Lesson Plan Cutting Metal Flexible Manufacturing

advertisement

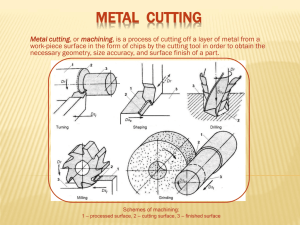

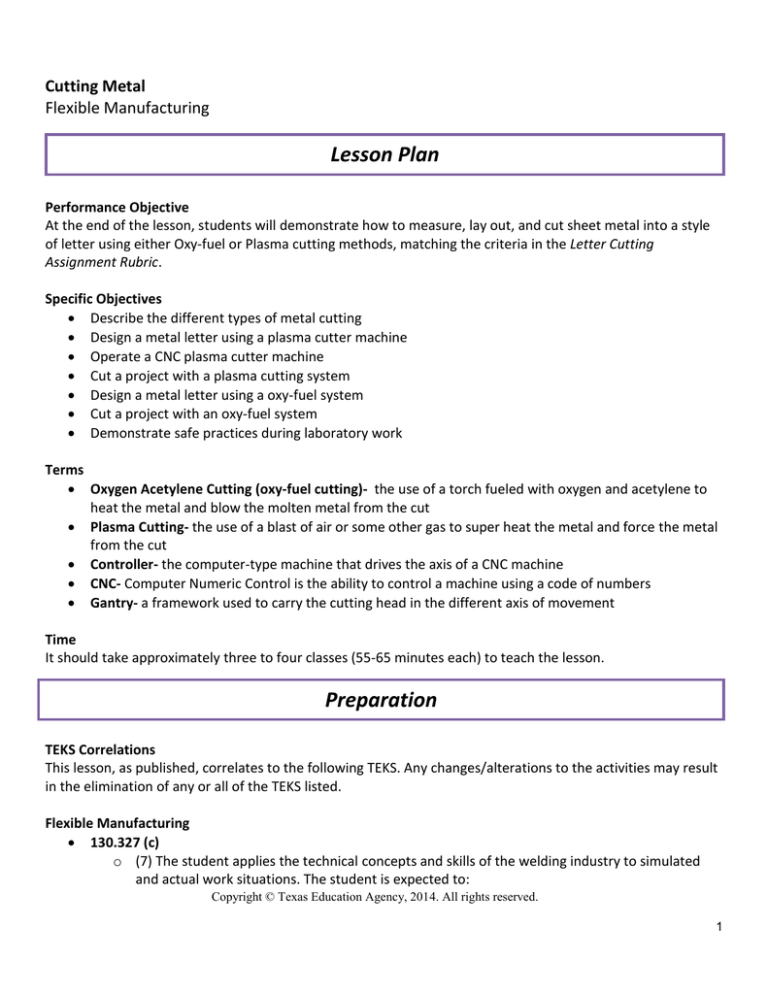

Cutting Metal Flexible Manufacturing Lesson Plan Performance Objective At the end of the lesson, students will demonstrate how to measure, lay out, and cut sheet metal into a style of letter using either Oxy-fuel or Plasma cutting methods, matching the criteria in the Letter Cutting Assignment Rubric. Specific Objectives Describe the different types of metal cutting Design a metal letter using a plasma cutter machine Operate a CNC plasma cutter machine Cut a project with a plasma cutting system Design a metal letter using a oxy-fuel system Cut a project with an oxy-fuel system Demonstrate safe practices during laboratory work Terms Oxygen Acetylene Cutting (oxy-fuel cutting)- the use of a torch fueled with oxygen and acetylene to heat the metal and blow the molten metal from the cut Plasma Cutting- the use of a blast of air or some other gas to super heat the metal and force the metal from the cut Controller- the computer-type machine that drives the axis of a CNC machine CNC- Computer Numeric Control is the ability to control a machine using a code of numbers Gantry- a framework used to carry the cutting head in the different axis of movement Time It should take approximately three to four classes (55-65 minutes each) to teach the lesson. Preparation TEKS Correlations This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Flexible Manufacturing 130.327 (c) o (7) The student applies the technical concepts and skills of the welding industry to simulated and actual work situations. The student is expected to: Copyright © Texas Education Agency, 2014. All rights reserved. 1 (A) examine the cutting processes such as oxy-fuel and plasma. o (10) The student understands the function and application of the tools, equipment, technologies, and materials used in sheet metal manufacturing. The student is expected to: (A) safely use equipment. Interdisciplinary Correlations Chemistry 112.35 (c) o Scientific processes. The student, for at least 40% of instructional time, conducts laboratory and field investigations using safe, environmentally appropriate, and ethical practices. The student is expected to: (A) demonstrate safe practices during laboratory and field investigations, including the appropriate use of safety showers, eyewash fountains, safety goggles, and fire extinguishers; (B) know specific hazards of chemical substances such as flammability, corrosiveness, and radioactivity as summarized on the Material Safety Data Sheets (MSDS); and (C) demonstrate an understanding of the use and conservation of resources and the proper disposal or recycling of materials. 112.35 (c) o (4) Science concepts. The student knows the characteristics of matter and can analyze the relationships between chemical and physical changes and properties. The student is expected to: (A) differentiate between physical and chemical changes and properties; (B) identify extensive and intensive properties; and (C) compare solids, liquids, and gases in terms of compressibility, structure, shape, and volume. Occupational Correlation (O*Net – www.onetonline.org/) Job Title: Cutting, Punching, and Press Machine Setters, Operators, and Tenders, Metal and Plastic O*Net Number: 51-4031.00 Reported Job Titles: Machine Operator, Press Operator, Set-Up Operator, Saw Operator, Slitter Operator, Punch Press Operator, Die Setter, Adjuster, Die Cutter, Machine Setter Tasks Measure completed work pieces to verify conformance to specifications, using micrometers, gauges, calipers, templates, or rulers. Examine completed work pieces for defects, such as chipped edges or marred surfaces and sort defective pieces according to types of flaws. Read work orders or production schedules to determine specifications, such as materials to be used, locations of cutting lines, or dimensions and tolerances. Load work pieces, plastic material, or chemical solutions into machines. Copyright © Texas Education Agency, 2014. All rights reserved. 