ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ ༰ሰ සקএ ԣݚࡹ

advertisement

৯࿐ࣉᅚ, 2015 ୍, ֻ 45 ज : 201505

ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

༰ሰ 1,2

සקএ 1

ԣ ࡹݚ3,4

࿏ࡹૼ 2,5

߰؍ਪ 1,2,†

Кࣘն࿐۽࿐ჽ৯࿐ა۽ӱ॓࿐༢, Кࣘ 100871

Кࣘն࿐۽࿐ჽႋႨაඌ࣮ᇏྏ, Кࣘ 100871

3

ഈݚն࿐ႋႨඔ࿐ა৯࿐࣮෮, ഈ ݚ200444

4

ഈݚն࿐࿐ჽ৯࿐༢, ഈ ݚ200444

5

Кࣘն࿐࿐ჽ, Кࣘ 100871

1

2

ᅋ ေ षᅚࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄࣮ؓॆڕᅶҋਘ֥ഡ࠹ࠣ۽ӱ

ႋႨऎႵᇗေၩၬ. ҋਘڕᅶഄིႋᇶေЇওҋਘჰሰ၍໊Ӂള֥ڕᅶಌ

ཊၛࠣႮّނႋӁള֥a֩ݛగุᄖᇉؓҋਘྟି֥႕ཙ. ࣁඋҋਘ֥ڕ

ᅶིႋᇶေЇওڕᅶ႗߄aڕᅶգ߄ڕބᅶಿэ֩. ھ໓ᇶေሸඍᄝ֮໑

(T < 0.3 Tm , Tm ൞ҋਘ֥ಶׄ໑؇) ڕ֮ބᅶ࠴ਈ༯, Ⴎჰሰ၍໊ഄӁള

֥ڕᅶಌཊ෮֝ᇁ֥ڕᅶ႗߄ྛູ, ࠧ൳ڕᅶಌཊ֥႕ཙ, ҋਘ఼֥؇߶ശ

ۚ. ҋਘ֥ࣖ৬Ԅժaࣖࢸၛࠣ໑؇֩ၹؓࣖ؟ҋਘ֥ڕᅶ႗߄ऎႵᇗေ

႕ཙ. ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄࣮൞۱؟Ԅ؇໙ี, ఃܴޡ৯࿐ྟି

࠻౼थႿັܴԄ؇ഈڕᅶಌཊ֝ᇁࣖ৬ଽ҆ࢲ֥ܒэ߄, ္౼थႿ༥ܴԄ؇

ഈࣖ৬ࡗ֥ཌྷቔႨ. ھ໓Ֆൌဒࢲݔaඔᆴଆބંଆٚ૫ሸඍࣁ

උҋਘ৯࿐ྟି֥ڕᅶ႗߄࣮ࣉᅚ. ᄝՎࠎԤഈ, ᅚຬਔھਵთᇏթᄝ֥

ᇶေ॓࿐໙ี.

ܱՍ ࣁඋҋਘ, ڕᅶ႗߄, ໑؇႕ཙ, Ԅժིႋ, ৯࿐ྟି

ᇏٳোݼ: O345

໓ངѓ്: A

DOI: 10.6052/1000-0992-14-071

൬۠ರ௹: 2014-11-27; Ⴈರ௹: 2015-04-08; ᄝཌԛϱರ௹: 2015-04-14

†

E-mail: hlduan@pku.edu.cn

ႄႨٚൔ: ༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ. ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ.

৯࿐ࣉᅚ, 2015, 45: 201505

Xiao X Z, Song D K, Chu H J, et al. Irradiation hardening for metallic materials.

Advances in Mechanics, 2015, 45: 201505

c 2015u৯࿐ࣉᅚvϱಃ෮Ⴕ

°

৯

2

1 ႄ

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

ෛሢԮ߄െିჷ֩၂Ցྟିჷ֥ᇯࡶ४ࢰၛࠣದোؓିჷླ֥҂؎ᄹӉ, ି

ჷ໙ีၘӮູ႕ཙದোളթ֥ᇗն໙ีᆭ၂. ཌྷбԮିჷط, ିނႮႿఃሧჷپ

ڶ, ିਈӁᆴۚطᄝ࠽ݓഈ൳ܼ֞ٗᇗ൪. ିނॖނູٳਚэିނބऊэିਆᇕ, ଢభ

ނਚэିၘ֤֞ࢠູӮඃ֥അြႋႨ, ൞ఃࢠི֥֮ੱބ၂֥קνಆ໙ี௧ದૌ

࿙۷ིۚ۷νಆ֥ିނ. ཌྷбނਚэି, ނऊэିऎႵ҂ॖูս֥Ⴊ൝, ऎႵّނႋ

ჰਘԥਈऍն, ٢ିིੱࠞۚၛࠣ࣍ެνಆಙ֩หׄ. ၹՎ, ނऊэିФ൪ູࢳ

थದোໃটିჷླ֥ᇶ֝ྙൔᆭ၂, ൌགྷॖӻ࿃ॖ॥ނऊэ, ؓࢳथದো෮૫ਢ֥

ିჷ໙ีऎႵ٤ُ֥ၩၬ.

ቋ࣍ඔ୍, ෛሢނ࠽ݓऊэିჷ֥࣮҂؎౼֤ྟࣉᅚ, หљ൞࠽ݓಣނ

ऊэൌဒؐ (ITER) ࠹߃ၘࣜࠆ֤ਔࢠն֥Ӯۿ, ದোႵຬᄝ҂ࣲ֥ࡼটൌགྷॖ॥֥

ܸྟჿඏނऊэ, ՖطՖ۴Чഈࢳथିჷ໙ี. ൞ଢభ࠽ݓಣނऊэൌဒؐᇏಯಖ

թᄝ؟ޓታླࢳथ֥໙ี, ఃᇏЇওೂޅ࿊౼৯࿐ྟିਅڕॆ֥ݺᅶҋਘ, ၛЌᅰނ

ऊэّႋልᇂνಆॖौ֥ᄎྛ. ᄝނඌ֥ؿᅚݖӱᇏ, ނҋਘᄝڕᅶ่ࡱ༯֥৯࿐

ྟି࣮ٳᇗေ, ఃᆰࢤ႕ཙّ֞ނႋؐڛၢ௹ࡗଽ֥ॖौྟބνಆྟ. ॖၛඪ,

ނඌ֥ૄ၂Ցؿᅚބ҄ࣉބҋਘॆڕᅶྟି֥ิശࣅૡཌྷܱ. ᄝऊэّႋؐᇏ,

ࢲܒҋਘ๙ӈေࣜ൳ۚ๙ਈ֥ 14 MeV ᇏሰڕᅶၛࠣฦၤሰ֥ሏࠌ, ఃڕᅶഄ࠴

ਈбགྷႵނᅟᇏҋਘ෮֥ࣜഄ࠴ਈۚ 104 Пၛഈ, ѩ߶ϴෛႵఃឭэӁ

֩ݛބ, ᇀࣂߎીႵڕॆޅᅶҋਘିડቀఃᄝ৯࿐ྟିഈ֥ေ (Shimada et al.

2007).

ނҋਘ֥৯࿐ྟିაڕᅶིႋૡ్ཌྷܱ. ڕᅶིႋ൞ᆷഝཌࠇᆀۚି৬ሰაᇉ

ཌྷቔႨᄯӮ֥ҋਘa৯࿐ྟିၛࠣࢲܒഈؿളэ߄. ҋਘڕᅶഄིႋᇶေЇ

ওҋਘჰሰ၍໊Ӂള֥ڕᅶಌཊၛࠣႮّނႋӁള֥a֩ݛగุᄖᇉؓҋਘྟି

֥႕ཙ.

ࣁඋҋਘ৯࿐ྟି֥ڕᅶིႋЇওڕᅶ႗߄ (irradiation hardening)aڕᅶգ߄ (irradiation embrittlement)aڕᅶಿэ (irradiation creep) ڕބᅶூস (irradiation fatigue)

֩. ھ໓ᇶေሸඍᄝ֮໑ (T < 0.3 Tm , Tm ൞ҋਘ֥ಶׄ໑؇) ڕ֮ބᅶ࠴ਈ༯, Ⴎჰ

ሰ၍໊ഄӁള֥ڕᅶಌཊ෮֝ᇁ֥ڕᅶ႗߄ྛູ. ๙ӈ, ّނႋ߶Ӂളնਈۚିᇏ

ሰބሰ, ᆃུۚି৬ሰऎႵ఼֥ࠞԬ৯, ࢲܒҋਘ֥ࣖ۬ჰሰ൳ఃሏࠌު, ߶ொ

ఃჰট໊֥ᇂѩྙӮնਈ໊ჰሰ (primary knock-on atom, PKA), ᆃ໊ུჰሰ

๙ࣉݖ၂֥҄ࠩ৳ஷሏݖӱ߶ဆ߄ྙӮگᄖ֥ಌཊࢲܒ, ೂࡗ༣ሰ (interstitials)aॢ

໊ (vacancies)a໊հߌ (dislocation loops, DLs)aҪհඹ૫ุ (stacking fault tetrahedrons,

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

3

SFTs) ( ׳ॢބvoids) ֩. ᄝ໑؇ڕބᅶ࠴ਈࢠ֥֮౦ঃ༯ (ڕᅶഄ఼؇ֆູ໊ dpa,

іൕჰሰन໊Ցඔ), ૫ྏ৫ุٚࣖ (FCC) ҋਘᇏ֥ᇶေಌཊো൞Ҫհඹ૫ุ,

ྏุط৫ุٚࣖ (BCC) ҋਘᇏ֥ᇶေಌཊ൞໊հߌ; ֒໑؇ڕބᅶ࠴ਈࢠۚൈ (ڕᅶ

ഄ఼؇ࢠۚ), ಌཊ๙ӈ൞ၛॢྙ֥׳ൔթᄝ (Osetsky & Bacon 2001, 2003; Osetsky

et al. 2000). ᆞ൞ႮႿᆃུնਈڕᅶಌཊ֥թᄝ, ֒ނҋਘ൳ຓᄛؿളෑྟэྙൈ, ః

ଽ໊҆հ֥ᄎࡼ൳ಌཊ֥႕ཙ, Ֆࢠطնӱ؇ֹڿэః৯࿐ྟି, ೂڕᅶ႗߄aڕ

ᅶգ߄ۿބ႗߄༢ඔ (strain-hardening coefficient) ༯ࢆ֩ (Beyerlein et al. 2013).

ॖၛुԛ, ڕᅶಌཊؓࣁඋҋਘ৯࿐ྟି႕ཙ֥࣮൞၂۱؟֥ׅԄ؇໙ี:

ᄝັܴჰሰԄ؇ഈۚି৬ሰაࣖ۬ჰሰ֥ཌྷቔႨ߶ڿэҋਘ֥ັุܴࣖࢲܒ, ྙ

Ӯ༥ܴࣖ৬Ԅ؇֥ಌཊ, ࣉط༥ܴҪՑุ֥ࣖڕᅶಌཊ߶႕ཙҋਘࣖ؟ܴޡԄ؇֥

৯࿐ྟି. ၹՎ, ູਔିܔ༢ֹٳ༅ڕᅶഄ൞ೂڿޅэࣁඋҋਘ֥৯࿐ྟି, ྶᄝ

҂Ԅ؇ഈषᅚڕᅶ႗߄֥࣮, ᄝਔࢳཌྷܱݖӱބቔႨࠏ֥ࠎԤഈ, ࡹ৫҂

Ԅ؇ᆭࡗ֥৳༢, Ֆނؓطҋਘ֥ڕᅶ৯࿐ྟିࣉྛႵི֥ٳ༅ބყҩ. ູਔഡ࠹

ିܔડቀ৯࿐ྟିေ֥ॆڕᅶҋਘ, ധೆฐ෬ڕᅶಌཊ֥ྙӮაဆ߄, ࢣൕҋਘэ

ྙഄࠏ, ѩ࣮ࣁඋҋਘ֥ڕᅶ႗߄ྛູ, ၘࣜᇯࡶӮ୍ູ࣍টݓଽຓ࣮֥ಣ

ׄ.

ࣁඋҋਘ֥ڕᅶ႗߄ٳ༅ॖ ູٳ3 ۱Ԅ؇֥࣮: ჰሰԄ؇ (ັܴҪՑ)aࣖ৬

Ԅ؇ (༥ܴҪՑ) ࣖ؟ބԄ؇ (ܴޡҪՑ). ᄝ҂Ԅ؇༯, ڕᅶ႗߄֥ٳ༅Ⴕఃᇶေ֥

ᢝԌ䆩偠

ᄺᗻ㛑

⌟䆩ᅲ偠

᳝䰤ܗ

㔎䱋

ᮁ㺖

ᄺ

TEM in-situ TEM

䖲㓁ҟ䋼ᄺ

ԡ䫭ࡼᄺ

⥛എ䆎

⛁ᄺ

ns-ms

ᯊ䯈ሎᑺ

ms-s

s-year decades

࣮ٚބم൭( ؍Wirth et al. 2004), ೂ 1 ෮ൕ. ᄝჰሰԄ؇, ӈႨ֥ٚمᇶေЇওඔ

ൟ

蒙特卡洛方法

ps-ns

分子动力学

TEM

第一性

原理计算

atomic-nm

PAS

nm-mm

mm-mm

mm-m

ぎ䯈ሎᑺ

1

ҋਘڕᅶ႗߄࣮֥؟Ԅ؇࣮ॿࡏ (Wirth et al. 2004). ϱಃ݂ιනືغԛϱഠ෮

Ⴕ

৯

4

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

ᆴଆ, ೂֻ၂ྟჰ࠹ෘaٳሰ৯࿐ଆ֩; ᄝࣖ৬Ԅ؇, ંଆ๙ӈູ࣮ڕ

ᅶ႗߄ิ܂ਔႵི֥ࣥ, ೂࠎႿ৵࿃ࢺᇉ৯࿐֥ڕᅶุࣖෑྟં; ᄝࣖ؟Ԅ؇, ࣁ

උҋਘ൳ڕᅶު֥৯࿐ྟି࣮ᇶေ๙ݖൌဒaંބඔᆴ࠹ෘ֩ٚم. ھ໓ࡼٳљ

Ֆൌဒܴҩaඔᆴଆބંଆ 3 ۱ٚ૫ሸඍଢభݓଽຓܱႿࣁඋҋਘᄝ֮໑֮

ڕᅶ࠴ਈ่ࡱ༯ڕᅶ႗߄࣮֥ᇶေࣉᅚ.

2 ࣁඋҋਘڕᅶ႗߄֥ൌဒܴҩ

ൌဒܴҩ൞࣮ࣁඋҋਘڕᅶഄིႋቋᆰࢤaቋॖौ֥ٚمᆭ၂. Ֆ 20 ൗࡀᇏ

௹ष, ࣁඋҋਘ֥ڕᅶིႋᇯࡶႄఏದૌ֥ܱᇿ (Blewitt et al. 1960), ѩෛሢൌဒ่

ࡱܴࠣҩ൭֥؍҂؎ࣉ҄ؿބᅚ, ೂഝሰཁັࣤ (transmission electron microscope,

TEM) ބೡ૭֡ཁັࣤ (scanning tunneling microscope, STM) ֥֩ԛགྷ, ದૌؓڕᅶ

ಌཊೂ֝ޅᇁڕᅶ႗߄֥ಪ്҂؎ധೆ. ༯૫, ࡼՖڕᅶಌཊ֥ྙӮaဆ߄ၛࠣఃؓ

ҋਘܴޡ৯࿐ྟି֥႕ཙᆃ 3 ۱ٚ૫ࢺകཌྷܱ֥ൌဒ࣮۽ቔ.

