Document 13967338

20

th

A

A

3 cell

=

−

R

1

R c c c

1 c c s

0

0

0

0

NNUAL

− (

R

R

1 c c s

R u c

1 f

2

1 c f c s

A

UTOMOTIVE

ROGRAM

+

R c c c

R

1

1 u c s

0 c s

0

+

( 1 −

+

R

1

R cc c s

R u

1 c f

1 cc c s

)

0

) 0

−

R

1 c c c

1

R c c s

0

0

− (

1

R u c s

R u

2

1 c

+

0

R

R

1

1 c c c

1 c s

R c c s f c s

0

+

+

R

1 cc c s

2

R cc c s

)

0

0

0

0

−

R

1 c

1 c c c c c

− (

R

1 c c s

0

0

0

+

1

R cc c s

1

R c c c

R u

1 c s

+

R

1 cc c s

) .

EVIEW

R

ESEARCH

May 21-22, 2014

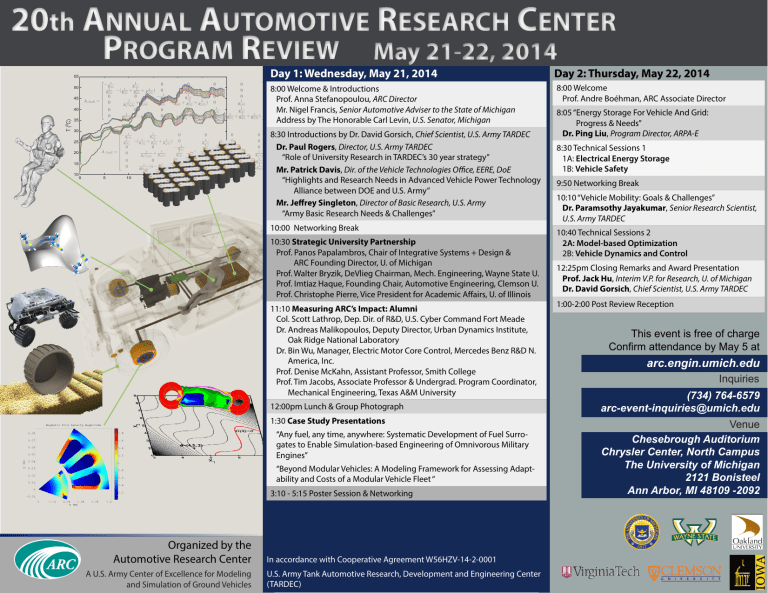

Day 1: Wednesday, May 21, 2014

8:00 Welcome & Introductions

Prof. Anna Stefanopoulou, ARC Director

Mr. Nigel Francis, Senior Automotive Adviser to the State of Michigan

Address by The Honorable Carl Levin, U.S. Senator, Michigan

C

ENTER

Day 2: Thursday, May 22, 2014

8:00 Welcome

Prof. Andre Boéhman, ARC Associate Director

8:05 “Energy Storage For Vehicle And Grid:

Progress & Needs”

Dr. Ping Liu , Program Director, ARPA-E

A

3 cell =

−

R c

1 c

1

R c c s

0

0

0

0 c

− (

1

R c c s

R u

2

1 c f

+

R c

1 c

1 c

R u c s

0 c s

0

+

+

R cc

1 c

1

R cc c s s

R 2 c

1 f c s

( 1 −

1

R u c

WPLQ f

)

Figure 11. OBSERVABILITY OF THE SAME SENSOR LOCATIONS

) 0

−

R

0

R c c

0

0 c bination would be placing the sensors at the 3

12

− (

R u

1 c s

R u

2

1 c

+

1

R cc c s

R

1 c c

1 c

R c c s c s

0

0

+

+

R

1

R cc c s cc c s

)

−

0

0

0

R c

1 c

1

R c c c

− (

1

R c c s

+

0

0

0

R

R c

1 cc c s

1 c

1 c

R u c s th

+

, 6

R

1

8:30 Introductions by Dr. David Gorsich, th

Dr. Paul Rogers , Director, U.S. Army TARDEC

“Role of University Research in TARDEC’s 30 year strategy”

) .

, 9

th and through the coolant flow, the former tends to have larger impact on the observability of the pack model. This may be related to

Chief Scientist, U.S. Army TARDEC

12 th

Mr. Patrick Davis , Dir. of the Vehicle Technologies Office, EERE, DoE

“Highlights and Research Needs in Advanced Vehicle Power Technology each other. But the heat convection through the coolant flow is

Alliance between DOE and U.S. Army”

Mr. Jeffrey Singleton , Director of Basic Research, U.S. Army

“Army Basic Research Needs & Challenges”

8:30 Technical Sessions 1

1A: Electrical Energy Storage

1B: Vehicle Safety

9:50 Networking Break

10:10 “Vehicle Mobility: Goals & Challenges”

Dr. Paramsothy Jayakumar , Senior Research Scientist,

U.S. Army TARDEC

UNDER DIFFERENT CONDITIONS

Table 3. NUMBER OF SENSOR POSITION COMBINATIONS GIVING

FULL OBSERVABILITY FOR A STRING WITH 12 CELLS AND 4 SEN-

SORS

10:00 Networking Break on the observability of the pack model. This may be related to

10:30 Strategic University Partnership

Prof. Panos Papalambros, Chair of Integrative Systems + Design &

ARC Founding Director, U. of Michigan

Prof. Walter Bryzik, DeVlieg Chairman, Mech. Engineering, Wayne State U.

Conditions

Full interconnection

Natural convection

FULL OBSERVABILITY FOR A STRING WITH 12 CELLS AND 4 SEN-

No cell to cell conduction observability is 4.

Conditions

No. of combinations

Full interconnection

Natural convection

106/495

52/495

1/495

No cell to cell conduction

No. of combinations giving full observability

106/495

52/495

1/495

Consequently, greater cell to cell heat conduction will be favored by the observability of the pack model. It is noted that

8 Conclusion

Prof. Imtiaz Haque, Founding Chair, Automotive Engineering, Clemson U.

Prof. Christophe Pierre, Vice President for Academic Affairs, U. of Illinois tion will facilitate the spread of such failure to other cells in the pack. This is not desirable from the safety perspective.

rent excitation of a real drive cycle and the resultant battery surface temperatures. The identified parameters and the measured

8 Conclusion

In this paper, an online parameterization methodology for a lumped thermal model of a cylindrical lithium ion battery cell has been proposed, designed and verified by simulation. By usfull observability. Under natural convection, where the coolant is not flowing between cells, only 52 combinations can satisfy lated coolant convection and cell to cell conduction, referred to as full interconnection in Table 3, 106 combinations will give full observability. Under natural convection, where the coolant is not flowing between cells, only 52 combinations can satisfy

11:10 Measuring ARC’s Impact: Alumni

Col. Scott Lathrop, Dep. Dir. of R&D, U.S. Cyber Command Fort Meade

Dr. Andreas Malikopoulos, Deputy Director, Urban Dynamics Institute,

Oak Ridge National Laboratory the battery lifetime, such online identification scheme can be reset on a monthly or yearly basis to track varying parameters due ditions under different scenarios, and the conclusion is summarized in Table 3. The minimum number of sensors that gives full observability is 4.

