-- -~-~

. . 1 - . - .

. .• . .

t--·----- .

Optimal Division of Total Standard

Minutes (at l 15 Avg. P&F Factor)

K-Factor

---'

· : :- ~ :-: ___ ~ - · _

·Q

·

~

._.__··_- _·__--_--_--_-_-_-+-

'

_a_ 1..,a_

1:

--i-

'

""A_-;.

!.1. ir

i

-

---c:

~..

~

'LJL-1 AT

_,,,,_

:ui

""Jt

. .: __...:::..:.::-..:==J ------t----+---+---+---+----+---,1---:~'-,_1_,7

. : _:--::·-: ~ ------=f

/

7

..L

-rt...•~

/

1

J

iZ-

y

' ]

·

!

77, ___ ----·

+--· -.

,77 :.=:lT -- --- - --··. 17 -

-?---~~as:

-7 • 7 1 ---

LLL

7

0

.c

0

---

6

: -_

~_-:_ ._-~ -~-._·:- -~_-_~:- ~-1-~--=-----.-_-_--+-

-+--+----'-

-+---7-19

-

/~±=L

_ . .: . 71=7 ~~~~

- ·-----T-i--- -

7-==z-Jl':-=+7--E-•-·

--+--~-~--'---+7-1

a::

0

.$

~

g

5

-<(

0

V ')

Q,)

:::J

c:

:2E

,__-l-'--"-.;.+..~-+---.;....j'=='iF==r==-1

·· . - -:----,

-

--+-

- - . ....

--ii---,----.!---++·-''----i- - ' - i - - -+---1---+---+---+-

--t- --- ----

-- - - - -· ~

-:I '

- -~ -

-

-· ·

- - --·- --___,---,~-+---J---+--:_;_•~-'>1-'-j;-4-+-'-;.;_

• '--iD:..--..

· _;_.-+--.-=I-.--i<---J

-+---.::!o.t---t----".:i.-.1 ---r-··-~ ~- --

Total Standard Minutes to Apportion

Between the Operator and Robot

Total Investment Conversion Chart

%

%

Expense

Salvage

Value

Months

Delay

0

0

~l~

18

0

10

20

~~

12

18

0

~l~

18

0

0~ 1 ~

18

0

ROI

5

10~1~

18

0

20~ 126

18

0

0~ 181 ~

0

10

10~1~

18

0

. zo~ 1 ~

18

Total

Investment

ROI

15

25

35

1. 70

1. 55

1. 40

1. 27

1. 74

1. S8

1. 43

1. 29

1. 77

1. 62

1. 46

1. 32

1. 71

1. S6

1. 40

1. 27

1. 74

1. 59

1. 43

1. 30

1. 78

1. 62

1. 46

1. 32

1. 72

1. 56

1. 41

1. 28

1. 75

1. S9

1. 43

1. 30

1. 78

1. 62

1. 46

1. 33

1. 14

1. 01

. 87

. 76

1. lS

1. 01

. 87

. 77

1. 16

1. 02

. 88

. 77

1. lS

1. 01

. 88

. 77

1. 16

1. 02

. 88

. 77

1. 17

1. 03

. 89

. 78

1. 16

1. 02

. 88

. 77

1. 17

1. 03

. 88

. 78

1. 18

1. 04

. 89

.78

. 85

. 72

. S9

. so

. 85

. 72

. S9

. so

. 85

. 72

. S9

. so

. 86

. 73

. 60

. 50

. 86

. 73

. 60

. 51

. 86

. 73

. 60

. 51

. 87

. 73

. 60

. Sl

. 87

. 74

. 60

. Sl

. 87

. 74

. 60

. 51

HO\

FORMING- SCRAPER BLADES

CUR RENT OPER.ATION

I

O PE~AToR

4-

P4RT /VVM6ERS

SI04

YEARL'/

-z.1+5

STANDA~O

fAJC..E.NTIVE

µtlNUTE S.

#olJ~S

PER..

