Lesson Plan Session Title:

advertisement

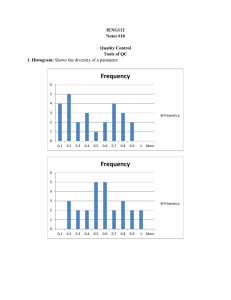

Lesson Plan Course Title: Manufacturing Engineering Session Title: Analyzing Quality Control Systems Performance Objective: After completing this lesson, students will be able to analyze quality control system issues in a computer integrated manufacturing process using concepts and principles of Pareto charts to the teacher’s satisfaction. Specific Objectives: Discuss the purpose of Pareto charts. Research and discuss terms used in the analysis of quality control issues. Discuss the importance of stratification in the development of Pareto charts. Preparation TEKS Correlations: This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Manufacturing Engineering: 130.329(c)(8)(D)(E) ...demonstrate the use of software to control instruments; …analyze attribute and Pareto charts. Interdisciplinary Correlations: Physics: 112.39(c)(2)(A)(B)(C)(D) ...know the definition of science and understand that it has limitations, as specified in subsection (b)(2) of this section; ...know that scientific hypotheses are tentative and testable statements that must be capable of being supported or not supported by observational evidence. Hypotheses of durable explanatory power which have been tested over a wide variety of conditions are incorporated into theories; ...know that scientific theories are based on natural and physical phenomena and are capable of being tested by multiple independent researchers. Unlike hypotheses, scientific theories are well-established and highly-reliable explanations, but may be subject to change as new areas of science and new technologies are developed; ...distinguish between scientific hypotheses and scientific theories; Copyright © Texas Education Agency, 2012. All rights reserved. 1 112.39(c)(3)(D) ...explain the impacts of the scientific contributions of a variety of historical and contemporary scientists on scientific thought and society; English Language Arts and Reading, English I: 110.31(b)(1)(E) ...use a dictionary, a glossary, or a thesaurus (printed or electronic) to determine or confirm the meanings of words and phrases... 110.31(b)(12) - Reading/Media Literacy. 110.31(b)(19) - Oral and Written Conventions/Spelling. 110.31(b)(24)(A) …listen responsively to a speaker by taking notes that summarize, synthesize, or highlight the speaker's ideas for critical reflection and by asking questions related to the content for clarification and elaboration; 110.31(b)(25) - Listening and Speaking/Speaking. Occupational Correlation: (reference: O*Net – www.onetonline.org) Industrial Engineers 17-2112.00 Similar Job Titles: Process Engineer, Engineer, Operations Engineer, Engineering Manager, Manufacturing Specialist, Plant Engineer, Supply Chain Engineer Tasks Plan and establish sequence of operations to fabricate and assemble parts or products and to promote efficient utilization. Review production schedules, engineering specifications, orders, and related information to obtain knowledge of manufacturing methods, procedures, and activities. Coordinate and implement quality control objectives, activities, or procedures to resolve production problems, maximize product reliability, or minimize costs. Recommend methods for improving utilization of personnel, material, and utilities. Apply statistical methods and perform mathematical calculations to determine manufacturing processes, staff requirements, and production standards. Soft Skills: Judgment and Decision Making; Complex Problem Solving; Critical Thinking; Listening Copyright © Texas Education Agency, 2012. All rights reserved. 2 Teacher Preparation: Teacher should review all supporting documents such as the Analyzing Quality Control Systems presentation and notes, Matching Terms and Definitions handout, and Pareto Chart Project worksheet. Teachers are also encouraged to conduct their own research on lesson material; and locate a variety of modern computerized manufacturing images to show students during the presentation such as, common products we purchase - phones, computers, shoes, cars and gaming equipment. Locate online videos of manufacturing processes that operate efficiently and address defects that occur during the production process to show during the introduction of the lesson. References: 1. O*Net – www.onetonline.org 2. Statistical Process Control: It's a Tool, Not a Cult, (2000) http://www.sme.org/Tertiary.aspx?id=35080&terms=statistical%20process%20control 3. The Secretary of Labor’s Report on OSHA Program Activity, P. 145-155, (2000) http://www.osha.gov/dep/fap/Final_Report_10_7_09.pdf 4. Improve your root cause analysis, (2005) http://www.sme.org/Tertiary.aspx?id=27486&terms=pareto%20charts Instructional Aids: 1. Analyzing Quality Control Systems presentation and notes 2. Matching Terms and Definitions answer key 3. Pareto Chart Project worksheet answer key 4. Warm-up activity (slide 3) Materials Needed: 1. Matching Terms and Definitions handout for each student 2. Pareto Chart Project worksheet for each student 3. Pen or pencil 4. Paper Equipment Needed: 1. Computer 2. Internet access (optional) 3. Overhead projector Learner Preparation: Students must have basic computer skills. Introduction Copyright © Texas Education Agency, 2012. All rights reserved. 3 Introduction (LSI Quadrant I): SAY: Having an understanding of analyzing quality control systems will greatly contribute to your career success. ASK: Have you ever thought about how we expect the products we purchase to be free of defects? SHOW: Images of common products we purchase such as, phones, computers, shoes, cars and gaming equipment. SAY: The analysis of quality control system issues in manufacturing help eliminate defective products from store inventory. ASK: When was the last time you had to return a product to the store because it was defective? SHOW: Online videos of manufacturing processes that operate efficiently and address defects that occur during the production process. Outline Outline (LSI Quadrant II): Instructors can use the presentation, slides, handouts, and note pages in conjunction with the following outline. MI Outline Notes to Instructor I. Introduction and Start of Lesson Begin the Analyzing Quality Control Systems presentation. Have students work on the Bell Work Activity. Slide 2 Warm-up Activity: Using the Matching Terms and Definitions handout, students will pair-share and teach each other the terms and definitions. They may do computer-based research to look up the meaning. Slide 3 II. Attribute data and Pareto charts A. Conforming Products B. Non-Conforming Products C. Vilfredo Pareto, creator of the Pareto chart Discuss the differences in conforming and nonconforming products and the importance of data collection to the Statistical Process Control (SPC) process. Inform students of the history and creator of Pareto charts. Slides 4-5 Copyright © Texas Education Agency, 2012. All rights reserved. 