2.1 ڕᅶಌཊ֥ো

ࣁඋҋਘ൳ۚି৬ሰڕᅶᆭު, ุࣖଽ҆߶ྙӮگᄖ֥ಌཊࢲܒ, ѩಌཊ֥ᇕ

োaૡ؇aնཬၛࠣྟᇉສສაڕᅶ่ࡱၛࠣҋਘྟᇉႵܱ. ᄝڕᅶ֥Ԛࢨ؍, ࣖ

ุҋਘᇏ֥ಌཊᇶေ൞ׄಌཊ໊ॢބ. ࣜݖ၂קൈࡗ֥ဆ߄, ᄝ֮໑ڕ֮ބᅶ࠴ਈ֥

่ࡱ༯, ุྏ৫ٚࢲܒҋਘᇏ֥ڕᅶಌཊᇶေၛ໊հߌ֥ྙൔթᄝ; طᄝ૫ྏ৫ٚࢲ

֥ܒҋਘᇏಌཊোߎაҪհିႵܱ, ؓႿҪհିࢠ֥֮ҋਘ, Ҫհඹ૫ุ൞ᇶေ֥

ಌཊো (Osetsky et al. 2000), ೂ 2 ෮ൕ. ֒໑؇ࢠۚൈ, ڕᅶಌཊᇶေ൞ၛॢ֥׳

ྙൔթᄝ. Վຓ, ๙ݖឭэّႋߎ߶Ⴕݛஞ֥Ӂള. ໊հߌॖູٳਆᇕ: ॢ໊ߌࡗބ༣

ߌ, ٳљ൞ڕᅶӁള֥ॢ໊ࡗބ༣ჰሰ๙ݖऊࠢ෯ཊྙӮ. Ҫհඹ૫ุ൞၂ᇕᆞඹ૫

ุࢲ֥ܒಌཊ, ၂Ϯ౦ঃ༯, ః၂֊ྙӮь٤ӈ໗ק. Վຓ, ൌဒܴҳؿགྷ, ҋਘ֥ࢲ

ܒҵၳؓಌཊো႕ཙࢠཬ, ২ೂ, ؓႿବࣖࣖ੶ބ૫ྏ৫ٚҋਘط, ෙಖఃଽ҆թ

ᄝնਈ֥ࢸ૫ࢲܒ, ڕᅶಌཊಯၛҪհඹ૫ุູᇶ (Nita et al. 2004; Yu et al. 2013),

ೂ 3 ෮ൕ.

ڕᅶಌཊ֥ૡ؇აڕᅶ࠴ਈ֥֮ۚႵૡ్֥ܱ༢ (Osetsky et al. 2000, Singh et al.

1997). ֒ڕᅶ࠴ਈࢠ֮ൈ, ಌཊ (໊հߌބҪհඹ૫ุ) ૡ؇აڕᅶ࠴ਈࠎЧӯཌྟ

ܱ༢; 4 іૼ, ֒ڕᅶ࠴ਈղ֞၂קਈൈ, ಌཊૡ؇߶ղ֞Ўބ, ෛሢڕᅶ࠴ਈ֥

࿃ᄹࡆ, ಌཊࣼ߶ဆэӮၛॢྙ֥׳ൔթᄝ. Վຓ, ᄝ၂ڕקᅶ֥࠴ਈ༯, ໊հߌބҪ

հඹ૫ุ֥Ԅժෛڕᅶ࠴ਈ֥э߄ཬޓ, ၂Ϯ౦ঃ༯Ҫհඹ૫ุ֥նཬᄝ 2∼3 nm, ໊

հߌ֥նཬᄝ 10 nm ቐႷ (Fabritsiev & Pokrovsky 2007, Fabritsiev et al. 2004).

ቋ֥࣮࣍іૼ, ڕᅶಌཊ֥ૡ؇ߎაҋਘ֥ັࢲܒႵܱ (Nita et al. 2004, Nita

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

5

b

a

100 nm

2

ڕᅶಌཊ, (a) ໊հߌ (Brimbal et al. 2011). ϱಃ݂ιනືغԛϱഠ෮Ⴕ; (b) Ҫհඹ૫

ุ (Briceno et al. 2013). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

0s

8 nm

5.7

nm

2.3

nm

Ta

Ta

3

੶ࣖၿᇏ֥ڕᅶಌཊҪհඹ૫ุ (Yu et al. 2013). ϱಃ݂ሱಖԛϱࠢ෮Ⴕ

et al. 2005, Rose et al. 1997, Sharma et al. 2013, Sharma et al. 2011). ๙ؓݖବࣖҋ

ਘ֥ڕᅶൌဒ࣮, ದૌؿགྷෛሢࣖ৬Ԅժ֥ࡨཬ, ࣖ৬ଽ֥҆ಌཊૡ؇߶ෛᆭࢆ֮,

֒ࣖ৬ԄժཬႿਢࢸԄժൈ, ڕᅶಌཊമᇀ߶ཨാ. ২ೂ, અථ֩๙ؓݖବ᪣ބသ߄

ࣉྛᇗሰڕᅶൌဒ, ؿགྷ֒သ߄ࣖ৬ཬႿ 15 nm ၛࠣ᪣ࣖ৬֥ԄժཬႿ 30 nm

ൈ, ཌྷႋ֥ဢᇏь҂߶թᄝڕᅶಌཊ (Rose et al. 1997), ೂ 5 ෮ൕ. ୄห֩ؓବ

ࣖڕᅶᆭުؿགྷ, ࣐ܵڕᅶಌཊোಯၛҪհඹ૫ุູᇶ, ಌཊૡ؇бԮࣖ؟

֥ಌཊૡ؇ေཬ؟ޓ, ၹطବࣖҋਘุགྷԛਅڕॆ֥ݺᅶྟି (Nita et al. 2005). ବ

ࣖҋਘ൳ڕᅶᆭު֥ಌཊૡ؇ᆭ෮ၛбԮࣖ؟ҋਘေ֮, ᇶေ൞ႮႿବࣖҋਘᇏࢠ

ն֥ࣖࢸб২. ൳ࣖࢸ֥႕ཙ, ڕᅶӁള֥ಌཊສສಸၞథ၍֞ࣖࢸࣉطФ་൬, ᆃ

ဢьࢆ֮ਔࣖ৬ᇏಌཊ֥ݣਈ, Ֆุطགྷԛࢠڕॆ֥ݺᅶྟି (Alsabbagh et al. 2013,

৯

6

࿐

ࣉ

ֻ 45 ज : 201505

ᅚ

1025

(0.22~0.27)Tm

㔎䱋ᆚᑺ/m-3

1024

1023

Cu

0.18Tm

1022

Fe

1021

0.29Tm

1020

10-5 10-4 10-3 10-2 10-1 100

䕤✻ࠖ䞣/dpa

101

4

a

ᱢ1015

㔎䱋ᆚᑺ/m-2

3

2

1

0

0

50

100

㉦ᇣ/nm

150

b

ᱢ1022

14

ሖ䫭ಯ䴶ԧᆚᑺ/m-3

ಌཊૡ؇აڕᅶ࠴ਈ֥ܱ༢ (Osetsky et al. 2000). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

12

10

8

6

4

2

0

10 20

30 40 50

ᄾ८ᑺ/nm

60

70

5

(a) သ߄ᇏಌཊૡ؇აࣖ৬Ԅժ֥ܱ༢ (Rose et al. 1997). ϱಃ݂ιනືغԛϱഠ

෮Ⴕ; (b) ၿᇏಌཊૡ؇ა੶ࣖި؇֥ܱ༢ (Yu et al. 2013). ϱಃ݂ሱಖԛϱࠢ෮Ⴕ

Matsuoka et al. 2007). ؓႿ੶ࣖҋਘط, ಌཊૡ؇ა੶ࣖࢸᆭࡗ֥ި؇္Ⴕܱ, ෛሢ

੶ࣖި؇֥ࡨཬ, ڕᅶಌཊૡ؇္߶ᇯࡶࡨഒ (Yu et al. 2013), ೂ 5 ෮ൕ, ᆃඪૼ

੶ࣖҋਘ္൞၂ᇕమᄝ֥ॆڕᅶҋਘ, طᇯࡶ൳ܱ֞ᇿ.

ڕᅶಌཊؓҋਘ৯࿐ྟି֥႕ཙაಌཊ֥ᇕোၛࠣ໑؇Ⴕܱ. ๙ӈ, ໊֒հ߁၍

მ֞ಌཊൈ, ಌཊ߶ఏ֞ףᄽ (pinning) ቔႨѩቅθ໊հ֥࿃߁၍, Ֆ֝طᇁڕᅶ႗

߄. ؓ҂֥ಌཊط, ఃቅθ໊հ߁၍఼֥ି৯൞҂֥; ဢ, ໑؇ؓಌཊა໊

հཌྷቔႨ఼္֥Ⴕࢠն႕ཙ (Fabritsiev & Pokrovsky, 2007, 2009, 2011). ২ೂ, ๙ݖ

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

7

ؓՂၛ֥ࠣࣁކҋਘࣉྛ҂໑؇่ࡱ༯֥ڕᅶ৯࿐ྟି࣮, ದૌؿགྷ֒໑؇

ശۚൈ, ಌཊቅθ໊հ߁၍֥ି৯ࡼࡨ, ࠧ໑؇ᄀۚ, ߁၍໊հᄀಸၞक़ڛಌཊ֥ቅ

θѩࡼಌཊ᛬ (annihilation) (Fabritsiev & Pokrovsky 2007), ೂ 6 ෮ൕ.

2.2 ڕᅶಌཊ֥ဆ߄

ڕᅶಌཊ֥ဆ߄აః෮ԩ֥ຓᄛߌၛࠣҋਘሱദ֥ັࢲܒႵܱ. ֒ҋਘؿളෑ

ྟэྙൈ, ߁၍໊հაಌཊ֥ཌྷቔႨ൞ಌཊဆ߄֥ᇶ֝ٚൔᆭ၂. ߁၍໊հაಌཊ

ཌྷቔႨ߶ڿэಌཊ֥োၛࠣඔਈ. ২ೂ, ໊֒հ߁၍მ֞ಌཊൈ, ಌཊॖିФሇ

эູఃো֥ಌཊࣉطФ᛬, ࠇᆀᆰࢤؿള᛬, Ֆ֝طᇁಌཊૡ؇֥ࢆ֮ (Matsukawa et al. 2008, Matsukawa & Zinkle 2004, Robach et al. 2006). ೂ 7 ෮ൕ, Ҫհ

ඹ૫ุა߁၍໊հཌྷቔႨၛުॖି֝ᇁఃᆰࢤ᛬ (Robach et al. 2006), ္ॖିФ

ሇߐӮمধक़ (Frank) ߌ (Matsukawa et al. 2008). Ҫհඹ૫ุᄝႿ߁၍໊հཌྷቔ

Ⴈᆭު, ߁၍໊հѩໃཨാ, ໊ࠧհაಌཊ֥ཌྷቔႨ๙ӈ҂߶ڿэ߁၍໊հ֥ૡ؇

(Briceno et al. 2013, Matsukawa et al. 2008), ೂ 7 ෮ൕ.

ᆴ֤ᇿၩ֥൞໊հაಌཊᆭࡗ֥ཌྷቔႨऎႵྟࡗॢ఼֥ޓ, ᆃ߶֝ᇁ൳ڕᅶު

֥ҋਘᄝຓᄛ่ࡱ༯ྙӮಌཊ (defect-free) ໊֥հ๙֡ (dislocation channel), Ֆطԛ

གྷۚ؇अთྟ (deformation localization) ֥ෑྟэྙ (de la Rubia et al. 2000). ൌ࠽ഈ,

ڕᅶӁള֥ಌཊᄝॢࡗ֥҃ٳѩ҂൞ܿᄵ֥, ؓႿ໊հߌᆃဢ֥૫ಌཊط, ߌ

෮ᄝ૫၂Ϯ൞ᄝ {111} { ބ100} ૫; ؓႿҪհඹ૫ุᆃᇕᆞඹ૫ุ֥ಌཊط, ః

ཌྷႋ֥Ҫհ૫๙ӈ္൞ᄝ {111} ૫ (Osetsky et al. 2000). ؓطႿ߁၍໊հط, ᄝ҂

ุุ֥ࣖ༢ᇏ, ః္ऎႵห߁֥ק၍ุ༢, ೂ૫ྏ৫ٚࢲุ֥ࣖܒଽ໊հ൞ᄝ {111}

300

DŽ

DŽ

Ttest=Tirr=80 C

DŽ

DŽ

pure Cu, RBT6, Tirr=80 C, ann

DŽ

pure Cu, RBT6, T =150 C

ሜ᳡ᑨ䞣/MPa

pure Cu, RBT6, Tirr=80 C

250

pure Cu, SM2, Tirr=80 C

200

irr

α=0.33

150

100

DŽ

Ttest=Tirr=150 C

50

α=0.17

0

0

5

10

15

20

-1

㔎䱋ᆚᑺ/m

25

30

ᱢ106

6

ಌཊა໊հཌྷቔႨ఼؇༢ඔބ໑؇֥ܱ༢ (Fabritsiev & Pokrovsky 2007). ϱಃ݂ι

නືغԛϱഠ෮Ⴕ

8

৯

࿐

ࣉ

ֻ 45 ज : 201505

ᅚ

B

ࡼᮍ

ԡ䫭䖤

E

H

C

F

G

D

A

50 nm

7

Ҫհඹ૫ุა߁၍໊հཌྷቔႨުؿള᛬໊طհಯթᄝ (Briceno et al. 2013). ϱಃ

݂ιනືغԛϱഠ෮Ⴕ

h110i ߁၍༢ഈ߁၍, ุྏ৫ٚࢲุ֥ࣖܒଽ໊հ߁၍ᄵᄝ {111} h110i, {111} h112i ބ

{111} h123i ߁၍༢. ႮՎॖ, ҂߁၍༢ഈ໊֥հაऎႵห֥҃ٳࡗॢקಌཊཌྷ

ቔႨऎႵૼཁ֥ॢࡗหྟ. ֒ᄝ၂ቆཌྷए߁֥࣍ޓ၍૫ഈ֥ಌཊა߁၍໊հཌྷቔ

Ⴈުؿള᛬, ь߶ྙӮ໊հ๙֡, ൈ߁၍໊հ෮൳֥֞ቅ৯ࡼննࡨཬ, ᆃဢ໊հ

ခՎ߁၍૫߁၍߶э֤ಸၞ, ֤ෑྟэྙᄝअ҆თ۷ಸၞؿള, Ⴟ൞ь߶ԛགྷۚ

؇अთྟ֥ෑྟэྙ (de la Rubia et al. 2000), ೂ 8 ෮ൕ.

Վຓ, ҋਘሱദ֥ັࢲؓܒಌཊ֥ဆ߄္ऎႵ႕ཙ. ২ೂ, ؓႿ൳ڕᅶު֥ବࣖҋ

ਘ, ൳նਈࣖࢸ֥႕ཙ, ࣖ৬ᇏौ࣍ࣖࢸ֥ಌཊಸၞథ၍֞ࣖࢸࣉطФ་൬, ᆃဢ֝ᇁ

ࣖ৬ᇏᄝौ࣍ࣖࢸ֥თଽ֥ಌཊཨാ, ྙӮ၂۱ಌཊთ, ᆃဢ֥ಌཊ҃ٳ҂न

ᄋྟ߶ᆰࢤ႕ཙಌཊᄝࣖ৬ଽ֥ဆ߄ (Nita et al. 2004, Nita et al. 2005). ဢᄝ੶ࣖ

ҋਘᇏ, ੶ࣖࢸ֥థ၍္߶აಌཊཌྷቔႨ, ൌဒ࣮іૼ, ੶ࣖࣖࢸ္ିఏ֞་൬ѩ

᛬ಌཊ֥ቔႨ, ࣉ֮ࢆطҋਘᇏ֥ಌཊૡ؇ (Yu et al. 2013), ೂ 9 ෮ൕ.

