PREDESIGN REPORT Old Harmon Building HVAC Renovation and New Harmon Building Reroofing

advertisement

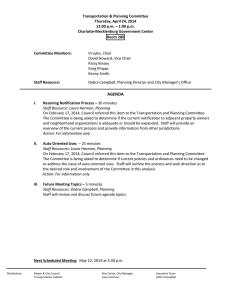

PREDESIGN REPORT For: Minneapolis Community and Technical College Management Education Center Old Harmon Building HVAC Renovation and New Harmon Building Reroofing Minneapolis, Minnesota January 9, 2015 Report Prepared By Ericksen Ellison & Associates, Inc., With consultants: Bentz Thompson Rietow Architects (Architecture/Code Review) Inspec (Roof) Schadegg Mechanical (Mechanical Cost Estimating) Page 1 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Signatures Predesign Report MINNEAPOLIS COMMUNITY AND TECHNICAL COLLEGE OLD HARMON BUILDING HVAC RENOVATION AND NEW HARMON BUILDING REROOFING Minneapolis, Minnesota Issued: January 9, 2015 I hereby certify that this Predesign Report for the MCTC Old Harmon HVAC/.Reroofing was prepared by me or under my direct supervision and that I am a duly registered professional engineer under the laws of the State of Minnesota. Page 2 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Project Team STATE OF MINNESOTA Minnesota State Colleges and Universities. Kenneth Oas – Facility Coordinator Greg Ewig - Facilities Director, Real estate MINNEAPOLIS COMMUNITY AND TECHNICAL COLLEGE – CAMPUS FACILITIES Roger Broz – Director of Facilities James Splett – Building Maintenance Foreman Rick O’Brien – Facilities, Plant Engineer ERICKSEN ELLISON and ASSOCIATES, INC 305 2nd Street NW, Suite 105 New Brighton, MN 55112 James Art, PE, LEED AP 651-632-2306 BENTZ THOMPSON RIETOW 801 Nicollet Mall, Suite 801 Minneapolis, MN 55402 Randy Moe, AIA, CID, LEED AP 612-332-1234 INSPEC 5801 Duluth Street Minneapolis, MN 55422 Cynthia Long, CDT, CSI, Associate AIA Gary C. Patrick, AIA 763-546-3434 SCHADEGG MECHANICAL 225 Bridgepoint Drive South St Paul, MN 55075 Dan McNamara, Project Manager 651-292-9933 Page 3 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Table of Contents i. ii. iii. Cover Signatures Project Team 1. Executive Summary Statement ……………………………………………………5 2. Project Background Narrative ……………………………………………………..7 a.) The Existing Systems b.) Statement of Statutory Requirements c.) The Project Program d.) Summary of the Project Planning Process e.) Backlog and FCI Summary f.) Code Review 3. Project Description …………………………………………………………………12 a.) Purpose and Rationale b.) Project Scope c.) Relationship of the Project to the Updated Facilities Master Plan d.) Other Considerations for this Project e.) Consequences of Delayed Funding 4. Sustainability…………………………………………………………………………18 a.) Opportunities for Sustainable Design Initiatives b.) Analysis of Alternative Energy Systems 5. Financial Information – Capital Expenditures…………………………………….22 a.) Summary of Financial Information b.) GESCs and HEAPR 6. Financial Information – Ongoing Operating Expenditures………………………24 a.) Utility Costs b.) 5-Year Projection of Operating Budgets c.) Debt Capacity 7. Schedule……………………………………………………………………………...26 Appendices…………………………………………………………………………………28 Appendix A: Detail of Construction Costs Appendix B: Meeting Notes Appendix C: Building Floor Plans Appendix D: Hazardous Materials Surveys Page 4 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 1. Executive Summary Statement Minneapolis Community and Technical College is planning to renovate the heating, ventilating, and air conditioning systems in the Old Harmon Building, which is part of the Management Education Center (MEC). Old Harmon consists of an underground level and four stories above grade. In 2011, the third floor of Old Harmon HVAC was renovated, with the introduction of a new, more efficient heating, ventilating and air conditioning system, sized for future extension to the fourth floor. The new system uses variable air volume distribution and hot water booster heating coils for zone temperature control. An old constant-volume packaged HVAC rooftop unit provides heating, cooling, and ventilation for Old Harmon (but no longer the third floor). When the other floors of Old Harmon are renovated, the old rooftop unit will be removed. Two old, inefficient steam boilers in the Health Science Building portion of MEC originally served the entire MEC block of buildings. However, they presently only provide steam heat for Old Harmon and a few other spaces. The rest of MEC is now heated with hot water furnished by a newer, more efficient boiler plant. When the HVAC is built out for the other floors of Old Harmon, heating for the remaining spaces with steam heat will be converted from steam to hot water. The old steam boilers, no longer needed, will be decommissioned and removed from the premises. Two small existing rooftop units will be converted from steam to hot water heating. Adjacent to Old Harmon, and within MEC, is the structure known as New Harmon, or Area E. To address maintenance needs and a potentially overloaded roof structure, New Harmon will receive a new roof. The entire roof on New Harmon should be replaced as part of the mechanical renovation project in order to eliminate obsolete roof penetrations, minimize the possibility of a catastrophic failure, and to install a long term durable roof system that will meet the MnSCU forty year life expectancy. The roof work is combined with the HVAC work because of the removal of the old rooftop unit and because of new roof openings which will be needed for the HVASC renovation. The HVAC work and the roof work are interwoven. A summary of the work of the project is as follows: • • • • • Expand the new third floor HVAC system to also serve the fourth floor of Old Harmon. Build another, similar HVAC system to serve the first and second floors of Old Harmon, replacing the old system. Remove the old HVAC rooftop unit which presently serves Old Harmon. Replace the roof of New Harmon. Remove the steam boilers from the health Science Building. The interior square footage in Old Harmon which will be affected totals about 21,300 gross square feet. With funding approved in June 2016, design will take place in the months that follow, and construction is likely to take place in 2017. As shown in the table in Section 5, the probable construction cost, in present day dollars, is $1,821,000. Adding a 10% contingency, along with other project costs (design and project management and Page 5 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing hazardous materials abatement), and then adding an inflation factor, the total project cost in 2016 dollars is expected to be $2,852,200. The backlog of deferred maintenance for Old Harmon is $4,439,000, and the FCI is 0.37. The backlog of deferred maintenance for New Harmon is $2,964,000, and the FCI is 0.18. Academic, operational, and workforce or economic development programs will not be affected by this project, except that they will need to be temporarily relocated during construction. Section 5 of this report presents a summary of the capital cost required. Section 