AUSTRALIAN HOP MARKETERS PTY. LTD Research Report

advertisement

AUSTRALIAN HOP MARKETERS PTY.

1979

Research

Report

LTD

AUSTRALIAN BOP MARKETERS PTY. LTD.

RESEARCH REPORT 1979.

PREFACE:

This Research Report documents part of the work in

hops research conducted by Australian Hop Marketers

Pty. Ltd. over the past year and outlines that work

proposed for the coming year. Most of the papers

included were initially written as internal papers

and tend to emphasise costs and commercial problems,

rather than academic and technical matters.

The report indicates something of the efforts being

made by Australian Hop Marketers Pty. Ltd. to improve

yields and returns to hop growers. I hope it will

also be of benefit to Brewers interested in reducing

freight costs and storage alpha acid loss and the

improvement of total alpha acid and hop quality.

M.G. CLEARY.

GENERAL MANAGER.

AUSTRALIAN HOP MARKETERS PTY. LTD.

CONTENTS

Research Programs 1979/'80.

Foliar Fertilizers, Report on the 1978/'79

PAGE

1

8

Trial.

Substitution of Soil-Applied Nitrogen with

10

Foliar Sprays.

Hormone Applications, Report on the 1978/'79

21

Trials.

Report on Miscellaneous Experiments,

29

Bushy Park Hop Nursery - 1979.

Antioxidants,Materials and Trials.

41

Vacuum Packed Pressed Hops, 1979 Report.

45

Vacunm Packing Pressed'Hops at High Density.

Whole Hop Pellets - 1979 Report.

Hop Growing in Tasmania. Some Notes on

49

57

64

Cultural Practices and Timing of Operations.

AUSTRALIAN HOP MARKETERS PTY. LTD.

HOPS RESEARCH 1979/80

I.J. Edwards

P.J. Versluys

SUMMARY:

A proposed hops research progranme is presented for 1979/80.

It consists of many routine and continuing experiments together

with the exploration of some new ideas which have a high risk,

but if successful could significantly improve the economics of

hop growing in Australia. These include a high intensity, low

budget, random breeding progranme, extensions of 1979 low trellis

experiments to include novel picking and cultural techniques,

trials to extend the harvest season with chemical sprays and

seme new propagation techniques.

A.H.M. Research 1979.

The following progranme of research is proposed for 1979/80.

1.

Hop Breeding

(IE)

With the appointment of Grahane Hughes to Carlton Jones, and the

sale of the Ringwood hop nursery by C.U.B., Australia no longer

conducts any breeding research into hops. On the other hand other

countries are rapidly advancing in this field with many conmercial

varieties now about the same alpha as Pride fo Ringwood (e.g. Wye

target 11%, Bullion 9-10%,) and experimental varieties around 15-16%

alpha. Since hops are generally brewed directly in proportion to

the alpha acid content, each 1% of alpha acid is worth approximately

25c/kg hops.

Traditional hop breeding prograimes usually test 300 - 400 new

varieties each year. Hops are selected from carefully controlled

crosses and are tested for storage stability, disease resistance,

alpha and beta acids, oils, vigour and time of maturity. The breed

ing progranme is generally expensive because of the labour involved

in monitoring all crosses, germinating seeds,

transplanting

seedlings two to three times, and analysing many parameters.

From discussions with hop breeders (P. Versluys, G. Hughes) and

observation of the new varieties arising fran breeding programmes,

it is apparent that hop breeding is more a matter of chance, than of

technique i.e. that there is no systematic method known of crossing

(apart from seme basic rules) that increases the liklehood of a new

successful variety arising.

What is proposed is that AHM, as part of its general research progranme,

plant a large number of seeds of Pride of Ringwood hops, selected

from a variety of sources to maximise the genetic variability (from

the male parent) and screen them primarily for alpha acid i.e a breed

ing progranme concentrating on cheapness, high numbers, and a single

parameter (alpha). Tne logic is based on the premise that a desirable

variety has a low probability of emerging, but that that probability

will be increased in proportion to the number of seedlings screened,

and not at all in preparation to the care taken in selecting crosses.

It is envisaged that from a breeding progranme costing $5,000/year in

analysis , materials and labour (mainly analysis) about 10,000 seed

ling/year will be screened for alpha. This will represent the number

of progeny tests arising fron about twenty years of conventional breed

ing and, with a high alpha parent to begin with, should show a real

chance of producing a 167<> alpha acid variety with acceptable vigour,

yield, flavour and storage stability characteristics.

2.

Low Trellis

(IE)

Tne small experimental area of low trellis yeilded up to 860kg/acre

for second year plants in 1979, with large cones formed virtually to

ground level. The yield would be expected to increase further for

third year plants, and for closer row spacings.

In the low trellis vines reach the wirework in December and then grow

under (80% of vines) or over the topwire and continue growing.

The growing tip is then subject to wind damage by being dashed against

the wire and adjacent vines.

Wind also moves the vines in the direct

ion of the prevailing wind direction, and they readily become tangled

in winds not strong enough to destroy the growing tip. If the growing

tip is killed, strong laterals emerge from the two to four topmost

pairs of buds, and these are also inclined to tangle.

Tangling of vines could be reduced by planting rows at right angles

to the prevailing westerly winds; also by increasing the separation

between strings, (currently 2') and by using a double top wire,

rather than a single. With this arrangement the vines could be

harvested more or less in the conventional manner using a car trailer

and with a man in front cutting the top and base of the vines. This

system would have substantial advantages over high wirework in cost

of establishment (probably $1,000.00/acre) but not in management

and harvesting.

To utilize the low trellis to its full premise, it would be desirable

to let the new vines grow up old vines for self training and then

picking without removing vines, i.e. a system with advantages:

(a)

(b)

(c)

(d)

Self training with no need for string (saving $200/acre off

present system).

Dense canopy with intertwining for full interception of sun

light and theoretically greater yield (10% yield is worth

$200/acre)

Harvesting of leaves and cones only, with full potential for

food reserves in vines to return to rootstock, thereby enhancing

yield in next year.

Harvesting by blowing or sucking off cones and leaves, with later

separation in existing stationary picking machines.

Potential

saving $100 - $200/acre.

The most difficult aspect of this system would be the development

of a suitable picking machine. Development of mobile harvestors for

normal trellis has been going on for many years by top engineers with

only limited success. This proposed system simply blows off the cones

and leaves, and these can be routinely separated in exisiting machines.

Although simple in principle, a harvestor relying onour movement to

dislodge cones and leaves has not been built, and may not prove

feasible. It is considered worth building a small experimental

machine though, since this could be constructed for $1,000 to $2,000,

and could be applicable to other crops.

Chemicals for Increasing Alpha Acid

(IE)

Alpha is influenced in an unknown way by soil nutrients. A pre

liminary trial in 1979 indicated that chemicals applied as foliar

sprays can have dramatic effects (mainly detrimental) on alpha.

Although the mechanics of any effects on alpha are unknown, applic

ation of foliar sprays is easily done and could readily become a

routine operation if consistent positive effects on alpha could be

demonstrated. For this reason it is proposed to further investigate

the possibilities of increasing alpha by applied chemicals.

Trials will involve applications of a range of chemicals, at differing

times and concentrations.

Pellet Plant Improvements

(IE)

A continuing programme of experiments at the pellet plant has the

following aims:1. Increasing throughput, without concurrently increasing die temp

erature, increasing alpha loss and lowering pellet density.

2.

3.

Reducing alpha losses.

Improving packaging at lower cost.

This year the main aims are:-

(a)

To produce most pellets at V (6.3 mm) diameter rather than 3/16"

(4.8 nm).

The 6 nm pellets are much easier to manufacture than

5 mm but generally have poor density characteristics if produced

from our current bronze die; or poor appearance if produced fron

our steel die.

A new bronze die has been ordered which should

increase throughput without reducing density adversely.

(b)

Most alpha loss occurs between the hammer mill and the pellet

die. The loss is caused by the hanmer milling, both by physical

loss of resin built up in the body of the hanmer mill, and by

oxidation in the air streamby the hanmer mill. Hanmer mill

screens must also be frequently changed, and hence lower through

put rates somewhat when alpha is high, as well as significantly

raising the proportion of physical resin loss.

With the new cyclone now installed for the whole hop pellets, there

is a possibility of bypassing the hanmer mill altogether i.e. feeding

intact hops into the pellet die. The commercial feasibility of this

is to be examined bearing in mind pellet particle size, throughput,

alpha loss reduction & pellet density.

