Math Lesson Plan Practicum in Fashion Design

advertisement

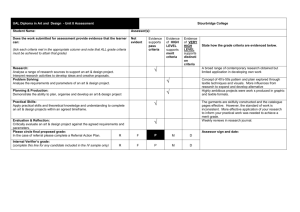

Math Practicum in Fashion Design Lesson Plan Performance Objective Upon completion of this lesson, each student will be able to perform the mathematical formulas to correctly compute fashion garment production costs and sell prices. Specific Objectives Students will analyze single garment costs. Students will calculate single garment profit costs. Students will differentiate overhead and marginal costs. Students will calculate costs using an apparel production sample cost sheet. Students will differentiate wholesale and retail mark ups. This lesson should take 10-12 class days to complete. Preparation TEKS Correlations This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. 130.95. Practicum in Fashion Design (c) Knowledge and skills (2) The student applies academic knowledge and skills in fashion, textile, and apparel projects. The student is expected to: (B) apply mathematics by demonstrating skills, such as the use of whole numbers, decimals, fractions; and knowledge of arithmetic operations; (11) The student implements an increasing understanding of the business aspects of fashion with emphasis on promotion and retailing. The student is expected to: (A) describe fundamentals of fashion buying by: (v) analyzing the price of a fashion product; (viii) composing a scenario plan for retail pricing, sales, inventory, and purchasing; 1 Copyright © Texas Education Agency, 2015. All Rights Reserved. Interdisciplinary Correlations English 110.42(b) Knowledge and skills (6) Reading/word identification/vocabulary development. The student uses a variety of strategies to read unfamiliar words and to build vocabulary. The student is expected to: (A) expand vocabulary through wide reading, listening, and discussing; and (B) rely on context to determine meanings of words and phrases, such as figurative language, idioms, multiple meaning words, and technical vocabulary. (7) Reading/comprehension. The student comprehends selections using a variety of strategies. The student is expected to: (F) identify main ideas and their supporting details; (G) summarize texts; and (J) read silently with comprehension for a sustained period of time. Speech 110.56 (b) Knowledge and skills (1)(A) Explain the importance of communication in daily interaction. (2)(E) Participate appropriately in conversations for a variety of purposes. (3)(A) Use appropriate communication in group settings. (E) Use appropriate verbal, non-verbal, and listening strategies to communicate effectively in groups. (5)(B) Use language clearly and appropriately. Tasks Students will utilize provided notes and slide presentation to complete notes pages. Students will complete worksheets. Accommodations for Learning Differences It is important that lessons accommodate the needs of every learner. These lessons may be modified to accommodate your students with learning differences by referring to the files found on the Special Populations page of this website (cte.unt.edu). Preparation Copy the handouts. Have multimedia presentations ready to show the class. Instructional Aids Student Notes sheet Student worksheets 2 Copyright © Texas Education Agency, 2015. All Rights Reserved. Materials Needed Copies Pencils Equipment Needed Teacher computer Projector (for slide presentation) Introduction Learner Preparation No special preparation is needed for this lesson. Lesson Introduction Ask students to recall a recently purchased fashion garment. Encourage students to discuss what the garment was, the cost and if the item was on sale. Ask students to hypothesize how much it would cost to make their item. Have students brainstorm a list of why designers mark up the price of their merchandise. 