4 III. Overview: Creating Pareto Charts A. Pareto chart example 1 B. Pareto chart example 2 Discuss the purpose of Pareto charts, how to use software to create them and all related terms. Slides 6-7 IV. Pareto Chart Project A. Assign project worksheet B. Teacher will go over worksheet in class Distribute and assign the Pareto Chart worksheet to the students. Teacher will go over the answers in class for better understanding. Slides 8-9 . Verbal Linguistic Logical Mathematical Visual Spatial Musical Rhythmic Bodily Kinesthetic Intrapersonal Interpersonal Naturalist Existentialist Application Guided Practice (LSI Quadrant III): Using Matching Terms and Definitions handout, students will pair-share and teach each other the terms and definitions. They may do computer-based research to look up the meaning. Independent Practice (LSI Quadrant III): Students will complete Warm-up Activity, doing computer-based research to look up and match the meaning of words on the handout, writing out definitions on a sheet of paper. Students will complete the Pareto Chart Project worksheet. Summary Review (LSI Quadrants I and IV): Question: How has the analysis of quality control system issues impacted the manufacturing industry? Answer: Quality control system analysis has contributed to the drastic reduction of defects and quality improvement of products in many industries. Products have fewer defects; and this increases customer satisfaction, resulting in more products being sold. Copyright © Texas Education Agency, 2012. All rights reserved. 5 Question: Identify the differences between conforming and non-conforming products. Answer: Conforming products meet customer specifications, non-conforming products do not. . Question: What is necessary to become skilled in the quality control system analysis process? Answer: Training and experience Evaluation Informal Assessment (LSI Quadrant III): Oral question/answer. Students will complete definitions teacher has on the board from terms in the Matching Terms and Definitions handout. Students will complete the Analyzing Quality Control Systems Pareto Chart Project worksheet and will go over it in class with the teacher. Formal Assessment (LSI Quadrant III, IV): No formal assessment in this lesson. Extension Extension/Enrichment (LSI Quadrant IV): 1. Students can work in groups to find examples of manufacturing processes that have been improved using quality control system analysis. Study them and discuss the results within the group. 2. Students can conduct research and identify a nearby manufacturing facility that has implemented quality control system analysis successfully, then contact the plant manager and request a tour of the facility to find out more about how the plant prepared for and implemented quality control system analysis. If allowed they can take photos and conduct interviews and create a presentation for class. Copyright © Texas Education Agency, 2012. All rights reserved. 6 Name______________________________Date_________________Class_________ Manufacturing Engineering Analyzing Quality Control Systems Matching Terms and Definitions Directions: Match the terms in Section 1 with the definitions in Section 2. Section 1: A. Variation B. Random defect C. Specific cause defect D. Brainstorming E. Stratification F. Pareto Chart G. Real time data H. Historical data Copyright © Texas Education Agency, 2012. All rights reserved. 7 Section 2: 1. _____ working with a group to create a list of possible options to correct a problem (or defect) 2. _____ in quality terms, the separation of the data into identifiable categories to allow for easier analysis 3. _____ defects that are within our control (preventable accidents like adding incorrect ingredients, incorrect temperature settings, inadequate training) 4. _____ a bar graph that shows the type and quantity of defects that exist in a process from highest to lowest 5. _____ collecting data from previous (historical) operational processes 6. _____ defects that occur during the work process 7. _____ defects that occur and the cause is outside our control (lightning, earthquakes, war, terrorist strikes, etc.) 8. _____ collecting data in an operational process while it happens Copyright © Texas Education Agency, 2012. All rights reserved. 8 Manufacturing Engineering Analyzing Quality Control Systems Matching Terms and Definitions Answer Key D. Brainstorming: working with a group to create a list of possible options to correct a problem (or defect) E. Stratification: in quality terms, the separation of the data into identifiable categories to allow for easier analysis C. Specific cause defect: defects that are within our control (preventable accidents like adding incorrect ingredients, incorrect temperature settings, inadequate training) F. Pareto Chart: a bar graph that shows the type and quantity of defects that exist in a process from highest to lowest G. Historical data: collecting data from previous (historical) operational processes A. Variation: defects that occur during the work process B. Random defect: defects that occur and the cause is outside our control (lightning, earthquakes, war, terrorist strikes, etc.) G. Real time data: collecting data in an operational process while it happens Copyright © Texas Education Agency, 2012. All rights reserved. 9 Name______________________________Date_________________Class_________ Manufacturing Engineering Analyzing Quality Control Systems Pareto Chart Project Directions: Using the information below and graphing software, create a Pareto Chart. Pareto Chart Project: Injection Molding Defects in Plastic Cups incorrect color - 6 poorly formed product - 9 warped lids - 3 burned product - 12 crushed product - 7 dirt particles on product - 10 Copyright © Texas Education Agency, 2012. All rights reserved. 10 Manufacturing Engineering Analyzing Quality Control Systems Pareto Chart Project Answer Key Copyright © Texas Education Agency, 2012. All rights reserved. 11