As shown in Table 3, among all the 495 combinations of

4 sensor locations in a cell string of 12, if there is both circu-

Dr. Bin Wu, Manager, Electric Motor Core Control, Mercedes Benz R&D N. face temperatures. The identified parameters and the measured cell surface temperature are adopted by an adaptive observer to estimate the unmeasurable core temperature of the cell. The estimated core temperature can be used as a more useful and critical reference for the on-board thermal management system and even the vehicle power management system. The next step will be to validate the model and the methodology with experiments. Over

12:00pm Lunch & Group Photograph

10:40 Technical Sessions 2

2A: Model-based Optimization

2B: Vehicle Dynamics and Control

12:25pm Closing Remarks and Award Presentation

Prof. Jack Hu , Interim V.P. for Research, U. of Michigan

Dr. David Gorsich , Chief Scientist, U.S. Army TARDEC

1:00-2:00 Post Review Reception

This event is free of charge

Confirm attendance by May 5 at

arc.engin.umich.edu

Inquiries

(734) 764-6579 arc-event-inquiries@umich.edu

1:30 Case Study Presentations Venue

“Any fuel, any time, anywhere: Systematic Development of Fuel Surrogates to Enable Simulation-based Engineering of Omnivorous Military

Engines”

“Beyond Modular Vehicles: A Modeling Framework for Assessing Adaptability and Costs of a Modular Vehicle Fleet “

3:10 - 5:15 Poster Session & Networking

Chesebrough Auditorium

Chrysler Center, North Campus

The University of Michigan

2121 Bonisteel

Ann Arbor, MI 48109 -2092

Organized by the

Automotive Research Center

A U.S. Army Center of Excellence for Modeling and Simulation of Ground Vehicles

In accordance with Cooperative Agreement W56HZV-14-2-0001

U.S. Army Tank Automotive Research, Development and Engineering Center

(TARDEC)

College of Engineering

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

SPEAKER INFORMATION

MR. NIGEL FRANCIS is senior automotive adviser to the state of Michigan and senior vice president,

Automotive Industry Office, Michigan Economic Development Corporation. Nigel is charged with developing, implementing and executing a comprehensive strategic plan and road map to promote, retain and grow the automotive industry in Michigan. He serves as the state’s central connection point for automotive industry stakeholders and engages with them to drive action that supports the industry and

Michigan’s overall economic growth strategy.

Nigel comes to state government with 29 years of executive experience in the global automotive sector encompassing both technical and technology management in North America, Europe and Asia. He has worked with multinational senior management both at OEMs and Tier I suppliers. Nigel has a global awareness of startups, small, medium and large corporations, turnarounds, and mergers and acquisitions. With a record of successfully building and leading diverse cross functional teams across different continents, he is well versed in global business cultures and values collaboration at all levels. He has spent a majority of his career in advanced design and engineering product development and in recent years has been closely involved with clean tech through EV/HEV/PHEV vehicle development. Nigel has held executive level positions at

OEM and Tier I companies in North America and Europe, including chief engineering and program management for Tata

Technologies; COO and chief technology officer at Trexa LLC; executive vice president, Bright Automotive; vice president, vehicle engineering at Mercedes-‐Benz Technology, and several C-‐level positions in product development and technology.

Nigel holds a Bachelor’s of Science degree from Brunel University in London, England. Professional affiliations include fellow,

Institute of Mechanical Engineers of Great Britain; chartered engineer-‐Great Britain; and advisory board member to the

University of Michigan's Michigan Mobility Transformation Center's (MTC) External Advisory Board and to Purdue University

School of Engineering Technology.

DR. DAVID GORSICH was selected for a Scientific and Professional (ST) position in January 2009 and serves as the Army’s Chief Scientist for Ground Vehicle Systems. His current research interests are vehicle dynamics and structural analysis, reliability-‐based design optimization, underbody blast modeling, terrain modeling and spatial statistics. He is the primary technical advisor to the Director of TARDEC and responsible for the organization’s science and technology strategy, as well as the review of TARDEC’s basic research programs. He is the organization's primary focal point to organizations such as DARPA and Army

Research Office (ARO), and serves as the technical expert for the U.S. Army National Automotive Center.

Previously Dr. Gorsich was the Director of Strategic Plans and Programs at TARDEC, and the Associate

Director for Modeling and Simulation.

As TARDEC's Associate Director for Simulation, he also was responsible for the Center's High Performance Computing program.

Before 2003, Dr. Gorsich served as a research scientist in TARDEC's Robotics Lab as well as the leader of the National

Automotive Center's Vehicle Intelligence team. He has held positions within the Program Managers’ offices, and with the Army in Washington D.C. He has published over 150 conference and journal articles in the areas of simulation, reliability-‐based design optimization, terrain modeling, spatial statistics and other approximation methods. He received his Ph.D. in applied mathematics from M.I.T. in 2000, his M.S. in applied mathematics from George Washington University in 1994, and his B.S. in electrical engineering from Lawrence Technological University in 1990.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

DR. PAUL ROGERS was selected to the Army Senior Executive Service in 2007. He currently serves as the

Director of TARDEC, which delivers advanced technology solutions for all Department of Defense ground systems and combat support equipment.

As TARDEC Director, Rogers manages a workforce of more than 1,700 engineers, scientists, researchers and support staff, and sets strategic direction affecting more than 270 Army systems.

Rogers previously served as the Deputy Program Executive Officer for Ground Combat Systems where he managed the development, systems integration, acquisition, testing, fielding, sustainment and improvement of ground combat systems in accordance with the Army's transformation campaign plan.

Prior to that, Rogers served as the TARDEC Executive Director for Research and Technology Integration, providing Army research and development in Ground Vehicle Power and Mobility, Survivability, Intelligent Systems, Vehicle Electronic and

Architecture Systems, and Platform Concept, Analysis, and System Simulation.

As a member of the Michigan National Guard, Rogers was activated and served in Iraq as the Battalion Commander for the

507th Engineer Battalion at Balad, Iraq, in support of Operation Iraqi Freedom from 2004-‐06.

Dr. Rogers holds a Ph.D. in Mechanical Engineering-‐Engineering Mechanics from Michigan Technological University (MTU), a

Master’s of Strategic Studies from the U.S. Army War College, a Master’s of Science in Engineering – Mechanical Engineering from the University of Michigan–Dearborn, and a Bachelor of Science in Mechanical Engineering from MTU. He has also served as an Adjunct Professor of Mechanical Engineering at Lawrence Technological University.

MR. PATRICK DAVIS is the Director of the Vehicle Technologies Office in the Office of Energy Efficiency and

Renewable Energy (EERE) at the U. S. Department of Energy (DOE). Patrick Davis leads an array of activities that help reduce America's dependence on foreign oil and secure a clean energy future. The Vehicle

Technologies Office supports about $330 million in annual research funding for hybrid drivetrains, advanced batteries, lightweight materials, advanced combustion and fuels, vehicle systems integration, and Clean Cities deployment activities.

He is responsible for three major government and private industry partnerships: the U.S. DRIVE Partnership

(Driving Research and Innovation for Vehicle Efficiency and Energy Sustainability), the 21st Century Truck Partnership and

DOE's EV Everywhere Grand Challenge. He also led the launch of the National Clean Fleets Partnership, the SuperTruck

Program, the Advanced Vehicle Power Technology Alliance with the U.S. Army, the EcoCAR2 collegiate competition, and the

Workplace Charging Challenge.

With more than 30 years of experience in the development of vehicle, alternative fuel, and electrochemical technologies, he adds a wealth of expertise to EERE. He previously served as EERE's Senior Advisor for Transportation Technologies, Acting

Director for EERE's Fuel Cell Technologies Office, Team Lead for Hydrogen Production, Team Lead for Fuel Cell Technology, co-‐ chair of two FreedomCAR and Fuel Partnership Technical Teams, and the U.S. representative to the International Energy

Agency's Hydrogen Implementing Agreement. He is a recipient of the Presidential Rank Award for Meritorious Executive. He holds a Bachelor of Science degree in Chemical Engineering from the University of Maryland.

MR. JEFFREY SINGLETON began his career as a research engineer with the Department of the Army, first in the field of experimental rotorcraft testing and analysis then later as Team Leader and Division Chief for rotorcraft dynamics, structural mechanics, and aeromechanics. His extensive background in science and technology investigation spans more than two decades of fundamental research, advanced technology development and acquisition.