2.3 ڕᅶಌཊؓ৯࿐ྟି֥႕ཙ

ڕᅶؓҋਘܴޡ৯࿐ྟି֥႕ཙၘႵ҂ഒൌဒ۽ቔ֥࣮ (Blewitt et al. 1960,

Sharp & Makin 1965, Singh et al. 2012, Singh et al. 2001, Singh et al. 1995, Singh & Zinkle

1993, Victoria et al. 2000, Zinkle & Singh 1993), ᇶေܱᇿڕᅶ࠴ਈaڕᅶჷބ໑؇ؓҋ

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

9

8

ڕᅶэྙުԛགྷ໊֥հ๙֡ (de la Rubia et al. 2000). ϱಃ݂ሱಖԛϱࠢ෮Ⴕ

9

Ҫհඹ૫ุაࢸࣖ੶۬܋ቔႨѩФ་൬ (Yu et al. 2013). ϱಃ݂ሱಖԛϱࠢ෮Ⴕ

ਘັࢲܒၛࠣ৯࿐ྟି֥႕ཙ. ᄝ֮໑ڕ֮ބᅶ࠴ਈ༯, ࣁඋҋਘ൳ڕᅶު֥৯࿐ห

ྟᇶေุགྷູڕᅶ႗߄aڕᅶգ߄ၛࠣۿ႗߄༢ඔ༯ࢆ֩.

ؓႿ૫ྏ৫ٚࢲࣁܒඋҋਘ, ࡼᇶေၛࣁඋູ২ࢺകఃڕᅶ৯࿐ྟି, ః૫

ྏ৫ٚࢲࣁ֥ܒඋҋਘऎႵোර֥ڕᅶིႋ. ྌ۬֩ (Singh et al. 2001, Singh et al.

৯

10

࿐

ࣉ

a 400

b 300

OFHCCu

Tirr=320 K

OFHCCu

0.1 dpa

0.01 dpa

ᑨ/MPa

ᑨ/MPa

0.3 dpa

0.2 dpa

250

0.1 dpa

300

ֻ 45 ज : 201505

ᅚ

䕤✻

200

200

䕤✻

0.01 dpa

150

100

100

50

Ttest=295 K

0

0

0

10

20

30 40

ᑨব/%

50

60

70

Tirr=Ttest=373 K

0

10

20

30 40 50

ᑨব/%

60

70

10

(a) ֥ڕᅶႋ৯ႋэ౷ཌ (295 K) (Singh et al. 1995). ϱಃ݂ιනືغԛϱഠ෮Ⴕ;

(b) ֥ڕᅶႋ৯ႋэ౷ཌ (373 K) (Singh et al. 2001). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

1995) ๙ؓݖބ֥ࣁކҋਘࣉྛਔ၂༢ਙڕᅶൌဒ, ؿགྷෛሢڕᅶ࠴ਈ֥ᄹࡆ,

ҋਘ֥౹ڛႋ৯߶҂؎ഈശ, ൈҋਘ֥ᅚྟ߶҂؎༯ࢆ, หљ൞֒ڕᅶ࠴ਈࢠն

ൈ (ڕᅶഄ఼؇նႿ 0.1 dpa), ҋਘ߶ԛགྷݖ౹ׄڛႋ৯༯ࢆ֥གྷའ, ࠧ౹ުڛೈ߄

(post-yield dropping/softening), ೂ 10 ෮ൕ. Ӂള౹ުڛೈ߄֥ᇶေჰၹ൞֒ҋਘؿ

ളෑྟэྙൈ, ڕᅶಌཊ߶ቅθ໊հ֥߁၍, ֤ҋਘ֥౹ڛႋ৯ഈശ, ෛሢຓᄛᄹࡆ

֞ቀၛ֤߁၍໊հࡼಌཊ᛬ࠇᆀߊಌཊ֥ቅθି৯, ໊հ߁၍֥ቅ৯ࡼࡨཬ,

Ֆ֝طᇁ౺໊հ߁၍෮ླ֥ຓࢸᄛཬࡨހ, ԛགྷݖ౹ުׄڛႋ৯༯ࢆ֥གྷའ. ᆴ֤

ᇿၩ֥൞, ᆃ۱གྷའᆺႵ֒ڕᅶ࠴ਈӑݖ၂קൈҌ߶ؿള, ൌ࠽ഈݖ౹֥ׄڛੀႋ

৯ဆ߄টሱႿਆ҆ࠏٳᇅ֥ࣩᆚ: ಌཊ᛬֝ᇁੀႋ৯֥ࡨཬ໊ބհᄹᆲ֝ᇁੀ

ႋ৯֥ᄹࡆ. ֒ڕᅶ࠴ਈࢠ֮ൈ, ಌཊૡ؇ࢠཬ, ః᛬ؓੀႋ৯֥႕ཙཬႿ໊

հᄹᆲ֥႕ཙ, ܣ҂߶ԛགྷݖ౹ׄڛੀႋ৯༯ࢆ֥གྷའ; ֒ڕᅶ࠴ਈࢠۚൈ, նਈಌ

ཊ֥᛬ؓੀႋ৯֥႕ཙնႿ໊հᄹᆲ֥႕ཙ, ߶ܣԛགྷݖ౹ުׄڛႋ৯༯ࢆ֥གྷ

འ.

ᄝุྏ৫ٚࢲࣁ֥ܒඋҋਘᇏ, ํࠣఃࣁކ൞ႋႨࢠູܼ֥ٗҋਘ, ္൞࣮֥

ᇗׄ (Jiao & Was 2010; Lee et al. 2001a, 2001b; Luppo et al. 2000). ๙ݖཌྷܱൌဒҩ

൫іૼ, ุྏ৫ٚࢲࣁܒඋҋਘ൳ڕᅶၛު֥৯࿐ྟିა૫ྏ৫ٚࢲܒҋਘ֥ࠎЧো

ර, ఃᇶေ֥ڕᅶ႕ཙဢЇওૼཁ֥ڕᅶ႗߄ڕބᅶգ߄གྷའ, ဢ໑؇ၛࠣҋਘ

ັܴࢲڕؓܒᅶིႋ္Ⴕཌྷႋ֥႕ཙ, ೂ 11 ෮ൕ.

ҋਘ֥ັܴࢲܒၛࠣࣖ৬֥Ԅժؓڕᅶ႗߄Ⴕཁᇷ֥႕ཙ. ؓႿֆࣖҋਘط,

֒ࣖ৬Ԅժࢠնൈ, ఃڕᅶ႗߄ིႋაࣖ؟ҋਘࠎЧ၂ᇁ (Victoria et al. 2000), ೂ

12 ෮ൕ. ൞֒ࣖ৬Ԅժࡨཬൈ, ڕᅶ႗߄ིႋࡼ൳֞Ԅժၹ֥႕ཙ. ২ೂ, ࠎବ֩

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

a 400

b

350

Tirr=Ttest=293 K

6

4

5

2

250

200

3

1.

2.

3.

4.

5.

6.

150

100

50

0

5

1

Fe, 未辐照

Fe, 0.0013 dpa

Fe, 0.0017 dpa

Fe, 0.33 dpa

Fe12Cr, 未辐照

Fe12Cr, 0.2 dpa

10

Tirr=Ttest=523 K

400

ᑨ/MPa

ᑨ/MPa

300

0

11

15

20

ᑨব/%

6

300

3

5

4

200

1.

2.

3.

4.

5.

6.

100

25

0

30

1

2

0

10

Fe, 未辐照

Fe, 0.008 dpa

Fe, 0.0014 dpa

Fe, 0.034 dpa

Fe12Cr, 未辐照

Fe12Cr, 0.2 dpa

20

30

ᑨব/%

40

50

11

(a) ํڕᅶ֥ႋ৯ႋэ౷ཌ (293 K); (b) ํڕᅶ֥ႋ৯ႋэ౷ཌ (523 K) (Luppo et al.

2000). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

a

b

100

75

未辐照

7.9ᱢ104 dpa

6.6ᱢ103 dpa

3.9ᱢ102 dpa

1.3ᱢ101 dpa

50

25

0

0

0.25 0.50 0.75 1.00 1.25 1.50

ᑨব

ሜ᳡ᑨ/MPa

࠾ߛᑨ/MPa

125

103

118 nm

130 nm

Cu(100) 䕤✻

Cu(100) 䕤✻

788 nm

102

ԡ䫭⑤ࠊऎ

ԡ䫭㔎䱋

⫼ࠊऎ

100

1 000

㉦ሎᇌ/nm

12

(a) ֆ֥ࣖڕᅶႋ৯ႋэ౷ཌ (Victoria et al. 2000). ϱಃ݂ιනືغԛϱഠ෮Ⴕ; (b)

Ԅժڕބᅶؓֆࣖ౹ڛႋ৯֥႕ཙ (Kiener et al. 2011). ϱಃ݂ሱಖԛϱࠢ෮Ⴕ

ؓဢԄժՖ 80 nm ֞ 1 500 nm ֥ֆࣖࣉྛڕᅶު֥৯࿐ྟିҩ൫, ؿགྷڕᅶֆࣖ

թᄝ၂۱ਢࢸԄժ, ֒ֆࣖԄժཬႿਢࢸԄժൈ, Ԅժིႋؓֆ֥ࣖ৯࿐ྟିఏᇶ֝

ቔႨ, ڕᅶ႗߄֥႕ཙॖၛޭ; ֒ԄժնႿਢࢸԄժൈ, ڕᅶ႗߄ࡼӮູᇶ֝ࠏᇅ,

ֆࣖԄժ֥ڿэؓః৯࿐ྟିࠫެીႵ႕ཙ (Kiener et al. 2011), ೂ 12 ෮ൕ. ൌ࠽

ഈ, ֒ֆࣖԄժࡨཬൈ, ၂ٚ૫ࣖ৬ଽ໊҆հჷ໊ࠗؿհ֥ၞӱ؇ࡼэ֤ᄀটᄀ,

ਸ਼၂ٚ૫ࣖ৬ଽ໊֥҆հބಌཊ൳֞ֆࣖሱႮі૫֥႕ཙ, ࡼಸၞՖሱႮі૫ฦၤ,

Ֆ֝طᇁࣖ৬ଽ໊֥҆հၛࠣಌཊૡ؇ࢆ֮, ᆃဢࣼࢆ֮ਔڕᅶಌཊ֥႕ཙ. ෮ၛթ

ᄝᆃဢ֥ਢࢸԄժ, ֒ࣖ৬ԄժཬႿਢࢸԄժൈ, ֆࣖ৯࿐ྟି൞Ⴎ໊հჷࠏك

ᇶ֝ (dislocation source limitation mechanism); ֒ࣖ৬ԄժնႿਢࢸԄժൈ, ః৯࿐ห

ྟᇶေႮ໊հაڕᅶಌཊ֥ཌྷቔႨथק.

৯

12

࿐

ࣉ

ֻ 45 ज : 201505

ᅚ

250

ሜ᳡ᑨ䞣/MPa

pure Cu & Ni

pure Cu, dose ~0.1 dpa

200

150

pure Ni, dose ~0.1 dpa

dose ~0.1 dpa

100

Ttest=Tirr

50

0

0.2

0.3

0.4

0.5

ᔦϔ࣪⏽ᑺ

13

໑؇ؓڕᅶ႗߄֥႕ཙ (Fabritsiev & Pokrovsky 2011). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

ᓊԌ⥛/%

50

b

60%䕤✻ⱘ䪰

53%,䕤✻ⱘCuB2,CuB1MOB

㒃䪰, SM2 reactor, Tirr=Ttest=353 K

MOB

CuB2

40

104

㒃䪰

ࡳ⹀࣪㋏᭄/MPa

a 60

CuB1

30

20

㒃䪰0.0013 dpa

㒃䪰0.0098 dpa

103

㒃䪰0.1150 dpa

10

0

10-4

0.0098 dpa

0.1150 dpa

10-3

10-2

10-1

䕤✻ࠖ䞣/dpa

100

㒃䪰䕤✻

102

0

䕤✻

0.0013 dpa

0.05 0.10 0.15 0.20 0.25 0.30 0.35

ลᗻᑨব

14

(a) ҋਘᅚྟაڕᅶ఼؇֥ܱ༢ (Fabritsiev & Pokrovsky 2003). ϱಃ݂ιනືغԛ

ϱഠ෮Ⴕ; (b) ҋਘۿ႗߄༢ඔაڕᅶ఼؇֥ܱ༢ (Fabritsiev & Pokrovsky 2003). ϱಃ

݂ιනືغԛϱഠ෮Ⴕ

໑؇္߶႕ཙҋਘ֥ڕᅶ႗߄ྛູ. ๙ݖᄝ҂໑؇่ࡱ༯ؓ૫ྏ৫ٚࣁඋҋਘ

ࣉྛࢠູ༢֥࣮, ದૌؿགྷᄝཌྷ֥ڕᅶ่ࡱ༯ൈ, ໑؇֥ഈശ߶ҋਘڕᅶ႗

߄֥ӱ؇ࡨ (Fabritsiev & Pokrovsky 2007, 2009, 2011), ೂ 13 ෮ൕ. োර֥ൌဒ

ࢲ္ݔॖၛՖྌ۬֩ (Singh et al. 2001, Singh et al. 1995) ֥ڕᅶൌဒࢲुݔԛ (ೂ

11 ෮ൕ), ֒ڕᅶ࠴ਈᄝ 0.1 dpa ѩ໑؇Ֆ 295 K ഈശ֞ 373 K ൈ, ౹ڛႋ৯ᄵՖ

300 MPa ༯ࢆ֞ 250 MPa ቐႷ. ໊հაಌཊཌྷቔႨ఼֥ა໊հ෮ԩ֥ିਈሑႵ

ܱ, ֒໑؇ശۚ, ໊հࡼ൳ಣࠗৣఃԬᄀಌཊ֥ିਈᚐᆴ༯ࢆ, ၹطक़ڛಌཊቅθ෮

ླ֥ຓᄛࢆ֮.

ڕᅶԢਔ߶֝ᇁҋਘڕᅶ႗߄ၛຓ, ߎ߶ႄఏڕᅶգ߄ۿބ႗߄༢ඔ֥ࢆ֮ (Fabritsiev & Pokrovsky 2003, 2009, Odette et al. 2008, Odette & Lucas 2001). Ֆ 14 ॖ

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

13

ၛुԛ, ڕᅶ߶ҋਘ֥ᅚྟၛࠣۿ႗߄༢ඔࢠໃڕᅶൈႵཁᇷ֥༯ࢆ, ѩᆃᇕ

႕ཙສສ൞٤ӈາག֥, ۽ӱᄎႨ෮ླေ֥ॆڕᅶҋਘсྶൈડቀ၂఼֥ק؇ބನ

ྟ, ᆃဢҌିЌᆣࢲ֥ܒνಆॖौ, ෮ၛฐ෬࠻ିऎႵਅڕॆ֥ݺᅶྟିႻऎႵࢠݺ

ನྟ֥ҋਘ൞֒ࣂނҋਘ࣮֥ᇗׄބׄ.