Alpha Losses

(IE)

Despite some documented drying losses in excess of IX (absolute) alpha

acid, (and seme tentative gains by the University of Tasmania) we

have little idea of the losses in picking, drying and pelleting for

all situations and all growers.

Since variation in alpha is so great, a large number of samples are

necessary just to properly cbcument drying losses in any single kiln.

The feasibility of properly monitoring drying losses in all kilns,

and conducting miscellaneous experiments on possible alpha losses

and gains hinges on economical analysis. Approval of the recent

application for $10,000 for automatic alpha analysing equipment will

greatly facilitate analysis of greater numbers of samples.

Storage Trials

(IE)

Alpha losses are well documented for whole hops in standard bales

and for hop pellets, but not for any of the other products manufact

ured by AHM.

It is proposed to set up a routine trial to test alpha losses in:

(a) Vacuum packs of pressed hops (with and without vacuum loss)

(b) Whole hop pellets (with and without vacuum loss)

(c) High density bales.

(d) Powder pellets and standard bales as control.

Preliminary trials and theory indicate that the vacuum bales will lose

less alpha than vacuum packed powder pellets. Losses in whole hop

pellets are not known at all.

Hormone Sprays

(PV)

After two years of trials, the potentials for increasing yields by

selected hormone applications in unclear. In 1977-78 a large increase

was recorded, whereas in 1978-79 the increase was very small. An

associated effect though shows promise of making hormone applications

worthwhile.

This is the effect of some hormones (and some other

chemicals) in delaying ripening.

It is proposed to continue trials with hormones to further document

possible yield increases and dates of maturity following hormone

applications.

Antioxidants

(PV)

Antioxidants are widely used in the food industry to prevent product

deteoration by oxidation. Preliminary trials with hop pellets last

year indicated that alpha losses could be reduced by antioxidants.

It is proposed to extend this work to include other chemicals with

antioxidant properties, and investigations of likely practical

implications (technical problems and customer reactions).

Soil Sampling

(PV)

All AHM growers receive fertilizer reconmendations based on soil

testing.

1979 analyses have revealed some high phosphorus readings

which are possibly due to low rainfall (with consequent low leaching)

and high Ph (from high lime applications). There are some indications

that these high Ph readings correspond to low alpha results.

It is proposed to conduct trials to determine the effect of high

phosphorus levels on alpha and yield. The work will involve applicat

ions of mono potassium phosphate at various concentrations and,

possibly, the monitoring of phosphorus movement within the plant using

radioactive tracers.

Foliar Fertilizers

(PV)

From trials conducted in the last two years, foliar fertilizer use

can be generally reconmended for Tasmanian conditions. It is proposed

to document the use of foliar fertilizers under Victorian conditions

during 1979/80.

Leaf Sampling

(PV)

Leaf analysis accurately measures the nutrients taken up by the plant

and shows potential for determining fertilizer reconmendations and

nutrient deficiencies,The leaf analysis though, varies throughout the

growing season.

Continuing routine sampling and analyses are proposed on six selected

paddocks to monitor

basic leaf data through the growing season.

It is anticipated that one more years results will enable practical

evaluation of the use of leaf nutrient status.

Hop Propagation

(PV)

Hop cuttings represent a significant proportion of the cost of hop

expansion. Some advances in techniques for providing large quantities

of planting material from limited parent stock have emerged in recent

years. The feasibility of these for possible rapid increases in

acreage of Shinshuwase, J 78, B 23, or other varieties is planned.

The most promising technique involves rooting leaves in large numbers

in polythene growth chambers (without using mist). Leaves would be

rooted in October and planted out to a nursery or permanent position

in November.

Carbohydrate Root Reserves

(PV)

Under natural conditions much of the stored carbohydrate in hop

leaves and stems moves to the rootstock before the above ground part

of the hop plant dies in autum. If the vines are harvested early

in the season this cannot take place and it is generally acknowledged

that early growth in the next year suffers becuase of inadequate

reserves in the rootstock.

It is intended to experiment with various defoliation procedures to

ensure maximum leaf material on the basal portion of the vine not

harvested. Tnis will involve modifying severity and time of defoliat

ion of the lower leaves (which facilitates harvesting) and chemical

tests to quantify carbohydrate reserves.

Harvest Date Determination

(PV,IE)

Proper determination of the optimum time of harvest can contribute

significantly to both yield and alpha content.

For 1979/80, it is planned to intensify work in this area, with

more intensive sampling and analysis, both using conventional tech

niques, and by observing lupulin glands under a stereomicroscope.

Spider Mite Control

(PV,IE)

The need for new outlooks on spider mite control is becoming more and

more apparent because of increasing mite resistance to many of the

mLticides (especially Tedion and Kelthane) and cost.

The spider monitoring service will be extended, and evaluation of

a synthetic pyrhethrum miticide will be- continued.

Triploids

(PV.TE)

Trials will continue on the use of triploid male plants for increasing

cone weight while maintaining near seedless condition.

Shinshuwase Variety

(PV, IE)

Layered cuttings from the few plants grown in 1978/79 will be planted

at both Bushy Park and Scottsdale for further bulking of material and

yield-quality evaluation.

Alternative Packaging

(TE)

A vacuum pack of pressed hops was introduced in 1978/79 with sales of

50 tonnes. It is proposed to further develop this pack by stream

lining the production,, increasing the density, and properly document

ing the storage alpha losses.

Other packaging initiatives involve further selling of pellets in

pouches without cartons, improvements in pack appearance with reductions

in transit damage, possible press modifications to produce cylindrical

bales for East German sales, and improvements in whole hop pellet

production and quality.

FOLIAR FERTILIZERS,REPORT ON THE 1978/79 TRIAL.

( J.P. Versluys )

July,1979.

Summary. A 16# increase in dry yield was obtained after four

applications of a complete foliar fertilizer on an

area of hops which had been affected by hail in November.

A similar trial which was undertaken the previous year

gave an increase in dry hop yield of nearly °ff>.

In both years,the absolute yield increase was approx.

100 Kg. of dried hops per acre.

Based on Grower-returns for the 1979-Crop,the extra

yield had a net value of $150 per acre,(after accounting

for the cost of materials and application,as

well as

for expenses related to picking and drying).

The efficiency of complete foliar fertilizers applied

in addition to

normal dressings of ground-applied

fertilizers has now been proven 'beyond reasonable doubt1

and routine-use of these products on a broad-acre basis

is recommended.

Trial Layout.

The material used was Wuxal (a Ciba Geigy-product),containing

9# N,4# P,6# K,and the trace elements B,Co,Cu,Fe,Mn,Mo,Ni,Zn.

Treated area: bays No.3,4,5, J.Butler,No.1-paddock.

Control:

bays No.1,2,

"

"

"

All bays have 300 plants,area per bay approx. 1/3 acre.

A total of H gallons/acre of Wuxal was applied,divided into four

applications,each at the rate of 3 pts./acre in 130 gallons of

water per acre. (4.2 litres in 1500 litres per hectare.)

The application dates were 8/1,27/1,19/2,28/2.

The first two applications were combined with Tedion/Kelthane

miticides.

Results.

The t r i a l area was machi tie-picked

on 16/3.

W/D ra^io

Kg.dry

# LCV (dry

Kg.green

# D.M.

Treatment,3

1018

4

5

1292

1113

21.3

20.3

22.0

4.32

4.53

4.18

235.6

285.2

266.3

15.3

15.4

13.3

1

800

958

22.7

21.7

4.05

4.24

197.5

2

225.9

14.5

14.7

Control,

(*) calculated on 8# moisture after drying

basis)

The outer three rows of non-treated bay No.1,on the boundary

of the paddock.were visibly affected by the prevailing westerly

winds: in a comparison of treated and untreated areas,the

results from bay No.1 have therefore been discarded.

Average yield/plant,treated area,(900 plants) 0.874 kg.dry hops

"

<>

« .control

(300 plants)

0.753 kg.dry hops

Discussion.

The dry yield increase per plant was 0.121 Kg.,or 109 Kg./acre.

At an average Grower-return of $2.10/Kg. in 1979,and at a

marginally costed harvesting expense of 45 c/Kg. (20 c picking,

25 c drying),the extra return per acre was about $ 180.

The cost of Wuxal in 1979 was $ 2.80 per litre.The quantity used

in four applications was 6.8 litres at a cost of $19/acre.

Two of the applications were put on at no extra cost in

combination with miticide-runs.If the two additio«al Wuxal

applications are costed at $5/acre each,the total cost of four

applications would be approx. $30/acre.

The extra net return per acre was $150.

In a report describing the results of the 1977/78 foliar

fertilizer trial (5/5/78),it was suggested that the percentage

of extra yield after applications would increase under

conditions of low yield in the non-treated areas.