3 Copyright © Texas Education Agency, 2015. All Rights Reserved. Outline NOTES TO TEACHER OUTLINE MI Slides 1-2 Introduction a. Title slide b. Objectives Each student should have a student notes sheet to complete during the multimedia presentation. Timeline of delivery is at discretion of instructor. Slides 3-11 a. Calculating single garment costing Slides 12-24 a. Calculating costing garments in bulk I. Have students take notes to keep in notebook. Upon completion of slide 11, give students the single garment cost worksheet. Upon completion of slide 24, give students the apparel production cost worksheet. Upon completion of both worksheets, students will assess knowledge by taking the Costing Garments Test. A test key is provided in this lesson. Multiple Intelligences Guide Existentialist Interpersonal Intrapersonal Kinesthetic/ Bodily Logical/ Mathematical Musical/Rhythmic Naturalist Verbal/Linguistic Visual/Spatial 4 Copyright © Texas Education Agency, 2015. All Rights Reserved. Application Guided Practice Students will use the provided slide presentation to complete the notes handouts pages. Independent Practice Students will complete single garment cost worksheet. Students will complete apparel production in bulk cost worksheet. Students will complete costing garments test. Summary Review What are the purposes of adding overhead and marginal costs to the price of production? Why is there a standardized markup added to all apparel production costs? What is the difference between wholesale and retail? Evaluation Informal Evaluation: The teacher will check frequently for understanding. Very small work group option (peer tutoring). Formal Evaluation: Worksheets and test over the material. 5 Copyright © Texas Education Agency, 2015. All Rights Reserved. Costing Garments Student Notes Single Garment Costing 1. ________________ is the economic value placed on ________________ to make a fashion ________________. 2. Fashion ________________ must know how to accurately cost an item. Accurate costing will ensure the designer is ________________ for all materials used to make the garment, ________________, and a ________________ percentage. 3. First: Calculate ________________: Multiplying the cost of fabric per ________________ by the number of yards ________________ to make the garment. Example: $7.99 per yard x 3 yards used = 23.97 4. Second: Calculate ________________ and ________________ (only if needed): Multiply the cost of lining/interfacing per ________________ by the number of yards ________________ to make the garment Example: $2.99/yard x 3 yards used = $8.97 5. Third: Calculate ________________: Add cost of notions to previous ________________ Example: 32.94 (fabric and lining) + .75 (1 zipper) + .15 (1 button) = $33.84 6. Fourth: Calculate the ________________ ________________ for ________________: Multiply the ________________ it took to cut the fabric (and possibly lining) by the amount you are willing to pay someone to cut Example: 1 hour to cut x $8.00 an hour wage = $8.00 $33.84 + 8.00 = $41.84 7. Fifth: Calculate ________________ ________________ for ________________: Multiply the ________________ it took to sew the fabric (and possibly lining) by the amount you are willing to pay someone to sew Example: 4 hours to sew x $12.00 an hour wage = $48.00 41.84 (cutting labor) + 48.00 (sewing labor) = $89.84 8. Sixth: Calculate ________________ costs: Add ______ of the subtotal to your cost. Overhead covers resources needed to _______________, such as facility rent or utility costs. Example: 89.84 x .12 = $10.78 (overhead) Add 10.78 to 89.84 = $100.62 new subtotal 9. Seventh: Calculate your ________________ cost of ________________: Add ______ of the subtotal to your cost. This cost is added for the extra ______________ it takes to make just one piece instead of multiples at once. Example: 100.62 x .20 = $20.12 (margin) Add 20.12 to 100.62 = $120.74 This is the total cost to make your single garment 10. Eighth: Calculate your ________________: Now you get to get paid! Multiply total cost by _______ This is the industry-________________ calculation to determine how much the designer should be paid. Example: 120.74 x 2.2 = $265.63 Final sells price of garment The garment cost $120.74, you make $144.89 on your garment 6 Copyright © Texas Education Agency, 2015. All Rights Reserved. Apparel Production in Bulk Costing 11. Designers use apparel production cost sheets to analyze their expenses in making garments and to analyze profit margins. In a professional cost sheet you will need to know how many ________________ you will order, the ________________ they are to be sold in retail, seam ________________ to be used in construction, a ________________ of the garment, sizes and colors you would like it made in, ________________ and price of fabrics and trimmings needed. 