Чࢫሸඍਔ࣍௹ܱႿڕᅶಌཊ֥ྙӮaဆ߄ၛࠣఃؓҋਘܴޡ৯࿐ྟି႕ཙ֥

ൌဒ࣮ࣉᅚ. ॖၛुԛ, ڕᅶ႗߄აҋਘЧദุ֥ࣖোaັܴࢲܒၛࠣຓᄛߌ

(ڕᅶ࠴ਈބ໑؇) ֩ၹૡ్ཌྷܱ. ؓႿ҂ุࣖࢲࣁ֥ܒඋҋਘ (૫ྏ৫ٚࢲࠇܒ

ᆀุྏ৫ٚࢲ)ܒ, ఃሹุ൝൞၂ᇁ֥, ൞֒ҋਘ֥ັܴࢲؿܒളэ߄ൈ, ఃڕᅶ

หྟࡼؿളૼཁэ߄. ෛሢ୍ུ࣍ັବඌ֥ؿᅚ, ऎႵັବࢲࣁ֥ܒඋҋਘᅚགྷ

ԛႪႿԮࣖ؟ҋਘ֥ڕᅶ৯࿐ྟି, ২ೂ൳ବࣖҋਘࢠնб২ࣖࢸ֥႕ཙ, ࣖ৬ଽ

҆ڕᅶಌཊбཌྷڕᅶ่ࡱ༯֥ࣖ؟ҋਘ֥ಌཊૡ؇ཬ, ุགྷԛਅڕॆ֥ݺᅶྟି,

൞ବࣖҋਘሱദ֥ᅚྟ҂ࡄ, ࡼܣཋᇅఃᄝॆڕᅶҋਘᇏ֥ႋႨ. ؓႿऎႵ੶ള

ࢸ૫֥ବ੶ࣖҋਘط, ఃหႵ֥੶ളࢸ૫ఃဢऎႵਅڕॆ֥ݺᅶหྟ, ൈ

੶ࣖҋਘ֥ᅚྟିਅݺ, ఃऎႵؿᅚӮູ༯၂սॆڕᅶҋਘ֥మିطӮູ࣮֥

ಣׄ. ॖၛु֞, ڕᅶ่ࡱ༯ࣁඋҋਘ֥৯࿐ྟିაᇭ؟ၹႵܱ, ๙ݖൌဒ࣮҂

ࢲܒҋਘᄝ҂ڕᅶߌ༯֥৯࿐ྟି, ିႵᇹႿؓҋਘڕᅶ႗߄ིႋັܴࠏ֥

ฐ෬, Ֆູط࣮ഡ࠹ਅڕॆ֥ݺᅶҋਘิ܂ሙಒॖौ֥ൌဒ၇ऌ.

3 ࣁඋҋਘڕᅶ႗߄֥ඔᆴଆ

ࣁඋҋਘ൳ڕᅶު֥ܴޡ৯࿐ྟିॖၛ๙ݖൌဒ֥ٚمᆰࢤܴҩ, ൞ࣁඋҋਘ

൳ۚି৬ሰሏࠌުೂྙޅӮ۲ᇕಌཊၛࠣڕᅶಌཊᄝັܴҪՑ֥ဆ߄ܿੰޓᆰࢤ

๙ݖൌဒٚൔট࣮. ᄝັܴԄ؇ၛࠣ༥ܴԄ؇, ඔᆴଆູದૌ࣮ҋਘڕᅶ႗߄

ིႋ֥ັܴࠏބ৯࿐หྟิ܂ਔ၂ᇕॖି֥ٚم, หљ൞୍࣍ট࠹ෘࠏඌ֥

ؿᅚ, ֤ᄎႨնܿଆ࠹ෘٚم࣮ҋਘڕᅶ႗߄֥ັܴࠏӮູॖି, ఃᇏቋᇶေ

ඔᆴଆٚمЇওٳሰ৯࿐ (MD) ଆ໊ބհ৯࿐ (DD) ଆ. ٳሰ৯࿐ଆ

ປಆ൞ࠎႿԮؘ֥৯࿐࠹ෘ৬ሰ (ჰሰࠇٳሰ) ᆭࡗ֥ཌྷቔႨ, ᄝ৬ሰࡗ൝ӆ

ಒࠎ֥קԤഈ, ؓ҂༢ሸᇏ֥৬ሰࣉྛ৯࿐࠹ෘ, ๙ૄؓݖ۱৬ሰ໊֥ᇂބ؇

֩ྐ༏ࣉྛ࠹ٳ༅, Ֆ֤֞طุ࣮༢෮ླ֥ܴޡਈ (ೂ໑؇a఼ࠇᆀႋ৯

֩). ໊հ৯࿐ଆ൞Ֆ༥ܴԄ؇ഈ໊࣮հဆ߄ၛࠣࣖ৬ҋਘܴޡ৯࿐ྛູ֥၂

ᇕႵི֥ٚم, ᄝุࣖڕᅶุ༢༯ିܔ໊࣮հაಌཊཌྷቔႨ֥ࠏѩყҩҋਘ൳

ڕᅶު֥ܴ҆ޡٳ৯࿐ྟି. ڕᅶಌཊؓҋਘ৯࿐ྟି֥႕ཙᇶေ๙ݖఃა໊հၛࠣ

ࣖࢸ֥ཌྷቔႨ, ༯૫ࡼՖٚ૫ؓҋਘڕᅶ႗߄ඔᆴଆ֥࣮ࣉᅚࣉྛࢺക: ໊

հაಌཊཌྷቔႨaಌཊაࣖࢸཌྷቔႨၛࠣڕᅶಌཊؓҋਘ৯࿐ྟି֥႕ཙ.

৯

14

࿐

a

ࣉ

ᅚ

ֻ 45 ज : 201505

b

15

(a) Ҫհඹ૫ุა໊հཌྷቔႨ; (b) Ҫհඹ૫ุაಫ໊հཌྷቔႨ (Osetsky et

al. 2005). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

3.1 ໊հაಌཊཌྷቔႨ

ࣁඋҋਘؿളෑྟэྙ൞๙ࣖݖ৬ଽ໊֥҆հ߁၍, ֒ҋਘ൳֞ڕᅶᆭު, ఃࣖ

৬ଽ҆߶Ӂളնਈ֥ಌཊѩቅθ໊հ֥߁၍, Ֆ֝طᇁڕᅶ႗߄֥Ӂള. ൞๙ݖൌ

ဒದૌޓᆰࢤܴҳ໊հაಌཊཌྷቔႨ֥ݖӱ. ๙ݖඔᆴଆ֥ٚم, ದૌॖၛՖ

ັܴҪՑ໊࣮հაಌཊཌྷቔႨ֥ݖӱ, Ֆطധೆࢳڕᅶིႋ֥ࠏ.

๙ٳݖሰ৯࿐ଆ࣮іૼ, ಫ໊հa໊հၛࠣࠁ໊ކհაҪհඹ૫ุ֥ཌྷ

ቔႨ൞گޓᄖ֥ (Lee et al. 2007, Lee & Wirth 2009, Wirth et al. 2002). ࣐ܵൌဒၘࣜ

ᆰࢤܴҩ֞Ҫհඹ૫ุФ߁၍໊հᆰࢤ་൬ؿطള᛬ (Matsukawa et al. 2006, 2008),

൞ٳሰ৯࿐ଆіૼҪհඹ૫ุᄝა໊հཌྷቔႨު߶ࣜ၂༢ਙگᄖ֥ဆ߄,

ѩᆃུဆ߄ݖӱაᇭ؟ຓࢸၹႵܱ (Lee & Wirth 2009, Osetsky et al. 2006, Robach

et al. 2006). ২ೂ, Osetsky ֩০Ⴈٳሰ৯࿐ଆ࣮ਔಫ໊հބ໊հაҪհඹ૫

ุ֥ཌྷቔႨ, ؿགྷఃࢲݔ൳ಌཊնཬaࠫܒࢲޅa໑؇ၛࠣࡆᄛႋэੱ֥႕ཙ߶Ӂ

ള 5 ᇕॖି֥ࢲݔ, ೂಌཊ҆ٳ᛬aಌཊؿള࿈ሇၛࠣಌཊФ۩ٳӮఃো֥ಌ

ཊ֩౦ྙ (Lee et al. 2007, Osetsky et al. 2006), 15 ෮ൕ. ࠁ໊ބհ൞ุࣖᇏቋӈ

໊֥հো, ֩๙ٳݖሰ৯࿐ଆؿགྷ, ࠁ໊ކհაҪհඹ૫ุࣉݖ၂Ցཌྷ

ቔႨޓ֝ᇁಌཊᆰࢤؿള᛬, طсྶࣜ؟ݖՑ၂༢ਙگᄖ֥ཌྷቔႨҌିಌཊ

ؿള᛬ (Lee & Wirth 2009).

ܱႿ໊հაڕᅶӁള໊֥հߌᆭࡗ֥ཌྷቔႨ, ္Ⴕ҂ഒٳሰ৯࿐ଆ֥ඔᆴ

࣮ (Drouet et al. 2014, Nogaret et al. 2007, Terentyev & Bakaev 2013, Terentyev et al.

2013), ೂ 16 ބ 17 ෮ൕ. ၂Ϯಪູ໊հߌა໊հ֥ཌྷቔႨაࠫܒޅၛ໊ࠣ

հ֥ྟᇉ (ಫ໊հࠇᆀ໊հ) Ⴕܱ, ఃࢲݔॖିႵ (1) ໊հߌؿളࡧ్; (2) ໊հߌሇ

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

a

b

c

d

e

f

15

16

Ҫհඹ૫ุა໊հཌྷቔႨުؿള᛬ (Saintoyant et al. 2007). (a) 0 ps, (b) 20 ps,

(c) 22.5 ps, (d) 25 ps, (e) 100 ps, (f) 140 ps. ϱಃ݂ιනືغԛϱഠ෮Ⴕ

a

b

L

R

c

C

d

17

໊հა໊հߌཌྷቔႨ (Terentyev et al. 2013). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

эູఃॖ߁၍֥( ;ܒ3) ໊հߌФ་൬ (Nogaret et al. 2007).

3.2 ಌཊაࢸ૫ཌྷቔႨ

ڕᅶಌཊԢਔა໊հཌྷቔႨၛຓ, ߎ߶൳ҋਘሱദࢸ૫֥႕ཙѩڿэః৯

৯

16

࿐

ࣉ

ֻ 45 ज : 201505

ᅚ

⬠

䗝ᢽᬊ 䯈䱭ᄤথᇘ

ぎԡᠽᬷ

18

ׄಌཊ໊ॢބ൳ࣖࢸ႕ཙ (Beyerlein et al. 2013). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

࿐ྟି, ೂࣖࢸ߶་൬նਈڕᅶӁള֥ׄಌཊ, ࣖ৬ଽ֥҆ಌཊૡ؇ࢆ֮ (Bai &

Uberuaga 2013, Bai et al. 2010); ڕᅶಌཊ߶ႄఏࣖࢸ߁၍ބథ၍ (Beamish et al. 2010;

Campañá et al. 2008), ࣖࢸ་൬ڕᅶӁള֥ׄಌཊᆭުఃࣖࢸଽनଉ҈༢ඔ߶նږ

؇ࢆ֮ (Borovikov et al. 2013), ဢڕᅶಌཊ߶֝ᇁ੶ࣖࢸ֥థ၍ (Song et al. 2014).

༯૫ࡼ୍߭࣍ܤটݓଽຓܱႿಌཊაࢸ૫ཌྷቔႨ֥ٳሰ৯࿐ଆࣉᅚ.

ܱႿࣖࢸೂޅ႕ཙࣁඋҋਘᇏڕᅶಌཊ֥ဆ߄, ః࣮ᇗׄᇶေࠢᇏᄝ૫ྏ৫

ٚࢲܒҋਘྏุބ৫ٚࢲܒҋਘ. ২ೂؓႿ૫ྏ৫ٚҋਘط, ದૌᇶေ࣮ਔၿ

(Sugio et al. 1998)a (Samaras et al. 2002, 2003)a (Bai & Uberuaga 2013, Demkowicz

et al. 2010, Demkowicz et al. 2008, Demkowicz & Thilly 2011) ֩ҋਘࣖࢸؓڕᅶಌཊ

֥႕ཙ; ؓႿุྏ৫ٚҋਘط, ᇶေၛํ (Perez-Perez & Smith 2000) ູᇶ. ࣐ܵҋਘ

ྟᇉ҂၂ဢ, ൞ࣖࢸؓڕᅶಌཊ֥႕ཙ൞၂ᇁ֥: ڕᅶ߶Ӂളնਈ֥ׄಌཊ໊ॢބ,

ఃᇏׄಌཊ၍֥ᚐᆴбॢ໊֮, ၹط۷ಸၞథ၍֞ࣖࢸطФ་൬, ൈࣖࢸ္߶ࠗ

ؿԛׄಌཊѩ၍ࣖ֞৬ଽ҆აڕᅶӁള֥ॢ໊ᇏބ, ᆃဢьࢆ֮ਔࣖ৬ଽ҆ׄಌཊ

໊֥ॢބૡ؇, Ֆط֤Ⴎׄಌཊ໊ॢބ๙ࣉݖ၂҄ဆ߄ྙӮ໊հߌބҪհඹ૫ุ֥

ඔਈࡨഒ, ุགྷԛ၂ڕॆ֥קᅶቔႨ (Bai et al. 2010, Beyerlein et al. 2013) , ೂ 18

෮ൕ.

ࣖࢸᄝ་൬նਈׄಌཊၛު, ః৯࿐ྟି္߶Ⴕࢠնڿэ. ቔູ૫ؓ֩ሰุ֥

ֻ၂уҋਘ, ࣁඋڕᅶ৯࿐ྟି֥࣮ऎႵᇗေၩၬ. ದૌ࣮ਔׄಌཊุؓྏ৫

ٚࢲܒࣖࢸ৯࿐หྟ֥႕ཙ, ؿགྷ֒ࣖࢸ་൬ׄಌཊၛު, ఃଉ҈༢ඔ߶նږ؇ࢆ

֮, ࠧࣖࢸ་൬֥ׄಌཊ߶֤ࣖࢸ߁၍э֤۷ࡆಸၞ, Ֆط֤ࣖࢸ֥৯࿐ྟᇉэ

ೈ (Borovikov et al. 2013). ᆴ֤ᆷԛ֥, ڕᅶުࣖࢸ֥৯࿐ྛູ࣮Ҍېېष, ಯթ

ᄝ؟ޓ໙ีᆴ֤࣮, ೂ൳ڕᅶުࣖࢸ֥ܴޡ৯࿐ྟି֩.

၂Ϯط, ࣖࢸԩႿࢠ֥֮ିਈሑ, ၹିطЌӻఃܒѩ໗קթᄝ. ֒൳֞ຓ

ࢸࠗৣೂۚ໑aႋ৯ቔႨൈ, ࣖࢸ֥ࢲࠣܒః໗ؿ߶ྟקളڿэ, Ֆطႄఏࣖࢸ߁၍

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

17

y

z

x

19

ڕᅶႄఏ֥ࣖࢸథ၍ (Campañá et al. 2008). ϱಃ݂ૅݓ࿐߶෮Ⴕ

ࠇᆀࣖࢸథ၍. ֒ࣖࢸ൳ڕᅶಌཊ֥႕ཙൈ, ఃࢲࠣܒ໗ྟקဢ߶ؿളڿэ. ದૌ

๙ٳݖሰ৯࿐ଆ, ࣮ਔڕᅶಌཊؓࣖࢸࢲࠣܒః໗֥ྟק႕ཙ, ؿགྷᄝڕᅶ่

ࡱ༯, ࣖࢸ֥߁၍ࠇᆀథ၍෮ླေ֥ຓࢸࠗৣбໃڕᅶ่ࡱ༯֥ཬ, ᆃॖି൞ၹູࣖ

ࢸԩ֥ڕᅶಌཊႵ০Ⴟ໊հӮؿ֥ނള, Ֆط֤ࣖࢸ۷ࡆಸၞ߁၍ࠇᆀథ၍,

19 (Campañá et al. 2008). ູਔ࣮ڕᅶಌཊؓ੶ࣖࢸ֥႕ཙ, ස֩๙ྏุؓݖ৫ٚࢲ

ํܒᇏ੶ࣖࢸ૫֥ڕᅶ৯࿐ྟି࣮, ؿགྷ (1) ڕᅶ҂ࣇ߶Ӂള՛֥ׄಌཊ,

ൈᄝࡧ్৯֥ቔႨ༯߶ᄝ੶ࣖࢸഈྙӮ੶໊ࣖհߌ, ѩႄఏ੶ࣖࢸథ၍; (2) ੶ࣖࢸഈ

֥ڕᅶׄಌཊॖିྙނӮ੶໊ࣖհߌ (Song et al. 2014).