Mr. Singleton earned his Bachelor of Science degree in Aerospace Engineering from West Virginia

University where he graduated magna cum laude in 1980. He also earned a Master of Science in Aerospace

Engineering from the Georgia Institute of Technology in 1988, specializing in aeroelasticity.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

He currently serves as Director for Basic Research and acting Director for Laboratory Management and Educational Outreach for the US Army, directing the basic research program as well as laboratory management policy for all Army laboratories, research, development and engineering centers—including the Army’s Basic Research programs spanning 12 basic research disciplines and 14 technology areas at the Army Research Laboratory, Army Research Institute, the Army Corps of Engineers, the Medical Research and Materiel Command, and the Space and Missile Defense Technical Center. He also oversees

Environmental Quality technology, Manufacturing Technology, Small Business Innovative Research, and Army High

Performance Computing programs—with a combined annual budget of approximately $500M. His responsibility encompasses policy for workforce development, personnel systems, laboratory infrastructure, and laboratory security.

From July 1984 to May 2006, Mr. Singleton was employed by the Army Aviation Systems Command and the Army Research

Laboratory Vehicle Technology Directorate located at NASA Langley Research Center in Hampton, Virginia. During this time,

Mr. Singleton was primarily responsible for experimental and analytical research exploring new technologies and designs for advanced rotor performance, reducing rotor vibrations, and measurement and prediction of rotor aeromechanical stability for both conventional helicopters as well as tiltrotor configurations. From May 2006 to January 2007, Mr. Singleton served as the

Army Research Laboratory liaison officer to the Office of the Deputy Assistant Secretary of the Army, Research and Technology.

In January 2007, Mr. Singleton returned to the Vehicle Technology Directorate to serve as the acting Division Chief for the

Mechanics Division, leading a group of researchers in the fields of structural mechanics, loads and dynamics testing and analysis, and rotor aeromechanics. From November 2007 through May 2010, Mr. Singleton served as the Deputy Director for

Research in the Office of the Deputy Assistant Secretary of the Army (Research and Technology). In May 2010 to January 2011, he was temporarily appointed to the Senior Executive Service as acting Director for Research and Laboratory Management for the Army.

Mr. Singleton’s awards include the 2006 Army Research Laboratory Honorary Award for Leadership, and in 2007 he received the Superior Civilian Service Award for his contributions to the US Army as Liaison Officer to the Office of the Deputy Assistant

Secretary of the Army, Research and Technology. Also in 2007 he was awarded the American Helicopter Society’s Howard

Hughes Award as team leader for the Army/NASA/Bell Quad Tiltrotor Aeroelastic Test Team given in recognition of an outstanding improvement in fundamental helicopter technology. Mr. Singleton has authored more than 50 journal articles, conference publications and presentations.

PROF. PANOS Y. PAPALAMBROS is the James B. Angell Distinguished University Professor and the

Donald C. Graham Professor of Engineering. He is a Professor of Mechanical Engineering, Professor of

Architecture, and Professor of Art and Design; and serves as the founding Chair of the Integrative

Systems & Design Division, College of Engineering, at the University of Michigan.

Born in Patras, Greece, he attended the National Technical University of Athens (Ethnikon Metsovion

Polytechnion) and earned a diploma in Mechanical and Electrical Engineering in 1974. Moving to

California he attended Stanford University and earned his M.S. degree (Mechanical Engineering) in 1976 and Ph.D. degree (Design Division, Mechanical Engineering) in 1979. At Michigan he has served as a faculty member since

1979.

During his tenure at Michigan he served as mechanical engineering department chair (1992-‐98, and 2007-‐08) and was the founding director of several laboratories and centers: Optimal Design (ODE) Laboratory (1980-‐); Design Laboratory (1990-‐92);

Ford Durability Simulation Center (1992-‐94); Automotive Research Center (1994-‐2003); General Motors Collaborative Research

Laboratory (1998-‐2002); the Antilium Project (2003-‐2008), and the Ford BlockM Sustainability Laboratory (2006-‐2009); he served as the founding chair and director of the University of Michigan interdisciplinary Design Science Doctoral Program

(2006-‐2011).

His research interests include design science and optimization, with applications to sustainable design of products, automotive systems, such as hybrid and electric vehicles; design of complex engineered systems; and architectural design. With D. J. Wilde, he co-‐authored the textbook Principles of Optimal Design: Modeling and Computation (1988, 2000). He has published over 320 articles in journals, conference proceedings, and books.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

He is a member of ASME, INFORMS, MOS, SME, SAE, ISSMO, AIAA, AAUP, ASEE, IEEE, INCOSE and serves as Vice President on the Board of Management of the Design Society. He served as Chief Editor of the ASME Journal of Mechanical Design (2008-‐

2012) and as associate editor of the Journal of Mechanisms, Transmissions and Automation in Design, Journal of Global

Optimization, Computer-‐Integrated Engineering, and the Japan Society of Mechanical Engineers International Journal. He currently serves on the editorial boards of the journals Artificial Intelligence in Engineering Design and Manufacturing,

Engineering Design, Engineering Optimization, Structural and Multidisciplinary Optimization, Journal of Reliability and Safety and Product Development.

He is a Fellow of ASME and SAE, and the recipient of the ASME Design Automation Award (1998), ASME Machine Design Award

(1999), Japan SME Design and Systems Achievement Award (2004), ASME Joel and Ruth Spira Outstanding Design Educator

Award (2007), and the Stephen S. Attwood Award (highest engineering honor in the University of Michigan, 2009).

PROF. WALTER BRYZIK Currently a professor at Wayne State University, Walter Bryzik served as the Chief

Scientist of the US Army Tank-‐Automotive Research, Development, and Engineering Center (TARDEC). He is one of two individuals who hold the Army's highest Scientific/Technical Rank (ST-‐5) in recognition of his pioneering technical achievements as a world class leader in advanced ground vehicle technology. He was

National Chair of the Army Senior Level Scientists organization and has served as Co-‐chair of the Defense

Senior Level Scientists organization. Bryzik served at TARDEC in various capacities since 1968, and previously as a research engineer at the Ford Motor Company Research Center.

He founded the SEA National Army ST Chapter, which won a Chapter of the Year Award in 1993. He has served as a prime advocate within SEA for Senior Level Scientific/Technical Professionals, working on issues such as pay equity, and presidential rank award recognition for senior professionals.

Bryzik received a Distinguished Presidential Rank award and has also been elected as a Fellow Grade member of the Society of

Automotive Engineers (SAE). Other awards include the Socius Collegii Award (Wayne State University), SAE Arch T. Colwell

Award, Army Science Conference Gold Medallion Award, Federal Scientist of the Year Award, and Japanese Government

National Award for Cooperative Science. He received a B.A. (Magna Cum Laude) in Engineering from the University of Detroit, an M.S. and Doctorate in Engineering from the University of Detroit; and an M.A. in Business Management, Central Michigan

University.

PROF. IMTIAZ HAQUE is Executive Director of the Carroll A. Campbell Graduate Engineering Center and

Founding Chair of the Department of Automotive Engineering at Clemson University. He is past chair of the

Department of Mechanical Engineering. His teaching and research interests lie in the general areas of dynamics, vibrations, mechanisms and machines, and manufacturing process simulation. He has been involved with the design, modeling, and simulation of mechanical systems including vehicles and transmissions since 1975. He led the development of the Graduate Program in Automotive Engineering at

CUICAR.

Dr. Haque is a Fellow of the American Society of Mechanical Engineers and a member of the Society of Automotive Engineers.