This situation happened to apply during the most recent trial:

all of J.Butler's hops were severely affected by a hail storm

in November: Yield per acre on Mr. Butler's property was

1075 Kg. in 1978,and 840 Kg. in 1979.

It is interesting to note that the absolute increases in dry

yield during the two years of foliar fertilizer applications

were of the same magnitude: + 99 Kg./acre in 1978,and + 109

Kg./acre in 1979.

Alpha-acids content was not affected by the treatment.'

10.

SUBSTITUTION OF SOIL-APPLIED NITROGEN WITH FOLIAR SPRAYS.

(J.P. VersluyB )

Summary.

August,1979.

The effect of complete foliar fertilizer solutions

on hops which had received normal dressings of

Nitrogen,Phosphorus,and Potassium has been described

in previous reports (May 1978,July,1979).

In an attempt to reduce the cost of soil-applied

Nitrogen,a trial was undertaken during 1978/79 in

which Poliverdol and Urea-solutions v/ere used to

compensate for a decrease in Nitram applications fron

8 cwt./acre to 2 cwt./acre.

Although yield in the low-Nitram plots was not

depressed in any of the treatments,plants in the lowNitrogen areas showed all the signs of Nitrogen-

deficiency despite application of 'compensating' foliar

sprays.

Reduced N-uptake in the low-Nitram areas was also

demonstrated by means of foliar analysis.This further

showed,that uptake of Potassium and Magnesium had been

depressed by conditions of low soil-N.

The trial again showed the beneficial effects of

complete foliar fertilizers given in addition to normal

levels of soil-applied fertilizers: a yield increase

of nearly 180 kg. of dried hops per acre.

Under similar conditions,applications of Urea-sprays

only had a minimal effect.Trial Layout.

( H.D. Davey,'Kinegar-Top')

(*) one of the sampling areas.

X1,X2,X3

A

= Control

,

„,

^ ..

a , . .,

= Nitram,8 cwt./acre + 3 applies. Poliverdol,total

B

= Nitram,2 cwt./acre + 3

I)

» Nitram,2 cwt./acre + 1

8 pts./acre

C

"

"

"

",

= Nitram,8 cwt./acre + 1 applic.Urea 10£ +2 appliCB.'

Urea \1>

"

"

+ 2

"

Each of the plots,X1,A,B,etc. is two bays (10 rows) wide and

approx. 2/3 acre in area.

All leaf samples were collected from the middle of each plot,

as in *.

11.

Nitram applications: all plots: 2 cwt./acre in mid-November

X1,A,X2,C,X3:2 cwt. in mid-December,2 cwt. in

mid-January,2 cwt. in mid-Febr.

A,B : 18/12 (1i pts./acre),12/1 (3 pts.),

( Poliverdol:

in 75

gals.

7/2 (3 pts.)

(

(

C,D : 18/12 (10?S solution), 12/1 (1*),

water/ ( Urea:

7/2 (1*).

acre

(N.B. An error was made in preparation of the first Urea-solution:

this went

scorching

was done.

rinsed in

on at 10$ instead of 1$.Apart from some minimal

on the leaf-edges of old leaves.no visible damage

Leaf samples collected on 22/12 and 3/1 were

water before oven-drying in order to wash off a

possible Urea-residue.)

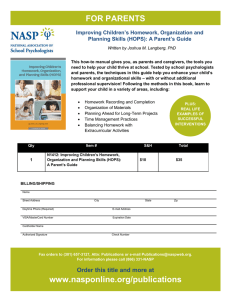

Yield.

On 30/3/79,60 plants from the sampling areas within each plot

were machine-picked;samples were taken for analysis of Dry Matter

$ and 1CT. The results are presented in the Table below,Plot

Yield/plant,

D.M. <f>

W/D ratio

(at 8^ moist)

(green) Kg.

Yield/pl.

(dry) Kg.

LCV

(d.b.

1.221

13.6

3.64

1.299

13.1

3.50

1.114

14.2

11

4.53

24.8

3.71

A

4.73

25.3

B

3.90

26.3

X2

3.51

25.7

3.58

0.980

12.4

C

4.H

25.7

3.58

1.156

13.8

D

4.40

24.7

3.72

1.183

12.9

X3

4.65

25.0

3.68

1.264

14.6

At 7' x 7' spacing (890 plants/acre):

Poliverdol effect*

Id/acre

Kg.

Control (X1+X2)

Normal Nitr.+ Poliverdol (A)

1156

low Nitram + Poliverdol (B)

991

(Treatment Control)

979

+ 177 Kg.

+

12

1029

+

30

1053

+

54

Urea effect:

Control (X2+X3)

Normal Nitr.+ Urea (C)

low Nitram + Urea (D)

999

12.

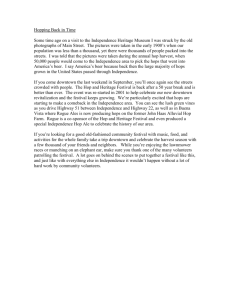

Leaf Analysis.

Leaf samples consisting of the first two pairs of fully-spread

leaves below the growing tip of main vine or lateral were

collected from each plot on 7/12,22/12,3/1,1/2,16/2,15/3;

15-20 plants per sample.Only the leaf tissue was dried and

analysed,petioles were discarded.

The results are given in Figures 1-8.

Discussion.

None of the treatments had a negative effect on hop yield.The

yield-'increase' of 12 Kg. after Poliverdol applications on the

^J

low-N plot is probably not significant.

Yield increases after Urea applications were small too,and rather

odd in that the low soil-N plot had a higher yield than the plot

which had received normal Nitram. If real,this difference cannot

be readily explained. (The results of a trial at the Tobacco

Research Station in Myrtleford in 1977/78 gave a similar,negative,

'

response to increasing rates of soil-applied Nitrogen.)

The decrease in leaf-Nitrogen content is immediately obvious

(Figures 1,2) in the low-Nitram plots despite application of

Poliverdol and,to a lesser extent,of Urea solutions.The quantities

of Nitrogen applied as Poliverdol and Urea were very small (0.4 Kg .

N in 1 gallon Poliverdol,and approx. 19 Kg. N in the three Ureasprays) in comparison with a reduction in soil-applied Nitrogen

from 138 Kg.N/acre to 34 Kg.N/acre and in relation to a total

removal of 50-60 Kg. Nitrogen per acre by cones,vines,leaves.

Phosphorus contents of the leaves were not affected by any of the

treatments (Figures 3,4),but both leaf-Potassium and leaf-Hagnesiui

were reduced in the low-Nitram plots (Figures 5-8).

!

Despite the fact that yield reductions did not occur in the lowNitram plots,the overall effect of Nitrogen fertilization on the

uptake of other elements is clearly demonstrated.

The possibility of a carry-over effect of low soil-Nitrogen on

the next crop will be investigated by recording the 1980-yield

of the same areas next year.'

Conclusion. The break-even point in Nitram reductions is approx.

2 cwt./acre: all of the savings are then offset by

the cost of material + application of 1 gallon/acre

of foliar fertilizer.lt was shown that a Nitramreduction of 6 cwt./acre is at least hazardous in

terms of general plant health.Substitution of,e.g.,

4 cwt.Nitram with conrolete foliar fertilizers would

mean a saving of approx. S20/acre.This is not consider

ed sufficiently attractive,and it is proposed to

stop this line of investigation.

!

7

.1...

-•-

. . . .

«•

—

...

. . .

.

. . . .

-.

.

. . . . .

."•...

—.

.

:::.:

—

..

:.:.

7\]

—

.

:.".!

..•:.

..... |

1

I

i •:::

'-•'—

I_._ *»

: ::<d

-•-U

.... -j

- •

...

<i>

x

, J3

c 3.

::

+

a

1_»

:_.:.

•

h

.:".:_ o>:.:

•r-f

z

..

. .

.

.

. o

- ^

.

. . ..

:. o..'

.. . o

i

A,

.:.:~:

"mi

-

.tttttt

~

N

•

•

•

:::.:

:.::.:

::

S

;•

-•—71

5 . . _H

•H

--"—

__.

' 777777

,.

_

-

i

777 7 i n : . ":~::

•• •

. . . . . .

—

•

:----"

•---;

•;:—

17777 777.77

:;::

.:: .7

;_-.:_ 7.Z

::•:!

• • i

i

•

'-'\-\ •' •' •

•

:•:!::::

.:::_:. - " :

:::i

:i::

.:'.".. :_.:. '•---•'

. .

. . . . . .

.in

| .

