Document 13840252

advertisement

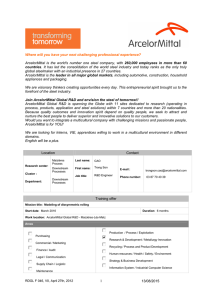

Where will you have your next challenging professional experience? ArcelorMittal is the world's number one steel company, with 260,000 employees in more than 60 countries. It has led the consolidation of the world steel industry and today ranks as the only truly global steelmaker with an industrial presence in 27 countries. ArcelorMittal is the leader in all major global markets, including automotive, construction, household appliances and packaging. We are visionary thinkers creating opportunities every day. This entrepreneurial spirit brought us to the forefront of the steel industry. Join ArcelorMittal Global R&D and envision the steel of tomorrow!! ArcelorMittal Global R&D is spanning the Globe with 11 sites dedicated to research (operating in process, products, application and steel solutions) within 7 countries and more than 20 nationalities. Because quality outcomes and innovation spirit depend on quality people, we seek to attract and nurture the best people to deliver superior and innovative solutions to our customers. Would you want to integrate a multicultural company with challenging missions and passionate people, ArcelorMittal is for YOU! We are looking for Interns, VIE, apprentices willing to work in a multicultural environment in different domains. English will be a plus. Location Research center: Cluster : Department: Contact Maizières Process Last name: CAO Downstream Processes First name: Trong Son E-mail : Dr. R&D Engineer Phone number: trongson.cao@arcelormittal.com Downstream Processes 03 87 70 40 39 Training offer Mission title: Computation and modeling of cold rolling using advanced semi-analytical models Start date: April 2016 (flexible) Duration: 6 months Work location: ArcelorMittal Global R&D, Maizières Process, Voie Romaine, 57280, Maizières-Lès-Metz, France. Areas Production / Process / Exploitation Purchasing Research & Development / Metallurgy Innovation Commercial / Marketing Recycling / Process and Product Development Finance / Audit Human resources / Health / Safety / Environment Legal / Communication Strategy & Business Development Supply Chain / Logistic Information System / Industrial Computer Science Maintenance RDGL F 046, V0, April 27th, 2012 1 14/12/2015 The purpose of the mission : During rolling of hard and thin strips, the work-rolls (WRs) undergo significant elastic deformation while the behavior of the strip is elasto-(visco)plastic. These situations are quite common during cold rolling of High Strength Steels or Advanced High Strength Steels (AHSS). Such important elastic deformation comes from both normal and shear contact stresses between the strip and WRs. Modeling of such complex phenomena requires numerical models which are often based on Finite Element methods. However, these kinds of models are very time-consuming and might not be the most adapted for industrial applications. For this reason, simplified analytical and semi-analytical models have been continuously developed for regulations and on-line applications. The main purpose of this work is to improve two advanced semi-analytical models (RollGap and Metalub) that have been developed at ArcelorMittal both for numerical and physical aspects. The mission : The works will focus on two advanced semi-analytical models: RollGap [1] and Metalub [2]. These models have been developed through collaboration between ArcelorMittal and academic partners. The RollGap model is based on the slab method to describe the deformation of the strip as well as the influence function method (IFM) to calculate the work-rolls elastic deformation. The accuracy of the IFM depends on the discretization method developed for the WRs. The Metalub model is more advanced rolling model that accounts for influence of oil’s characteristics on friction condition (see [2]). However, in this model, the elastic deformation caused by the shear contact stress has not been taken into account. There are thus real needs to improve these two models both in terms of numerical and physical aspects and to perform comparisons between them. Detailed works to be carried out are: 1. Improvements of the RollGap model to be able to account for the automatic discretization of WRs; 2. Improvements of the Metalub model to account for the elastic deformation of the WRs coming from the contact shear stress; 3. Carry out the comparative study between the developed models ; 4. Comparisons between numerical models and industrial or pilot trials data; 5. Possible scientific publication in international journals. [1] T. Dbouk, P. Montmitonnet, N. Suzuki, Y. Takahama, N. Legrand, T. Ngo and H. Matsumoto, Advanced roll bite models for cold and temper rolling processes, Int. Conf. ROLLING 2013, Venice, 10-12 June 2013 [2] Y. Carretta, R. Boman, A. Stephany, N. Legrand, M. Laugier, and J.-P. Ponthot, MetaLub – a slab method software for the numerical simulation of mixed lubrication regime in cold strip rolling, Proc. IMechE Vol. 225 Part J: J. Engineering Tribology, 2010 The environment: This internship will be carried out in the Downstream Process (DP) department of Process center at Maizières-lès-Metz, France. Inside the DP department, the student will work in an international environment involving around sixty specialists, R&D engineers and technicians. Trainee’s profile Studies level: Baccalaureate +5 Discipline : Mechanical engineering / computational mechanics School/University : Engineering schools Required profile and competencies - - Mechanical engineer student. Autonomy and team-working. A good English level is required and French is recommended for daily use. Good knowledge in programming (FORTRAN, C++, python). Knowledge about rolling process and strong background in mathematics will be a plus. RDGL F 046, V0, April 27th, 2012 2 14/12/2015 RDGL F 046, V0, April 27th, 2012 3 14/12/2015