He has conducted research for and served as consultant to private industry and federal agencies. In 1996-‐97 he spent his sabbatical year at the BMW Research and Engineering Center in Munich, Germany. Dr. Haque has published over 100 refereed papers and has served as Pi or co-‐PI on grants totaling over $100M. He serves on the editorial board of the International

Journal of Heavy Vehicle Systems and as paper and proposal reviewer for numerous journals, conferences, and funding agencies.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

PROF. CHRISTOPHE PIERRE A Professor of Mechanical Science and Engineering, Christophe Pierre received his engineer diploma from Ecole Centrale de Paris (France) in 1982, M.S. degree from Princeton University in 1984, and Ph.D. from Duke University in 1985. Dr. Pierre is a distinguished scholar in the fields of vibrations, structural dynamics and nonlinear dynamics. His pioneering research on mode localization in disordered periodic structures led to his development of vibratory response models and prediction software that have been licensed to all major jet engine manufacturers worldwide, the U.S. Air Force, and

NASA. Formerly a chaired professor of mechanical engineering at the University of Michigan and the Dean of Engineering at McGill University, he came to Illinois in 2011 in his current role as the chief academic officer for the University of Illinois.

COLONEL SCOTT LATHROP is a former Armor/Cavalry officer and currently an Information Systems

Management Officer (Functional Area 53) in the United States Army. He is currently assigned as the

Deputy Director, Advanced Capabilities Directorate, United States Cyber Command Fort Meade,

Maryland. Colonel Lathrop’s previous assignments include strategic development, United States Cyber

Command, Associate Professor and Senior Research Scientist, Department of Electrical Engineering and

Computer Science, United States Military Academy, West Point, New York; Computer Science and

Information Technology Mentor, National Military Academy of Afghanistan, Kabul Afghanistan; Chief, Data

Support Division, United States Command and Control Agency, Army Operations Center, Pentagon; Tank

Company Commander, 1-‐32 Armor, Chief Plans Officer, 3d Brigade, 2d Infantry Division, and Personnel planner, I Corps G-‐1,

Fort Lewis, WA; Troop Executive Officer, 1/16 Cavalry, Fort Knox, Kentucky; and Troop Executive Officer and Scout Platoon

Leader, 11th Armored Cavalry Regiment, Bad Hersfeld, Germany. Colonel Lathrop is a distinguished graduate from the United

States Military Academy (USMA) and holds a Ph.D. in Computer Science and Engineering from the University of Michigan. His research interests include cyber-‐physical systems, robotics, and cognitive architectures. Colonel Lathrop received the Draper

Leadership Award as a Tank Company Commander, was recognized for teaching excellence while a professor at West Point, and is a nationally known researcher publishing over 20 articles in peer reviewed conferences, journals, and books. He is an early developer of the Military Academies and the National Security Agency’s nationally recognized Cyber Defense Exercise and also an early contributor to the United States Military Academy’s robotics program.

DR. ANDREAS MALIKOPOULOS is the Deputy Director of the Urban Dynamics Institute and an Alvin M.

Weinberg Fellow with the Energy & Transportation Science Division at Oak Ridge National Laboratory

(ORNL). He received a Diploma in Mechanical Engineering from the National Technical University of Athens,

Greece, in 2000, and M.S. and Ph.D. degrees from the Department of Mechanical Engineering at the

University of Michigan, Ann Arbor, in 2004 and 2008, respectively. Before he joined ORNL, he was a Senior

Researcher with General Motors Global Research & Development, conducting research in the area of stochastic optimization and control on advanced propulsion systems.

His research interests span several fields, including analysis, optimization, and control of stochastic systems; stochastic optimal control; nonlinear optimization and convex analysis; large-‐scale optimization; and learning in complex systems. The emphasis is on applications related to energy, transportation, and operations research. Dr. Malikopoulos is the recipient of several prizes and awards, including the 2007 Dare to Dream Opportunity Grant from the University of Michigan Ross School of Business, the

2007 University of Michigan Teaching Fellow, and the 2010 Alvin M. Weinberg Fellowship at ORNL. He has been selected by the National Academy of Engineering to participate at the annual 2010 German-‐American Frontiers of Engineering Symposium, and the 2012 NAKFI conference, The Informed Brain in a Digital World.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

DR. BIN WU is currently the Manager of Electric Motor Core Control at Mercedes-‐Benz Research and

Development, North America (or MBRDNA). MBRDNA is a wholly-‐owned subsidiary of Daimler with four divisions and various locations in California and Michigan. MBRDNA was founded in 1994 and is dedicated to developing safe, sustainable and technologically advanced vehicles for Mercedes-‐Benz Cars and other

Daimler Group business units. At his current position, Bin is leading an engineering group in developing electric motor control software. The e-‐motor control software has been used in two generations of traction inverters for electrified Daimler vehicles. For automotive application, lots of efforts are focused on diagnostics and functional safety features in addition to making the motor run. Before joining MBRDNA,

Bin worked as Product Engineer for DaimlerChrysler and later for Chrysler LLC. He was responsible for Hybrid Electric Vehicle powertrain operating strategy. He was a member of the Hybrid Development Center-‐-‐the joint venture to develop Two-‐Mode full hybrid vehicles by GM, DaimlerChrysler and BMW from 2005 to 2009. The hybrid operating strategy was used in several vehicles under Mercedes-‐Benz, Dodge, Chrysler, Cadillac, Chevy and BMW brand names. Bin is an alumnus of Automotive

Research Center. He graduated from the University of Michigan with his PhD degree in Mechanical Engineering in 2006. He got his Master degree in Electric Engineering from the same school in 2003. He also holds a Master Degree in Thermal Engineering in 2005 and a Bachelor Degree in Thermal Engineering in 1995, both from Tsinghua University, Beijing, China.

PROF. DENISE McKAHN is an Assistant Professor of Engineering Science at Smith College, Northampton,

MA, United States. Dr. McKahn obtained her B.S. (2002, Humboldt State University, CA) in Environmental

Resources Engineering with a focus on Renewable Energy Power Systems. She then received her M.S.

(2005, University of Michigan, MI) in Mechanical Engineering and Ph.D. in Environmental Engineering

(2008, University of Michigan, MI). Prior to graduate school, she was a Research Engineer at the Schatz

Energy Research Center (1998-‐2002).

Dr. McKahn is dedicated to the development of renewably derived fuel and electricity generation technologies through the design, modeling and control of dynamic and complex systems. She is particularly interested in both fuel cell electricity and electrolytic hydrogen production in power system applications that span the automotive, residential and aeronautic industries.

PROF. TIM JACOBS is associate professor and undergraduate program coordinator of mechanical engineering at Texas A&M University, College Station, Texas. His research interests lie in the general area of thermodynamics with specific emphasis on internal combustion engines, alternative fuels, and emissions reductions.

His teaching interests include thermodynamics and internal combustion engines. He received his BSE, MSE, and Ph.D in 1999, 2002, and 2005, respectively, from the University of Michigan (Ann Arbor). His MSE research was funded by the Automotive Research Center at University of Michigan between 1999 and

2002, where he conducted studies of exhaust gas recirculation on heavy-‐duty diesel engines observing its effect on engine efficiency and emissions.

MR. DAVID THOMAS is the director of the U.S. Army Tank Automotive Research, Development and

Engineering Center’s (TARDEC’s) National Automotive Center (NAC). His focus is on facilitating joint efforts between industry, government and academia to address critical gaps in the TARDEC ground vehicle community research, development and engineering community

Prior to joining the NAC, Mr. Thomas served as TARDEC’s associate director for Ground Vehicle Robotics. In his more than seven years there his responsibilities included managing and directing a portfolio of more than 40 projects in human machine interface and robotic systems design, development and evaluation. He oversaw various laboratories and more than 60 engineers and scientists developing and leading the state of the art in perception, control, interface and platform solutions.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

Earlier in his career he served in a number of capacities as one of TARDEC’s research engineers with a focus on topics from image processing and simulation to material sciences. Later in his career, Mr. Thomas designed, launched and managed

TARDEC’s skunk works facility. In this facility he and his staff designed, fabricated, and tested a number of unique specialized classified vehicles.