1

i

1

-'•'-"•

.:.':! ..: i :

• t

• • • i

• •

:.:

i

i

.... j

:

.

. . .

. -.

...

: :|

• • • i

i

. .i

_,.:_:_*.

I

•

i

t

t

a

"77 '

...'].'...

_

-

—

i(

T- —

—7__

—

. I l l 7777!.

..

••t:I

7171

77717 _j. I .-T

lEI 3,rn-

-

^ ^

^--

-* T '

b

J

-f

n __ I _

1111

_^

iHi.

•~-T

1111

.

-. v.]::-

——-

177777

.__.

_ . —

7771

.::::|:.:-:

.: 7.:

inr

— • —

_7.. .

777.17

J 77 7

——--

— — -

'. 717 :1771

177777

—

1777.1: :7777777

—

.

"-—'

.

1/

*

7

.

..

t

-

-

.

.

.

7

.

.

I-H

'

rii-ii85:.:

•

77": In :

.777

—

7

. 7 : :::

_

•-— /

- - - - -

,

7

,

77777

i •/

. . . . .

t

"777"'

?-;>

7 777

.

^

-...^.j . . . .

*

-7.77..:

•

:.:.

717... .7177.

:"'

1

CM

11-

7777777

i5i

:ia}

_:::

ii77

H

O

o

7 o:

±T7

7 177

'~-

7117 177717

I77i

7711 -7717.

1*77777 1117

111Z- 1.777777 7177777"

1111

"IT

:777

.

^l

777_

'7771

-77777

.1

2EI

F

—L

7;:

,

71:7

.777.

:1777

7Z71'

•-TIT.:

.

i

•

l

7i77J-7777

77 7

j

"

-

—

—

s

.

—

•••

i

t

i-

i

"77777.: 77 777

.7777777

•

- • «*'

.

.

.

7771.

7.77.7

• - -

•

17177

1

1

• k

—

:.. 7 ..i:

i

'.

'

-

_:

_>

77*.

.

H

: pq

1

71./.

' '. i

.77::

777777;

1

. .

»

1.

1

.

. . .

-

..- .

J_§Ifi:

77_777

"717 't

.in:

<

1 .777.

I

._ /

•-.-

EZ 7/7

je-MNf

*

.

.

.

1

-

~-

777 7

7 777

17.77

„

—.7-

.

- I

.»*

-

effC

•

7717

_1777T7

t rr

^

"

.:_;'

0

-

-777

:—

7

1

i

1

1

1

1

• j

.. .

j .

•

-

•

• -

1

|

1

" . U3

.

.

...

-

1

- 1

'

:-

-

-•••|:::-i

i

">s,!'

.

tAt

. . . t ...

77-r"|:l.

in

.

i-^p:.!-

C\J|

'{.:•.-

7: P-j. in

1

in

!™r.lll

T—,

' j

"o,f:-:;.:

-

1

—

C\J

. -

" • ITk,

i

. . . . j .. ...

"'

... ^f :.;.

\o

. .

j

....

CM

-j

!

|

f"

i •

CNJ!

!

r~->

-_ ^^ .....

•

!

1

- ;

I

1

1

•i

i

• \ !

:

. j.77

__.

... CMj

cm! - • - •

M>

•S-

::S'-^

1 .

"^ —177 17 "I .77 7

.

—-—1

;:;_-^":L-;

7^

"*"""

"1777

•

1171 717717

—

.

—

-

777771

j

JiE

—

— —

-^

— 7-7

-

l

—

"# 7~

.

»

j

^-777_

~

771"'

. . . . —

•

M

•

717777' .7771

... .

7.7::

7717. 77

7 777

, 77:

.... i

•

::.:.:|::-: ::•:.: j:..;

....)...

• ••

77 77j17_ -

1

/:.(::-::

t

i

LI -1 777777. 17771 .77711'

:7:/j ::::

!/

?nf

,

7 7777

.77777.

——-

7777777

r~~

771177

T1771

— —

111'

"77777" '777"~

77 ~:

1717

—

/

"r7::- "7.:_

.7777.

...

• t *»• • •

• '-'•••

_.

. . . .

. .

j::::

t

'.' . i

...

7:..

-:

i.

1

•

1

\--rl\*E- :">?•..:

y

A

: e ^ Vi7-

F::!:A:

77:7 17771'

777711. 77 77

- - - - -

77 17 17717

.7 111

-

titti

""77771

:: 7 _

• - - - t— —

:.:::

.

.'

.

i

<

cc

«

~y^\

X^

1• :

• • • i

7 777

•

::: 7

272-11." 777717.

"77777. 77777.

777H. .771.

~

.777 7

-

:_...,.—

lE

7717.7

771777

.

•

'"^r "^M

. J ./:•

•/

i

.

•

,1

.

::::j/:r.:

....

. . .

t

1 *

S

>

*

...

,.

:.

• :.

-

i

•i

;

1

i

co

si 9

Q.£

o

pv

Si

j._ . o

1

i

i

Q)

—

x

CM

i

!

u

CO

S

•

—-+>-

I

S —1

u

zzzz

ZZZZ.

•

g

a

E

!

O

.

.

.

:...

.

— -~:

— —

- - • — -

h-:;

N

X

. . . .

'ZZ

. . . . . .

zzzz

. . . _ .

::

. — —

T

! .

—

-

j . .

-----

:::_:

_

.

"

—-''

i —

i

,

- -;-

~T__

-

zz :z

-

.

~....•

-

—.._

—

. . . .

~..~~z

.

.

:i:::

::_'.:

.:.-.:]::•:

zzz:\.zz:

-

zzzz

.

- - •

- -

-

_ _ _ _ _

'-——-

- — •

-

• 9

—

—

_r__.

zzy'i:

.

>

.

.

.

.

~TT"

- - - - -

X

x^_ •s:--

:.:.:_. ZZZ z

x

_

— - —

-1

_ -

::•<.

:...:

. .

. . . .

......

•

.

.

.

•

•-!

•

.

ZZZZZ' :_:i:

—

•Ezi

-

-

i

.

.

. -

•

- _

1

.

.

.

. .: . :

-

: . •

-

•

.;:;. .:..

- - — -

''ZZZ'

ZZ ZZ

ZZZZ-

zzzzz

^

111,

71

.

—:;

—

zzzzz

'

_.:: .

- - - - -

— . .

\i — •

—

zz\z

— - —

_:__.'

.

ZZZ—.

-

..

- •

•-

-

-

':::

•{••-

--

zzzzzz z

-•--"

-

;:—_ .:_.:_ zz::

~! t

- - - - -

"~~t

L

--"- ^

. .

CM

« I' :l

.

—

^ zll :;::.

- - - - -

.::: : :

'ZZZ

zzzz.

::::

:_.::

. _

l • 1

^,

zzzz. : t ^ .

-

. .

___.;

_ _ _ _ .

- — ~

ZZZ z^ .:_ n

—

. _

-::}.....

•

zzzz

_ . _ _ _ .

:::~i

"^_-~"

.-.__

zzzzz

It

—~--

1 • • 1 •

'

zzzzz. zzzzzz

._—1_

^^v

^xS

1

zUz

.

r_rz:

.rrzi-

(

::.1=...l.. .1O

:..-.

. . . .

ZZ "_•. zzzz.

zzzzzz

_::__.

zzzzzz zzzz

zzzzzz. zzzz..

••••<//•---•

'

k

i

1 1

ri

'—..'•••.

-.-— -

i~:

;:_.l,_.

:: >

TZ1.1'

^ •--

)

•

zzzzz. zzz:

_r_~" zzzzz:

•

,

J."_V_ -"—--:__::

—

• /

.... .

/

' 1

zzrz. ZZZ

•

'' /

: / _..:

I'~Z~~

*

"V"""'

/ —

>—

.

T1ZZZZzzzzz

t

*t • •--

.... . /

'

zzzzz: 'ZZZZZ'T

—

r—

-•-—-

:::""

Is

\\~

...!.•__

- - —

ZZZZZ. ._rr_.

- —

ZZZZZ

ZZZZZ _r_z:

-

•: — -i

ZZZZZ

ZZZZZ ZZZZ1-

'> ^s ^V

\t\-.

^

----"

..

zzzzzz)-—

\ zzz \ zzz. . . . j .. ...

.

:i_].;__.

zz\zz:

—

~--—

'••

._

t

:itz4

— .

: : : . ' --'•'-

:.:.::.

:zn:

^V

—---

~:\-\:z •

:_ .:. ^ --:

z\z\zz

-

1

ZZZ.. :.::.

~—~

-

__.:_.

—

- -

'•"--... :;::

—

zzzz.