6 addresses ongoing costs. Section 7 includes a proposed project schedule. The main purpose for the project is to address current deficiencies and to transform Old Harmon into a more energy-efficient and sustainable building. This is in keeping with the College’s Master Plan and strategic goals. The project supports MCTC’s vision and mission by providing a comfortable, energy efficient space for teaching and learning. Page 6 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 2. Project Background Narrative a.) The Existing Systems Minneapolis Community and Technical College (MCTC) is planning to renovate portions of the Management Education Center (MEC). This mostly academic building, located at 1314 Harmon Place (at S 13th St) in Minneapolis, houses the Continuing Education and the Business Department. It is adjacent to the Health Science Center. Within the MEC, in the northeast section, is a structure known as Old Harmon. It consists of an underground level and four stories above grade. Each floor is about 7,100 gross square feet. Refer to Appendix C for drawings of the MEC building, with the Old Harmon area highlighted. Adjacent to Old Harmon, and within MEC, is the structure known as New Harmon, or Area E. Constructed in 1912, Old Harmon is mainly office space. An old packaged HVAC rooftop unit provides cooling and ventilation for Old Harmon, but no longer the third floor. This rooftop unit is mounted on the roof of New Harmon and is ducted across to Old Harmon. It is in poor condition due to its age, and the replacement cost was previously quoted at about $92,000. The old air handling unit delivers air to the first, second, and fourth floors through old VAV boxes with pneumatic controls. All of the heat for these floors is provided by steam radiators, using an old-fashioned one-pipe system. There is only one steam control valve for the entire Old Harmon building. Two steam boilers in the Health Science Building originally served all of the MEC building. However, they presently only provide steam heat for Old Harmon and another classroom. The boilers are more than 40 years old. The rest of MEC is now heated with hot water furnished by a newer boiler plant. The old steam boilers are much less efficient. In 2011, the third floor of Old Harmon was renovated, with the introduction of a new heating, ventilating and air conditioning system, at a cost of about $860,000. This included a full gut-and-rebuild of the floor. The new HVAC system consists of a central HVAC air handling unit, located in a room on the third floor, previously used as a vault. Heating water and chilled water is generated at the Campus central plant, and this is connected to the air handling unit on the third floor of Old Harmon. The College’s intent has been to phase out the original heating and ventilation system which is inefficient, difficult to control, and in poor condition. According to reports, in 2010 the third floor of Old Harmon was tested for asbestos and none was found. Some lead paint was found in walls and ceilings in Old Harmon. Presently, there is some lead based paint at the windows. It is possible that the renovation might disrupt materials which still have lead paint, but it is not clear at this point. The project budget includes $30,000 for hazardous materials abatement. The MEC block of buildings has two electric utility meters. One serves Old Harmon and the Health Science Center. The other serves New Harmon, and the rest of the MEC Page 7 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing block. There is a natural gas utility meter in the boiler room in the Health Science Center, which only meters equipment serving Old Harmon. Management Education Center (MEC) Building According to the 2011 MCTC Master Plan, roof replacements, including New Harmon roof, is among the top HEAPR requests. During the initial predesign process, it was discovered that two built-up roofs of MEC are currently in place and the roof structure could potentially be overloaded. Overloading of a roof deck and its support structure is very serious and should be considered a life safety issue. In addition, roof core samples showed no adhesion or attachment of the second roof system to the original built-up roof system. It is, in effect, floating above the original roof. This lack of attachment could result in catastrophic failure of the over-roof, with it either being partially or completely torn off in a windstorm. Immediate attention to this particular roof area is strongly Page 8 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing recommended. Because of the seriousness of the matters discussed above, this area was moved up from its original rotation in the 0 – 5 reroofing budget. b.) Statement of Statutory Requirements The following statutes apply (from Appendix D: “Statute Requirements for Projects Receiving State Funding”): • • • • • • • • • • MS 16B.323 Solar Energy in State Buildings – Up to 5% of appropriation to be used on solar energy systems when doing substantial reconfiguration or replacement of energy systems MS 16B.325: Apply Sustainable Guidelines (B3-MSBG) for major renovations exceeding 10,000 SF. This also includes MS 216B.241 Sustainable Building 2030 requirements MS 16B.326 Written plan with predesign to consider providing geothermal and solar energy heating & cooling systems on new or replacement HVAC systems MS 16B.327 Recycle 50% of construction and demolition waste (75% in compliance with Minnesota Sustainable Design Guidelines) MS16B.33(3a) Designer Selection board requirements (If construction cost is greater than $2 million) MS 16B.335, subdivision 1 Notification to House & Senate Committees MS 16B.335, subdivision 4 Energy Conservation Standards (Energy Code – MN Rules 1322/1323 MS 16B.335, subdivision 3c Consider the use of MINNCOR products MS 16B.35, subdivision 3c Percent for Art – When considered in the original legislative request and when the construction cost is $500,000 or higher MS 177.42.44 Prevailing Wage Rates must be paid be Contractor c.) The Project Program At this time, there are no plans to change the building program. It is intended that walls will not change, and the present activities will remain the same after the renovation takes place. d.) Summary of the Project Planning Process Campus Facilities has been planning this project for the past few years. The 2011 renovation of the HVAC systems for the third floor of Old Harmon could be considered the first phase. In preparation, asbestos abatement has been accomplished. The College has made application for HEPR money to fund this project. Minutes of the initial project team meeting for predesign can be found in Appendix B of this Report. Page 9 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing e.) Backlog and FCI Summary Old Harmon: 35,487 GSF; the backlog is $4,439,000; the FCI is 0.37; for the proposed project, Old Harmon will undergo a renovation of the