Mr. Thomas’s career at TARDEC spans 32 years with research specialties in Vehicle dynamics, advanced sensors, machine vision, artificial intelligence, mobile robotics and human machine interface as well as survivability technologies. Mr. Thomas has written and co-‐authored more than 40 technical papers in these areas and is a regular speaker on these topics. Mr.

Thomas earned a bachelor’s of science in Electrical Engineer from Michigan Technological University in Houghton, Mich., and a master’s of science in Computer Science from Wayne State University in Detroit, Michigan.

DR. PING LIU currently serves as a Program Director at the Advanced Research Projects Agency – Energy

(ARPA-‐E), where he initiated and manages the RANGE program aimed at developing innovative energy storage solutions for electric vehicles. In addition, he has broad interests in advanced materials for energy efficiency and manages the REACT program which develops rare-‐earth free permanent magnetic materials.

Dr. Liu was previously Manager of Energy Technology at HRL Laboratories, an industrial research company jointly owned by the Boeing Company and General Motors. At HRL, Dr. Liu led a broad range of research activities in energy conversion and storage for owner companies as well as government and commercial customers. Prior to joining HRL in 2003, Dr. Liu was a member of the technical staff at the National

Renewable Energy Laboratory (NREL). At NREL, Dr. Liu conducted research in thin film batteries, electrochromics, and optical hydrogen sensors. He contributed to several inventions that have been transitioned to industry for commercialization and received an R&D 100 Award from R&D Magazine for a solid-‐state battery technology. Dr. Liu has published more than 60 archival journal papers and has more than 40 issued or pending patents. He received his B.S., M.S. and Ph.D., all in chemistry, from Fudan University in China.

DR. PARAMSOTHY JAYAKUMAR is a Senior Research Scientist, SAE Fellow, and a member of the Analytics

Team at the U.S. Army Tank Automotive Research, Development, & Engineering Center (TARDEC) in

Warren, Michigan. Prior to joining U.S. Army TARDEC, he worked for BAE Systems, Ford Motor Company,

Altair Engineering, and Engineering Mechanics Research Corporation in the areas of multibody dynamics software development, vehicle dynamics modeling & simulation consulting, simulation technology development, durability load simulation, vehicle instrumentation & loads measurement, and road load engineering. Jayakumar has written more than 100 technical publications including journals papers and conference proceedings. His research in terramechanics and multibody dynamics won the best paper awards at the National Defense Industrial Association's Ground Vehicle Systems Engineering and Technology Symposium in

2011 and 2012. He holds a U.S. patent for a system for virtual prediction of road loads and tire modeling. He was also instrumental in developing seven SAE standards for tire testing for the purpose of tire modeling for which he received the SAE

2014 James M. Crawford Technical Standards Board Outstanding Achievement Award. Jayakumar is a member of the U.S. Army

Acquisition Corps, an Honorary Fellow of the Department of Mechanical Engineering at the University of Wisconsin – Madison, and an Associate Editor for the ASME Journal of Computational and Nonlinear Dynamics. He received his M.S. and Ph.D. degrees in structural dynamics from Caltech, and B.Sc. Eng. (Hons, First Class) from the University of Peradeniya, Sri Lanka.

AWARDS COMMITTEE

DR. RAVI THYAGARAJAN serves as Deputy Chief Scientist at the U.S. Army Tank Automotive Research,

Development and Engineering Center (TARDEC), and was selected to the Researcher Review Board as a

Senior Technical Specialist in June 2012. His research pursuits are in the areas of underbody blast modeling and design, occupant protection and fast-‐running modeling methodologies. He received his Ph D in Applied

Mechanics from Caltech in 1990, and has over 15 years of prior experience in the automotive industry at

Ford and Visteon. He is a past recipient of the Forest R McFarland Award from SAE, holds two patents and has co-‐authored over 40 technical papers.

20 TH ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

DR. THOMAS MEITZLER received his B.S. and M.S. in Physics from Eastern Michigan University, completed graduate coursework at the Univ. of Michigan, and received a Ph.D. in Electrical Engineering from Wayne

State University in Detroit. His doctoral dissertation in Electrical Engineering at Wayne State Univ. was on

Modern Methods for Computing the Probability of Target Detection in Cluttered Environments .

During the time from 1988 to present, Dr. Meitzler has been a research engineer at the US Army TACOM

Research and Engineering Center (TARDEC) in Survivability. For the U.S. Army, Dr. Meitzler has been involved with the validation, verification, and development of electro-‐optical and human visual acquisition models and atmospheric simulation. Dr. Meitzler was the principal scientist of the TARDEC Visual Perception Laboratory and the principal investigator on a CRADA with GM and Ford M.C. to apply visual acquisition models to vehicle conspicuity and novel sensors to automobile 360 degree safety. Dr. Meitzler has been the lead on several CRADA’s with NASA’s Kennedy Space

Center and with the Columbia University College of Physicians and Surgeons. He has authored/co-‐authored many papers in the area of Electro Optic system simulation and visual detection, sensor validation, and non-‐destructive testing and evaluation of armor materials.

Dr. Meitzler is currently developing and integrating technologies for embedded health monitoring, armor NDE and embedded signal detection His research interests include infrared sensor characterization, non-‐destructive testing, nano electronics, and spintronics. Dr. Meitzler proposed a method for embedded armor health assessment that involves piezoelectric transducers and nano electronics and built a laboratory around that idea. Dr. Meitzler is a Survivability Senior Technical Expert.

MS. JILLYN ALBAN is currently an Electrical Engineer at the U.S Army Tank Automotive Research,

Development and Engineering Center (TARDEC). She is working with the Ground Domain Planning and

Integration group to develop the 30-‐year strategy and funding associated to the prioritization within the strategy.

Prior to joining the GDPI team, Ms. Alban represented TARDEC as a Liaison Officer at Office of Assistant

Secretary of the Army (Acquisitions Logistics and Technology) where she was responsible for any TARDEC related occurrence within Army Headquarters. She then moved to the Office of Secretary of Defense to engage with the tri-‐service ground vehicle related efforts focusing on the ground vehicle platforms going through the DoD acquisition cycle and energy and power technology development. Her final assignment in Washington DC was with the Office of Naval Research (ONR) serving as a project engineer in Expeditionary Maneuver Warfare and Combating Terrorism

Department. At ONR she focused on the Survivability, Advanced Mobility and Maneuver Enablers within the Maneuver Thrust.

Ms. Alban has a B.S. in Electrical Engineering and a M.S. in Engineering Management from Oakland University as well.

She received the Army Research and Development Achievement Award for Ground Vehicle Control Aids for Improved Mobility with Indirect Vision, Drive-‐By Wire Crew Stations. She is also an Army Acquisition Corps Member.

PROF. BOGDAN EPUREANU is a professor of Mechanical Engineering, University of Michigan. He obtained his Ph.D. in Mechanical Engineering at Duke University, 1999; Graduate Studies at University of

Valladolid, 1994; M.S. in Mechanical Engineering at Galati University, 1993; and Graduate Studies at École

Nationale Supérieure des Mines de Paris, 1992. His research interests include structural health monitoring and sensors based on nonlinear dynamics and chaos, linear and nonlinear reduced order models, pattern formation and control of chaos, computer fluid dynamics of unsteady flows, and nonlinear unsteady aerodynamics.