PAa'tT

Optimal Division of Total Standard

Minutes (at l 20 Avg. P&F Factor)

K-factor

:r <I

:_..__...

'

'

:

I

'

.:r

'

'

I

''

==

,

--r

I

.±

I

t£:::

,,

·7

_L

I

'

'I

f

=:

==

J:

I

'

.

T

_L

~.

r7

-7

:-± ,=zJ_

•

-7-

7_ .

,L

-7-

r7

r

-0

..c

0

a:::

: ::t

=

0

~

ca

u

0

<(

0

7

7

17

717,

V)

u

Q)

:::J

-:z_

7

77

c:

~

7

-v

7

7

1

7

z

''

~

L

;

L

7f777T7

"E

_,,

L

7--!-i--lz-JC-+----+--,-+-~-+----+--

7

Z

7

7

L

:L

;

:

'

':::

ca

"C

c:

J9

V>

:

:

:::;: ,

j

::: . '

.:::;+ :±:I:P:: :-±. .:r. :±

'

'

I

' =t:±

:I . ' ,

'

,

I

J

,

i

•o

,

.

I

. ,

:::

'

'

j

I

I

Total Standard Minutes to Apportion

Between the Operator and Robot

j

J:

:±

I

;

'll"f

1

~

:

HOT FORMING OF SCRAPER BLADES

ROBOT APPLICATION

RACK

D

OPERATOR©

FURNACE

ORIENTATION

TABLE

D

[!]

0-

PRESS

ROBOT

OPTIMAL WORK DISTRIBUTION

.95

I 20

I

MINS.

M IN s

AC TVAL WORK

TO ROBOT

I

TO 0 PE RATO R

D\ST~l BUTI

ON

I. 2 7 MINS TO 0 PER.ATOR

fO.~

"lo LABOR

~EDVcTIOtJ

ROBOT ANALYSIS -- U.S. FACTORIES

TOTAL ANNUAL HOURS VS. JUSTIFIABLE CAPITAL EXPENDITURE

(@ % DIRECT LABOR REDUCTION AND % MACHINE UTILIZATION)

13

MORE THAN ONE

ROBOT REQUIRED

(100% MACHINE UTILIZATION)

12

11

10

9

8

TOT

ANN INC'/

HRS

(XK)

5

1

· - ---+·-

- - - - + - - - + - - ---+

·---+---+--+-<~t-,-..-..---+~-~----+-.--+----__.-- -+---~--+-------+-- -----· -

=~-:-=-~~ ~~~:~

: ~ : 7$ :·:-:--:i

---+---- --~----

·--- -- - .; . . . -

·-

-

··- -

. -· . . . . - . . ··-

-MACH NE

LOADING

o ~-=i -s~.=:i

.:

--- --~ ·

---~

.APRI~ 1980 - --- ·· --·---- --- ---'. _;_

-·-~.-

o~-:-_1

s=~i

; -; .

o::=z?s.=-~~ 2 o~-= -:z7s =:-:- ·3~0 :__:: :::n s__

. ·_

-). -:-:··i1-:---:--:-- -

- - ··-- ··-'-·-- -'-

:.; · - ---·- ·"

i ......, .. - -

-~

- -- -

:

.

:~

. .

j ..

:_ : : ~- :

3fO

·------~------- 1 · ----t--·-

-==-=r=:-=- _--._____. )_ ___

- ----·--i-- - -

.j_.

•

. ·- - - ·- • . ··- -----

j , .... ,

' . - - j------ ...

:·:: :-:-:] =-~~-:

_,-:,·-:-t ------ ·- --· -·-·;---- ---· -· -· ··. -

·

· - · --- ---------

RESULTS:

t I SO, 000

JUSTIFIABLE CAP ITAL

@. -zs?o ROI

&,7%

MUF

LOW HOUR ANALYSIS OVERVIEW

OBJECTIVE:

TO ANALYTICALLY DETERMINE THE YEARLY

HOURS THAT AN OPERATION MUST RUN

BEFORE IT BECOMES ECONOMICALLY

FEASIBLE TO AUTOMATE IT.