HVAC systems New Harmon: 55,546 GSF; the backlog is $2,964,000; the FCI is 0.18; for the proposed project, New Harmon will undergo a roof replacement The 2011 MCTC Master Plan indicated a backlog of repairs value of $3,790,000 and a Facility Condition Index (FCI) of 0.36. f.) Code Review BUILDING CODE SUMMARY FOR MCTC HARMON CENTER BUILDING AREA SUMMARY OLD HARMON BUILDING – (Built 1912) Basement 6,690 SF First Floor 7,100 SF Second Floor 7,100 SF Third Floor 7,100 SF Fourth Floor 7,100 SF Total 35,090 SF NEW HARMON BUILDING – (Built 1976) Basement 17,915 SF First Floor 15,910 SF Second Floor 18,275 SF Total 52,100 SF OCCUPANCY TYPE: B TYPE OF CONSTRUCTION: Type IIB BOTH BUILDINGS ARE FULLY SPRINKLED ALLOWABLE HEIGHT: 4 Stories/55’ ALLOWABLE AREA: Basic Allowable Area: 23,000 SF Area Increase for Fully Sprinkled: 23,000 x 2 = 46,000 SF Area Increase for Multiple Stories: 46,000 X 2 = 92,000 SF Page 10 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing FIRE RESISTANCE RATINGS (Table 601) Structural Frame 0 Interior Bearing Walls 0 Exterior Bearing Walls 0 Interior Nonbearing Walls 0 Floor Construction 0 Roof Construction 0 (A 2-hour rated Fire Wall exists between New and Old Harmon, effectively creating two separate buildings. This was needed prior to both buildings being fully sprinkled and is likely no longer a requirement to meet existing and allowable area requirements.) TOTAL ASSUMED OCCUPANT LOAD Basement Occupant Load: 179 = 86 Women + 86 Men First Floor Occupant Load: 392 = 196 Women + 196 Men Second Floor Occupant Load: 502 = 251 Women + 251 Men Third Floor Occupant Load: 57 = 27 Women + 27 Men: Fourth Floor Occupant Load: 57 = 27 Women + 27 Men: Total Occupant Load: 1187 MINIMUM PLUMBING FIXTURES (Table2902.1) Water Closets: 25 Required / 35 Provided Lavatories: 16 Required / 32 Provided Drinking Fountains: 12 Required / 12 Provided? Page 11 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 3. Project Description a.) Purpose and Rationale This section describes the new work which will address the current deficiencies. The proposed renovation is needed in order to transform Old Harmon into a more sustainable building, in the following ways: 1.) By addressing deferred maintenance 2.) By providing a more comfortable working and learning environment for building occupants 3.) By improving energy efficiency 4.) By addressing life safety concerns, by replacing the New Harmon roof b.) Project Scope The following paragraphs summarize the scope of the MEC renovation project, including HVAC systems construction, equipment demolition, and roof work. 1 - The Continued HVAC Build-Out of Old Harmon In addition to a new indoor air handling unit, the recent third-floor HVAC replacement included new air ducts and air distribution through variable volume controllers (VAV boxes) and duct-mounted hot water booster heating coils for zone temperature control. The air handling unit was sized to also serve the fourth floor, through an extension of the supply and return air ductwork. As part of the continuing renovation, the fourth floor will be builtout in a similar way. Also, another, similar indoor air handling unit will be installed, along with VAV boxes and coils, to serve the first and second floors of Old Harmon. The additional air handling unit will be located in a space directly below the third floor fan room. Heating water and chilled water pipes were stubbed into the room. The new air handling unit will include a supply fan, a return-relief fan, heating coils, cooling coils, filters, and automatic dampers. The fans will be powered through adjustable speed motor drives for variable air volume control of fan speed according to demand. Outdoor air will be extended from the roof to the new air handling unit for fresh air ventilation, and a means of allowing excess air to exit the building will be provided. Chilled water piping will be extended to cooling/dehumidification coils in the new air handling unit. Heating water piping will be extended to coils in the air handling unit and to booster heating coils in supply air ductwork. Electric power will be extended to the new fan motors. Generally, each room will be a temperature zone, with a room temperature sensor and a dedicated VAV box with a booster heating coil. Some smaller rooms with similar occupancies will share zone terminals. The HVAC equipment will be monitored and controlled by the MCTC Campus building automation system (BAS). New electronic Page 12 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing automatic controls will be installed for this purpose. The BAS is based on Invensys Niagara (presently Schneider Electric/TAC). It is estimated that there will be about 80 to 100 additional points of monitoring and control by the BAS. This will include monitoring of motor status and space temperatures. It will include control of dampers, VAV boxes and coil valves. The BAS will facilitate energy conservation measures, including air-side economizer control, variable volume air supply, demand ventilation (using space CO2 sensors), and automatic supply air temperature and pressure re-set. Old heaters in two Old Harmon building entries will be replaced with new hot water cabinet unit heaters with automatic control. The HVAC retrofit will also include replacing the present steam heat with hot water heat in a classroom and in the loading dock. At this time, there are no plans to change the building program. It is intended that walls will not change, and the present activities will remain the same after the renovation takes place. There will be some additional, general construction activities associated with the HVAC renovation. It is possible that some of the existing ductwork in the first, second, and fourth floors could be re-used, but this would need to be cleaned, and there would be much work involved in fitting this to new VAV boxes and heating coils. In any case, ceilings will be temporarily removed and then restored, in order to install new equipment and materials. Additional shaft space will be created for ductwork. Some fire sprinkler piping and heads might need to be modified or relocated to a small extent. Along with ceilings, light fixtures will need to be removed temporarily and reinstalled. A sanitary drain and vent will be needed in the new fan room on the second floor. During the Predesign, other HVAC options have been given some consideration, such as heat pumps and variable flow refrigerant systems. However these have been dismissed in favor of the central AHU/VAV/booster heating coil system described herein. The proposed HVAC system is considered to be the most energy –efficient option and the most practical for the space. It would be impractical to install an HVAC system for Old Harmon, other than the one which has been started with the remodeling of the third floor, which included the installation of a central air handling which was sized and selected to also serve the fourth floor. Refer to the section on Sustainability in Section IV of this Predesign report for information about alternative energy systems. Page 13 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Some general construction is anticipated, in order to support the HVAC renovation. The proposed new second floor fan room for a new air handling unit will be fitted with an acoustic door. The walls of this might also need some acoustic treatment. Depending on the location of the new air handling unit, some reinforcement of the structural floor system might be needed. Openings will need to be cut and holes drilled for new air ducts and pipes to this room. Some lay-in ceilings will need to be dismantled and reconstructed, in order to install ducts and pipes above ceilings. In some rooms, drywall soffits might be needed to conceal air ducts. Some small vertical pipe chases will need to be constructed. 