2 Set up, operate, or tend machines to saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal or plastic material. Start machines, monitor their operations, and record operational data. Test and adjust machine speeds or actions, according to product specifications, using gauges and hand tools. Install, align, and lock specified punches, dies, cutting blades, or other fixtures in rams or beds of machines, using gauges, templates, feelers, shims, and hand tools. Clean and lubricate machines. Position, align, and secure work pieces against fixtures or stops on machine beds or on dies. Soft Skills Operation Monitoring Active Listening Operation and Control Quality Control Analysis Monitoring Reading Comprehension Critical Thinking Speaking Accommodations for Learning Differences It is important that lessons accommodate the needs of every learner. These lessons may be modified to accommodate your students with learning differences by referring to the files found on the Special Populations page of this website. Preparation Have materials and equipment ready for students to make the assigned project. Have examples of the different types of cut letters and projects. References Webster’s new compact office dictionary (2003). New York, NY: Houghton Mifflin Harcourt Publishing Co. Instructional Aids Cutting Metals slide presentation Letter Assignment Instructions Letter Assignment Worksheet Letter Cutting Assignment Rubric Introduction The purpose of this lesson is to help students understand the terminology of CNC Plasma Cutting and to know how to use oxy-fuel and plasma methods of cutting. Show Copyright © Texas Education Agency, 2014. All rights reserved. 3 o These projects have been made by cutting them out of metal sheets. Ask o Can you think of a project that you could cut out of a piece of sheet metal? Ask o You have cut with the oxy-fuel and plasma cutters, would you like to cut your name out? Say o The slide presentation will show you how to cut the different projects. Outline MI OUTLINE I. Cutting Metal A. Oxy-fuel cutting B. Plasma cutting II. Terminology A. Controller- the computer-type machine that drives the axis of a CNC machine. B. CNC- Computer Numeric Control is the ability to control a machine using a code of numbers. C. Gantry- a framework used to carry the cutting head in the different axis of movement. III. Oxy-fuel Cutting A. Explanation of when to use oxy-fuel cutting B. How to cut a letter IV. Plasma Cutter A. Explanation of when to use a plasma cutter B. Hand-held plasma cutter C. CNC plasma cutting system i. Terms ii. How to use a CNC plasma cutter V. CNC Plasma Cutter Projects VI. Assessment A. The Lettering Assignment Worksheet will be graded for completion B. The Letter will be graded by the rubric Multiple Intelligences Guide NOTES TO TEACHER Have different projects for the students to examine. Begin the Cutting Metals slide presentation. After the presentation, hand out the Letter Assignment Instructions and the Letter Assignment Worksheet. The students will use these to develop their letter to be cut out of a 1/8” metal sheet. The student will make the pattern on the computer, or draw it. The letter will be cut out using one of the methods described in the presentation. When the letter is finished, it will be graded by using the Letter Cutting Assignment Rubric. The Lettering Assignment Worksheet will be graded with the project. Copyright © Texas Education Agency, 2014. All rights reserved. 