12. A. Date field: Enter the __________ you plan to ______________ your order B. Style #: Enter a style number that you ____________ to your garment. This will help keep your orders ____________ when ordering more than one garment C. Allowance: Enter the ____________ allowance you want used when your garment is being constructed D. Description: Enter a short description of your garment for the manufacturer’s ____________ E. Season: Enter what season this garment will be ____________ and sold to F. Colors: Enter what colors you want the ____________ to be made in G. Size ranges: Enter what __________ you want the garment to be made in H. Wholesale price: Enter what the garment will be _______ for at wholesale I. Retail price: Enter what the garment will be sold for at ___________ 13. A. ____________ is the outside ____________ of the garment. B. Yards, price, and amount fields for self: Multiply yards needed to make all shorts by ____________ per ____________. This will give you the total cost of your self fabric needed. Example: 150 x 2.5 = 375.00 7 Copyright © Texas Education Agency, 2015. All Rights Reserved. C. Yards, price, amount fields for lining and interfacing: You would need to do the same calculation for the lining and interfacing needed. In this example, our shorts do not need interfacing or lining. 14. A. For each trimming item, multiply it’s ____________ amount by its __________ amount for its cost. B. Before you order from the manufacturer, you will need to confirm the amounts of each ____________ they need to make your full ____________ of garments. 15. A. For each labor cost, multiply the __________ it took to perform the __________ by the __________ amount paid to that worker to get the total amount that employee was paid for his or her labor. B. Before you order your garment, you can get an ____________ cost for each labor item. Know that it is possible for the ____________ amount to change ____________. 8 Copyright © Texas Education Agency, 2015. All Rights Reserved. 16. For each garment you are seeking to get manufactured, include a garment ____________ of what you are wanting it to look like. Include the garments ____________ and ____________ in your sketch. In an actual cost sheet, you will use graphic design software. This example has a mock sketch using clip art. 17. Calculating total cost: After you have filled out all portions of your cost sheet, you are ready to get your ____________ ___________. For our example, you would add: 375 + 6.75 + 22.50 + 52.50 + 18.75 + 11.25 + 11.25 + 7.50 + 90 + 300 + 20 + 10 = $925.50 total cost 18. Add overhead cost: Overhead cost is typically __________. Calculate what _________ of your total cost is and add it to your total cost. Example: 925.50 * .12 = $111.06 overhead cost 925.50 + 111.06 = $1036.56 total with overhead 19. Add FOB cost: FOB cost is the amount you would have to pay to get the garments ____________ to you, either by ____________ or _______. Sea freight is calculated based on your garments’ ____________. Airfreight is based on your garments’ ____________. You should ____________ to decide what freight works best for your garments based on your timeline and price before you start ____________ of garments. Ask your manufacturer for an approximation of volume and weight to get an estimate for your ______ cost. 20. Calculating mark-up: Once you have your total cost, overhead and FOB, you will need to determine your ____________. Mark-up is the ____________ you add after all the expenses to ____________ from your garments. Add your total cost, overhead and FOB 925.50 + 111.06 + 32 = 1068.56 Multiply this total by 2.2 to get your mark-up 1068.56 x 2.2 = $2350.83 Your cost with mark-up is what you would _________ your garments for at ____________. 21. Calculating wholesale cost: Wholesale is what you, the designer, would ________ your shorts for to the ____________ that will then _________ them to the ____________. Example: $2350.83 / 75 (number of shorts made) = $31.34 price per unit (shorts) 22. The ____________ will then ____________ the cost of the shorts so that the ____________ can also ____________ from each sale. For example, if the store paid $31.34 per shorts, they may mark up the price 50%. This would make the shorts $47.01 to the customer. 