3.3 ڕᅶಌཊؓҋਘ৯࿐ྟି֥႕ཙ

Li ֩ҐႨٳሰ৯࿐ଆ֥ٚم࣮ਔڕᅶ༯ֆ֥ࣖ৯࿐ྛູ (Li et al. 2013,

2014), ھଆุ༢࣮֥൞ᇠཟࡆᄛ֥ବཌ, ܋Ї ݣ11 705 ۱ჰሰ, ᄝ҂ೆഝ

ሰ֥ڕᅶ่ࡱ༯, ܴҩڕᅶಌཊ֥ဆ߄ݖӱ, ၛࠣؓݣႵಌཊ֥ֆࣖࣉྛঘഥ

ބ෪֩৯࿐หྟ֥࣮, ೂ 20 ෮ൕ. ᄝڕᅶ࠴ਈࢠ֥֮౦ঃ༯, ֆࣖଽᇶေӁ

ളׄಌཊ: ॢ໊ࡗބ༣ሰ, ఃᇏࡗ༣ሰޓಸၞథ၍aঔѩऊࠢӮ, ໊ॢطສສ҂ၞ

థ၍. ڕᅶಌཊ߶֝ᇁֆ֥ࣖဗ൦ଆਈؿളڿэ: ෪ဗ൦ଆਈෛሢॢ໊֥ᄹࡆ༵

эնުࡨཬ, طঘഥဗ൦ଆਈᄵෛॢ໊֥ᄹࡆ၂ᆰࡨཬ, ೂ 21 ෮ൕ. ڕᅶభު, ֆ

֥ࣖෑྟэྙ൞๙໊ݖհᄝ {111} h112i ߁၍༢֥߁၍. ᄝڕᅶಌཊԩ, ໊հॖၛ

ྙނѩؿഝԛট, Ֆ֮ࡨطֆ֥ࣖ౹ڛႋ৯.

ҐႨ໊հ৯࿐ଆট࣮ڕᅶಌཊؓҋਘ৯࿐ྟି֥႕ཙᇯࡶӮ୍ູ࣍টඔ

ᆴଆ֥Ⴕི൭( ؍Arsenlis et al. 2012, de la Rubia et al. 2000, Khraishi et al. 2002, Li

et al. 2011). ২ೂ, ದૌ০Ⴈ໊հ৯࿐֥ٚمᇶေ࣮ਔุྏ৫ٚࢲڕํܒᅶ႗߄

৯

18

ࣉ

ֻ 45 ज : 201505

ᅚ

䕤✻

0.2 keV

0.5 keV

1.0 keV

2.0 keV

5.0 keV

6.0 keV

7.0 keV

6

ᑨ/GPa

࿐

4

2

0

-2

-0.02

0

0.02

0.04

0.06

0.08

ᑨব

20

ڕᅶႋ৯ႋэ౷ཌ (Li et al. 2013). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

b 80

a

Etp

य़㓽ᴼ⇣䞣/GPa

ᢝԌᴼ⇣䞣/GPa

66

䕤✻ḋક

64

䕤✻ḋક

62

60

58

75

70

Ecp

65

䕤✻ḋક

䕤✻ḋક

0

10

30

20

ぎԡ᭄䞣

40

c

d

80

75

0

10

60

55

50

20

30

ぎԡ᭄䞣

40

䕤✻ḋક

Etp

65

ᢝԌᴼ⇣䞣/GPa

60

य़㓽ᴼ⇣䞣/GPa

56

䕤✻ḋક

䕤✻ḋક

70

65

Ecp

60

䕤✻ḋક

45

0

100

200

ぎԡ᭄䞣

300

55

0

100

200

ぎԡ᭄䞣

300

21

ڕᅶު֥ঘഥࠣ෪ဗ൦ଆਈ (Li et al. 2014). ϱಃ݂ႇݓ࿐߶ԛϱഠ෮Ⴕ

֥ࠏၛࠣಌཊ໊֥հ๙֡ྙӮ֥ݖӱ (Arsenlis et al. 2012), ೂ 22 ෮ൕ. ھଆ

ุ༢ҐႨшӉູ 1.3 µm ֥৫ุٚ, ఃᇏЇݣਔԚनᄋ໊֥҃ٳհࠣ҂ૡ؇֥

໊հߌ, ๙ݖᇠཟࡆᄛٳ༅ఃܴޡ৯࿐ྟି. ෛሢڕᅶಌཊ (໊հߌ) ૡ؇֥҂؎ഈശ,

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

a 1 200

19

b

2.64h1022 m-3

8.15h1021 m-3

21

-3

3.61h10 m

21

-3

ᑨ/MPa

1.63h10 m

800

8.15h1020 m-3

䕤✻

400

0

0

0.4

0.8

ᑨব/%

1.2

1.6

22

(a) ڕᅶํ֥ႋ৯ႋэ౷ཌ (Arsenlis et al. 2012). ϱಃ݂ιනືغԛϱഠ෮Ⴕ; (b) अ

თྟ֥ෑྟэྙ໊ބհ๙֡ (de la Rubia et al. 2000). ϱಃ݂ሱಖԛϱࠢ෮Ⴕ

᮴㔎䱋

㔎䱋ᆚᑺ=1.63×1021 m-3

㔎䱋ᆚᑺ=8.15×1021 m-3

㔎䱋ᆚᑺ=8.15×1020 m-3

㔎䱋ᆚᑺ=3.61×1021 m-3

㔎䱋ᆚᑺ=1.63×1022 m-3

23

҂Ԛ໊հߌૡ؇༯֥ෑྟэྙ (Arsenlis et al. 2012). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

ҋਘ֥౹ڛႋ৯߶ෛᆭᄹࡆ, ѩ໊֒հߌૡ؇նႿ 3.61 × 1021 m−3 ൈ, ੀႋ৯߶

ᄝݖ౹ؿުׄڛളૼཁ֥༯ࢆགྷའ. ູਔՖັܴࠏᇅഈٳ༅ఃӁള֥ჰၹ, ದૌٳ༅

ਔ໊հ໊ࠣհߌᄝؿളෑྟэྙൈ֥ဆ߄౦ঃ, Ֆ 23 ॖၛुԛ, ֒Ԛ໊հߌ֥

ૡ؇նႿ 3.61 × 1021 m−3 ൈ, ෑྟэྙ߶Ֆჰট֥न၂߄эྙሇэູۚ؇अ҆߄֥ෑ

ྟэྙ, ѩᄝ (11̄2̄) ૫ྙӮૼཁ֥ಌཊ๙֡. ൙ൌഈ, ᄝ (11̄2̄) ૫ഈఃࡧٳႋ

৯ቋն, ෮ၛᄝᆃ۱૫ഈ֥ಌཊࡼቋಸၞФ߁၍໊հ᛬, ၂֊ಌཊषؿള᛬,

৯

20

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

ᄝః૫ഈ߁၍໊հმ֥֞߁၍ቅ৯ࡼ༯ࢆ, ᆃဢࡼ֝ᇁܴޡੀႋ৯֥༯ࢆ, ൈ

Ӂളअთྟ֥ෑྟэྙѩྙӮಌཊ໊֥հ๙֡.

Чࢫᇶေሸඍਔ০Ⴈඔᆴଆٚم࣮ڕᅶಌཊဆ߄֥ັܴࠏၛࠣڕᅶಌཊ

ؓࢲܒ໗ބྟק৯࿐ྟି֥႕ཙ. ๙ݖඔᆴଆॖϺᇹਔࢳڕᅶಌཊဆ߄֥ݖ

ӱ, ൈႵᇹႿࢳڕᅶಌཊؓҋਘܴޡ৯࿐ྟି֥႕ཙ. ॖၛुԛ, ڕᅶಌཊሱദ֥

ဆ߄҂ࣇ൳ҋਘଽᄝࢲ֥ܒ႕ཙ, ᄝؿളෑྟэྙൈߎ߶ა߁၍໊հؿളگᄖ֥ཌྷ

ቔႨ, ᆞ൞ᆃུັܴԄ؇֥ಌཊ໊ބհ֥ဆ߄֝ᇁҋਘᄝܴޡԄ؇ഈุགྷԛڕᅶ

႗߄. ০Ⴈඔᆴଆ֥ٚم࣮ڕᅶ႗߄֥ࠏ, ؓࡹ৫ཌྷܱڕᅶંଆၛࠣഡ࠹

ਅڕॆ֥ݺᅶҋਘऎႵᇗေၩၬ.

4 ࣁඋҋਘڕᅶ႗߄֥ંଆ

ࠎႿൌဒܴҳބඔᆴଆ֥ࢲݔ, ٳ༅ཌྷܱ֥эྙࠏ, ࡹ৫ཌྷܱڕᅶ႗߄ં

ଆ, ൞࣮ڕᅶ႗߄ིႋѩყҩڕᅶಌཊؓҋਘܴޡ৯࿐ྟି႕ཙ֥Ⴕི൭؍. ଢ

భݓଽຓ֥ڕᅶ႗߄ંଆᇶေ࣮໑؇ٓຶᄝ 0.3 Tm ၛ༯a֮ڕᅶ࠴ਈൈࣖ؟

ࣁඋҋਘ֥৯࿐ྟᇉ. ሺܴڕᅶ႗߄֥ંଆ, ॖູٳো: (1) ॉ੮ັܴڕᅶಌཊ

აڕܴޡᅶ႗߄৳༢֥ڕᅶ႗߄ଆ, ھଆିקܔਈ૭ඍڕᅶಌཊૡ؇ა౹ڛႋ৯

ᄹਈ֥ܱ༢, ൞҂ି૭ඍҋਘᄝᆜ۱ࡆᄛݖӱᇏ֥ڕᅶ৯࿐ྛູ; (2) ࠎႿԮุࣖ

ෑྟં֥ڕᅶุࣖෑྟଆ, ھଆࡼڕᅶ႗߄ིႋॉ੮ุ֞ࣖෑྟંॿࡏ༯,

҂ࣇିٳܔ༅ҋਘ֥ڕᅶ႗߄ྛູ, ط๙໊ݖհૡ؇ބಌཊૡ؇֥ဆ߄ܿੰ, ॖၛ

Ⴕི૭ඍݖ౹ުׄڛҋਘ֥ڕᅶ৯࿐ྛູ, ીႵॉ੮ಌཊა໊հ֥ॢࡗཌྷቔႨ;

(3) ڕᅶุࣖᅦਈଆ, ھଆᄝڕᅶุࣖෑྟଆ֥ࠎԤഈ, ࢠ֥ݺॉ੮ਔڕᅶಌཊ

ა໊հ֥ॢࡗཌྷቔႨ, ିܔሙಒֹ૭ඍڕᅶಌཊؓҋਘ৯࿐ྟି႕ཙ֥ݖӱ. ༯૫,

ࡼٳљࢺകᆃোଆ֥ᇶေଽಸ.

4.1 ڕᅶ႗߄ଆ

ࠎႿᄪ௹ؓҋਘ൳ڕᅶު৯࿐ྟᇉ֥ൌဒܴҩ, ༆۬ٳ֩۬ྌބљิԛਔཌྷႋ֥

ڕᅶ႗߄ଆটࢳႵܱ֥ڕᅶགྷའ (Blewitt et al. 1960, Kojima et al. 1991, Lucas

1993, Odette & Frey 1979, Singh et al. 1997). ࣁඋҋਘ൳ڕᅶު, ؿളෑྟэྙൈ, ః

౹ڛႋ৯߶ഈശ, ູਔࡹ৫ັܴڕᅶಌཊაڕܴޡᅶ႗߄ᆭࡗ֥৳༢, ༆۬ิԛਔ

ჰሰ႗߄ (dispersed barrier hardening, DBH) ଆ. ھଆಪູڕᅶ႗߄টჷႿڕᅶ

ಌཊؓ߁၍໊հ֥ቅθ, ᄝύઅຣ఼֥؇ંॿࡏ༯ (Orowan 1942), ڕᅶ႗߄ؓ౹ڛ

ႋ৯֥܊ངॖіൕູ

√

τ = α′ µb N d

(1)

ఃᇏ, µ ބb ٳљ൞ҋਘ֥ࡧ్ଆਈބѵ۬൏ਈ֥նཬ, N ބd ٳљ൞ಌཊૡ؇ބն

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

21

ཬ. α′ ൞ಌཊ఼؇ҕඔ, Ⴈট૭ඍ҂ಌཊؓڕᅶ႗߄֥܊ང. ൌဒܴҳіૼ, ၂Ϯط

ؓႿ໊հߌ α′ ≈ 0.3; Ҫհඹ૫ุ α′ ≈ 0.2; ॢ ׳α′ ≈ 1. ൞ჰሰ႗߄ଆᆺ

ି࣍රყҩҋਘႮႿڕᅶಌཊ֝ᇁ֥౹ڛႋ৯ᄹਈ, ؓطႿ౹ׄڛᆭު֥৯࿐ྛູೂ

ު౹ڛೈ߄֥གྷའ, ჰሰ႗߄ଆѩ҂ି۳ԛཌྷႋ֥ંࢳ. ູՎ, ᄝ҃၈

ห֩۽ቔ֥ࠎԤഈ (Blewitt et al. 1960), ྌ۬֩ิԛਔಌཊࠩ৳Ⴚ֝ჷ႗߄ (cascadeinduced source hardening, CISH) ଆ (Singh et al. 1997), ఃᇶᆻනམ൞ಪູڕᅶ֝ᇁ

֥౹ڛႋ৯ഈശটሱႿمধक़ – ֣ (Frank–Read) ໊հჷᄝڕᅶ่ࡱ༯ၛࠗؿԛ

໊հ. ൞ൌဒіૼ, ಌཊࠩ৳Ⴚ֝ჷ႗߄ଆѩ҂ି֥ݺޓ૭ඍ၂ུࣁކҋਘ֥ڕ

ᅶ৯࿐ྟି (Robach et al. 2003), ൈ္ીႵॉ੮ڕᅶིႋაڕᅶ࠴ਈ֥ܱ༢ (Singh

et al. 1997), ၹطऎႵ၂֥קअཋྟ.

4.2 ڕᅶุࣖෑྟଆ

୍࣍ট, ູਔିܔႵֹིყҩڕᅶࣁඋҋਘ֥ܴޡ৯࿐ྟି, ದૌषᄝԮ֥

ุࣖෑྟં (Asaro & Rice 1977, Hill 1966, Hill & Rice 1972) ֥ࠎԤഈॉ੮ڕᅶ႗

߄ིႋ֥႕ཙ, ࣉؿطᅚਔڕᅶุࣖෑྟંଆ, ѩᄝՎࠎԤഈٳ༅໑؇aҋਘ

ࢲ֩ܒၹؓڕᅶࣁඋ৯࿐ྟି֥႕ཙ. Ԯุࣖෑྟંಪູ໊հ߁၍֝ᇁҋਘؿ

ളෑྟэྙ, ߁၍༢ α ֥ෑྟႋэੱ၂ϮҐႨૢՑمᄵ (Hutchinson 1976, Peirce et al.

1982)

α

γ̇ = γ̇0

µ

τα

τcα

¶ m1

sign(τ α )

(2)

ఃᇏ, γ̇0 ބm ٳљ൞ҕॉႋэੱބႋэੱૹۋ༢ඔ, τ α ൞ཌྷႋ߁၍༢֥ࡧႋ৯ٳਈ.

τcα ൞ਢࢸ్ႋ৯ (CRSS), іᆘ໊հᄝཌྷႋ߁၍༢߁၍֥ၞӱ؇. ؓႿԮڕᅶ

႗߄ིႋุ֥ࣖෑྟંଆط, ਢࢸ్ႋ৯၂ϮЇওҋਘܥႵ֥ࣖ۬ቅ৯ (lattice

friction)τ0 a໊հཌྷቔႨ໊ؓհ߁၍֥ቅ৯ τnα (໊հຩྙӮ֥Мႋ৯ (back stress))

ၛࠣҋਘັࢲ໊ؓܒհ߁၍֥႕ཙ τsα , ೂุࣖԄժིႋ (Hall 1951, Petch 1953, von

Blanckenhagen et al. 2001, 2003) ࠇᆀ੶ࣖҋਘᇏ੶ࣖࢸ֥႕ཙ (Lu et al. 2009). ֒ॉ

੮ڕᅶ႗߄ིႋൈ, ໊հᄝ߁၍༢ഈ֥߁၍ߎ߶მ֞ڕᅶಌཊ֥ቅθቔႨ τdα , ڕܣᅶ

ุࣖෑྟଆᇏਢࢸ్ႋ৯֥၂Ϯྙൔॖіൕູ

τcα = τcα (τ0 , τnα , τdα , τsα )

(3)

༯૫, ࡼࡥေ୍߭࣍ܤটܱႿڕᅶุࣖෑྟંଆ֥࣮ࣉᅚ.