_ _ . . . .

.

_i —

..,. j —

........

. . . 1... _

j . . .

c > . . .;

.:i:i'::i-:.i-:!;:.:j:-:-"iM:-.

•

• • <3 • • : •

;::.- :: 17

. . . . .

i

.... i

•

O

•

-<:^-

<

C

O—

h j P

in j

*w*

x

W «~ j -H

+*

1

3t

en • • a

x^——o —+*—}

H

o

C

1

1

•>

!

1

pq o

rH

—

z :z.

- -

. - _ .

—

•

\

rH

o

-_

.

---'-

z zzzz zzzz

zzzzz

ZZZZZ

ft

C

r-i

t4

3

)

,

I

1

::::

:.:r~

..::.:

.:

K\'

-h

I

!.

i:.

1

.

:.:::

:_::

:.:.:::

—j.....

- - —

zzz:: ZZZZ

—j

— . . .

-

:Ir .111

'-'••

-

- - - - -

—

—

- —

. . . .

p**:

• | - - • •

• "1" '

: .|_*ure

-

. . ..4

:::!::"'•

:•:::::

:••}-.:

j '

• •' i • - • -

: 1-:::

j. ...

• 1 -•

..

. i::

1

:.;.::

- - -

-::

-

. . . .

. :..

i-:

•

. . . .

•

1 ^

to

T—

•

KV

_V_„„

r~

CM

^x

CM

- - - - -

CM

^x.

T—'

CM

"V .

^>

CM

^x, -

•

;::.:.

: _ zzz

„

.

_,.

zzziz

_

ZZZZ

- - - - -

——y--

zzzzzz

zzzzz

-'••-••

zzzzzz

— —

zzzzz

._,__

'-'•"

zzzz.

• -::

ZZZZ

zzzzzz.

zzzzzz

zzzzzz

i_EE

ZZZZZ-

-1^^

"to .

CM

*x> --

-

CM

r—

CO

_f—

T—

CM -

r-

•J^Xi.l.

::r:

.

15

. : •::

•;•::.

-

-

-

-

. 1

1

t

.

'i

'::"

:::.:

—

.

zzlz

-

zzzz

:;::

::::

],z.

z:.

•

x

X-*

ro ^

g

i

u

! re

-T- • f

p

iP.

to

:h

r-l

i i

io

|+»

re

•

•

P.

O

p.

o

E

p.

6

P3

f . . cm

r£

r^|

.a

1 -

:ii:

: i:;.

::::

- - - - -

--

zzz.

'••'•

X

.. Ill

- - - - - -

^N

x

zzzz

— —

•

ZZZZZ-Z. zzzzz

,1 .

:

1

•

-i-

•!

1

^

'••'•

'• '•

.

•

•

—

..___.

: zzzzz

r™:

: :_i:

nn

-

-

. . . . .

—

Z

———

zzzz

zzzzz

zzzzzz ~z~zz

:r_ii:

zzzz

f .

._

-

•

—

„

•

w

If

•

1/

--*

_ _ _ .

.1.

zzz A f:

i_::.

.

::::

. . . _

.

._

. . . . .

—

i:ii

zzzzz

/

-

-

zzz.

-~

. T^_

_ _ . _ _

- _ _ _

"

i::.:

zzzz

. . . _ _

..-_—

Sjv

.X

/

::::

. . . .

:::

:.::_

:th

.

zzzz

. . . . .

*

. . _ - .

V

""•/'

/•—• •/_.-.

- •>!• •>

.

m

— „

_ _ _ _ .

- — - -

,

HIT

— _

-—...

zzzzzz.

- —

.—

-•

—

ZZZZZZ' Hll.

r-—

. . . . .

-

-

.

•

-

—

• •--;

,

_,

:.n;

*.

-

zzzzz

zzzzz

_

:___r.

::;_:

———

zzzzzz

-

'•'••'•

-—

-

'•

ZZZ 1

zzzzz.

ZZZ.Z

-

-

*

. . . .

- -

.

. . _ . .

..

— —

—

,

-

.

-

z_. .

—

,

zzzz

zzzzzz . m i

——

—,—

—~;

— -

1

. ZZZiZZ z

zzzz

ZZZZzz. :...;:

!•

i:iiL.;i:

_h—i

zzzz

zzz z

ZZZZ1

zzzzz zzzz z

i.—

•«

.

n m __i:

_.._)...

—i

—.--t- -

i

i

...

... j ..

cm

:::

• !

1

r.

zzzz.

......

(

j

":::!:::'

\c.

-

=z

f£

"_ii

lit

zZZZZZZ

—-i—

»-—

-»•-••

zzzzz.

___!". zzzzzz i m .

z/izz

z.

zzzz

zzzzz.

11

...

zz.zzz nni" zzzzz. zzzz

—.

zzzzz

_ _ —

—,

zzzzz

mi 7zz

zzz z

- —

__4_- mSzz

zzzz

•x

_____

- —

111".

-

im:

in:

zzzz .. : i i :

Z ZZ

:zzz

ZZZ'

- -

zzzzzz

•

—_

-

T"

zzzzzz

zzzzzz

pN

~^_

zzzz

- - - - -

.

ZZZZ."

ZZZZ"

./..

_m

-

zzzzzz.

—

. . . .

:n:

'

- . _ . . 'ZZZZZ.

. .

: i;:

.

.j

"

;

o

•' •

o • 1

(hi

.. .,

t. i ...:[ :--:1

.•-:

1 -

::..:

.zzzzzz. " m i

~

._:_«/:y f •-/..

#

T.

V

-

-A-1

.

1

t

•.'1:1

$> , jr. -•i•••«*-

•J

..

ZZZZZZ'

zzzzz zzzzz.. zzzzzz ZZZZZ'

ZZ.

Z~'::

Z~Z

zzzz

zzzzz zzzZzZ

zzzz

ZZZZzZ

...

!"

zzzz

|.:."V:iN_ ::::

"ii:

m i zzzzz

::.:.:. zzzzzz

zzzz. zzzzzz

;:...

ZZ ZZ

zzzz..^

zzzz

ZZZZ'

zzzz

-' •--'- ;: _:.

•

imi. ZZZZ

-•

i.:i|-.ii

:ni

*x

\>_____

.:.:.::

P

H

-Q,

:m

iO

•ro

H

•

U ': . .

=>•

ZZZ,.

zzz z

~~'zzzz

:zzz zzzz : : t t

zzzzz

zzzzz

-

ZZ... z. ZZ z z

-

. . . . .

:.:. i

_____

.

zzzz zzzzzz

ZZI-Z

zzzz

-

ZZZZZ. ZZZ".

zzzzz. z zzz. zzzz. zzzzz..

zzzzz zzzzz

zzzzz zzzzz:

zzzzz. zzzzzz zzzz

zzzz zzzz

____"_ —'—- :_:.;. : n .

zzzz

i__i

zzzz.

------

i

i

j

!

• --""

fe>

1

ti

11 _L z::.:. i:..:. zzzz

ZZZZ : i r :

~T:

--- 1 *i-

:::_

<

i-i

_:-_:.

zzzz.

zzzzz

—f—\

-

.

- - - - -

•

zzzz.

•

mini.

.... _|....

-1

.

.. j...

ZZ z.

-

. . . . . .

zzi

i

j

i

!

.].-

T

.*•---

-

-

-

-

-

^x.

z: z i

. ;ii

— -

_

-—ZZZZ

'ZZZZZ.

zzzzz

—i—

::-]mE:

CO

__--_-

F~—in

CM

<M

'•'•.-

......

--._—

- i 1

—.__-

ZZ

..

.:_:::.

zzzz

zzzzzz

ITs, . . . .

ZZZZ

CM

coi

**•»;

«—

.__

T—

CM

•xT

" In

-

•

r-i

CMi

^x

t~

"CM

__

"N

P[X_

—

-

-

'•'

: : r.i

" ^1111

•'

_

.

-

*

-

!

r

.

t -

I

i:

-i

03

tg :

- ~ - Hp

p

.....

-

O

H

_

•

.

> • • ••

-H

. .

H ::::

:fl::::

.

<

p

Z 111

zzzz

ZZ ZZ

Z ZZZ

zzzz

-ZZZZZ

. . . .

. r i.

-

11

.

-——

•----

.zzzz

—

"•y-k

".'

' zzzz "ZZZZ

_in

zzzz

' ~: mm

—

i.- - • •

gi-i

j.: :

.

mi

d :.

S

i

•'

-1

i •

i.

j: •

:

U

3

0*

Oil

. . 1

; .

i

•| • •

-H.