31.34 x .5 = 15.67 15.67 + 31.34 = $47.01 9 Copyright © Texas Education Agency, 2015. All Rights Reserved. Costing Garments Student Notes Key Single Garment Costing 1. Costing is the economic value placed on resources to make a fashion product. 2. Fashion designers must know how to accurately cost an item. Accurate costing will ensure the designer is paid for all materials used to make the garment, shipping, and a profit percentage. 3. First: Calculate fabric: Multiply the cost of fabric per yard by the number of yards used to make the garment. Example: $7.99 per yard x 3 yards used = 23.97 4. Second: Calculate lining and interfacing (only if needed): Multiply the cost of lining/interfacing per yard by the number of yards used to make the garment Example: $2.99/yard x 3 yards used = $8.97 5. Third: Calculate notions: Add cost of notions to previous total. Example: 32.94 (fabric and lining) + .75 (1 zipper) + .15 (1 button) = $33.84 6. Fourth: Calculate the labor cost for cutting: Multiply the hours it took to cut the fabric (and possibly lining) by the amount you are willing to pay someone to cut. Example: 1 hour to cut x $8.00 an hour wage = $8.00 $33.84 + 8.00 = $41.84 7. Fifth: Calculate labor cost for sewing: Multiply the hours it took to sew the fabric (and possibly lining) by the amount you are willing to pay someone to sew. Example: 4 hours to sew x $12.00 an hour wage = $48.00 41.84 (cutting labor) + 48.00 (sewing labor) = $89.84 8. Sixth: Calculate overhead costs: Add 12% of the subtotal to your cost. Overhead covers resources needed to operate, such as facility rent or utility costs. Example: 89.84 x .12 = $10.78 (overhead) Add 10.78 to 89.84 = $100.62 new subtotal 9. Seventh: Calculate your marginal cost of production: Add 20% of the subtotal to your cost. This cost is added for the extra time it takes to make just one piece instead of multiples at once. Example: 100.62 x .20 = $20.12 (margin) Add 20.12 to 100.62 = $120.74 This is the total cost to make your single garment 10. Eighth: Calculate your profit: Now you get to get paid! Multiply total cost by 2.2. This is the industry standard calculation to determine how much the designer should be paid. Example: 120.74 x 2.2 = $265.63 Final sells price of garment The garment cost $120.74; you make $144.89 on your garment 10 Copyright © Texas Education Agency, 2015. All Rights Reserved. Apparel Production in Bulk Costing 11. Designers use apparel production cost sheets to analyze their expenses in making garments and to analyze profit margins. In a professional cost sheet you will need to know how many garments you will order, the season they are to be sold in retail, seam allowance to be used in construction, a diagram of the garment, sizes and colors you would like it made in, quantity and price of fabrics and trimmings needed. 12. A. Date field: Enter the date you plan to place your order B. Style #: Enter a style number that you assign to your garment. This will help keep your orders organized when ordering more than one garment C. Allowance: Enter the seam allowance you want used when your garment is being constructed D. Description: Enter a short description of your garment for the manufacturer’s reference E. Season: Enter what season this garment will be marketed and sold to F. Colors: Enter what colors you want the garment to be made in G. Size ranges: Enter what sizes you want the garment to be made in H. Wholesale price: Enter what the garment will be sold for at wholesale I. Retail price: Enter what the garment will be sold for at retail 13. A. Self is the outside shell of the garment 11 Copyright © Texas Education Agency, 2015. All Rights Reserved. B. Yards, price, and amount fields for self: Multiply yards needed to make all shorts by price per yard. This will give you the total cost of yourself fabric needed. Example: 150 x 2.5 = 375.00 C. Yards, price, amount fields for lining and interfacing: You would need to do the same calculation for the lining and interfacing needed. In this example our shorts do not need interfacing or lining. 