2 - Removal of the Old Rooftop Unit When the proposed HVAC renovation of Old Harmon is completed, the rooftop unit will not be needed. At that point, it will be removed. It is located on the roof of New Harmon, and its removal has implications for reroofing of that building (Refer to the next item). 3 - MEC-New Harmon Roof Replacement The entire roof on New Harmon should be replaced as part of the mechanical renovation project in order to eliminate obsolete roof penetrations, minimize the possibility of a catastrophic failure, and to install a long term durable roof system that will meet the MnSCU forty year life expectancy. The existing concrete deck has little to no structural slope, and therefore, a fully-tapered insulation system will be required. The existing gravel stop style roof edge will be raised Page 14 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing to accommodate the necessary base flashings heights required to meet current MnSCU standards. Select masonry wall surfaces will be covered with plywood, underlayment, and sheet metal wall panels. The walls appear to be solid wall construction and do not appear to have through-wall flashing; therefore on these roof areas, the existing reglet will be removed or cut off and raised to accommodate the 12" minimum base flashing height as required to meet current MnSCU standards. This work will require the services of a masonry consultant. The walls appear to be cavity wall construction. Therefore on these roof areas, new double through-wall flashing will be required to provide a weathertight condition and accommodate the 12" minimum base flashing height as required to meet current MnSCU standards. This work will require the services of a masonry consultant. Various holes and assorted defects in adjoining or intersecting masonry walls will be repaired in conjunction with this project. This work will require the services of a masonry consultant. There are several windows and/or other penetrations through the masonry wall that may need to be raised to accommodate the necessary base flashing height. This work will require the services of mechanical, masonry, and window consultants. The existing drains and leaders will be replaced with a larger size, or additional drains added, to meet current code requirements. Also, overflow drains and/or scuppers will be provided. The existing mechanical curbs will be raised to accommodate the necessary base flashing height. All associated mechanical/electrical/g as modifications will be incorporated. Mechanical equipment will be relocated as necessary to provide a symmetrical and unobstructed drainage layout. The existing electrical lines located on the surface of the roof will be removed and relocated to the interior of the building. The existing lights will be removed and relocated to an exterior wall surface and the conduit will be relocated to the interior of the building. This work will require the services of an electrical consultant. The obsolete capped curbs, vent stacks, and sleeper curbs will be removed and deck replacement provided where necessary. The existing access ladders will be removed, Page 15 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing modified, and/or replaced with new OSHA-approved access ladders in order to meet current code requirements. In addition, two new OSHA-approved roof access ladders will be provided at two new locations that were without proper roof access. This work will require the services of a structural consultant. On the New Harmon Area E, the existing roof membrane and insulation will be removed down to the existing concrete deck. A base layer of 1" rigid insulation will be mopped in asphalt to the existing concrete deck followed by a two-ply asphalt vapor retarder. A new fully-tapered rigid insulation system with isocyanurate insulation filler boards will follow topped by a 1" top layer of rigid insulation and a four-ply asphalt built-up membrane with gravel surfacing. 4 - Removal of Two Existing Boilers After the Old Harmon renovation is completed, the two old steam boilers will no longer be needed, since all of the heat will be provided by the newer hot water boilers. As part of the project, these will be removed. In addition, abandoned piping which connects to the boilers will be removed wherever they can be accessed. Openings left in walls and floors by the removal of pipes will be patched. Concrete housekeeping pads will also be removed, so that the floor is more useable. Page 16 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing c.) Relationship of the Project to the Updated Facilities Master Plan Among the goals of the 2011 MCTC Master Plan is reducing the asset preservation backlog. And among the top priority HEAPR projects is energy system improvement. Among the strategic goals of MCTC is to reduce energy consumption by at least 20% and to reduce the emission of greenhouse gasses. This project will help toward accomplishing these goals. The project will eliminate two very old, inefficient steam boilers, as well as a rooftop unit that has four condenser motors, a 30 HP blower and two 30 ton dx compressors. d.) Other Considerations for this Project Most of the work of this project will probably take place during the summer of 2017. It is assumed that the renovation cannot take place while spaces are occupied. Faculty, staff and students will need to relocate temporarily, while the work takes place. The HVAC might need to be separated into stages, as described in Section 7, “Schedule”, with some of the renovation taking place after the summer. The roof work on New Harmon would happen during the summer, after the old rooftop unit is removed. At this point, the old rooftop unit would no longer be needed. At this time, the College does not anticipate a need to construct temporary space or lease off campus. It is assumed that space for relocating faculty and staff offices will be available on campus. c.) Consequences of Delayed Funding for this Project The existing HVAC equipment is aging and