ᄝჰሰڕᅶ႗߄ଆ֥ࠎԤഈ, ದૌᆌؓ૫ྏ৫ٚࢲܒҋਘࡹ৫ਔࠎႿ໊հ

ૡ؇֥ڕᅶุࣖෑྟଆ (Arsenlis et al. 2004). ᄝھଆᇏ, ҋਘ఼؇টჷႿ໊հᆭ

ࡗ֥ཌྷቔႨၛ໊ࠣհაಌཊ (Ҫհඹ૫ุ) ֥ཌྷቔႨ, ѩھଆࡌഡಌཊ఼؇

22

৯

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

ᆺაಌཊնཬႵܱൈڕᅶಌཊุ֥ࠒٳඔᄝෑྟэྙݖӱᇏЌӻ҂э. ๙ࣖࡼݖ৬

ڕᅶЧܱܒ༢აႵཋჭ࠹ෘٚކࢲم, ದૌٳ༅ਔڕࣖ؟ܴޡᅶ֥ঘഥ৯࿐ྟି,

ѩି֥ྟקܔაൌဒඔऌбࢠ, ିܔႵི֥ख़߂ڕᅶ႗߄֥གྷའ, ѩ႗߄ӱ؇ෛ

ڕᅶ࠴ਈ֥ᄹࡆطഈശ. ൞ھଆࡌഡಌཊૡ؇ෛࡆᄛݖӱطᄹࡆ, ᆃაൌဒܴҳ

ٳބሰ৯࿐ଆ֥ࢲݔཌྷິМ.

क़༐ବ֩ؿᅚਔࠎႿੱܱં֥૫ྏ৫ٚࢲܒҋਘڕᅶุࣖෑྟଆ (Krishna et al. 2010). ھଆಪູਢࢸ్ႋ৯ᇶေটჷႿ໊հཌྷቔႨၛ໊ࠣհაಌཊཌྷ

ቔႨ, ѩఃཌྷႋ֥ဆ߄ܿੰࠎႿ၂֥קࠎԤ. ᄝࣖ৬Ԅ؇ࣖ؟ބԄ؇, ھ

ଆି֥ݺࢠܔ૭ඍҋਘᄝ౹ׄڛభު֥ڕᅶ৯࿐ྛູ, Їওڕᅶ႗߄ުބ౹ڛೈ߄

ၛࠣڕᅶభުੀႋ৯҂ᇗކ. ဢࢲކႵཋჭ֥ٚم, ૌ০Ⴈھଆଆਔڕᅶ

ࣖ؟֥৯࿐ྟି, ѩაཌྷܱൌဒࢲݔ໖ݺࢠކ, ุགྷԛھଆ၂ކ֥קྟ.

ᄝఃંଆ֥ࠎԤᆭഈ, ૌࣉؿطᅚਔᆌุؓྏ৫ٚҋਘ᪬֥ڕᅶંଆ

, ఃᇶေٳ༅ਔᄝ֮໑ (0.05 < T /Tm < 0.2) ڕ֮ބᅶ࠴ਈൈࣁඋ᪬หႵ֥ڕᅶೈ߄

གྷའ (Krishna & De 2011). ھଆࡼਢࢸ్ႋ৯ູٳಣཌྷܱބಣܱਆ҆ٳ, ఃᇏಣ

ܱ֥҆ٳႮ໊հૡ؇ބಌཊૡ؇थק, طಣཌྷܱ֥҆ٳҐႨ໑؇ݦඔট૭ඍ. ๙ݖ

ંٳ༅, ڕᅶೈ߄აਢࢸ໑؇Ⴕܱ, ᄝ၂ڕקᅶ࠴ਈٓຶଽ, ਢࢸ໑؇ෛڕᅶ࠴ਈ֥

ഈശ֮ࢆط, Ֆ֝طᇁᄝ၂ק໑؇ٓຶଽڕᅶ౦ঃ༯֥ੀႋ৯бໃڕᅶ౦ঃ༯֥۷

֮, ѩაཌྷܱൌဒඔऌ໖ݺࢠކ.

ஂหঘބચक़֡غᆌุؓྏ৫ٚࢲܒҋਘࡹ৫ਔࢠູ༢֥ڕᅶંॿࡏ (Patra

& McDowell 2012, 2013). ھଆ҂ࣇٳљॉ੮ਔڕᅶӁള֥ׄಌཊ໊ބհߌෛࡆᄛݖ

ӱ֥ဆ߄ܿੰ, ߎٳ༅ਔڕᅶಿэ (Bullough & Wood 1980, Matthews & Finnis 1988)a

໊հࢌ߁၍ (cross-slip) (Rhee et al. 1998) ໊ބհ၍ (dislocation climb) (Mansur 1979)

֩ၹؓҋਘ৯࿐ྟିڕᅶིႋ֥႕ཙ. ๙ݖაႵཋჭٚކࢲم, ھଆିྟקܔ૭

ඍڕᅶӁള֥अ҆߄ෑྙэྙགྷའ, ѩંყҩ֥ڕࣖ؟ܴޡᅶࢲݔაൌဒඔऌ໖

ݺࢠކ. ൞ႮႿھଆॉ੮֥႕ཙၹࢠ؟, ֤ଆҕඔݖႿگᄖ.

ၛഈڕᅶุࣖෑྟଆ൞ࡼڕᅶ႗߄ིႋॉ੮֞Ԯุ֥ࣖෑྟંॿࡏଽ,

ᄝ໊հ߁၍֥ݖӱᇏ, ҂ࣇॉ੮໊հཌྷቔႨߎЇݣਔڕᅶಌཊ໊ؓհᄎ֥ቅθቔ

Ⴈ, ၹุܔିطགྷڕᅶ႗߄ིႋ. ᄝಌཊૡ؇֥ဆ߄ݖӱᇏ, ໊հ߁၍၂Ϯ߶֝ᇁڕᅶ

ಌཊ֥᛬ࠇಌཊྟᇉ֥ڿэ, ֤ಌཊૡ؇ෛෑྟэྙط҂؎ࢆ֮, ᆃ߶֝ᇁҋਘ

ؿളअ҆߄ෑྟэྙགྷའၛࠣ֒ڕᅶ࠴ਈղ֞၂קਈൈԛགྷݖ౹ׄڛੀႋ৯༯ࢆ

֥౦ঃ. ൞ᄝഈඍڕᅶંଆᇏ, ڕᅶಌཊ๙ӈ൞Ⴈѓਈྟᇉ֥эਈটख़߂,

ః҂ିܔႵֹི૭ඍڕᅶಌཊა߁၍໊հ֥ॢࡗཌྷቔႨ. ๙ݖൌဒܴҳބඔᆴଆ

іૼ, ڕᅶӁള֥ಌཊႵሱദ֥หᆘ૫, ໊طհ߁၍္൞ᄝห߁֥ק၍༢, ෮ၛ

ಌཊა໊հ֥ཌྷቔႨऎႵྟࡗॢ఼֥ޓ, ູਔ۷ࡆሙಒֹ૭ඍಌཊა໊հ֥ཌྷ

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

23

ቔႨ, ఃཌྷቔႨ֥ॢࡗྟсྶჍၛॉ੮. Վຓ, ࡹ৫Ֆࣖ৬Ԅ؇֥ڕᅶЧܱܒ༢֞ޡ

ܴࣖ؟ҋਘ৯࿐ྟᇉ֥ॴԄ؇৳༢๙ӈҐႨԮႵཋჭ࠹ෘٚم, ൞ᆴ֤ᆷԛ֥൞

Ⴕཋჭٚم๙ӈ൞ࠎႿীྙൔ֥न၂߄ંট֤֞ૄ၂۱ࠒܴޡ֥ׄٳ৯࿐ྟᇉ

(Taylor 1938), ޭطਔࣖ৬ᆭࡗႮႿ౼ཟၛࠣࣖࢸ֩ၹ֝ᇁ֥ႋ৯҃ٳ҂नᄋྟ

(Wang et al. 2010a), ൈႵཋჭࢠն֥࠹ෘਈᄝ၂קӱ؇ഈ္ཋᇅਔఃܼٗᄎႨ, ၹ

ࡹط৫۷ሙಒ۷Ⴕི֥ॴԄ؇൭ࡼ؍ऎႵᇗေၩၬ, ೂᬪෑྟሱటં (Coulibaly

& Sabar 2011, Paquin et al. 2001, Paquin et al. 1999, Sabar et al. 2002).

4.3 ڕᅶุࣖᅦਈଆ

ቋ࣍, Ϙٳؘ֩љᆌุؓྏ৫ٚࢲބܒ૫ྏ৫ٚࢲڕ֥ܒᅶࣁඋҋਘิԛਔཌྷႋ

֥ڕᅶุࣖᅦਈଆ (Barton et al. 2013, Xiao et al. 2015a), ࢠ֥ݺॉ੮ਔ໊հߌ (ุ

ྏ৫ٚҋਘᇏ֥ᇶေಌཊ) ބҪհඹ૫ุ (૫ྏ৫ٚҋਘᇏ֥ᇶေಌཊ) ა߁၍໊հ

֥ॢࡗཌྷቔႨ, ࣉܔିطႵི֥ଆ൳ڕᅶ႕ཙҋਘؿളෑྟэྙൈӁള֥अ҆߄

ෑྟэྙགྷའ. ೂ 24 ෮ൕ, ໊֒հ߁၍૫აಌཊ෮ᄝหᆘ૫ཌྷࢌൈ, ߁၍໊հ

с߶קაಌཊؿളཌྷቔႨ; ໊֒հ߁၍૫ა໊հߌ෮ᄝหᆘ૫ྛൈ, ໊հა

໊հߌ֥ཌྷቔႨ҂߶ؿള; ໊֒հ߁၍૫აҪհඹ૫ุ෮ᄝหᆘ૫ྛൈ, ౦

ঃࡼэ֤گᄖ၂ུ, ႮႿҪհඹ૫ุऎႵ၂ۚޅ֥ࠫק؇, ෮ၛᄝᆃᇕ౦ঃ༯໊հა

Ҫհඹ૫ุಯթᄝཌྷቔႨ֥( ੱۀKrishna et al. 2010). ༯૫ࡼၛ૫ྏ৫ٚࢲູܒ২

ࢺകڕᅶุࣖᅦਈଆ֥ऎุଽಸ, ൈٳ༅Ԅժིႋބ໑؇ིႋؓҋਘڕᅶ৯࿐ྟ

ି֥႕ཙ, ܱႿุྏ৫ٚࢲڕ֥ܒᅶุࣖᅦਈଆॖҕॉ໓ང (Barton et al. 2013).

ᄝڕᅶ૫ྏ৫ٚࢲܒҋਘᇏ, ໊հ߁၍ᇶေ൳֞Ҫհඹ૫ุ֥ቅθቔႨ, ᄝ߁၍

༢ α ᇏ, ڕᅶ႗߄ིႋॖіൕູ (Xiao et al. 2015a)

v

u Nd

u X α

N : Hβ

τdα = bµthd

(4)

β=1

ఃᇏ, hd ൞ಌཊ႗߄఼༢ඔ, Nd ൞ಌཊหᆘ૫֥ඔਈ, ؓႿҪհඹ૫ุط Nd =

4. N α ބH β ٳљ൞૭ඍ໊հބಌཊ֥ࢨؽᅦਈ, ఃקၬູ

N α = nα ⊗ nα

(5)

α

H β = Ndef ddef (I − nβ ⊗ nβ + Pann

δαβ nβ ⊗ nβ )

(6)

ބ

ఃᇏ, Ndef ބddef ٳљ൞ಌཊุૡ؇ބնཬ, nα ބnβ ٳљ൞߁၍໊հބಌཊหᆘ

α

૫֥مཟਈ, δαβ ൞क़અଽक़ݼژ, Pann

൞໊հაಌཊؿളࢤԨ֥( ੱۀKrishna et al.

2010). Ֆඔ࿐ᄎෘഈٳ༅, ᄝൔ (4) ᇏ, N α ބH β ֥෪ѩၩሢ֒ nα ބnβ ྛൈ

৯

24

࿐

ࣉ

nα

a

nα

b

ԡ䫭

α||β

ԡ䫭⦃

nβ

ԡ䫭

n

α

⒥⿏

ሖ䫭ಯ䴶ԧ

β

α

ᮍ

⒥⿏

ᮍ

β

ԡ䫭

nα

ԡ䫭

nα

α

α||β

⒥⿏ᮍ

⒥⿏ᮍ

d

ԡ䫭⦃

ሖ䫭ಯ䴶ԧ

d

α

n

β

n

β

Ld

β

c

α||β

ֻ 45 ज : 201505

ᅚ

β

β

24

໊հߌބҪհඹ૫ุა໊հ֥ॢࡗཌྷቔႨ (Xiao et al. 2015a). ϱಃ݂ιනືغԛϱ

ഠ෮Ⴕ

ࡼ໊հ૭ඍᅦਈ N α ႕֞ಌཊหᆘ૫֥مཟٚཟ, ֒طnα ބnβ ҂ྛൈࡼ໊

հ૭ඍᅦਈ N α ႕֞ಌཊหᆘ૫్֥ཟٚཟ (Wang et al. 2010b); Ֆၩၬഈ

ٳ༅, ֒ nα ބnβ ྛൈ, N α ބH β ֥෪ѩіൕ໊հބಌཊ֥ࢤੱۀԨૡ؇, ֒ط

nα ބnβ ҂ྛൈ, N α ބH β ֥෪ѩіൕ໊հބಌཊ֥ࢤԨૡ؇. ࠧ۴ऌൔ (4)∼ ൔ

(6), ֒ nα ބnβ ҂ྛൈ

N α : H β = Ndef ddef [1 − (nα · nβ )2 ]

(7)

іൕࢤԨૡ؇, ֒ nα ބnβ ྛൈ

α

N α : H α = Pann

Ndef ddef

(8)

іൕ໊հބಌཊ֥ࢤੱۀԨૡ؇. ߁၍໊հაಌཊཌྷቔႨᆭު, ಌཊ๙ᖻÖ໒ၹط

ಌཊૡ؇֥ဆ߄္ა໊հބಌཊ֥ॢࡗཌྷቔႨႵܱ, ၹՎ, Ϙิؘ֩ԛਔᆷඔಌཊ

කࡨمᄵ (Barton et al. 2013)

.

H β = −η

Ns

X

α=1

(N α : H β )N α |γ̇ α |

(9)

ఃᇏ, η ൞ಌཊ᛬༢ඔ, ؓႿ૫ྏ৫ٚࢲطܒ Ns = 12. Ֆൔ (9) ॖၛुԛ, ᄝ β

૫֥ಌཊဆ߄൳֞෮Ⴕ߁၍༢ഈ໊հ֥႕ཙ, ѩᆃᇕ႕ཙ൞ॢࡗྟ֥.