4 Existentialist Interpersonal Intrapersonal Kinesthetic/ Bodily Logical/ Mathematical Musical/Rhythmic Naturalist Verbal/Linguistic Visual/Spatial Application Guided Practice The teacher will guide the students as they begin to cut their letter. Independent Practice The students complete the assignment by cutting the letter out, grinding and filing the edges, and applying a finish. Summary Review The students will be able to describe the different types of metal cutting. Evaluation Informal Assessment The students will be evaluated by teacher observation as they work in the lab. Formal Assessment The students’ Letter Assignment will be graded with the Letter Cutting Assignment Rubric. Enrichment Extension The students could cut different design and letters. Copyright © Texas Education Agency, 2014. All rights reserved. 5 Name _________________________________________ Date _____________ Period ______ Letter Assignment Instructions 1. 2. 3. 4. Open a word processing document and select a word art application. Select a solid letter, the best option for this project. Notice the difference between the various font themes. Notice the difference between the font size 36 and the font size 320 in letter “C” below. Word Art Styles 5. When the letter is the font theme and size that you want, print it out on heavy paper stock. 6. After printing the letter, cut it out for a pattern to draw on the 1/8” metal sheet. 7. Draw the letter on the sheet metal using a soapstone. 8. Cut the letter out using either Oxy-fuel or Plasma methods of cutting. 9. The project may have more than one letter. 10. Print all letters as stated above and lay them out on the metal touching each other. 11. The letters can be welded together or have a support to make the letter stand up. Copyright © Texas Education Agency, 2014. All rights reserved. 6 Name _________________________________________ Date _____________ Period ______ Letter Assignment Worksheet Use the graph below to sketch your letter or letters. Method of metal cutting used: Oxy-fuel Hand Held Plasma CNC Plasma Cutter Explain the processes for making the letter: Copyright © Texas Education Agency, 2014. All rights reserved. 7 Name _________________________________________ Date _____________ Period ______ Letter Cutting Assignment Rubric Task Statement: Students will lay out and cut a letter or letters. Task Assignment: Students will work as individuals to measure, lay out, and cut a letter or a group of letters. Criteria Concepts/Skills to be Assessed Basic shape Criteria Categories (Novice to Exemplary) Novice Developing 1 2 Accomplished 3 Exemplary 4 The letter is misshaped The letter has four or more gouges on the edges The letter has one to three gouges on the edges The letter has no gouges on the edges (0-8 points) (9-17 points) (18-26 points) (27-33 points) The edges are rough from cutting; no grinding or filing has been done The edges are rough from grinding; no filing has been done The edges are rough from filing The edges are smooth and even (Possible 33 points) (0-8 points) (9-17 points) (18-26 points) (27-33 points) Overall appearance The letter is not sanded; no finish The letter is sanded; no finish The letter has a rough finish The letter is smooth and has a good finish (Possible 33 points) (0-8 points) (9-17 points) (18-26 points) (27-33 points) (Possible 33 points) Edge finish A = 79-100 points; B = 52-78 points; C = 25-51 points; D = 0-24 points Points Earned Total Points: ___________ Copyright © Texas Education Agency, 2014. All rights reserved. 8