Lesson Plan Stop Clamp Parametric Modeling Skill Builder

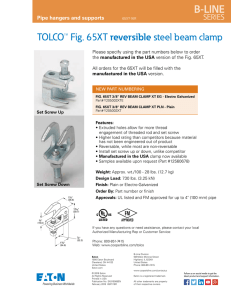

advertisement

Stop Clamp Parametric Modeling Skill Builder Advanced Engineering Design and Presentation Lesson Plan Performance Objective At the end of the lesson, students will able to create the six parts of the Stop Clamp, assemble them, create an exploded assembly, place them into an 11 in. X 17 in. layout, and annotate to match the criteria in the Stop Clamp Parametric Modeling Skill Builder Rubric. Specific Objectives Create the six parts required to specifications given Assemble the six parts correctly Create exploded view of the six-parts assembly Place the exploded view into the 11 in X 17 in layout; use balloons and parts list to explain the exploded views Place the assembled view into the 11 in X 17 in layout Place each of the parts into the 11 in X 17 in layout and annotate them correctly Terms Parts- what makes up the object/project. Planes- X, Y, and Z that you can select to create a sketch on. Copyright © Texas Education Agency, 2014. All rights reserved. 1 Assembly- when all the parts are put together to create the object/problem. Exploded view- when all of the parts have been assembled and then “tweaked” so that they are separated for the annotation process. Annotation- dimensions of the parts. Copyright © Texas Education Agency, 2014. All rights reserved. 2 Parts List- a table that explains what all of the parts are and/or materials used. Balloon- a type of annotation that identifies parts given in the parts list. Layout- is the title block or paper that you place everything into, so that you can then print it for the customer. Copyright © Texas Education Agency, 2014. All rights reserved. 3 Sketch- the surface or plane area that you can draw your part on. Extrusion- when you make a sketch have mass or take away/cut a part of the mass. Fillet- a rounded edge. Copyright © Texas Education Agency, 2014. All rights reserved. 4 Chamfer- a straight edge. Time It should take approximately 15 minutes to teach the lesson and 45 minutes for each of six lab sessions. TEKS Correlations Preparation This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Advanced Engineering Design and Presentation 130.366 (c) o (2) The student participates in team projects in various roles. The student is expected to: (B) use teamwork to solve problems; and (C) serve as a team leader and a team member and demonstrate appropriate attitudes while participating in team projects. o (3) The student develops skills for managing a project. The student is expected to: (A) use time-management techniques to develop and maintain work schedules and meet deadlines; and (B) complete projects according to established criteria. o (4) The student demonstrates principles of project documentation and work flow. The student is expected to: (A) complete work orders and related documentation; and (F) read and interpret technical drawings, manuals, and bulletins. Copyright © Texas Education Agency, 2014. All rights reserved. 5 o (5) The student applies the concepts and skills of computer-aided drafting and design software to perform the following tasks. The student is expected to: (A) prepare drawings to American National Standards Institute and International Standards Organization graphic standards; (B) customize software user interface by creating blocks, attributes, and symbol libraries; (C) prepare advanced sectional views and isometrics; (D) draw detailed parts, assembly diagrams, and sub-assembly diagrams; (E) indicate tolerances and standard fittings using appropriate library functions; (J) prepare advanced development drawings; and (K) identify the functions of computer hardware devices. o (6) The student practices safe and proper work habits. The student is expected to: (A) master relevant safety tests; (B) follow safety guidelines as described in various manuals, instructions, and regulations; and (F) handle and store tools and materials correctly. Interdisciplinary Correlations Geometry 111.41 (c) o (1) Mathematical process standards. The student uses mathematical processes to acquire and demonstrate mathematical understanding. The student is expected to: (A) apply mathematics to problems arising in everyday life, society, and the workplace; (B) use a problem-solving model that incorporates analyzing given information, formulating a plan or strategy, determining a solution, justifying the solution, and evaluating the problem-solving process and the reasonableness of the solution; (C) select tools, including real objects, manipulatives, paper and pencil, and technology as appropriate, and techniques, including mental math, estimation, and number sense as appropriate, to solve problems; (D) communicate mathematical ideas, reasoning, and their implications using multiple representations, including symbols, diagrams, graphs, and language as appropriate; (E) create and use representations to organize, record, and communicate mathematical ideas; (F) analyze mathematical relationships to connect and communicate mathematical ideas; and (G) display, explain, and justify mathematical ideas and arguments using precise mathematical language in written or oral communication. o (5) Logical argument and constructions. The student uses constructions to validate conjectures about geometric figures. The student is expected to: (A) investigate patterns to make conjectures about geometric relationships, including angles formed by parallel lines cut by a transversal, criteria required for triangle congruence, special segments of triangles, diagonals of quadrilaterals, interior and exterior angles of polygons, and special segments and angles of circles choosing from a variety of tools; Copyright © Texas Education Agency, 2014. All rights reserved. 