_

- - j - Px.

. . .

.

ni:

zz i:

in"

.mi

...

.

- -:

zzz (.Tin

-

::::

- —

- - - - -

. . . . J —___-._

•

_ . .

-

:... I....;

•:. 1::::

i...

"\"Z

.

_

-

-z\zzzz

-

... J

-»

zzzz.

<

:.. i:

inn. n i l

• CJ

: :i:

- --:

zzzzz

zzz:

ZZ"

Till

z:::

zzz. '. zzzz

zzzzz

ZZZ~'

zzzzzz

/

.zzzzz

n m . zzzz

zzzz

"ZZ'

-

zzzziz^

_

Till

mm

_

— _ . . .

— —

'

;

—____.

,

: zzz

z:_..:

"

— -

.

- . . _

::::

.

: 'zzz.

zzz.:.

. .s.

-

" -

z zzz

J

.

zzzz

.

.

zzzz

z .

zzzzz

/

f. - y

,

—

. .

-%

V

ZZZf

J

.zzzzz

Tim zzzz

zzzz

*-—--

zzzz

mil'

——

z in. . nn

\Vn

\\Vm

\

V \

i->

—

•

.

_r

i

,

:...:

::n

^

. . . .

•

/

/

~_

: i ;i

'•

——.—*—

-

_..-

—•

_^.

-

.

.

..

.

.

.

JH

:::!."»»>

i

+

1-

s

><

t - •x

i

i

•

_,

C->

3

P

Imjn 11

!

••J

P.

P

-- • I

11..-

_:.,.

-,.

•

*

.*»»

•

•

. T"

._

1

.

".".'

. ..:.

zzz z *

— _ _

m::

1 *

f

•

-

.

.mm

. . . .

. _ _ —

.

———'

'

mi

mm

—

. . . .

. . . .

_

—n

-.._....

;

-ZZZZZ

_

.—.-,

•

4.

zzzzz.

-

•

-

a

• •

.

-

•

'

"•

-

'-'•''•

...j...

• • •

ks :::

I"—

*^x

f •

to. '• Z '

i.ili:::

1

•

- -

- -•

>s.

-

•

•*—r

-——

CM

-11

in—

.n oJ :i i:

--

. . . —

zzz ^.zzz

—.—m

. . . . .

—

in

.. .

CM

.. - ^ ....

.... r7

—

-

.... - j — -

_ i: V:.:.::

—

:*<:"::

CM

:i:._7iin

nn|:Ti:

-

•

-

*—

•

_

...

_

.._T-I

-

—

*

'•"- '• •

-

^z'zz

1 r

——i i

t>—--

::^nn

._.«v ._•...

_i3e_

——*

-

C-—

I**

-

mm

— _

___-.

— .

mi.

—...

I . .T.

,

.

-H —

IO..

:::!^T.

*

"Z.~Z 1 ••

..

'zzz

mm

.—

—-r—

. .

-nm

"•*"•

-*--•

In"'

—

— —

-

— . .

___.

—__.

_.

—

—-i —

——

— — -

•e—

- - - - -

— -

—:—

nm:

—- -H

•

*b—

__

•

nm: mn

HT'l

Z" \ z

.

_^_.

_

zzzzzz

nzm

:=Jm_r"

•

:__tmi

,

zzzzzz m n

ZZZZZ

i.

T'S.Z

•—*

..im

•

• ••/-:•:

___

• •

*

>. . :

-

nnr

,

— -

.

•

— _

—;

.

•—

•——

-

. -

————

. . . . .

— -

—__.

_.._

•

-——

-i——

mm

/-—

___-

_

——

—

_

_. .

—r —

/___—

\

L .

.

:.:.:.:. p

r.::"o•p5

•

<*

-^1

C•?....

/.zzz

...-••—

—

vm

V

—V—

*

-\...

•

:nv

•

__•—

-1—-

.

.......

nnT nrn^

r

• - • *|

••)•••

r

T n n mm: m m

-*•*•—

~zzz

/:: m:

/

——

—

—

•

_ - _

—

—

—

—

-

iin <—

-

— . .

i»:t_

/TIT

\

V—

. . . . .

_.-V-4

.

..i\;n_n

Izzl

_ —

ZIZZZ

/

zlzz

Z'~t

•*

—

'

.

•

5-

'::•:! ::::,L

....'-

.:..

ZZZZZZ n m

1

—/- J • •

—4—

-=+

.... .f

_.

—!

mm

—.—

7Z^~."

.

zzzz

I—.

•».,,.,.

Jzzz

zzzz /__

jr

•

——--

'T

I

.

:::: (

_ _ _ . .