14. A. For each trimming item, multiply its quantity amount by its price amount for its cost B. Before you order from the manufacturer, you will need to confirm the amounts of each trimming they need to make your full order of garments. 15. A. For each labor cost, multiply the hours it took to perform the labor by the wage amount paid to that worker to get the total amount that employee was paid for his or her labor. B. Before you order your garment, you can get an approximate cost for each labor item. Know that it is possible for the pre-order amount to change post-production. 12 Copyright © Texas Education Agency, 2015. All Rights Reserved. 16. For each garment you are seeking to get manufactured, include a garment sketch of what you are wanting it to look like. Include the garments front and back in your sketch. In an actual cost sheet, you will use graphic design software. This example has a mock sketch using clip art. 17. Calculating total cost: After you have filled out all portions of your cost sheet, you are ready to get your total cost. For our example, you would add: 375 + 6.75 + 22.50 + 52.50 + 18.75 + 11.25 + 11.25 + 7.50 + 90 + 300 + 20 + 10 = $925.50 total cost 18. Add overhead cost: Overhead cost is typically 12%. Calculate what 12% of your total cost is and add it to your total cost. Example: 925.50 * .12 = $111.06 overhead cost 925.50 + 111.06 = $1036.56 total with overhead 19. Add FOB cost: FOB cost is the amount you would have to pay to get the garments shipped to you, either by flight or sea. Sea freight is calculated based on your garments’ volume. Airfreight is based on your garments’ weight. You should research to decide what freight works best for your garments based on your timeline and price before you start production of garments. Ask your manufacturer for an approximation of volume and weight to get an estimate for your FOB cost. 20. Calculating mark-up: Once you have your total cost, overhead and FOB, you will need to determine your mark-up. Mark-up is the increase you add after all the expenses to profit from your garments. Add your total cost, overhead and FOB. 925.50 + 111.06 + 32 = 1068.56 Multiply this total by 2.2 to get your mark-up 1068.56 x 2.2 = $2350.83 Your cost with mark-up is what you would sell your garments for at wholesale. 21. Calculating wholesale cost: Wholesale is what you, the designer, would sell your shorts for to the retailer that will then sell them to the customer. Example: $2350.83 / 75 (number of shorts made) = $31.34 price per unit (shorts) 22. The retailer will then mark up the cost of the shorts so that the store can also profit from each sale. For example, if the store paid $31.34 per shorts, they may mark up the price 50%. This would make the shorts $47.01 to the customer. 31.34 x .5 = 15.67 15.67 + 31.34 = $47.01 13 Copyright © Texas Education Agency, 2015. All Rights Reserved. Single Garment Costing Worksheet Complete this worksheet with the following information: You, the designer, are asked to make one formal gown. After taking measurements, you calculate you will need five yards of fabric at $11.00/yard and five yards of interfacing at $6.00/yard. You will need one 14-inch invisible zipper at $3.15 and a spool of thread for $2.19. You will pay yourself $7.00/hour for the labor. It will take you two hours to cut and eight hours to sew the gown. 1. Fabric ______________ yards needed x $_____________ cost per yard = $___________ 2. Lining/interfacing ___________ yards (lining) x $______________ cost per yard = $______________ _________ yards (interfacing) x $_____________ cost per yard = $______________ 3. Notions ____________ quantity x ____________ quantity x ____________ quantity x $_____________ price per unit = $______________ $_____________ price per unit = $______________ $_______________ price per unit = $______________ 4. Cutting Labor ____________ hours to cut x $___________ an hour wage = $____________ ____________ hours to sew x $____________ an hour wage = $____________ 5. Sewing Labor 6. Overhead Calculate subtotal = $______________ $____________ subtotal x $____________ overhead + 7. Marginal cost 12% = $____________ overhead $____________ subtotal = $____________ new subtotal $____________ new subtotal x 20% = $____________ margin $____________ margin + $____________ new subtotal = $____________ This is the total cost to make your single garment 14 Copyright © Texas Education Agency, 2015. All Rights Reserved. 