LOW HOUR ANAL Y.SIS

EXAMPLE. - WE.LDJNG-

NUMBER OF :'.:>ET VPS PER YEAR 5E T UP TIME FOR OPE.RATION

SET VP TIME FOR ROBOT

-

INCREMENTAL TOOLING COST ROBOT C05T

3/+ 1-4~

'/2

HR

~IS K

- '100 K

DIRECT LABOR COST PLUS

F.B.

-

$15/H-R

PA'l'BACI<. PAC.TOR

-

3.0

PERCENT LABOR REDVCTION

-

PE RC ENT DELAYC:,

20

YEARLY 1-IOURS = 1223

~

Of= PA RT~

-

10.5

LOW HOUR ANAL Y51S

EXAMPLE. - IVlACHtNE. LOADING-

NUMBER OF

~ET UPS

PER YEAR -

12

Yz.

5E T UP TIME FOR OPE.RATION

-

~ET

- V-z. HR

VP TIME FOR ROBOT

HR

INCREMENTAL TOOLING COST - .i4 /<.

- ~75 K.

ROBOT C05T

DIRECT LABOR COST PLUS

-

1 IS/»1

-

'3. O

F.B.

PA '<BACK FAC.TO R

PERCENT LABOR REDVCTION

PERCENT

DELAY~

YEARLY HOURS

it

Of= PARTS

4S

-

=

=

·309. l

37. 51

ZS

ONE ROBOT/ONE OPERATOR

ALL WORK CURRENTLY BE ING PERFORMED

VZ7//77/ZZZZ/ZZ/1/Z/1

I• ROBOT CAPABLE WORK

·I

75

OPTIMAL DISTR I BUT ION 50/50

VZZ/Z/LZ/L/7/LJ

I

k-cvCLE TIME

)

=

50

~

SAVINGS = 50

DUPLICATE SYSTEM (SUB-OPTIMIZATION)

SAVINGS = 100

1100

SYSTEM OPT IM IZAT ION

lWO ROBOTS/ONE OPERATOR

" fZZZ/f/Z/fl7ZZZZZL1 .· ..

-

- -

...

-

-- -

---

...

OPTIMAL DISTRIBUTION

1/3,

113,

V/7//ZZZ/~//7/1

W/Z/77/ZZ777JJ

I

I

I

I<

Cycle

Time = 200

·- -··

Cycle Ti me = 66

SAVINGS = 134

>[

113

66

66

66

EXAMPLE

MULTIPLE ROBOT ANALYSIS

NO.

ROBOTS

A

% SAVINGS

PER OPERATION

B

TOTAL ROBOT

COST

c

SAVINGS

PER SHIFT

1 SHIFT

D

ROI

2 SHIFTS

1

40.5

100

9,584

4.5

15.4

25.0

2.

52.6

200

24,894

8. 0

21. 2

33.2

3

63.0

300

44,724

10. 8

26.0

40.3

4

69.6

. 400

65,880

12.5

29.0

44.9

5

74.3

500

87,910

13.7

31. 1

48.2

ASSUMPTIONS

A.

3 SHIFTS

ROBOT PERFORMS AT OPERATOR'S NORMAL PACE

1. 15 AVG. P&F

1. 15 WAF TOTAL

130% INCENTIVE OP;POR TUNITY

10% OF INC. STD. REMAINS AS "D" TIME

B.

$100, 000 PER ROBOT SYSTEM

$20, 000 SALVAGE VALUE

C.

SAVINGS= 8 HRS/SHIFT X 232 DAYS/YR X 85% UTILIZATION X $15/HR X % SAVINGS

D.

