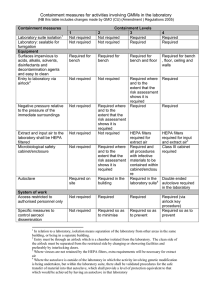

The SACGM Compendium of guidance

advertisement