6 (B) construct congruent segments, congruent angles, a segment bisector, an angle bisector, perpendicular lines, the perpendicular bisector of a line segment, and a line parallel to a given line through a point not on a line using a compass and a straightedge; (C) use the constructions of congruent segments, congruent angles, angle bisectors, and perpendicular bisectors to make conjectures about geometric relationships; and (D) verify the Triangle Inequality theorem using constructions and apply the theorem to solve problems. o (9) Similarity, proof, and trigonometry. The student uses the process skills to understand and apply relationships in right triangles. The student is expected to: (A) determine the lengths of sides and measures of angles in a right triangle by applying the trigonometric ratios sine, cosine, and tangent to solve problems; and (B) apply the relationships in special right triangles 30°-60°-90° and 45°-45°-90° and the Pythagorean theorem, including Pythagorean triples, to solve problems. o (10) Two-dimensional and three-dimensional figures. The student uses the process skills to recognize characteristics and dimensional changes of two- and three-dimensional figures. The student is expected to: (A) identify the shapes of two-dimensional cross-sections of prisms, pyramids, cylinders, cones, and spheres and identify three-dimensional objects generated by rotations of two-dimensional shapes. o (12) Circles. The student uses the process skills to understand geometric relationships and apply theorems and equations about circles. The student is expected to: (B) apply the proportional relationship between the measure of an arc length of a circle and the circumference of the circle to solve problems. Occupational Correlation (O*Net – www.onetonline.org/) Job Title: Mechanical Engineers O*Net Number: 17-2141.00 Reported Job Titles: Mechanical Engineer, Design Engineer, Product Engineer, Mechanical Design Engineer, Process Engineer, Equipment Engineer, Design Maintenance Engineer, Systems Engineer, Chassis Systems Engineer, Commissioning Engineer Tasks Read and interpret blueprints, technical drawings, schematics, or computer-generated reports. Assist drafters in developing the structural design of products using drafting tools or computer-assisted design (CAD) or drafting equipment and software. Research, design, evaluate, install, operate, and maintain mechanical products, equipment, systems and processes to meet requirements, applying knowledge of engineering principles. Confer with engineers or other personnel to implement operating procedures, resolve system malfunctions, or provide technical information. Recommend design modifications to eliminate machine or system malfunctions. Conduct research that tests or analyzes the feasibility, design, operation, or performance of equipment, components, or systems. Investigate equipment failures and difficulties to diagnose faulty operation, and to make recommendations to maintenance crew. Copyright © Texas Education Agency, 2014. All rights reserved. 7 Develop and test models of alternate designs and processing methods to assess feasibility, operating condition effects, possible new applications and necessity of modification. Develop, coordinate, or monitor all aspects of production, including selection of manufacturing methods, fabrication, or operation of product designs. Specify system components or direct modification of products to ensure conformance with engineering design and performance specifications. Soft Skills Critical Thinking Operation and Control Monitoring Reading Comprehension Accommodations for Learning Differences These lessons accommodate the needs of every learner. Modify the lessons to accommodate your students with learning differences by referring to the files found on the Special Populations page of this website. Preparation Due to the levels of difficulty of the Parametric Modeling Skill Builder lessons, it is recommended they are presented in the following order: 1. Wood Clamp 2. Stop Clamp 3. C-Clamp 4. Pipe 5. Crazy for Reading Straw Provide paper or electronic copy of the rubric and finished example drawings for students Review how to create sketches on planes (X, Y, and Z) Review how to make extrusions Review how to change material types and colors Review how to create assemblies Review how to create exploded views Review how to place views into multiple sheets Review how to annotate Students may work together in a team of two to create the parts References Layout Page 1, Layout Page 2, and Layout Page 3 provided with lesson Stop Clamp Parametric Modeling Skill Builder slide presentation Instructional Aids Computer with parametric modeling software issued by your district Stop Clamp Parametric Modeling Skill Builder slide presentation to help guide students through the steps Paper or electronic copy of the Stop Clamp Parametric Modeling Skill Builder Rubric Copyright © Texas Education Agency, 2014. All rights reserved. 