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

25

๙ࡹݖ৫ڕᅶุࣖᅦਈଆ, ҂ࣇॖၛყҩҋਘ֥ڕᅶ႗߄ྛູ, ߎॖၛབྷ༥֥

ٳ༅ಌཊა໊հဆ߄֥༥ࢫ. ೂ 25 ෮ൕ, ᄝ҂֥߁၍༢ᇏಌཊ໊ބհ֥ဆ߄ܿ

ੰ൞ປಆ҂၂ဢ֥, ൈڕᅶಌཊ߶႕ཙ߁၍໊հૡ؇֥ဆ߄. ֒ൈॉ੮ҋਘ֥Ԅ

ժིႋڕބᅶིႋൈ, ః৯࿐ྟିэ֤۷ࡆگᄖ. ࠎବ֩ؓ҂Ԅժ֥ڕᅶֆࣖࣉ

ྛਔ৯࿐ྟି࣮, ؿགྷᄝ၂ڕ֥קᅶ࠴ਈ༯ҋਘթᄝ၂۱ਢࢸԄժ, ֒ֆࣖԄժᄝ

ਢࢸԄժᆭഈൈ, ڕᅶིႋ൞႕ཙҋਘ৯࿐ྟି֥ᇶေၹ; ֒طֆࣖԄժཬႿਢࢸ

Ԅժൈ, Ԅժིႋᅝᇶ֝ቔႨ (Kiener et al. 2011). ᄝഈඍڕᅶุࣖᅦਈଆ֥ࠎԤഈ

ॉ੮ࣖ৬Ԅժིႋ֥႕ཙ, ླٳ༅ਆ҆ٳ႕ཙၹ: (1) ࣖ৬նཬ໊ؓհࠗؓ( ؿֆࣖ

ط) ࠇᆀ໊հ߁၍ (ؓطࣖ؟) ၞӱ؇֥႕ཙ, (2) ࣖ৬նཬ໊ؓհၛࠣಌཊٳ

֥҃႕ཙ.

ؓֆࣖطࣖ؟ބ, Ԅժིႋؓҋਘ౹ڛႋ৯֥႕ཙॖၛႨೂ༯ࣜဒ܄ൔ (Kraft

et al. 2010) ۳ԛ

σy = σ0 + kdn

(10)

ఃᇏ, σy ބσ0 ٳљіൕҋਘ֥౹ڛႋ৯ุބҋਘ֥౹఼ڛ؇, d ൞ҋਘ֥ࠫޅԄժ.

k ބn ൞ҋਘӈඔ. ؓႿࣖ؟ҋਘ, n = −0.5, ൔ (10) ࠧնࡅඃᆩ֥ࠉ – غఅ (Hall–

Petch) ܱ༢ (Cottrell 1958, Hall 1951, Li 1963). ؓႿֆࣖҋਘ, n ၂ϮՖ −0.5 ֞ −1

(Kiener et al. 2011, Uchic et al. 2009). ॖၛु֞, ෛҋਘԄժ֥ࡨཬ, ః౹ڛႋ৯߶

ᄹࡆ. ൞, ᆴ֤ᇿၩ֥൞, ֆ֥ࣖࣖ؟ބԄժིႋࠏ൞ປಆ҂၂ဢ֥. ࣖ؟ҋਘุ

གྷ֥ࠉ – غఅིႋটሱႿ߁၍໊հᄝࣖࢸԩ֥ؐࠒ (dislocation pile-up) ቅθ໊հ

֥ࣉ၂҄߁၍, طֆࣖҋਘ֥Ԅժིႋᄵ൞ႮႿ໊հჷ႗߄ࠏ, ࠧෛሢֆࣖԄժ

֥ࡨཬ, ࣖ৬ଽ໊֥҆հჷඔࡨഒ, ໊֤ࠗؿհӁളෑྟэྙᄀটᄀ, ਸ਼၂ٚ૫ॖ

b

600

τc1

τc2

500

1

τSFT

2

τSFT

τn1

τn2

1015

400

ԡ䫭ᆚᑺ/m2

CRSSঞ݊ߚ䞣/MPa

a

300

200

1014

pn1 䕤✻

pn2 䕤✻

pn1 䕤✻

pn2 䕤✻

1013

100

0

0

0.01

0.02

ᑨব

0.03

0.04

1012

0

0.01

0.02

ᑨব

0.03

0.04

25

(a) ਢࢸ్ႋ৯ࠣఃٳਈᄝ҂߁၍֥ဆ߄; (b) ໊հૡ؇ᄝ҂߁၍֥ဆ߄ (Xiao et

al. 2015a). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

৯

26

࿐

ࣉ

ֻ 45 ज : 201505

ᅚ

߁၍໊հ߁၍֞ሱႮі૫ൈ߶Ֆі૫ฦၤ, ֝ᇁ໊հૡ؇ࡨഒ, ູܣЌᆣႵቀ໊֥ܔ

հ߁၍Ӂളෑྟэྙ, ຓࢸᄛࣼৣ֥ࠗހсྶෛֆࣖԄժ֥ࡨཬطᄹࡆ (Kraft et al.

2010; von Blanckenhagen et al. 2001, 2003). ၹط, Ԅժིႋؓҋਘ౹ڛႋ৯֥܊ང τsα

ॖіൕູ

τsα

=

−0.5

,

kd

ࣖ؟

1 µ b κq

ln , ֆࣖ

s 2π q

b

(11)

ఃᇏ, s ބκ ൞ҋਘӈඔ, q = d/3 ൞໊հჷԄժ (Kraft et al. 2010). Վຓ, ࣖ৬Ԅժ

໊ؓհࠣಌཊ҃ٳऎႵ႕ཙ: ൮༵, ൳ֆࣖሱႮі૫ࠇᆀ֥ࢸࣖࣖ؟႕ཙ, ौ࣍ࣖ৬ሱ

Ⴎі૫ࠇᆀࣖࢸ֥і૫თଽ໊֥հڕބᅶಌཊ߶๙ݖሱႮі૫ฦၤࠇᆀФࣖࢸ་

൬, Ֆط֤і૫თଽ໊֥հބಌཊૡ؇ࡨഒ; ఃՑ, ࣖ৬Ԅժ֥ࡨഒ߶֝ᇁ໊հࠗ

ؿᄀটᄀ. ၹՎ, ࣖ৬Ԅժ֥ࡨཬ߶֝ᇁ໊հᆭࡗཌྷቔႨ఼֥؇ၛ໊ࠣհაಌཊ

ཌྷቔႨ఼֥؇ࡨ. ູႵིॉ੮ࣖ৬і૫ིႋ֥႕ཙ, ॖҐႨྉ॔ଆ (Xiao et al.

2015a), ೂ 26 ෮ൕ. ھଆࡼࣖ৬ູٳྉ॔ބਆ҆ٳ: ᄝ॔თ, ൳ሱႮі૫ࠇᆀ

ࣖࢸ႕ཙ, ໊հބಌཊཨാ; ᄝྉთ, ໊հཌྷቔႨ໊ࠣհაಌཊཌྷቔႨ҂൳і૫

ིႋ႕ཙ. ໊ܣհཌྷቔႨ໊ࠣհაಌཊཌྷቔႨ֥Ⴕིთุ֥ࠒб fVn ބfVd ູ

¶ς

µ

d − 2ω

n

d

fV = fV =

(12)

d

ఃᇏ, ω ൞॔თ֥ॺ؇, 2 6 ς 6 3 ൞૭ඍ֥ࠫܒޅҕඔ. ܣॉ੮Ԅժིႋؓಌཊ

႗߄఼༢ඔ hd ֥႕ཙ

hd = hd0 fVn fVd = hd0

µ

d − 2ω

d

¶2ς

(13)

ఃᇏ, hd0 іൕุҋਘ֥ಌཊ႗߄఼༢ඔ. Ֆൔ (13) ॖၛुԛ, ෛሢࣖ৬Ԅժ֥ࡨ

ཬ, ಌཊ႗߄఼༢ඔ߶эཬ, ุགྷԛࣖ৬Ԅժ֝ᇁ֥і૫ིႋؓڕᅶིႋ֥႕ཙ.

ؓႿֆุࣖҋਘ֥ڕᅶ৯࿐ྟି, ڕᅶ߶֝ᇁҋਘؿളૼཁ֥ڕᅶ႗߄གྷའ,

ൈᄝڕᅶ࠴ਈູ 0.1 dpa ൈ, ߶ԛགྷݖ౹ڛႋ৯ׄੀႋ৯༯ࢆ֥གྷའ. ֒ൈॉ੮Ԅ

ժིႋڕބᅶིႋൈ, ໊հჷ႗߄ࠏ໊ބհაಌཊཌྷቔႨࠏ߶ཌྷࣩᆚᇶ֝ҋ

ਘ֥৯࿐ྛູ: ؓႿ҂֥ֆࣖҋਘᄝ҂֥ڕᅶ่ࡱ༯, ߶թᄝ၂۱ਢࢸԄժ, ᄝਢ

ࢸԄժᆭ༯, ҋਘ֥৯࿐ྟି൳໊հჷ႗߄ࠏ॥ᇅ; طᄝਢࢸԄժᆭഈൈ, ڕᅶིႋ

߶ᇶ֝ҋਘ֥৯࿐หྟ, ೂ 27 ෮ൕ.

ԢਔڕᅶིႋބԄժིႋ, ໑؇္൞ࡼ႕ཙࣁඋҋਘ৯࿐ྟି֥ڕᅶིႋ. ໑؇

֥႕ཙᇶေЇও҆ٳ:

ֻ၂, ໑؇֥э߄߶ڿэҋਘ֥ྟӈඔ. ᄪᄝ 20 ൗࡀੂ୍ս, ၘႵնਈ֥

ંބൌဒ࣮іૼҋਘ֥ྟӈඔა໑؇Ⴕܱ, ѩႮຐ༆ୄิԛ֥ࣜဒ܄ൔିܔ

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

ω2

27

㢃

L

ω1

d

26

ྉ॔ଆൕၩ (Xiao et al. 2015a). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

a

b

103

200

0.10 dpa

0.05 dpa

0.01 dpa

䕤✻

100

0

0

0.04

0.08 0.12

ᑨব

0.16

270 MPa

200 MPa

600 nm

2

ԡ䫭⑤ࠊऎ

170 MPa

800 nm

470 nm

10

0.20

0.100 dpa

0.010 dpa

0.005 dpa

䕤✻

Cu(100)

ሜ᳡ᑨ/MPa

ᑨ/MPa

300

ԡ䫭㔎䱋

⫼ࠊऎ

1000

100

㉦ሎᇌ/nm

27

(a) ֆࣖڕᅶႋ৯ႋэ౷ཌ; (b) Ԅժڕބᅶིႋؓ౹ڛႋ৯֥႕ཙ (Xiao et al.

2015a). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

ֹݺޓކն҆ٳൌဒඔऌ (Varshni 1970)

0

Cij (T ) = Cij

−

sij

exp(T0 /T − 1)

(14)

0

൞ 0 K ൈ֥ྟӈඔ, sij ބT0 ൞ൌဒކҕඔ. ၹط໑؇ཌྷܱ֥ࡧ్ଆਈ

ఃᇏ, Cij

ॖіൕູ (Zhang et al. 2013)

µ(T ) =

p

C44 (T )(C11 (T ) − C12 (T ))/2

(15)

ֻؽ, ໑؇߶႕ཙ໊հૡ؇֥ဆ߄ݖӱ. ໊հૡ؇֥ဆ߄Їও໊հᄹᆲ໊ބհ᛬

৯

28

࿐

b

a 350

ᅲ㒓: [111]

280 㰮㒓: [100]

ऩ䪰

295 K

373 K

210

523 K

373 K

140

523 K

70

ֻ 45 ज : 201505

ᅚ

350

ᅲ㒓: 295 K

㰮㒓: 373 K 0.10 dpa

280

ᑨ/MPa

ᑨ/MPa

ࣉ

210

0.01 dpa

䕤✻

140

ऩ䪰

0.01 dpa

䕤✻

70

0

0

0

0.04

0.08 0.12

ᑨব

0.16

0.20

0

0.04

0.08 0.12

ᑨব

0.16

0.20

28

(a) ໃڕᅶֆࣖ҂໑؇҂ࡆᄛٚཟ֥ႋ৯ႋэ౷ཌ; (b) ֆࣖ҂໑؇҂ڕ

ᅶ่ࡱ༯֥ႋ৯ႋэ౷ཌ (Xiao et al. 2015b). ϱಃ݂ιනືغԛϱഠ෮Ⴕ

, ۴ऌॉक़ථބચड़ಣࠗં (Kocks 1977, Mecking & Kocks 1981), ໊Ⴟ߁၍༢ α ഈ

໊֥հૡ؇ ραn ֥ဆ߄ॖіൕູ

h p

i

α

α

α

ρ̇α

k1 ρα

n = γ̇

n − k2 (ε̇, T )ρn

(16)

ఃᇏ, k1 ൞ა໑؇ܱੱܱ૭ඍ໊հᄹᆲ֥༢ඔ, k2α ൞ა໑؇ੱބཌྷܱ૭ඍ໊հ

᛬֥༢ඔ (Beyerlein & Tome 2008). ໑؇֥ഈശ߶֝ᇁ໊հ᛬ࠏᇅ֥ᄹ఼, Ֆط

֤Ў໊ބհૡ؇༯ࢆ, ᄝܴޡഈ֝ᇁҋਘ֥ੀႋ৯ࡨ֮, ೂ 28 ෮ൕ. Վຓ, ໊հ

ૡ؇֥ဆ߄߶႕ཙಌཊૡ؇֥ဆ߄, ܣ໑؇္߶႕ཙಌཊૡ؇֥ဆ߄.

ֻ, ໑؇֥э߄߶႕ཙ໊հཌྷቔႨၛ໊ࠣհაಌཊཌྷቔႨ఼֥. ๙ݖൌ

ဒؿགྷ, ಌཊ႗߄఼༢ඔ hd ߶ෛ໑؇֥ശ֮ۚࢆط, ᆃіૼᄝࢠۚ໑؇༯, ߁၍໊

հԬᄀѩ᛬ڕᅶಌཊ߶эಸၞ, Ֆط෮ླ֥ຓࢸᄛހ༯ࢆ, ೂ 28 ෮ൕ.

Чࢫᇶေሸඍਔݓଽຓཌྷܱڕᅶ႗߄ંଆ֥࣮ࣉᅚ. ሹ֥টඪ, ଢభ֥ڕ

ᅶ႗߄ંၘࣜ౼֤၂֥ק࣮ࣉᅚ, ିܔᄝ֮ڕᅶ࠴ਈ֮ބ໑่ࡱ༯, ࢠ֥ݺ૭ඍ

ڕᅶؓࣁඋҋਘ৯࿐ྟି֥႕ཙ, Їওڕᅶ႗߄aۿ႗߄༢ඔ༯ࢆaݖ౹ުׄڛႋ৯

༯ࢆၛࠣअ҆߄ෑྟэྙགྷའ֩. ᆴ֤ᆷԛ֥൞, ଢభಯಖթᄝ؟ޓਵთታླં

۽ቔ֥࣮, ೂۚڕᅶ࠴ਈۚބ໑ߌ༯֥ڕᅶંଆaڕᅶ֝ᇁҋਘգ߄֥ં

ٳ༅ၛࠣ҂ࢲܒҋਘ (ೂବࣖ੶ބҋਘ) ֥ڕᅶ৯࿐ଆ֩. ॖၛु֞, ڕᅶં

ଆ֥࣮๙ፄߋʰଟዝࡌطഡ֥ॖौྟაކྟႻླေაڕᅶൌဒܴҳބඔᆴଆ

֥ࢲݔཌྷဒᆣ. ധೆषᅚڕᅶંଆ֥࣮ؓਔࢳҋਘڕᅶིႋ֥ࠏၛࠣഡ࠹

ਅڕॆ֥ݺᅶҋਘऎႵޓᇗေ֥ၩၬ.

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

29

5 ᅚຬ

ࣁඋҋਘڕᅶ৯࿐ྟି֥࣮ᄝุܥ৯࿐ބҋਘ॓࿐ਵთၘࠆ֤၂ؿ֥קᅚ, ๙

ݖൌဒaඔᆴଆބં࣮֥൭؍, ᄝັܴԄ؇, ದૌؓڕᅶಌཊ֥ྙӮaဆ߄ၛࠣ

ఃა໊հࠇᆀҋਘັବࢲܒཌྷቔႨ֥ࠏႵਔࢠູಆ૫֥ಪ്; ᄝܴޡԄ؇, ದૌ

ؓڕᅶಌཊ֝ᇁ֥ҋਘؿളڕᅶ႗߄ڕބᅶգ߄֩ࠏᇅ֥࣮౼֤ਔࢨ֥ྟ؍Ӯݔ.

