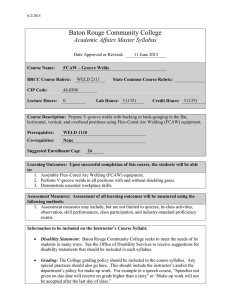

Lesson Plan

advertisement

Lesson Plan Course Title: Advanced Welding Session Title: Mild Steel Welding ( Flat, Vertical, and Horizontal) Performance Objective: Upon completion of this assignment, the student will be able to mig weld using mixed gas, and weld flat, vertically, and horizontally with mild steel. Specific Objectives: 1. Develop the ability for gas arc welding 2. Weld flat 3. Weld vertically 4. Weld horizontal 5. Perform lap welds 6. Pass qualifying test Preparation TEKS Correlations: This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Advanced Welding: 130.324(c)(8)(A)(B)(C) …observe safe operating practices; …apply safe handling of compressed gases; and …perform advanced cutting processes according to accepted welding standards. 130.324(c)(9)(A)(B) …observe safe operating practices; and …perform advanced shape cutting processes according to accepted welding standards. 130.324(c)(10)(A)(B) …use safe operating practices; and …demonstrate advanced knowledge of qualified welding positions using accepted welding standards. 130.324(c)(11)(A)(B)(C)(D) …use safe operating practices; …perform fillet welds; …perform groove welds; and Copyright © Texas Education Agency, 2012. All rights reserved. 1 …perform welds in all appropriate positions according to accepted welding standards. 130.324(c)(12)(A)(B)(C)(D) …use safe operating practices; …perform fillet welds; …perform groove welds; and …perform welds in all appropriate positions according to accepted welding standards. 130.324(c)(13)(A)(B)(C)(D)(E) …use safe operating practices; …perform fillet welds; …perform groove welds; …perform welds in all appropriate positions according to accepted welding standards; and …perform welds on metals such as carbon steel, stainless steel, pipe, and aluminum. Interdisciplinary Correlations: English: 110.42(6) – Reading/word identification/vocabulary development 110.42(6)(A)(B) …expand vocabulary development through wide reading, listening, and discussing; …rely on context to determine meanings of words and phrases such as figurative language, idioms, multiple meaning of words, and technical vocabulary; Instructor/Trainer References: 1. Jeffus, Larry; Welding Principles and Applications Third Edition, Delmar Publishers Inc.ISBN 0-8273-5048-1; Chapter 27. 2. Miller, R.T., Welding Skills Second Edition, American Technical Publishers, Inc. ISBN 0-8269-3007-7; Chapter 25 3. Gellerman, Mike; Welding Fundamentals; Delmar Publishers ISBN 0-8273-5937-3; Unit 6 4. American Welding Society http://www.aws.org/ Copyright © Texas Education Agency, 2012. All rights reserved. 2 Instructional Aids: 1. Mild Steel Welding PowerPoint 2. Rubric for grading mild steel Materials Needed: 3 x 6 3/8” steel plate .035 mig wire Gas 75%-25% (argon, carbon dioxide) Equipment Needed: Personal safety equipment Mig machine Mig gun Learner Knowledge of safety in the welding classroom. Introduction Introduction (LSI Quadrant I): SAY: Mild steel is the easiest metal to gas weld. At the conclusion of this lesson you will be able to weld flat, vertically, and horizontally. Outline Outline (LSI Quadrant II): I. Set - up A. Equipment B. Material needed C. Coupons (from previous lesson) II. Weld Lab 1 Flat Welding Lab 2 Vertical Welding Lab 3 Horizontal Welding Lab 4 Lap Welding Copyright © Texas Education Agency, 2012. All rights reserved. 3 III. Clean-up and inspection A. General clean-up B. Visual inspection Application Guided Practice (LSI Quadrant III): The teacher will demonstrate the different position of the welds in the different labs. Students will then work in the labs to complete the welds. Independent Practice (LSI Quadrant III): Lab 1 – Flat weld Lab 2 – Vertical weld Lab 3 – Horizontal weld Lab 4 – Lap weld Summary Review (LSI Quadrants I and IV): Monitor the students correct their welds as the lesson progresses. Evaluation Informal Assessment (LSI Quadrant III): The assessment will be visual and discussion. Formal Assessment (LSI Quadrant III, IV): The students will weld coupons and will be graded using a rubric. The rubric will include uniformed welds, not undercuts, and a good cosmetic look to the coupon. The rubric is similar to the one used in VICA competition. Extension/Enrichment (LSI Quadrant IV): The students that show mastery of the skill will weld personal projects or outside projects. Copyright © Texas Education Agency, 2012. All rights reserved. 4 RUBRIC FOR GRADING MILD STEEL Grading for Flat mild steel weld Grading for Horizontal steel weld Uniformed Uniformed No under welds No under welds Cosmetic Cosmetic Total Score Total Score 5-best score for each 1-lowest score for each 15-Perfect score Grading for vertical mild steel weld 5-best score for each 1-lowest score for each 15-Perfesct score Grading for lap weld for mild steel Uniformed Uniformed No under welds No under welds Cosmetic Cosmetic Total Score Total Score 5-best score for each 1-lowest score for each 15-Perfect score 5-best score for each 1-lowest score for each 15-Perfesct score Copyright © Texas Education Agency, 2012. All rights reserved. 5