8 Layout Page 1, Layout Page 2, and Layout Page 3 Introduction The purpose of this lesson is to help students build their 3D/parametric modeling skills. When skill builder problems are completed, students will begin their own designs and prototypes. However, to get to this stage, they must know how to do the building steps. Day 1 Show o Say o Ask o o Ask o o The completed layout of the Stop Clamp This is what you will be working on over the next week. How many parts does this problem have? Answer: six How would you start to create this problem? Answer: create a folder for the project; create the six parts and save to this folder; create assembly; create exploded view; place all views and annotate to match the example/rubric Ask o What are these measurements given in, English standard or Metric? o Answer: English standard or inches Day 1-2 Say o You will have one to two days to model the cap and wedge. Day 3-4 Say o You will have one to two days to model the adjust screw, screw, set screw, and washer. Days 5-6 Show o How to place all the views into the layout and annotate them Say o You will have one to two days to do this. Copyright © Texas Education Agency, 2014. All rights reserved. 9 Outline MI OUTLINE I. Introduction to a Stop Clamp and its parts A. Cap B. Wedge C. Adjust screw D. Screw E. Set Screw F. Washer II. Review how to make parts A. Planes B. Sketch C. Extrusions D. Threads III. Review how to make assembly A. Place parts B. Move/rotate parts C. Constrain parts IV. Review how to make exploded views A. Place the assembly B. Tweak or move out the parts V. Review how to place the exploded view into the layout A. Place the exploded view B. Parts list C. Balloons VI. Review how to place views and annotate them in the layout A. Place the parts B. Annotate them VII. Students create their own Stop Clamp VIII. Assessment NOTES TO TEACHER Show the students the completed example of what their Stop Clamp should end up looking like. Show the Stop Clamp Parametric Modeling Skill Builder slide presentation that helps guide them through the process of creating the Stop Clamp. After slide presentation, have students start to create their own Stop Clamp. Grade using the Stop Clamp Parametric Modeling Skill Builder Rubric. Copyright © Texas Education Agency, 2014. All rights reserved. 10 Multiple Intelligences Guide Existentialist Interpersonal Intrapersonal Kinesthetic/ Bodily Logical/ Mathematical Musical/Rhythmic Naturalist Verbal/Linguistic Visual/Spatial Application Guided Practice The teacher will show students how to make one part of the six parts, assemble, exploded view, and create the layout per the example and rubric. Independent Practice The students will create the six parts, assemble, exploded view, and create the layout per the example and rubric. Summary Review The students should now be able to use the design software to begin to come up with their own designs and/or prototypes. Evaluation Informal Assessment The teacher will observe students working on the Stop Clamp. Formal Assessment Students will be graded using the Stop Clamp Parametric Modeling Skill Builder Rubric. Enrichment Extension The students will be allowed to come up with their own Stop Clamp design, should they finish early, or start the next skill builder problem. Copyright © Texas Education Agency, 2014. All rights reserved. 11 Layout Page 1 4 3 2 1 ITEM 1 2 3 4 5 6 PARTS LIST PART NUMBER 1-Cap 5-Washer 4-Screw 3-Adjust Screw 6-Set Screw 2-Wedge QTY 1 1 1 1 1 1 MATERIAL Steel, Cast Stainless Steel Steel, Alloy Steel, Galvanized Generic Steel, Wrought 3 B B 2 4 5 1 A A 6 TITLE: OWNER: UNIV. NORTH TEXAS 4 3 2 SIZE B DWG NO STOP CLAMP DATE: DRAWN BY: MRS. BAXTER SHEET 1/6/2014 1 OF 3 1 4 3 Layout Page 2 2 1 CAP SCALE= 1:1 WEDGE SCALE= 1:1 B .88 .38 .44 1.07 16 UNC-3B B 1.50 .31 .44 NOTE: ALL FILLETS ARE 1/16" OR 1/32" 4.06 2.03 .34 .38 .07 1.40 .75 R.50 (2) .69 .63 R.44 1.50 .13 .38 16 UNC-3B 1.44 16 UNC-3B 1.84 1.16 100° A 80° .41 .33 .42 2.57 .37 .30 TITLE: OWNER: UNIV. NORTH TEXAS 4 3 2 SIZE B DWG NO A 130° STOP CLAMP DATE: DRAWN BY: MRS. BAXTER SHEET 1/6/2014 2 OF 3 1 4 3 Layout Page 3 ADJUST SCREW 1 SCREW SAE 1040 HEAT TREAT THREADS 16 UNC-3A SAE 1040 HEAT TREAT THREADS 16UNC-3A SCALE= 2:1 SCALE= 2:1 B 2 SET SCREW B SAE 1040 HEAT TREAT THREADS 16 UNC-3A .63 SCALE= 2:1 R.13 (2) 135° .25 .63 .25 .63 1.00 1.00 .63 .25 .25 .56 .38 .75 .25 1.00 .50 A A .38 WASHER SAE 1040 HEAT TREAT .13 TITLE: OWNER: SCALE= 2:1 UNIV. NORTH TEXAS R.06 (2) 4 .44 3 2 SIZE B DWG NO STOP CLAMP DATE: DRAWN BY: MRS. BAXTER SHEET 1/6/2014 3 OF 3 1 Name ______________________________________________Date___________________Class___________ Stop Clamp Parametric Modeling Skill Builder Rubric # Criteria Requirements Points Points Possible Earned 1 Parts For every part you create (five points per part) 30 2 Threads Apply the correct type of threads to the screw 10 3 Assembly For every part assembled (five points per part) 30 4 Annotation For each part of the finished assembly sent to the layout and annotated/dimensioned Tabloid 11 in X 17 in Three pages Five points per part Should look like the example given. 30 TOTAL 100 Copyright © Texas Education Agency, 2014. All rights reserved. 12