~

__>___

: zzzzz Z ZZ. z

..inT

: i 'zz --••—T . zzzz

: m

nn

- '-11

-— Y f'~

--•// —

. _—/

zzzz

Z'ZZZ

\\m

A

—

—

_____

mm

•••-1\\ -

z%=

—

imr

-—_«»•

nte

-

~~~-

•

—-—-

-

>j

•

:>

(

-__.-_

: m;

in:

1• •

zzzzzz zzzzzz.

r::\

.ZZZZ IZ'....'.

____

,

•

:- j

t

_.. ^^

in: ivO*

.

zzzlzzz

<!_

-\

i l l : : i:

j

H•

zz:.:

i

-tm_____T

:.:.

-

: __•

i

17

mrf::-i

. j .

_ . .

....

..

z

.

.

-

_

•

-.

-

«

vi

p'

-

*~*

"

-••••a

__.

__.-•.

-_

rj . . .

in

--

.:: -3r:n:

—,

_.

i n:

: :n

mn

. . . .

: n:

in:

TT1T

: tit

Z.ZZZZ t

zzzzz

:: i:

. . . .

_;.:

z.zzz

—...

zzzz.

in.

: zzz

zzzzz

zzzz

T/T

. _ —

:" :t

•

——-

_ _ _ _ _

m™

—

: n:

-_C*^_

zzzz

T/m

—

.

' " •"'"'

-Til

mm

*

•

S.z

-

• —

\»

zzzz

zzzzz

_

.

.

: n

.-*

zzzz

zzz/

_

M^

'

,

_

z zzz

._

-V

zzzz

\

._

-

,

.

y-

-

'

to

_«

+

x

CM

-

4

:

-

O

f 1

+> o

c

CJ

.zzz

ZZ

7:

... .

inr:

nm-

—

; -

:m::

_nn

tit :

>

Tim:

•/zzz

r

/-

- -:

f.

.-____

—

-

mi

Ezz

- -

_ —

—

-

i

t

-H

. r

P5

-

. ...

-

E -•-.

p.

05

n: a : : :

...

::

.

__

. d

.

zzzzzz

z zzz

;ram

-j

.

—

.

:

— —

..

—:

,

'•"• -;

ro

•

- a ---

p. ••

:.:.+>:.

-

::::,,:::

..-.

.... H....

... _ . ,

_:/

/- .

__

H

'-.-'•

... i

'

"*

*

•

...

ii. *

IT _ : . :

"m:

im.i ..;:..

.—

—

-_-—

-

in;

1 __

; .

-

—-H

——

zzzz:

ni: .::::

~~ ,

..: n

.

.....

—r

-

.

-

.

-

!

::::

-

:__.

ZZZ'

_ 1. .

z.zzz.

zzzzz

.. —

1

1

-

i: n

.

.

::;

*

ZZZZZ

18.

Z-ZZZ

«+.

-——

--.-

(S: it

,

' :i-kSim

.;::."

:

1

.

.:__pll

u

n:c.in

mri

—4__._

_

in

'*(. ___

_

in...

::n^Er. .

. .

.

— . —

CM

... s<-....

:n^_"in

.

• —

' ii'"sx.:._

-

_

_____

o

«—"'

: n:_

—64

XX,

"•——e

;}-.•

: inx^nm.

—

.

-—

-..__

—'

T

":r.«!r....

.

x

• CM-

. . . _ _

.:: r

'-'--•

-: —- i n . .

•1 :'z-\

•

. . . . . . .

' i

n|n

TTTT

<^

—

- — _ .

'ZZ— zzzz

'*—:

m m ZZ . '

•;::i::-;

---I--

-_::::.j::..

•*-

i : m zzzzz'" : : : :

r—

'm

zzzz

TTn

::::o::

-

*.z~zz

zzzzz.

-ZIT-zzzzz

nE

nr."

-im: zzzz

.

.

- —

_ _ _ _

———

_ _ _ _ _

,

—r-—

. _ _ _ . .

—

...—

1—T" zzzzzz

-'—T-

^

. . . . . .

—

i,.

. . . _ .

—,—_

—

..

.__,_.

———~-

TTTTl. t t t t .

•

<d"

: \1

- - -

ZZZZ m i l

1

• !

zzzz

\CM

1—-

__i_

——•

•

TmT

.zzzz nm: -Tim

— . _

" "ZZ

.•

in^nrT

.

-

/z\zz

—

—

Z'J.

-J

—:

,

. . . .

.

- - - - -

n m zzzzzz

_

-——

n m zzzzz.

—

. . . _ - . .

,

-—

_____

-

....,_.

—>—.—

.

-:!•'-

._

———t-

.

-*—

.

__—

1

•

'i '.":T". i'

in

i

*"

:"ttt|^:

%

•—!-

-—r-r-r-

-i—*

mm.

,

zzzy

*

_

_

-_

•

u.

-4-

i

-,---_-.

i

—

'•-

-

'•'—-'•

ZZZZZ. n n

i

•i

z z. z

»

!

;—

zzzz

zzzz.

.

/' ' '

./—..

~*

—

ZZ'ZZ*

.

zzzzz. zzzzz

mm

mm

\—

\n

\

—\-

_ >2

—

—

•-•—-

;

i:ti:

_.—

—

_—,

<?1

i

—i—

Y\

i: v

'ZZZ

ZZ I

f—

.

•

/_._-

- -

1*

.

•J

11::

mm

———

1 . i

.

-/]

/ / .•—

j

. . —

_,

s;:^

v

mm

:::_

'*

A

zzzz

ZZ.zzz

::*:::

I-—i

mm

in:

-- /

7

\

.

-__\\_

/ i*-'' £

-VAi•\=

:\.

.

--

zzzzz: : : : :

—

—__

— —

.

nm

—

.

-'X/

/

Z.Z'zZ

...'

)

i

1

zzzzz.

zzzz

*

V

.::

j

/. z

zzzz

ro

::

zzz: :.

a; • •

: zzz z.zzz

rizZz zzzzz.

'zzzzzz

zzzzz.

-

— —

•

-... -

:

z zzz

t__:

o) p. : : i

tp -. .

:: _

-*-*-•

—.—.

:.:::

: :.i:

"ZZZZZ .zzzz. zzzzz. z zzz

.->

_ .

——

: 'zzz.

—

-

.

: t: :

mm

: zzzzz T i n

:: _:

:

•1••

» '::

6b

-Hi

pm

— .

n. t :

i- •-

m n . zzzzzz.

. . —

"ZZZZZ.

'ZZZZZ zzzzz

zzzzz.

m n zzzzz.

mm

zzzzzz.

——

—1

•

z

: zzzz.

•

t;

•* ' !

• 1CM

1

:::::: 11.1

•

mm

- ~ ~ zzzzzz.

Till

Tin.

Tin.

t: t

**-

\

-

-I-— zzzzz. zzzz. -—'•

—

mm inn

: :n

: i.:

.

. . P.!

.

"ml:.-

.

•:::

. . .

-

_ —

.

: zzz.

. _ _ . .

.

———

•

..

.

.

—"

._l_.. .

-

.

' 111'

J

1

• '• -*

_

I.I

•

ii.

i

-1

l

.::.

: i : •

'.in

•

ij

-.'"

<

1

.

-

,

'

!

Mil

i1!1 Mii 1HI

Mil

#JMg_

'lii

_mi.

.1

. i li

M

iij,

•

t

.

i

Ml.

.

.

i

i

»*-»

ill! il ii liii

; . i ,

. ,

• i

*—•_

.

i

•

0. /

,.\z j

, . ! .

—

i 1 1..

.

.

::.: i

:.; i

fi—

t

•

t

.

i 1ij

. 1 l .

1.

ilii

MM

~

ilt-

1

Ml

• •

|

M

•

Mm Ili!

. i 1 .

.

-M;

M.i

Ml

|

1

Mi

t

1 »

•|ii

I

• :

.

1

* •

.

.

1:1; MM

•ft

V/ i :4—

mm

-

i

•

,

1

•

•

...

i

1!; i

•i

I:

"

-

t

i

I.I,

ill! M

ii!

!ii: il mJj-L !!!!

•it

i . 11

..

• * •• i

' '___.• "^•'^

:i

!

I !-

• I.I

1

..

'ii!

>.

iil_:mi IM! I

!

•

•

S

i

•,.;

i.

•

i

•

: ! ! !

! i !

. : .

!

t> ,2z-

-**• **

11

; ; • ;

t

I

•Mi

II1' A1 i M ! in!

! ;: 11

MM

-——

• i : i

i . I .

»•

.i!,

MM

>

Im.

! 1:1

M . |

--—-

MM

i:

i

II!

!

i i I

i

iri-7

I

.

i

;.| | i

1

.

M : ;

NI

• ,

.

•

•

1

•

: | • i

•

t

i

'

1 .

t!

; !; 1

M;i lii!

Mil

:

; l ; |

,

,

'!

i ! !

i

• 1

MM

'-

•

i

>

iiii

;: i;

I

•i '

.

!;

i

ii

i

i

i

11

!U

i;i'

" Z I'll

11

Ilii ii1

Z-l iM

I1

fl

Mi

m

ii::

Mi.

1| . .

.

lii:

• i, i

• M

Ilii

Mil Ml

Mil

i

1 ! M

i

...

i

1 Ml

i

. M

•

l

i

i

;

III-

Tm>

:

Ml;

i .

'•

Ml!

i ii i

! >i l

, i

. |.:

;!:

iii.

.. i , t

. i

im.

MM

•

i

t

•

h'Mi!

iii

!>

-1_A^

11 ' 11 •

il :!|:

M

'

t

i

i

.

.

.

'

•

•

*

•

*

. i . ;

•

>

.

— —

|i:

iii:

ii

; 11

Mil

i i i

I M:

I

.

ilii

M

I

1

i 1i ! .

:;!'

i

i.

- •

.

ill!

1

t

i' • •

M ::

:

,

*"n

2.;/i!i

Til

...

i

:i:i'

rn

1| i .

. 1 M

'

,

'

i

: '

.

i

MM

.

.

,

l

.

.

i;

i

!|i!

>ii Mm

Mm

ii M ii.

•

.

,

5

.

i

1

i-

j—111

111

.

i|!l

•ii Ml!

iii

i:M

~Tp"

11t '

| iii

1

I

ii M

1 1

Ml

Mi

i

i

i 4 t I

•II:

i

lit.

i

.

i

MM

Mi:

Mi.

i i i i

•

!li: iij: iiii

•

•

i- ii

i M

i M

i- i .

'

»

.Mi

t

• • M

i ii i

::.;.;

Mji

i'M

Mil

'•*•*•!