8. Profit $____________ total cost x 2.2 = $____________ final sells price of garment $____________ final sells price - $____________ total cost to make garment = $____________ your profit on garment 15 Copyright © Texas Education Agency, 2015. All Rights Reserved. Single Garment Costing Worksheet Key Complete this worksheet with the following information: You, the designer, are asked to make one formal gown. After taking measurements, you calculate you will need five yards of fabric at $11.00/yard and five yards of interfacing at $6.00/yard. You will need one 14-inch invisible zipper at $3.15 and a spool of thread for $2.19. You will pay yourself $7.00/hour for the labor. It will take you two hours to cut and eight hours to sew the gown. 1. Fabric 5 yards needed x $11.00 cost per yard = $55.00 2. Lining/interfacing 5 yards (lining) x $6.00 cost per yard = $30.00 0 yards (interfacing) x $0 cost per yard = $0 3. Notions 1 quantity x $3.15 price per unit = $3.15 1 quantity x $2.19 price per unit = $2.19 0 quantity x $0 price per unit = $0 4. Cutting Labor 2 hours to cut x $7.00 an hour wage = $14.00 5. Sewing Labor 8 hours to sew x $7.00 an hour wage = $56.00 6. Overhead Calculate subtotal = $160.34 $160.34 subtotal x $19.24 overhead + 7. Marginal cost 12% = $19.24 overhead $160.34 subtotal = $179.58 new subtotal $179.58 new subtotal x $35.92 margin + single garment 20% = $35.92 margin $179.58 new subtotal = $215.50 This is the total cost to make your 8. Profit 16 Copyright © Texas Education Agency, 2015. All Rights Reserved. $215.50 total cost x 2.2 = $474.10 final sells price of garment $474.10 final sells price - $215.50 total cost to make garment = $258.60 your profit on garment 17 Copyright © Texas Education Agency, 2015. All Rights Reserved. Apparel Production in Bulk Costing Worksheet Complete this worksheet with the following information. In one week, you are going to order 150 juniors pants for fall, style #8510 in black and navy, sizes extra small through extra large. For construction, you will need 225 yards of fabric ($5.50/yard) and lining ($2.75/yard), 50 spools of thread (.45 each) and have it sewn on a ¼ inch seam allowance. Each pant will need a 7-inch zipper ($45 for 150), one button ($15 for 150), a label and a care label (each is $24 for 150) and a hangtag ($15 for 150). It will take a total of 81 hours to equally grade, mark and cut. Employees will be paid $2.50/hour. It will take a total of 120 hours to sew the pants. Employees that sew will be paid $4.00/hour. Total weight of the pants will be 25 pounds; airfreight will cost $1.75 per pound. Retail mark-up is 50%. Date: Description: Size Range: Materials Self Style #: Season: Wholesale price: Allowance: Colors: Retail price: Yards Price Amount Trimmings Quantity Price Amount Labor Cutting Sewing Grading Marking Hours Wage Amount Garment front and back Lining Interfacing Total cost: Overhead cost: FOB cost: Mark up: Wholesale cost per garment: 18 Copyright © Texas Education Agency, 2015. All Rights Reserved. Apparel Production in Bulk Costing Worksheet Key Complete this worksheet with the following information: In one week, you are going to order 150 juniors pants for fall, style #8510 in black and navy, sizes extra small through extra large. For construction, you will need 225 yards of fabric ($5.50/yard) and lining ($2.75/yard), 50 spools of thread (.45 each) and have it sewn on a ¼ inch seam allowance. Each pant will need a 7-inch zipper ($45 for 150), one button ($15 for 150), a label and a care label (each is $24 for 150) and a hangtag ($15 for 150). It will take a total of 81 hours to equally grade, mark and cut. Employees will be paid $2.50/hour. It will take a total of 120 hours to sew the pants. Employees that sew will be paid $4.00/hour. Total weight of the pants will be 25 pounds. Airfreight will cost $1.75 per pound. Retail mark-up is 50%. Date: 1 week from today Description: juniors pants Size Range: XS-XL Style #: 8510 