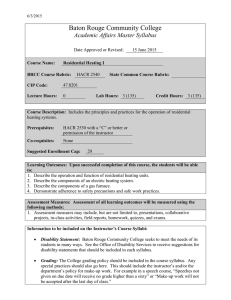

Electric and Other Types of House Heating Systems 3 LOUIS SLEGEL

advertisement