Time-resolved diffraction profiles and atomic dynamics in short-pulse laser-induced structural

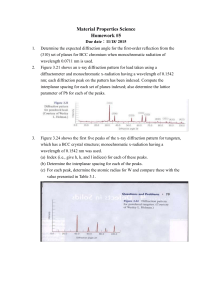

advertisement