Season: Fall Wholesale price: $44.73 Allowance: ¼ inch Colors: black and navy Retail price: $67.10 Materials Self Yards 225 Price 5.50 Amount 1237.50 Garment front and back Lining Interfacing 225 0 2.75 0 618.75 0 Trimmings Thread 7” zippers Buttons Label Care label Hangtag Quantity 50 150 150 150 150 150 Price .45 .30 .10 .16 .16 .10 Amount 22.50 45.00 15.00 24.00 24.00 15.00 Labor Cutting Sewing Grading Marking Hours 27 120 27 27 Wage 2.50 4.00 2.50 2.50 Amount 67.50 480.00 67.50 67.50 Total cost: $2684.25 Overhead cost: $322.11 FOB cost: $43.75 Mark up: $6710.24 Wholesale cost per garment: $44.73 19 Copyright © Texas Education Agency, 2015. All Rights Reserved. Costing Garments Test Part I: Single garment costing. 1. Why is costing important to a designer? 2. What are overhead costs? 3. What is the formula to calculate overhead? 4. What are marginal costs? 5. What is the formula to calculate margin? 6. What is the formula to calculate the garment cost with profit? Complete the single garment fields with the information provided: Your Subtotal is $823.00: 7. Calculate your overhead: $ ________________ 8. Calculate your new subtotal (with overhead added): $_____________________ 9. Calculate margin: $ ________________ 10. Calculate your new subtotal (with margin added) : $ ________________ 11. Calculate cost with profit: $ ________________ final sells price of garment 12. Calculate your profit from garment: $ ________________ Part II: Apparel production in bulk costing. 13. What is self-material? 14. What are trimmings? 15. Why is having a garment sketch useful in an apparel production cost worksheet? 16. What is FOB? Why is the calculation different if it is by air or sea? 20 Copyright © Texas Education Agency, 2015. All Rights Reserved. Complete the single garment fields with the information provided: Your Subtotal is $1435.00: 17. Calculate overhead: $ ________________ 18. Calculate your new subtotal (with overhead) and add $47 FOB: $ ________________ 19. Calculate mark up: $ ________________ 20. Calculate your wholesale cost per garment (with 500 units): $ ________________ 21 Copyright © Texas Education Agency, 2015. All Rights Reserved. Costing Garments Test Key Part I: Single garment costing. 1. Why is costing important to a designer? Designers must ensure they know what to pay for all their materials, labor and other expenses. Designers must also know how to calculate their profit margins. 2. What are overhead costs? Costs needed to operate, such as facility rent or utilities. 3. What is the formula to calculate overhead? Add 12% to your subtotal 4. What are marginal costs? Costs added to make a single garment item 5. What is the formula to calculate margin? Add 20% of your subtotal to your cost 6. What is the formula to calculate the garment cost with profit? Multiply subtotal by 2.2 Complete the single garment fields with the information provided: Your Subtotal is $823.00: 7. Calculate your overhead: $ 98.76 8. Calculate your new subtotal (with overhead added): $921.76 9. Calculate margin: $ 184.35 10. Calculate your new subtotal (with margin added) : $ 1106.11 11. Calculate cost with profit: $ 2433.44 final sells price of garment 12. Calculate your profit from garment: $ 1327.33 Part II: Apparel production in bulk costing. 13. What is self-material? The outside shell of the garment 14. What are trimmings? Notions, labels, care labels, poly bags, hangers, size tickets 15. Why is having a garment sketch useful in an apparel production cost worksheet? It helps the manufacturer understand what you are looking for in the garment 22 Copyright © Texas Education Agency, 2015. All Rights Reserved. 16. What is FOB? Why is the calculation different if it is by air or sea? FOB is the cost you need to pay to get the garments shipped. It is calculated by volume for sea freight; calculated by weight for airfreight Complete the single garment fields with the information provided: Your Subtotal is $1435.00: 17. Calculate overhead: $ 172.20 18. Calculate your new subtotal (with overhead) and add $47 FOB: $ 1654.20 19. Calculate mark up: $ 3639.24 20. Calculate your wholesale cost per garment (with 500 units): $ 7.28 23 Copyright © Texas Education Agency, 2015. All Rights Reserved.