in poor condition. The main heating coil has sprung leaks. There are life-safety issues with the roof and environmental control. Systems are inefficient, and the energy cost is higher than it needs to be. Delaying funds will exacerbate these conditions. Page 17 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 4. Sustainability a.) Opportunities for Sustainable Design Initiatives The Minnesota Sustainable Building B3 Guidelines are applicable to all new State buildings and to buildings larger than 10,000 square feet, which undergo major remodeling. This project includes the continued renovation of the Old Harmon HVAC system and the re-roofing of New Harmon, and this presents opportunities for improvements in the areas of Energy Efficiency and Indoor Environmental Quality. Energy Efficiency Improvements: • The Old Harmon HVAC system will no longer use steam heat from the old health Science boilers, and it will instead utilize hot water from the newer, more efficient central plant boilers. • The old, inefficient rooftop unit will no longer be used for ventilation and air conditioning; instead new, indoor air handling units with a more modern variable volume air distribution will be used. • New automatic controls will provide improved zone temperature control and system performance; the Campus building automation system will monitor and control the systems, to help optimize their operation. • The reroofing will improve the thermal characteristic of the roof system for New Harmon. Indoor Environmental Quality Improvements: • The amount of outdoor air intake can be automatically regulated according to the varying occupancy of spaces (demand ventilation). • The new HVAC systems and improved zone controls will be better able to maintain comfortable conditions; occupants will have better control of space temperatures. This will have a distinct, positive impact on long-term sustainability and on energy conservation. In addition, there are opportunities to use alternative energy systems, to supplement the main energy systems, as discussed in the next section. b.) Analysis of Alternative Energy Systems General Information Predesign reports for projects for State agencies are required to undergo an analysis for including alternative energy sources, to provide at least 2 percent of the building’s annual energy consumption. Sources to be considered are geothermal (using ground source heat exchange), solar thermal (generating hot water), solar electric (using photovoltaic), and wind. Page 18 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing The Renovation at Minneapolis Community and Technical College will involve major remodeling of about 28,300 square feet in Old Harmon. The State of Minnesota Department of Administration B3 Benchmarking Website stores energy data for State buildings, including MCTC. In the following analysis, the energy consumption data is taken from these records. According to the B3 Database, the Old Harmon building consumes about 1,535,000 kilo-watts of energy in a normal year. This includes energy for all purposes – heating, cooling, power, lighting, domestic water heating, etc. As part of the renovation, the new HVAC systems will incorporate sustainable design measures which will reduce the energy consumption. It is not expected that the boilers and chillers will change, so the energy improvements will be limited to measures which can be taken with the air handling equipment, air terminals, and automatic controls. It is reasonable to assume that a savings of at least 30 percent is achievable, so the required energy for Old Harmon is expected to be 1,075,000. On this basis, the normal annual energy load for the renovated project area (1st, 2nd, and 4th floors of Old Harmon) is expected to be 79% of 1,075,000 or 849,000 KWH per year. The alternative energy systems should be sized to produce an amount of energy equal to at least 2% of this figure, or 16,980 KWH per year. Converted to BTUs, this equals about 58 million BTUs per year. The Clean Energy project Analysis Software of RETScreen International was used to forecast the capacity and performance of the following systems: solar photovoltaic, solar thermal, and wind. The analysis for a geothermal system was hand-calculated. The software of RETScreen International was developed by Natural resources Canada, with sponsorship by NASA, United Nations Environment Program, Renewable Energy and Energy Efficiency Partnership, and World Bank. The software allows for input of local weather conditions, capital costs, design costs, and local energy prices. It was specifically designed as a decision-making tool for the analysis of renewable energy systems. For each type of alternative energy system, a present-value cost analysis has been performed, using the RETScreen software. Cost figures are present-day values and include design, materials, labor, general conditions, overhead & profit, and a contingency amount. Incentives and grants may be available to partially offset some of the capital cost. Use of these incentives and grants are generally conditioned on ownership by taxable entities. Analysis of eligible ownership structures and applicable incentives is beyond the scope of this general screening of renewable energy systems. Savings are the present value of amount of energy cost avoided by using the alternative system. The energy required to operate the alternative systems is a small number compared with savings, and so this has been discounted. A Solar Photovoltaic System A solar collector array was installed on the roof of the loading dock section of MEC. This is only used by the instructors and students as part of a class being taught at the College. For this analysis, a larger new solar array is assumed. Page 19 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing An array of solar panels with photovoltaic cells could be installed on the building roof or possibly on grade near the building. Other equipment would be required to transfer the electrical energy to the main building system. In order to generate 16,980 KWH of electricity per year, the array would consist of 42 panels, and would require an area of about 742 square feet. This could produce as much as 13.4 KW under conditions of full sunlight exposure. The total of the first costs is $137,800. The computer model indicates an annual energy savings of 15,975 KWH and an annual dollar savings of $1,628. The simple payback is, therefore 85 years. This does not include the cost of additional roof structure support, if needed. It does not include additional maintenance cost. A Solar Thermal System An array of solar collectors could be used to heat or preheat domestic water. These could be installed on the building roof or possibly on grade near the building. The panels could be the flat-plate type with water tubing inside. In addition to the solar panels and supporting structure, the solar thermal system would include an