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

CASE STUDY ABSTRACTS

CASE STUDY 1

Any Fuel, Any Time, Anywhere: Systematic Development of Fuel Surrogates to Enable Simulation-

Based Engineering of Omnivorous Military Engines

The Army’s diesel engines must be capable of consuming globally sourced JP-8 fuels with a broad range of chemical and physical properties. The extent of these properties can be challenging, complicating operations such as cold starting and the combustion phasing control required for optimal engine efficiency and durability.

New military engine and control system designs are necessary to capitalize on continuous advances in power density, durability, and fuel economy and fuel flexibility. However, the emissions constraints and associated hardware and fuel requirements of the commercial sector are creating a divergence between military and commercial sector designs. The next generation of military engines must therefore be developed specifically for the Army’s unique requirements. The development process will involve an analytical component requiring a simplified representation of the real fuel, known as a surrogate.

A unique modeling framework has been developed here for the prediction of the surrogate fuel composition required to reproduce the chemical and physical properties of the real fuel. Experiments are then performed to validate and refine the surrogate and to provide further insight into its behavior relative to the real fuels. This framework is relevant to challenges faced by both the military and commercial sector, as alternative JP-8 and diesel fuels with widely varying properties become more prevalent.

CASE STUDY 2

Beyond Modular Vehicles: A Modeling Framework for Assessing Adaptability and Costs of a

Modular Vehicle Fleet

Whether to maintain the competitive edge in the commercial world or to maintain the dominance on the battlefield, it is critical more than ever to increase adaptability and flexibility to remain agile and responsive in rapidly changing and uncertain environments, to keep up with the fast-paced technological advancements, and to be highly cost effective while accommodating increasing complexity of ground vehicle systems.

Modularity in vehicle systems is considered by both the industry and Army to be a path to achieve this desired adaptability and flexibility and to create enduring value. This case study takes this idea further by envisioning a future where not only a vehicle, but the entire vehicle fleet is modular, and develops a comprehensive modeling framework to assess fleet adaptability and cost. The considered fleet comprises vehicles with diverse functionality and specifications, assigned to complete missions modeled stochastically. The framework models powertrain and armor, fleet operations, and transportation, operating, acquisition and retirement costs. Resupply strategy is optimized for a limited initial inventory.

Comparisons between the simulated conventional and modular fleets across several scenarios show that the modular fleet can improve adaptability while also lowering cost.

20

TH

AUTOMOTIVE RESEARCH CENTER ANNUAL PROGRAM REVIEW

22 MAY 2014

TECHNICAL SESSION 1

8:35 – 9:00

9:00 – 9:25

9:25 – 9:50

1A: Energy Storage

Session Leads: Mr. Paul Decker, Drs. Yi Ding

and Larry Toomey

Electro-Thermal Modeling of Large-Format Prismatic

Cells

Parametric Reduced-Order Models of Battery Pack

Vibration Including Structural Variation, Pre-Stress, and

Temperature Effects

Nano-Materials Design for Enhanced Thermal and

Mechanical Properties

TECHNICAL SESSION 2

1B: Vehicle Safety

Session Leads: Drs. David Lamb and Ravi Thyagarajan,

and Mr. Harry Zywiol

Eliminating Hysteresis Losses in Track Pads using

Meta-Materials

Light Weight Vehicle Structures that Absorb and Direct

Destructive Energy Away from the Occupant

Soldier Modeling for Improved Accommodation and

Safety

10:35 – 11:00

2A: Model-Based Optimization

Session Leads: Drs. Matt Castanier, Abul Masrur

and Wes Zanardelli

Identifying Experts in Crowdsourced Evaluations

11:00 – 11:25 New Time-Dependent Reliability Method for Vehicle

Systems with Application to Accelerated Life Testing

11:25 – 11:50 Multi-Objective Optimization and Thermal Management of the Vehicle Power System

11:50 – 12:15 Advanced Models for Electric Machines

2B: Vehicle Dynamics & Control

Session Leads: Drs. P. Jayakumar, Dariusz Mikulski

and Mark Brudnak

–

A Multi-Stage Optimization Formulation for Vehicle-

Dynamics-Conscious Obstacle Avoidance in

Autonomous Ground Vehicles

Flexible Multibody Dynamics Approach for Tire

Dynamics Simulation

Teleoperation of UGVs with Latency: Understanding

How Constant and Variable Latencies Affect User

Performance

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

TECHNICAL SESSION ABSTRACTS

Day 1 Technical Session 1A – Energy Storage

Session Leads: Mr. Paul Decker, Drs. Yi Ding and Larry Toomey

1A1: Electrochemical-Thermal Modeling of Large-format Prismatic Cells

Quad members: Charles W. Monroe (PI), Lynn Secondo, Saeed Khaleghi Rahimian, Jason Siegel, and Anna

Stefanopoulou, University of Michigan; Yi Ding, U.S. Army TARDEC; Dyche Anderson, Ford

Large-format prismatic Li-ion cells exhibit significant in-plane temperature variation during operation at high power, which may impact performance and battery life. Experimental data and analytical theory have been produced to illustrate how the characteristic properties of materials within battery cells and heat-transfer characteristics of cell surfaces determine the thermal response and the distribution of charge state within electrode materials. A data-fitting approach based on dimensionless parameters predicts surface-average temperature, as well as maximum and minimum temperature, in a large-format A123 prismatic cell at various C-rates. An augmented, five-parameter mechanistically based model has been developed to account for the possibility of front/rear temperature asymmetry, and to account for the time variation of cell voltage during pulse charge/discharge experiments. Coupling between the distribution of charge state and thermal response of battery cells will be illustrated, as will changes in effective heat- transfer coefficients due to air flow past the battery cell.

1A2: Parametric Reduced-Order Models of Battery Pack Vibration Including Structural Variation, Pre-Stress, and Temperature Effects

Quad members: Jau-Ching Lu, Kiran D’Souza, Bogdan I. Epureanu (PI), University of Michigan; Matthew P.

Castanier US Army TARDEC

Designing complex battery packs used in hybrid electric vehicles is time-consuming due to the variety and large range of parameters involved. To efficiently predict the structural dynamics of a pack, a method is developed to construct parametric reduced-order models (PROMs). PROMs capture three types of parametric variations: (1) variation of the pre-stress level from joining cells in the pack, (2) cell-to-cell variation in structural parameters such as stiffness or thickness, and (3) temperature variation due to heating and cooling in charge-discharge cycles that cause thermal stresses. The PROMs are built only once.

They take parameter values as inputs, and they can then be used to predict the structural dynamics of the pack for the ranges of interest without the additional use of full-order finite element models (FEMs) and without computationally expensive reanalysis. The PROM results are validated by comparisons with results from much more expensive FEMs of the same system.

1A3: Nano-Materials Design for Enhanced Thermal and Mechanical Properties

Quad members: Levi Thompson (PI), Siu on Tung, University of Michigan; Yi Ding, U.S. Army TARDEC; Hans

Herferth, Fraunhofer USA

Layered transition metal oxides are widely used in commercial lithium ion batteries due to their high capacities and energy densities but their rate capabilities and stabilities are relatively poor. We aim to improve these properties by modifying the two-dimensional nano-architecture via introduction of nano-scale pillars between the lattice layers. As a proof of concept, we produced layered vanadium oxide (V

2

O

5

) xerogels pillared with aluminum keggin ions (Al

13

O

4

(OH)

24

(H

2

O)

12

7+

) ). The interlayer spacing increased by 2 Å while the specific capacity increased from 120 to 150 mAh/g at C/10. The rate capability improved significantly as evidenced from the increased capacity at high currents. Furthermore, the pillared material was able to withstand temperatures up to 350 °C compared to 300 °C, the temperature where the unlayered material typically collapses.

This work serves as an example that the rate capability and thermal stability of layered metal oxide materials can be improved via a pillared nano-architecture.