BASED ON NUMBER OF SHIFTS OF CURRENT WORK LOAD

EXAMPLE:

FOUR OPERATIONS - OPERATOR WORK PERCENTAGES

%OPER 1

=

• 90

%OPER2

=

• 25

%OPER3

=

.30

%OPER4

=

•70LL

WITHOUT BALANCING OF

RANDOM WORKCELLS, THESE

OPERATIONS WOULD BE EXCLUDED

FROM ROBOTIC AUTOMATION

DUE TO THE HIGH% OF MANUAL

WORK ELEMENTS •

BY BALANCING, WE WOULD TRY TO RUN JOBS (1) AND (2) TOGETHER,

AND (3) AND (4) TOGETHER.

BENEFITS OF SYSTEMS APPROACH

GREATER SAVINGS

~~...,GREATER

ROI'S

ABLE TO BALANCE LOW ROBOT PERCENT

OPERATIONS WITH HIGH ROBOT PERCENT

OPERATIONS

MAY START EFFECTING OVERHEAD ACCOUNTS

FOR EVEN GREATER SAVINGS

ADVANTAGES OF ANALYTICAL TOOLS

TEST SENSITIVITY

KNOW WHAT THE VARIABLES ARE

CONCENTRATE ON IMPORTANT VARIABLES

SUMMARY OF ANALYTICAL TOOLS

USE

TOOL

OPTIMAL DIVISION OF

WORK ELEMENTS

BALANCE WORK ELEMENTS

TO MAXIMIZE ROB OT AND

OPERATOR UTILIZATION

ROBOT ANALYSIS

DETERMINES JUSTIFIABLE

CAPITAL EXPENDITURE,

TOTAL HOURS, OR

% REDUCTION

LOW HOUR ANALYSIS

HELPS ANALYZE AUTOMATION

OF LOW HOUR OPERATIONS

SYSTEMS ANALYSIS

FOR MULTIPLE ROBOT

APPLICATIONS

EXPENDITURE

CONVERSION CHART

CONVERTS JUSTIFIABLE

CAPITAL AT VARYING ROI'S

AND START-UP DELAYS

.

ROBOT APPLICATION LOGIC CHART

Part Numbers

Quantities

Incentive Standards

Machine Standards

Analyze Current Operation

Define Factory Criteria

Planning Year

Shifts/Day

Utilization Goals

Days/Year

Production Level

Analyze Future Operation

New Part Numbers

Part Redesigns

Long Range Plans

Check Initial Feasibility

l Determine Equipment

Requirements

I

Management Review

Parts Routing

Man/Machine Work Dist.

Combined Operations

Floor Layout

Part Families

Veri~ Part Numbers

l

Machine Utilization

Robot Utilization

I

Detailed Evaluation

Evaluate Alternatives

I

Sensor Interface

System Controller

I

Reclaim Work

Estimate Incentive Standards

Direct Overhead

l

Estimate Project Cost

I

Test Economic Feasibility

Pick & Place Devices

Servo Controlled Robot

Hard Automation

Methods hnprovements

Alternative Method

Calculate ROI

.l

Formulate Production &

hnplementation Plans

Management Review

Request Budgetary Quotes

I

Experimentation

Write Performance

Specifications

.l

Request Quotations

_l_

Evaluate Quotes &

Select Vendor

Prepare & Submit AFE

:I

Establish Support Services

Required

l

Issue Purchase Orders

I

Install Equipment

Preventative Maintenance

Plan

Inspection Plan

Tooling & Gages

Equipment & Relocation

Utilities

Training

Programming

Incentive Standards

Material Handling

· suMMARY

• ANALYTICAL TOOLS ARE AVAILABLE TO ASSIST ENGINEERS

WITH ROBOT INVESTIGATIONS

• ROBOTS DO NOT HAVE" TO PERFORM ALL TASKS CURRENTLY

BEING PERFORMED BY OPERATORS

• MULTIPLE ROBOTIC SYSTEMS PROVIDE BENEFITS THAT MAY

NOT BE OBTAINED IN SINGLE ROBOT SYSTEMS

• ROBOTS CAN WORK WITHIN THE DEERE INCENTIVE SYSTEM

• OPERATORS ARE AFFORDED GOOD INCENTIVE OPPORTUNITY