indoor storage tank, circulating pump, heat exchange, controls, and wiring. In order to generate 58 million BTUs of heat per year (2%), the array would consist of 8 panels, and would require an area of about 318 square feet. The heat collected could be as much as 66,500 BTUs per hour. The total of the first costs is $29,450. The computer model indicates an annual dollar savings of $458. The simple payback is, therefore 64 years. A Wind Energy System An array of wind-powered electric generating turbines could be installed on the building roof or possibly on grade near the building. Other equipment would be required to transfer the electrical energy to the main building system. In order to generate 16,000 KWH of electricity per year, the array would consist of a single wind turbine, requiring an area of about 200 square feet. This could produce as much as 3 KW under ideal conditions. The total of the first costs is estimated to be $57,200. The computer model indicates an annual energy savings of 16,000 KWH and an annual dollar savings of $1,608. The simple payback is, therefore 36 years. A Geothermal System A ground-source (geothermal) heat pump system could be installed to provide a portion of the annual heating and cooling energy consumed by Old Harmon (including lights, plug loads, HVAC, etc.). The system would work in conjunction with the heating water and chilled water feeds to the new air handling units serving Old Harmon. The geothermal system would consist of a ground heat exchanger (well field) outside of the building, waterto-water heat pumps, buffer tanks, circulating pumps, piping, wiring and controls. The balance of the heating and cooling for HVAC will be supplied by the Campus boilers and chillers. There is limited space at the site for a well field. It could be constructed below an existing parking lot next to the Loading Docks. There would be space for about 12 wells. In the analysis, it is assumed that the geology at this site is fairly normal, and it is Page 20 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing estimated that a well field consisting of (12) 200-foot deep well bores could be installed. It is estimated that this would provide sufficient ground heat exchange for about 12 Tons of cooling effect and an equivalent amount of heat extraction. It is also estimated that this will supply about 8% of the annual heating and cooling for the entire Old Harmon building, and that this represents about 3.6% of the total annual energy usage of areas in Old Harmon affected by the proposed HVAC renovation, or 30,740 KWH/year. About half of this energy is for heating and half is for cooling, in order to maintain a balance of heat extracted and heat rejected to the ground. During the design phase, a test bore and a soil conductivity test should be undertaken, in order to verify the size. The overall system cost would be approximately $86,000 including the cost of design and soil testing. Based on the cost of generating central plant steam ($8.40 per million BTUs output), the savings for heating is about $2,180. Based on the average cost of electricity ($0.10 per KWH), the annual savings for cooling is calculated to be about $7,580. The total savings is $9,760 per year. The payback period would be 9 years. Summary Type of System Capacity Annual Avoided Energy % Annual Load Annual Avoided Expense Capital Cost Payback in Years Page 21 of 31 Solar PV 13.4 KW 16,980 KWH 2.0% $1,628/Year Solar Thermal 66 kBTUH 62 million BTUs 2.1% $458/Year $137,800 85 $29,450 64 Wind 3 KW 16,980 KWH 2.0% $1,608/Year $57,200 36 Geothermal 145 kBTUH 30,740 KWH 3.6% $9,760/Year $86,000 9 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 5. Financial Information – Capital Expenditures a.) Summary of Financial Information A summary of capital expenditures for this project is shown in Table 1, on the next page of this Predesign Report. More detail is presented in Appendix A. Table 1 includes project schedule information, and more detail is presented in the chart in Section 7, “Schedule”. b.) Funding Sources The construction will be funded with HEAPA money. will be funded with the general operating budget Temporary relocation of people c.) GESCs and HEAPR As a result of the governor’s executive order 11-12, MnSCU has been encouraged to consider all building energy efficiency projects as candidates for guaranteed energy savings contracts before including them in a HEAPR request. As part of the Predesign, research was conducted to determine the eligibility of each of the major project components. In a conversation with the GESP Program Manager at the State Dept. of Commerce, it was determined that the reroofing and the boiler demolition would not be eligible for the GES contract and will need to be covered by HEAPR funds. The HVAC renovation probably also needs to be covered by HEAPR funds, unless the payback period is attractive (or attractive if it is bundled together with other projects); then it possibly could be eligible for the guaranteed energy savings contract. Page 22 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing TABLE 1 - PROJECT COST FORM – MCTC MEC/OLD HARMON RENOVATION TOTAL PROJECT COSTS All Years and All Funding Sources Project Costs (Dollars) Prior FY FY 2014/15 2016 Years Start FY 2017 Finish All Years 1. Property Acquisition 1a) Land and Easements Options 0 0 0 0 0 1b) Buildings and Land 0 0 0 0 0 SUBTOTAL 0 0 0 0 0 2. Predesign 07/14 12/14 SUBTOTAL 0 20,000 0 0 20,000 3. Design Fees (8% of Construction Cost) 0 0 146,000 0 146,000 3a) Schematics (20% of Design Fee) 0 0 29,200 0 29,200 07/16 09/16 3b) Design development (25% of fee) 0 0 36,500 0 36,500 09/16 11/16 3c) Construction Documents (30%) 0 0 43,800 0 43,800 11/16 12/16 3d) Construction Administration (25%) 0 0 36,500 0 36,500 01/17 09/17 SUBTOTAL 0 0 146,000 0 146,000 4. Project Management (6-8% of Constr. Cost) 4a) State Staff Project Mgmt (8% of Cost) 0 0 146,000 0 146,000 01/17 09/17 4b) Non-state Construction Mgmt (2%) 0 0 36,400 0 36,400 01/17 09/17 4c) Commissioning (0.5% of Constr. Cost) 0 0 9,100 0 9,100 08/17 09/17 4d) Testing/Quality Assurance (1%) 0 0 18,200 0 18,200 08/17 09/17 SUBTOTAL 0 0 209,700 0 209,700 5. Construction Costs 5a) Site and Building preparation 0 0 0 0 0 5b) Demolition/Decommissioning 0 0 Inc. in 5c 0 Inc. in 5c 06/17 07/17 5c) Construction (See Appendix C) 0 0 1,821,000 0 1,821,000 05/17 09/17 5d) Infrastructure/Roads/Utilities 0 0 0 0 0 5e) Hazardous Materials Abatement 0 0 30,000 0 30,000 5f) Constr. Contingency (10%) 0 0 182,100 0 182,100 SUBTOTAL 0 0 2,033,100 0 2,033,100 6. Art (NA) SUBTOTAL 0 0 0 0 0 7. Occupancy (4-10% of Construction 5c) 7a) FFE (NA) 0 0 0 0 0 7b) Telecommunications (NA) 0 0 0 0 0 7c) Security Equipment (NA) 0 0 0 0 0 SUBTOTAL 0 0 0 0 0 SUBTOTAL, SECTIONS 1 THROUGH 7 0 20,000 2,388,800 0 2,408,800 8. Inflation 8a) Mid-point of construction (July 2017) 8b) Multiplier (Calculated by system office) 0 0% 18.56%* -8c) Inflation Cost (By System Office) 0 0 443,400 443,400 SUBTOTAL 0 0 443,300 443,400 9. Other SUBTOTAL 0 0 0 0 0 GRAND TOTAL 0 20,000 2,832,200 0 2,852,200 * The 18.56% inflation in the 2016 column is the CPMI inflation index, at the mid-point of construction. Page 23 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 6. Financial Information – Ongoing Operating Expenditures a.) Utility Costs The B3 Database for buildings at MCTC shows that Old Harmon consumed the following amount of fuel and electricity for the 12 months prior to the start of this predesign: Electrical usage and cost: One electrical meter for Old Harmon (1300 Hennepin Ave.) Old Harmon Electrical (9/12/2013 to 9/14/2014) = 516,400 KWH; $50,540 = $0.10/KWH. With a total of 35,490 GSF, the average cost of electricity per square foot is presently $1.42 per year in Old Harmon. Natural gas usage and cost: Three Meters for Old Harmon: 1.) 