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

Day 1 Technical Session 1B – Vehicle Safety

Session Leads: Drs. David Lamb and Ravi Thyagarajan, and Mr. Harry Zywiol

1B1: Eliminating Hysteresis Losses in Track Pads Using Meta-Materials

Sampath V. Dangeti, Dr. Georges Fadel (PI), Dr. Gang Li, Dr. Nicole Coutris, Clemson University

The highly dynamic nature of road wheel-track interaction and the inherent hysteretic property of elastomers, cause high temperatures in track pads. The objective of this work is to explore the use of linear elastic meta-materials with optimized topology to replace elastomers and reduce or eliminate the effect of hysteretic loss.

This work presents a methodology to design an alternate meta-material that can provide some of the desired elastic properties of the track pads. To determine the requirements for linear elastic meta-materials, dynamic numerical analyses of a rollover event were conducted. These analyses revealed that failure in track pads may occur due to a combination of tension, compression and shear stresses. Due to nonlinearity of elastomers, tangent stiffness matrices are required to update the stress state in consequence of a new strain increment. The tangent operators determined at a set of strain levels, can be used as prescribed constitutive parameters to tailor the meta-material unit-cell topology.

1B2: Light Weight Vehicle Structures that Absorb and Direct Destructive Energy away from the Occupant

Quad members: Weiran Jiang, (GSRA, Presenter), Dr. Nick Vlahopoulos (PI), University of Michigan; Dr. Syed

Mohammad, M-ATV (Army), SFAE-CS-MRAP/MS 298; Dr. Ravi Thyagarajan, U.S. Army TARDEC; Dr. Nam

Purush, BAE Systems

Pursuing occupant centric vehicle structures that provide safety from explosive threats while at the same time make the operation of the vehicle comfortable and safe for the soldiers, comprises one of the main thrusts in the Army S&T activities. It has been previously demonstrated that delaying and controlling the contact between a vehicle and an occupant reduces the loads developed in the occupant’s members. The characterization of properties associated with a “softer” steel material that can be used for absorbing the destructive energy through deformation is considered. Utilization of anisotropic material properties will be investigated for guiding the destructive energy into sacrificial parts of the vehicle structure made out of “soft” steel and away from the occupants. A summary of the research which has been conducted during the first year of this project will be presented.

First the use of anisotropic material and energy dissipation concepts were investigated for a flat plate. Based on the lessons learned, a model of the TARDEC V-Hull structure was used for increasing the occupant survivability by reducing the dynamic response index for injury. The direction of the research after completion of this initial effort will also be discussed.

1B3: Soldier Modeling for Improved Accommodation and Safety

Contributors: Matthew P. Reed, Jingwen Hu, Jonathan D. Rupp, K. Han Kim, Jionghua Jin, Yaser Zerehsaz,

University of Michigan; Zissimos Mourelatos, Dorin Drignei, Oakland University; Harry Zywiol, Gale Zielinski,

Rebekah Gruber, U.S. Army TARDEC

The recent ARC Seated Soldier Study provided a detailed set of data on Soldier postures and body shapes in vehicle seats, including the effects of body armor and body borne equipment. A range of projects currently underway are applying the knowledge gained in that study to improve Soldier accommodation and safety in future vehicles. A laboratory study is being conducted to quantify the effects of body armor and body borne gear on seated reach difficulty and capability. We are extending the Seated Soldier Study to focus on unusual driver workstation configurations, and a new seat measurement tool for squad conditions is being developed and evaluated. Finally, an extensive study involving simulation and physical testing is being conducted to improve protection in tactical vehicles for frontal crash and rollover conditions.

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

Day 2 Technical Session 2A – Model-based Optimization

Session Leads: Drs. Matt Castanier, Abul Masrur, Wes Zanardelli

2A1: Identifying Experts in Crowdsourced Evaluations

Presenters: Richard Gerth, Alex Burnap, Max Yi Ren; Contributors: Panos Papalambros (PI), Honglak Lee, Rich

Gonzalez, Max Yi Ren, Alex Burnap, University of Michigan; Richard Gerth, Kenneth Miller, Andrew Dunn, Lisa

Graf, Pradeep Mendonza, U.S. Army TARDEC; Damien DeClercq, Local Motors

Crowdsourced evaluation has shown promise in tasks such as large-scale image annotation for image databases.

Extending its use in engineering design evaluation presents a challenge as such tasks require ability that the majority of the participating crowd may not have. Identifying the relative number of high-ability evaluators (or experts) within the crowd is important for useful crowdsourced design evaluations. Previous work has shown that both experts and non-experts tend to cluster around particular design evaluations, so the new challenge is distinguishing the correct clusters of experts. In this talk, we discuss the impact of evaluator behavior (e.g., response time) and evaluator performance on related tasks (e.g., mechanical reasoning) along with recent advances in machine learning on identification of expert.

2A2: New Time-Dependent Reliability Method for Vehicle Systems with Application to Accelerated Life

Testing

Quad members: Zissimos P. Mourelatos (PI), Monica Majcher (Presenter), Igor Baseski, Oakland University;

Amandeep Singh , Igor Baseski, U.S. Army TARDEC

Reliability usually degrades with time, increasing the product lifecycle cost. It is desirable to use accelerated testing to predict vehicle reliability using a few tests of short duration and available simulation models. Because vehicle parameters and excitation are random, many vehicles must be tested which is impractical. To address this challenge, we use available tests to calibrate a simulation model which is then used to calculate the time-dependent reliability or failure rate of the vehicle fleet. Our approach depends on the calculation of time-dependent reliability. For that, we will present a new time-dependent reliability analysis method for dynamic systems with input random variables and input random processes. The total probability theorem is employed using time-dependent conditional probabilities which are computed exactly using FORM and a composite limit state of linear instantaneous limit states. Highlights of a new simulation-based approach will be also provided.

2A3: Multi-objective Optimization and Thermal Management of the Vehicle Power System

Quad members: Xinran (William) Tao, Xueyu Zhang, Andrej Ivanco (co-PI), John Wagner (PI) , Zoran Filipi (PI),

Clemson University; Denise Rizzo, Peter Schihl, U.S. Army TARDEC; Bin Wu , Mercedes-Benz Hybrid LLC; Dee

Kivett, Thermo-Pur Technologies

A unified, multi-physics hybrid electric vehicle simulation tool for the next-generation military trucks has been enhanced with the addition of the (a) finite element electric machine model provided by Dr. Hofmann’s group, (b) holistic cooling system design and control for the electrified powertrain, and (c) high-fidelity battery aging model. The new capabilities enable development of a framework for multi-variable, multi-objective optimization of the Vehicle Power System (VPS), integration and smart control of the e-driveline cooling system, and optimization of component design for system level goals.

Main highlights include: (i) E-machine cooling system controller for improved tracking of motor temperature with minimum actuator power consumption, (ii) Development of an implementable control strategy for VPS w/ battery cooling, and

(iii) integration of the battery fading model and pre-optimality study to guide model reduction and inclusion of the battery health objective in control optimization.

2A4: Advanced Models for Electric Machines

Quad members: Heath Hofmann (PI), Kan Zhou (student), University of Michigan; Wesley Zanardelli, Denise Rizzo,

U.S. Army TARDEC; Lei Hao , GM; Xiao Hu, ANSYS

In collaboration with: John Wagner, Xinran Tao, Zoran Filipi, Andrej Ivanco, Clemson University

The goal of this project is to provide computationally-efficient simulation and analysis tools for electric machines; specifically, tools which can aid in the design and control of electrified powertrains. In the past year, several aspects of advanced electric machine modeling have progressed and will be presented. First, thermal experiments of an entire electric machine were conducted to validate the 3D computationally-efficient thermal model developed in previous years. Locked-rotor test results show a good match between simulation and measurement. We have also made modifications to the model that have resulted in significant further reductions in computation time. Furthermore, a new scaling technique based on pole/slot scaling has been added to the efficiency map generation tool created last year to allow an extra degree-of-freedom for reshaping the efficiency maps of electric machines. Finally, preliminary results of our proposed reduced-order magneto-quasi-static machine model are presented.