!'ii

' M

(

MM.

ilii rttrr iifl

i

.

,

i i..i...

MM

l M i

t

(

•

.

..,.

i . , .

i

Ilii

Mm

iii;iii

...

MM

i

Mm Ml;

i

iiii

liii

•

-* *

i

.

.

.

t

ill;

.

.

!

:

'

'

.

i

IT!

.

.

:

•

i

.

.

' ' M

1 .

M

1.

.

iiii

.

i.Mi

11; i

.

,

j

,

iii: .i Ij tm.

•_•^'/•_^• :

l-i

• i

::: i

.

i.i.

t

;;;. i

! ! i !

I

M!|

i

MM

i....

Ml'

Ilii

iMi

MM

i:M

i:::

.

iiii

1 . . i

liii

! • •- •

.

:_. i j

MT :,i|

i : ;

Nlltran

: Mi

•

-t i

/-a--25724 |i.7/5_i.. :

••< Mi

t

-,—1

•.

MM

BTlJW

MM

MM

ill;

iiii ii;: MM

M;

k,normal Nitram

it..

i -

' !

li

il

«•.

Uli Il:'

11

'

si>r

(X1 +X2)

Control

1

. J • .

Mil

i M . liii

|

ill.

!

i

i' M

—?r~

M • ',

T7^

i l-i .

im

:::;

.

• Mi

M

::;:

' ' __•*'

"Hi

M 1 1 ij •;

II!

ili

i

.it.

M

1

ii>'

.

TTii,

!>^ i;,;

ii J_

.Ml

1 ! M

iii.

| ;

m;^| T.

t'

iiii

'Ml

Mi

'

1

... 1

.

. .

iiii '•'>*' 'MM

'•>' *j^*'

MM !•'><!

-iii

Hi; 1-1 ii

.

M

i; Hi

•>

ill! ^

% TTT'

Mil Ml:-'!

IM

! •

i

1I . 1 , .

-

.

M

i

i , .

• •

n—

Mil

M il ::;:

'• i : ' 1Ilii

1' . M

i M '

i

..M

M

;: i:

ii i;!

M

;; ii

1

• •

MM

'

>

|M!

t 1 ' •

1

1

It1-

i

jlii Iii •'

1M 1

...

♦

i;

:::l

i'

'• '•

. • . -

11

11:: ' i1

1M • '

i i . i

1 1

I'm

•.

M

i

M;: i;<:

:|'> <i •'.:

'

: i i

M

j ,

-___r.._

i

1

•

:M:

11...

;|i;

M!|

i '. '•

•

11

; Piet i r e 7-'

i

'

ii

I i

i i:

i

iii-. -M iii! ! \\

II.

1

....

'Mi.

•

•

. i •

i.ii

.II!

t

.

,i!i

! M II

i i . t

•

i

_____

,

!

MM

M Il::

; • i ;•

i

i

: ':! j:

it

tpT

i ;i Ii

. •

ih:

'

ii

.

ii;:

.iii

..I.

Ijlif !l i| I ii

ilii

i

. i

i

1 1 .

•

•

M i•

M

I

W

1

MM

'

M

*.

i>;' i

MM

MM

i i " ' 1-1 1 M1j

1 l-l.l

.

. i

;

, ! , .

.

\y< II I M

j i-^ _

"J- (

i.

» .

it..

.

I

• 1 M

' •

1! ! • -

1 .

l»M

•

M 1

Mi!

fees-r*r

P*

i

till

1

,-x" k-_L

i

i

i I .

1i i ! 1 . i

jii' M

,

i

i

iiii

1 -1 >

!Mlj

-A—

1

1

1

I iifl

1

.

i •i •';

M •

t

ii t...

•

1

i

1 1

i

ijij ItM m

11 1 ' ' 1

Lver iol/ Leaf ^Magnesium

Ilii

M" ThT" i M l| : t°!

| 1M

| i 'Ml

ili:

t

. . 1.

Mil.!

Lii.. l! M.|

ill |!

.iii

• M

t

• i •

i

i

,

.

i .

1 11

1 1

.

'' M

.

M

.

M i|i

jiiiT

MMp

•Ml 1

Lii

Mm

-I—-

: M

Hi liill!

Mm

-

i' i

.

• I I

iMi 1 i! lh! I

!Mi i

III- il'

Mi

1 '' P

Ii; !,. J|

i

ii!i

i

!

i

NM i

ilii

1 ( . .

Mii

i

iiii

i

' M

.

Ml.

M

» ' • 1

nn Ii IMM Mi:

• ' r !

IV"

,., . . .

i i !

• . i

• • 1 :

;: I;

'1 MM ' 1i •

' ' ;

i

1

> >

t •

i 1

i M

M ':

:; i i

ilii ii! i ii :M

.

4 m

.

I! ill!

iiii 11

!" 1 1

.mi

i.ii : 1 1! j

ij-j I

1 I !

MM

JLILIl

I'll III Lli-L_LL

j

i.

i II

. i.. t

i

i.i.

i

! 1 • i

II i

;! i.i

•

•

1 1 •»

;ji! M

-

i

-a

•' i ii

: i::

; j .,.

T)

Mi!

>

Mi:

;: :ii;

i

: i • j

i

'-i! 1 -IM

:;:; j Mil !l :.! i.jj

MM M

1

Mil

1

I l . . 1

•

.

.

nil

lilii- . i

II!!

i M

.1.1

1

i;

i.i;

•

j -

1

ilii

MM

.

> .

I

1 MM

MM

M

•

M

•

•

z.:\

1

.

.

.

.

-

i

.

I

!

.

i , . i : . :M. j| i .

i M: . *. i - f • *; ( : I v ! 1:: iM: iM. lii:

• • i •

» - -

i

t-t--. i

i

ii :MM

; I' -i! M

Mi! r|!i ;.M! MM

il! : I' Mil

Mi MM! ilM M

• M

4*

Mg.

ilii

.

.

...

. ,

M

Mi.

•

i: m

•

i •

M

-

•

••ii

' '

; i

•

11 M

. i

I'M

1M

•

j

1 ;

It*'

t

;

,

j I:

.

•

• i

.

ili:

i

Mil

-I

ni.

i '

•.-.

: i

I'*

1. M

—°

Ml [-Ml iIM Mmj 1i !' 1 !

:(- I j 1 i M. llM IIli I'M 1 ! Mi

III!

;m :

Mil M• i "

-no: •

1

M! • -M lj 1 :l n

i

iiii ; -il i ;-i i ..

•

Mr.. H:: ii

'iii

• M

.iii

•

* -•

•

fi—m

>T>

t

'

•

.

I

Mii

-

i

.

.

MM

•

•

1

•

4«-

•hi

• i i i

•

•

t

'

M|

• •j '| |I

M . ..

' t i

•Mi

Mil

ihi

mi

;

.Ml

I

!

i

1

M • .iij .|i, •

. .

. 1 . •

<

i •

•M

.

-

,

•

' I i

! : ' '

i M i

MM

• : t 1

—0

* t i i

1 • •

•

. M

.

• ; l

1 11

!

iiii

'.

t

• •:

MM

M

'

i

t

i

i

•

•

1

-

•

,

Mm

MM

M

| . • 1

ii

I

M

1

III!

i •

-M

hii|ii il il !

ni: Am

! |i '

ill

Ml.

Ml

•

ii M' '

MM

-i |

1 Mi

M

.,i Ill

. M

; i .

:

! *

MM M '

i r

i

i " '

"" '

t

iiii

m

• .

i t

1

i

Mi

i

1!

•1 i !

M II I fi!

M

M hi

i

i-i

!! 1 1

mii

i' i

i

i : 1

mm

i i:

i

•

MM:

Mj!

Mil

' 11 j. m I ; i I •

iliiMMii

mm

;

•'

MM

iiii

, . i .

iiii

I ' • !

I

. ii.

it.

'•, M

I:

• t

Hi!

•

<

i

1

. . 1

Mm

.

! 1i '

IM

i

.

• 1 M

t

<

'

iln

'

'

Mij 1

Ml 1

i

•

i

:

i •

M : •

•

.

•

•

• i

1

i

1

i

Ml

iiii

;: M

•

1

MM

i

!i

\I

11

j 1

MM

!1

Mii

M

'

•

• i i ;

• *'.

•M*

MM

i M '

'

ill'

||

i M

i

ii

MM

....

r

iij:

i

• • 1 '

t

i

i

•

•

11

i

MM

!•- ! i

1 1!

i!i5!

.

MM

' M i

i i.j 1

ll.!1

i.{M

111,

t

MM

Mj!

iiii

ili'

ii

i

4

.

1'

!!

: 1

i

Mi:

iii!

M

iiii

.

D«ioW Ni tran

'

.

.

1 i i

ilii

t i i

Ml!

ilii

iiii

•

*

i

i •

ilii

1

!

.

.

•

•

.

i

.

i

iM|

,

,

.

.

III1

•

i

•

....

.

t..

....

Mm

. j. ..

IMi

M . .

Mii

•

iii:

i

.

•

.

Mm

i|M

Mii"

•

-I:

: ! • •

) . • ,

ijl! iiii

li

i ...|.,

I

i •

i

!M

MM

iiii Ml: mm

• ii •

lj M

ili'

ii' '

MM

i

•

•

iiii

•

1"!

Mil

iii!

IM

:1m

•iii

i '

MM

• 111

iim

i

.

•

•

•

, M

•

i

•

•

:

.

Mm

•Ml

MM

:

17/p 1i1 i'17/3

Ms 5/2

t '

l-i i i

I

.

i i M

. M .

• < M

.

liii iiii

i ] ! ' ill!

1!! ii!; mi

'2M

I,..

:!'i

>-•:

• 1 •

|'M

i

Di no rmal -Nii 1

....

ill

iiii

Mm

i!

Mil

y"Cpntr o___i( X2+X

.

-1-*"*.

1

iiii ill!

M

1

0*.\:

*n_> < • t i t

1 ,

Ml- ^,-- <M

!! P

1i I

I

il

'2V\

l

.

• • ' ^ <*!..:

,

.

j

• **•

'

ii

li

| |

\l IMi

1i

iiii iij!

.

i

>i

11

1

1

' Mj

.^.

jr • •

i

i i

1

i

i

'

Mii'

iii'

MM

I'M

i

i

1!

liii

!,'

1

1

•

i

M ''

I'M

!

i

i •

i'1

;

i!

•

1:

i

_.l}_

t

:

i

i

li

• ' • \

"\ \ '