1300 Harmon Place: (09/03/2013 to 09/03/2014) = 1,260 Therms; $1,202 = $0.96/Therm 2.) 1301 Hennepin Avenue #1: (09/03/2013 to 09/03/2014) = 2,290 Therms; $2,139 = $0.93/Therm 3.) 1301 Hennepin Avenue #2: (10/01/2013 to 09/30/2014) = 29,990 Therms; $21,776 = $0.73/Therm Total = 33,540 Therms; $25,117 = $0.75/Therm, or $7.50 per million BTUs input (average). This is equal to $8.40 per million BTUs system output, using 89% as the average heating efficiency. With a total of 35,490 GSF, the average cost per square foot for natural gas is presently $0.71 per year in Old Harmon. Post-project estimate of electricity consumption and cost (adjusted): According to weather data, there were 760 cooling degrees days in Minneapolis during this 12-month period. In an average year there are 1064 cooling degree days in Minneapolis. It is estimated that approximately 35% of the electricity consumed is for summer air conditioning, and the other 65% is for lights, plug loads, and equipment. Normalizing the electricity consumption results in a normal building consumption of (0.65 x 516,400) + (0.35 x 516,400 x 1064/760) = 588,700 KWH/Year. As explained in section 4, Sustainability, implementation of the energy conservation measures in this project will reduce the amount of electricity consumption in a normal year significantly. A reduction of 30% is reasonable. Therefore, the electricity consumption in a normal year is expected to be about 70% of 588,700 KWH = 412,100 KWH. Using the average cost per KWH in 2014, the present cost of electricity in a normal year following construction would be $0.10 x 412,100 = a projected $41,200 per year for electricity. However, the unit cost of electricity is likely to escalate, raising this figure over time. And changing weather conditions from year to year will also be a major factor. Page 24 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Post-project estimate of natural gas consumption and cost (adjusted): According to weather data, there were 8658 (base 65F) heating degrees days in Minneapolis during this 12-month period. In an average year there are 7877 heating degree days in Minneapolis. It is estimated that approximately 90% of the natural gas consumed is for winter heating of the structure and the other 10% is process (domestic water). Normalizing the heating consumption results in a normal building heating consumption of (0.10 x 33,540) + (0.9 x 33,540 x 7877/8658) = 30,820 Therms. As explained in section 4, Sustainability, implementation of the energy conservation measures in this project will reduce the amount of natural gas consumption in a normal year significantly. A reduction of 30% is reasonable. Therefore, the natural gas consumption in a normal year is expected to be about 70% of 30,820 Therms = 21,570 Therms. Using the average cost per Therm in 2014, the present cost of natural gas in a normal year following construction would be $0.75 x 21,570 = a projected $16,180 per year for natural gas. However, the cost of natural gas is likely to escalate, raising this figure over time. And changing weather conditions from year to year will also be a major factor. b.) 5-Year Projection of Operating Budgets Removal of the old boiler and the use of the newer, more efficient boiler will have a significant effect on operating cost. Similarly, removal of the old rooftop HVAC unit and replacement with a more efficient variable volume system and more efficient equipment will have the effect of reducing energy consumption and operating cost. By connecting systems to the Campus energy management system, to monitor and control the operations, a further reduction in operating cost is expected. No additional operating expenditures are anticipated, and maintenance will be reduced due to the operation of new equipment. Staffing levels will not be impacted because of the project scope. The maintenance work load will be reduced. Using the figures in part a) Utility Costs, above, the amount of electricity usage is expected to be $41,200 for electricity and $16,180 for natural gas, for a total energy budget of $57,380 per year. In a 5-year period, the present-value savings in energy amounts to $286,900. This does not include inflation. c.) Debt Capacity Minneapolis Community and Technical College’s current debt is well within acceptable parameters. No College debt from this project is expected, due to the availability of HEAPR funding. Page 25 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing 7. Schedule It is most likely that design and construction will take place during the 2016/2017 biennium. With funding approved in June of 2016, design will take place during the months that follow. It is assumed that construction in Old Harmon cannot take place while the building is occupied. The occupants will need to relocate in order for the work to take place. Time would be needed to move out following the end of semester, and so mobilization would begin in May 2017. It is estimated that at least 3 solid months will be required to replace the HVAC systems. This doesn’t include commissioning and closeout. It also doesn’t include dealing with unknown conditions. Because it is an older building, it is likely that there will be hidden conditions that must be addressed. Therefore, it is recommended that four to five months should be allotted for the HVAC construction. In order to minimize the time when floors need to be vacated, the HVAC construction could take place in two stages. The first stage would be the build-out of the fourth floor and the tie-in to the existing third floor air handling unit. The second stage would be the HVAC installation in the first and second floors. At the end of the first stage, the third and fourth floors could be occupied again, while the first and second floors are being finished. This is shown on the following schedule: Proposed Project Schedule: 2016 M Funding Request (10/14) Funds Available Schematic Design MNSCU SD Review Design Development Construction Documents MNSCU CD Review Bidding and