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

Day 2 Technical Session 2B – Vehicle Dynamics & Control

Session Leads: Drs. P. Jayakumar, Dariusz Mikulski and Mark Brudnak

2B2: A Multi-Stage Optimization Formulation for Vehicle-Dynamics-Conscious Obstacle Avoidance in

Autonomous Ground Vehicles

Presenters: Jiechao Liu, University of Michigan; Brian Rapp, U.S. Army Research Lab.

Quad members: Jeffrey Stein (PI), Tulga Ersal (co-PI), Jiechao Liu (student), University of Michigan; Paramsothy

Jayakumar, U.S. Army TARDEC; Mitchell Rohde, Steve M. Rohde, Quantum Signal LLC

The dynamics of an autonomous unmanned ground vehicle (UGV) that is at least the size of a passenger vehicle are critical to consider during obstacle avoidance maneuvers to ensure vehicle safety. This talk will present a model predictive control based obstacle avoidance algorithm for high-speed, large-size UGVs that accounts for the dynamic limitations of the vehicle and the sensing and control delays, and provides smooth and continuous optimal solutions to safely minimize travel time. The obstacle avoidance problem is formulated as a multi-stage optimal control problem with a unique optimal solution. To solve the optimal control problem, it is transcribed into a nonlinear programming problem using a pseudo-spectral method, and solved using the interior-point method. The talk will also highlight our collaboration with the U.S. Army Research Laboratory to leverage the high power computing technology to meet the real-time computation requirements without compromising the problem formulation.

2B3: Flexible Multibody Dynamics Approach for Tire Dynamics Simulation

Quad members: Hiroyuki Sugiyama (PI), Hiroki Yamashita, The University of Iowa; Paramsothy Jayakumar, U.S.

Army TARDEC; Ryoji Hanada, Yokohama Rubber; SeeChew Soon, Caterpillar Inc.

Development of high-fidelity computational models for tire and soil interactions is crucial for accurate maneuverability evaluation of military ground vehicles in battlefields. In this investigation, the three- dimensional physics-based high-fidelity tire model is developed for off-road mobility simulation using the finite element absolute nodal coordinate formulation (ANCF) in the context of flexible multibody dynamics. To this end, a new locking-free shear deformable ANCF shell element was developed using general continuum mechanics approach for modeling the tire structure with anisotropic and incompressible material properties, and integrated into the general multibody dynamics computer algorithms. It is demonstrated with some numerical examples that the Enhanced Assumed Strain and Assumed Natural Strain approaches introduced to the continuum mechanics based bi-linear shear deformable ANCF shell element successfully alleviate thickness and shear locking.

Furthermore, the modeling procedure for the ANCF tire model for off-road mobility simulation is outlined.

2B4: Teleoperation of UGVs with Latency: Understanding How Constant and Variable Latencies Affect User

Performance

Quad members: Justin Storms, Dawn Tilbury (PI), University of Michigan; Dave Daniszewski, Paul Muench, U.S.

Army TARDEC; Mitch Rohde, Quantum Signal

Over the past few decades, many driver models for humans operating automobiles have been developed. However, driver models of humans teleoperating unmanned ground vehicles (UGVs) are as well-studied. Fundamental differences between operating manned and teleoperated vehicles stem from sensory feedback, input devices and latency. In an ARC project that finished last year, Vozar developed one of the first human driver models for UGV teleoperation. The long-term research objective of this project is to develop models that can be used to predict the performance of users controlling teleoperated mobile robots under different latency conditions and with semi-autonomous behaviors. Recent simulation results using driver models indicate that the mean and variance of the latency distribution are sufficient to describe the performance impact.

Ongoing user test results will expand existing models to higher fidelity teleoperation situations and wider latency characteristics.

#

1.10

1.13

1.15

1.16

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

Poster Session

Loca%on: Chrysler Center Gallery

#

2.7

Poster Title

3.1

Teleopera%on with Semi-‐Autonomous Behaviors and Latency:

User Modeling to Maximize System Performance

Commercializa%on of Research Code I-‐RBDO & Forma%on of RAMDO

Solu%ons, LLC

3.2

3.7

Confidence-‐Based Method for RBDO

Advanced Models for Fa%gue Life Predic%ons of Hybrid Electric Vehicle

BaYeries

Poster Title

Ultracapacitor and Lead-‐Acid Electric and Thermal Model

Valida%on using Electrochemical Impedance Spectroscopy and Pulse-‐Relaxa%on Methods

Reconfigurable Control for Energy and Thermal Management in

Unmanned Vehicles

Vehicle-‐Dynamics-‐Conscious Real-‐Time Hazard Avoidance in

Autonomous Ground Vehicles

Flexible Mul%body Dynamics Approach for Tire Dynamics

Simula%on

PI

Vahidi

Tilbury

Stein

Sugiyama

PI

Tilbury

Choi

Choi

Epureanu

3.8

3.9

3.10

4.4

4.6

4.9

Light weight vehicle structures that absorb and direct destruc%ve energy away from the occupant

Meta-‐material design for tank track pads

Valida%on Framework for Computer Simula%on

Op%miza%on of the Series-‐HEV system with Considera%on of the Trac%on

Motor Design and the Impact of BaYery Fading Losses

Surrogates for Predic%ve Combus%on Modeling – a Six-‐Component

Surrogate PaleYe for Various JP-‐8 fuels

Hybrid Electric Vehicle Thermal Management – Modeling and Control of the

BaYery Pack, Engine with Generator, and Electric Motor Temperatures for

Improved Efficiency and Cooling Stabiliza%on

Vlahopoulos

Fadel

Choi

Filipi

Violi

Wagner

4.12

4.13

4.15

4.17

4.18

4.19

4.20

4.21

4.22

5.3

5.7

5.8

5.A18

5.A24

Advanced Models for Electric Machines and Drives

Combined numerical and experimental study of baYery cooling towards ac%ve control

Electrochemical-‐Thermal Modeling of Prisma%c Li-‐ion Cells

Reac%on Pathway and Elementary Igni%on Behavior of Surrogates for JP-‐8 and

Alterna%ve JP-‐8 Fuels

Simula%on and Control of Combus%on in Military Diesel Engines

Valida%on of JP-‐8 Surrogates in an Op%cal Engine

Nano-‐Materials Design for Enhanced Thermal and Mechanical Proper%es

Bulk Modulus of Compressibility Measurements of

Conven%onal and Alterna%ve Military Fuels

Warm-‐up of Lithium-‐ion BaYeries from Sub-‐zero Temperatures

Development and Laboratory Implementa%on of an Accelerated Tes%ng

Method for Vehicle Systems using Time-‐Dependent Reliability / Durability

Principles

Henein

Jansons

Thompson

Boehman

Hofmann

Ma

Monroe

Boehman

Stefanopoulou

Mourelatos

Reliability, Maintenance and Op%mal Opera%on of Repairable Systems with

Applica%on to a Smart Charging Microgrid with V2G Capability

Iden%fying Experts in Crowdsourced Evalua%ons

A Novel Integrated Approach for a Resource-‐efficient Design Valida%on Co-‐ process

Beyond Modular Vehicles: A Modeling Framework for Assessing Adaptability and Costs of a Modular Vehicle Fleet

Mourelatos

Papalambros

Mourelatos

Papalambros

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

North Campus Map

Key

20

TH

ANNUAL AUTOMOTIVE RESEARCH CENTER PROGRAM REVIEW

For your internet needs on campus

•

Connect to MGuest WiFi network

•

Open your web browser;

the MGuest login page will appear

•