Award Shop Drawings Mobilization/Prep Work 1st & 2nd Floors Vacated 3rd & 4th Floors Vacated 4th Floor HVAC 1st & 2nd Floor HVAC Boiler Demolition Rooftop Unit Removal Re-Roofing 3rd/4th Flr Commissioning 3rd & 4th Floor Occupancy 1st/2nd Flr Commissioning 1st & 2nd Floor Occupancy Page 26 of 31 J 2017 J A S O N D J F M A M J J A S O N D Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Prior to the last week of May 2017, the Contractor will prepare shop drawings, order equipment, fabricate materials, and make other preparations for construction. The last week of May, 2017, Old Harmon will be vacated, and the Contractor will begin demolition and installation of equipment and materials. The numbers of staff, faculty and students which will need to be temporarily relocated is unclear at this time. The College believes that there will be sufficient space available in another Campus building. Options would include the Technology Building, Helland Hall, and the basement of New Harmon. As long as Old Harmon is unoccupied, the removal of the old rooftop unit can take place any time after people leave. The reroofing of New Harmon can take place after the old rooftop unit is removed. The demolition and removal of the steam boilers can take place at any time, as long as the new heating water piping has been installed. Appendices The following documents are included in the appendices: Appendix A: Detail of Construction Costs Appendix B: Meeting Minutes (planning and review) Appendix C: Building Floor Plans Appendix D: Hazardous Materials Surveys Page 27 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Appendix A: Detail of Construction Cost Following is an opinion of the probable construction cost. The numbers are present value (January 2015). The cost summary table in Section 5 of the Predesign Report includes an inflation factor, as well as a construction contingency. The table in Section 5 also includes design, construction administration costs, and commissioning. The construction cost is as follows, separated into HVAC work and roof work: HVAC WORK 1.) HVAC Build-out of Old Harmon 1st, 2nd, and 4th floors (approximately 21,000 SF): a. b. c. d. e. f. g. h. i. j. k. l. m. n. o. p. q. r. s. t. General Requirements Demolition – Piping Air Handling Unit and ASDs Labor for items a through e VAVs, SAs, EFs, GRDs, & Dampers Ductwork and Accessories Shop Field Piping Labor for item k Automatic Controls Testing and Balancing Mechanical Insulation Rigging and Rentals Concrete Saw Cutting Permit Other General Construction Fire Sprinkler Plumbing Electrical and alarm monitoring Subtotal $7,500 $22,500 $39,600 $6,000 $60,000 $40,000 $60,000 $170,000 $162,500 $136,400 $125,000 $16,000 $125,000 $8,500 $10,000 $8,500 $38,000 $6,000 $16,000 $27,500 $1,085,000 2.) Removal of the Old Rooftop Unit a. HVAC/Demolition b. Reroofing (included in item 3) Subtotal $15,000 $15,000 3.) Removal of the Old Steam Boilers a. Demolition Subtotal Page 28 of 31 $15,000 $15,000 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing TOTAL HVAC CONSTRUCTION COST = $1,115,000 ROOF WORK 1.) MEC/New Harmon Roof Replacement a. b. c. d. General Construction – Roof Work Sheet Metal, Masonry, and Window Work mechanical/Electrical Structural TOTAL ROOF CONSTRUCTION COST = $413,000 $60,000 $219,000 $14,000 $706,000 TOTAL HVAC and ROOF WORK = $1,115,000 + $706,000 = $1,821,000 Page 29 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing Appendix B: Meeting Notes DATE: September 10, 2014 TIME: 1:30 PM to 2:30 PM PROJECT: MCTC MEC Old Harmon HVAC/Roofing Predesign PROJECT # 6301 MEMO BY: Jim Art SUBJECT: Initial Meeting for the Predesign THOSE PRESENT: James Splett, Scott Allie, Jim Holmquist, and Rick O’Brien – MCTC; Randy Moe – BTR Architects; Cynthia Long – Inspec; Jim Art - EEA COPY OF MEMO TO: Roger Broz (MCTC), Todd Peterson (EEA) and those present The initial Predesign meeting took place today in Conference Room T1500. The following subjects were discussed at the meeting: The scope of the predesign was reconfirmed. It will address the following: • Extension of the existing third floor HVAC system in Old Harmon to also serve the fourth floor of Old Harmon • Installation of a similar new air handling system to serve the first and second floors of Old Harmon • Removal of an existing rooftop unit on the roof adjacent to Old Harmon • Replacement of a portion of the roof or the entire roof of the building where the rooftop unit is located • Remove the existing boilers in the Health Science basement The MNSCU guidelines for a predesign report require an evaluation of system options. During the discussion today, it was established that it would be impractical to install an HVAC system for Old Harmon, other than the one which has been started with the remodeling of the third floor. This included the installation of a central air handling which was sized and selected to also serve the fourth floor. The MNSCU guidelines for a predesign report also require an evaluation of alternative energy systems such as geothermal, solar thermal and solar photovoltaic. It was pointed out in the meeting that some structural supports were constructed on the roof for a future solar array, but that they might not actually be practical to use. EEA will give further study to alternative energy systems. BTR was the architectural firm for the Old Harmon third floor remodeling. They have conducted code reviews in the past, and this information is likely to be relevant for the predesign. It was reported in the meeting that hazardous materials have been abated from the areas of this project. The consultants requested a copy of the most current Facility Master Plan from MCTC. Page 30 of 31 Predesign Report for Minneapolis Community and Technical College MEC/Old Harmon HVAC Replacement and New Harmon Reroofing It is our understanding that there are no plans to expand the building or to change the current building program significantly. The academic program will, of course, be impacted due to construction activities. The predesign report will address the subjects of energy-efficiency and sustainability. Today we talked about the College’s expectations for energy conservation improvement. The new systems will be much more efficient than the original systems. It is likely that the building systems will be required to meet the Minnesota B3/SB2030 sustainable design requirements. A tentative schedule was proposed. A 50% draft report will be issued on October 31st. A 95% draft report will be issued on November 26th. It is expected that, following each issue, MNSCU will spend about two weeks reviewing the draft. A schedule for funding and construction could not be determined today. * * * End of Memo * * * Appendix C: Building Floor Plans The following pages are copies of Building Floor Plans with Old Harmon Highlighted. Appendix D: Hazardous Materials Surveys The following pages are copies of past survey reports. Page 31 of 31