ෛሢൌဒഡСބіᆘ൭֥؍҂؎ิശaնܿଆඔᆴ࠹ෘି৯҂؎ᄹ఼ၛࠣڕᅶં

ଆ֥҂؎ປ, ՖັܴԄ؇ധೆ࣮ಌཊ֥ဆ߄ݖӱބෑྟэྙൈ֥ࠏᇅࡼؓ

ҋਘ൳ڕᅶުܴޡ৯࿐ྟି֥ં࣮ิ܂ਅ֥ݺᆦӻ, ѩູഡ࠹ऎႵႪਅॆڕᅶྟ

ି֥ࢲܒҋਘิ܂ॖौ֥ൌဒඔऌބંᆦӻ. ଢభ, ھਵთ֥࣮Ⴕೂ༯ࠫٚ૫ᆴ

֤ᇗ൪:

(1) ۚڕᅶ࠴ਈۚބ໑่ࡱ༯ҋਘ֥ڕᅶ৯࿐ྟି. ᄝ༯၂սऊэّႋؐᇏҋਘ

ᇶေԩႿۚڕᅶۚބ໑ߌ, ၹՎ, षᅚࠞ؊่ࡱ༯, ࣁඋҋਘ৯࿐ྟି֥ڕᅶིႋ

࣮ऎႵᇗေ֥ၩၬ. ۚڕᅶ࠴ਈ߶ҋਘᇏ֥ಌཊၛॢູ׳ᇶ, ᄝຓᄛ่ࡱ༯, ॢ׳ॖ

ିؿളӉնགྷའ, ൈ໊հაॢ֥׳ཌྷቔႨ္ࡼ႕ཙҋਘܴޡ৯࿐֥ྟି, षᅚཌྷ

ܱඔᆴଆaൌဒ࣮ၛࠣંٳ༅۽ቔ, ࣮ऎႵڕᅶॢܒࢲ׳ҋਘ֥৯࿐หྟ൞

ታླࢳथ֥໙ีᆭ၂.

(2) ڕᅶգ߄֥ັܴࠏބંٳ༅. ڕᅶིႋቋᇶေ֥หᆘЇওڕᅶ႗߄ڕބ

ᅶգ߄. ܱႿڕᅶ႗߄ࠏ֥ಪ്ၘбࢠౢ༉, ѩંٳ༅္ࢠູປ. ൞

གྷႵܱႿڕᅶգ߄֥࣮ࢠູႵཋ, ๙ݖնܿଆٳሰ৯࿐ଆ҂ັବࢲܒ൳ڕᅶ

ಌཊ႕ཙ༯֥؎ਚหྟၛࠣࡹ৫ંଆყҩڕᅶҋਘ֥؎ਚྛູ൞٤ӈऎႵ็ᅞ

ྟ֥۽ቔ.

(3) ڕᅶಌཊა໊հཌྷቔႨ֥ധೆ࣮. ڕᅶಌཊ߶ቅθ߁၍໊հ֥ᄎ֝ᇁ

ڕᅶ႗߄, ൈ߁၍໊հᄎ൳֞ቅθުॖିؿളࢌ߁၍ࠇᆀ၍གྷའ, Ֆطಡݖಌ

ཊ࿃߁၍. ᆃᇕࢌ߁၍གྷའࡼ֝ᇁҋਘଽྙӮ၂ॺק؇֥ಌཊ߁၍๙֡, Ֆ֝ط

ᇁअ҆ෑྟэྙ֥Ӂള. ധೆٳ༅໊հაಌཊཌྷቔႨ֥۲ᇕࠏؓࢳࣁඋҋਘ

൳ڕᅶ႕ཙު֥ܴޡ৯࿐ྟିऎႵᇗေၩၬ.

(4) ବࢲࣁܒඋҋਘ֥ڕᅶ৯࿐ྟି. ෛሢ୍࣍টବඌ֥҂؎ؿᅚ, ྍବ

ࢲࣁܒඋҋਘᅚགྷԛႪႿԮࣖ؟ҋਘ֥৯࿐ྟି, ೂൈऎႵࢠ఼֥ۚ؇ބਅݺ

֥ನྟ. ๙ؓݖବࣖࣖ੶ބҋਘ֥ڕᅶൌဒؿགྷ, ఃӁള֥ಌཊбࣖ؟ҋਘഒ, ุགྷ

ԛਅڕॆ֥ݺᅶྟି. ൞ؓႿବࢲࣁܒඋҋਘ֥ڕᅶྟି࣮ಯಖٳႵཋ, ๙

ݖնܿଆٳሰ৯࿐࣮ڕᅶಌཊაࣖࢸࠇᆀ੶ࣖࢸ֥ཌྷቔႨؓఃࠏ֥ࢳࡼ

Ⴕᇗေ֥ၩၬ, ൈषᅚବࢲࣁܒඋҋਘ֥ڕᅶ৯࿐ྟିҩ൫ࡼູંٳ༅ყҩิ

ࠎ܂Ԥ.

৯

30

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

(5) ࣁඋҋਘ৯࿐ྟିڕᅶ႗߄࣮֥؟Ԅ؇ॿࡏ. Ⴕིყҩࣁඋҋਘ৯࿐ྟି

֥ڕᅶིႋ൞၂۱؟֥ׅԄ؇໙ี, ఃᇶေЇওਔਆ۱Ԅ؇֥ॴᄀ: ჰሰԄ؇ (ັ

ܴҪՑ) ֞ࣖ৬Ԅ؇ (༥ܴҪՑ) ၛࠣࣖ৬Ԅ؇ (༥ܴҪՑ) ֞ࣖ؟Ԅ؇ (ܴޡҪՑ) ֥

ॴᄀ. Ֆࣖ৬Ԅ؇֥ڕᅶุࣖෑྟଆ֞ࣖ؟Ԅ؇֥ܴޡҋਘ৯࿐ྟି֥ყҩॖҐ

ႨႵཋჭބ༥ܴ৯࿐֩ٚم, ൞ࡹ৫ՖჰሰԄ؇֥ڕᅶഄაࣖ৬Ԅ؇֥ڕᅶุࣖ

৯࿐ྛູ֥৳༢ಯླնܿଆඔᆴ࠹ෘ֥༢ྟ࣮.

ሹᆭ, ܱႿڕᅶؓࣁඋҋਘ৯࿐ྟି႕ཙ֥࣮ಯႵྸ؟ታրധೆ࣮֥ज़ี,

ᆃུज़ี࠻ऎႵაҋਘ࿐֥॓Мࣟ, ۷ऎႵ৯࿐࿐֥॓หᆘ, ླေ৯࿐۽ቔᆀ֥

ҕა, മᇀᇶ֝. ෛሢؓڕᅶིႋࠏ֥ࣉ၂҄ࢳބંაൌဒ۽ቔ֥ࣉ၂҄ധೆ,

ࡼູഡ࠹ऎႵਅݺ৯࿐ྟି֥ॆڕᅶҋਘࠣఃᄝ۽ӱᇏ֥ൌ࠽ႋႨࡔקൌ֥ࠎԤ.

ᇁ ྆ ࢭࡅݓԛౝ୍॓࿐ࠎࣁཛଢ (11225208) ބഈݚ൧תٚ࿐ᆀཛଢሧᇹ.

ҕॉ໓ང

Alsabbagh A, Valiev R Z, Murty K L. 2013. Influence of grain size on radiation effects in a low carbon steel.

Journal of Nuclear Materials, 443: 302-310.

Arsenlis A, Rhee M, Hommes G, Cook R, Marian J. 2012. A dislocation dynamics study of the transition

from homogeneous to heterogeneous deformation in irradiated body-centered cubic iron. Acta Materialia,

60: 3748-3757.

Arsenlis A, Wirth B D, Rhee M. 2004. Dislocation density-based constitutive model for the mechanical

behaviour of irradiated Cu. Philosophical Magazine, 84: 3617-3635.

Asaro R J, Rice J R. 1977. Strain localiazation in ductile single-crystals. Journal of the Mechanics and

Physics of Solids, 25: 309-338.

Bai X M, Uberuaga B P. 2013. The influence of grain boundaries on radiation-induced point defect production in materials: A review of atomistic studies. Jom, 65: 360-373.

Bai X M, Voter A F, Hoagland R G, Nastasi M, Uberuaga B P. 2010. Efficient annealing of radiation damage

near grain boundaries via interstitial emission. Science, 327: 1631-1634.

Barton N R, Arsenlis A, Marian J. 2013. A polycrystal plasticity model of strain localization in irradiated

iron. Journal of the Mechanics and Physics of Solids, 61: 341-351.

Beamish E, Campañá C, Woo T K. 2010. Grain boundary sliding in irradiated stressed Fe–Ni bicrystals: a

molecular dynamics study. Journal of Physics: Condensed Matter, 22: 345006.

Beyerlein I J, Caro A, Demkowicz M J, Mara N A, Misra A, Uberuaga B P. 2013. Radiation damage tolerant

nanomaterials. Materials Today, 16: 443-449.

Beyerlein I J, Tome C N. 2008. A dislocation-based constitutive law for pure Zr including temperature

effects. International Journal of Plasticity, 24: 867-895.

Blewitt T H, Coltman R R, Jamison R E, Redman J K. 1960. Radiation hardening of copper single crystals.

Journal of Nuclear Materials, 2: 277-298.

Borovikov V, Tang X Z, Perez D, Bai X M, Uberuaga B P, Voter A F. 2013. Influence of point defects on

grain boundary mobility in bcc tungsten. Journal of Physics-Condensed Matter, 25: 035402.

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

31

Briceno M, Kacher J, Robertson I M. 2013. Dynamics of dislocation interactions with stacking-fault tetrahedra at high temperature. Journal of Nuclear Materials, 433: 390-396.

Brimbal D, Decamps B, Barbu A, Meslin E, Henry J. 2011. Dual-beam irradiation of alpha-iron: Heterogeneous bubble formation on dislocation loops. Journal of Nuclear Materials, 418: 313-315.

Bullough R, Wood M H. 1980. Mechanisms of radiation-induced creep and grouth. Journal of Nuclear

Materials, 90: 1-21.

Campañá C, Boyle K, Miller R. 2008. Grain boundary motion assisted via radiation cascades in bcc Fe.

Physical Review B, 78: 134114.

Cottrell A H. 1958. The 1958 institute of metals division lecture—theory of brittle fracture in steel and

similar metals. Transactions of the American Institute of Mining and Metallurgical Engineers, 212:

192-203.

Coulibaly M, Sabar H. 2011. New integral formulation and self-consistent modeling of elastic-viscoplastic

heterogeneous materials. International Journal of Solids and Structures, 48: 753-763.

de la Rubia T D, Zbib H M, Khraishi T A, Wirth B D, Victoria M, Caturla M J. 2000. Multiscale modelling

of plastic flow localization in irradiated materials. Nature, 406: 871-874.

Demkowicz M J, Bellon P, Wirth B D. 2010. Atomic-scale design of radiation-tolerant nanocomposites. Mrs

Bulletin, 35: 992-998.

Demkowicz M J, Hoagland R G, Hirth J P. 2008. Interface structure and radiation damage resistance in

Cu-Nb multilayer nanocomposites. Physical Review Letters, 100: 136102.

Demkowicz M J, Thilly L. 2011. Structure, shear resistance and interaction with point defects of interfaces

in Cu-Nb nanocomposites synthesized by severe plastic deformation. Acta Materialia, 59: 7744-7756.

Drouet J, Dupuy L, Onimus F, Mompiou F, Perusin S, Ambard A. 2014. Dislocation dynamics simulations

of interactions between gliding dislocations and radiation induced prismatic loops in zirconium. Journal

of Nuclear Materials, 449: 252-262.

Fabritsiev S A, Pokrovsky A S. 2003. The effects of grain size and helium accumulation on radiation

hardening and loss of ductility of pure copper for ITER application. Fusion Engineering and Design, 65:

545-559.

Fabritsiev S A, Pokrovsky A S. 2007. Effect of irradiation temperature on microstructure, radiation hardening and embrittlement of pure copper and copper-based alloy. Journal of Nuclear Materials, 367:

977-983.

Fabritsiev S A, Pokrovsky A S. 2009. Effect of irradiation temperature and dose on SHC of pure Cu. Journal

of Nuclear Materials, 386-88: 268-272.

Fabritsiev S A, Pokrovsky A S. 2011. Effect of irradiation temperature and dose on radiation hardening of

some pure metals. Journal of Nuclear Materials, 417: 940-943.

Fabritsiev S A, Pokrovsky A S, Ostrovsky S E. 2004. Effect of the irradiation-annealing-irradiation cycle on

the mechanical properties of pure copper and copper alloy. Journal of Nuclear Materials, 324: 23-32.

Hall E O. 1951. The deformation and ageing of mild steel. 3. Discussion of results. Proceedings of the

Physical Society of London Section B, 64: 747-753.

Hill R. 1966. Generalized constitutive relations for incremental deformation of metal crystals by multislip.

Journal of the Mechanics and Physics of Solids, 14: 95.

Hill R, Rice J R. 1972. Constitutive analysis of elastic-plastic crystals at arbitrary strain. Journal of the

Mechanics and Physics of Solids, 20: 401.

৯

32

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

Hutchinson J W. 1976. Bounds and self-consistent estimates for creep of polycrystalline metarials. Proceedings of the Royal Society of London Series a-Mathematical and Physical Sciences, 348: 101-127.

Jiao Z, Was G S. 2010. The role of irradiated microstructure in the localized deformation of austenitic

stainless steels. Journal of Nuclear Materials, 407: 34-43.

Khraishi T A, Zbib H M, De La Rubia T D, Victoria M. 2002. Localized deformation and hardening

in irradiated metals: Three-dimensional discrete dislocation dynamics simulations. Metallurgical and

Materials Transactions B-Process Metallurgy and Materials Processing Science, 33: 285-296.

Kiener D, Hosemann P, Maloy S A, Minor A M. 2011. In situ nanocompression testing of irradiated copper.

Nature Materials, 10: 608-613.

Kocks U F. 1977. Theory of an obstacle-controlled yield strength-report after an international workshop.

Materials Science and Engineering, 27: 291-298.

Kojima S, Zinkle S J, Heinisch H L. 1991. Radiation hardening in neutron-irradiated polycrystalline copper:

Barrier strength of defect clusters. Journal of Nuclear Materials, 179: 982-985.

Kraft O, Gruber P A, Moenig R, Weygand D. 2010. Plasticity in confined dimensions. Annual Review of

Materials Research, 40: 293-317.

Krishna S, De S. 2011. A temperature and rate-dependent micromechanical model of molybdenum under

neutron irradiation. Mechanics of Materials, 43: 99-110.

Krishna S, Zamiri A, De S. 2010. Dislocation and defect density-based micromechanical modeling of the

mechanical behavior of fcc metals under neutron irradiation. Philosophical Magazine, 90: 4013-4025.

Lee E H, Byun T S, Hunn J D, Yoo M H, Farrell K, Mansur L K. 2001a. On the origin of deformation

microstructures in austenitic stainless steel: Part I—Microstructures. Acta Materialia, 49: 3269-3276.

Lee E H, Yoo M H, Byun T S, Hunn J D, Farrell K, Mansur L K. 2001b. On the origin of deformation

microstructures in austenitic stainless steel: Part II—Mechanisms. Acta Materialia, 49: 3277-3287.

Lee H J, Shim J H, Wirth B D. 2007. Molecular dynamics simulation of screw dislocation interaction with

stacking fault tetrahedron in face-centered cubic Cu. Journal of Materials Research, 22: 2758-2769.

Lee H J, Wirth B D. 2009. Molecular dynamics simulation of the interaction between a mixed dislocation

and a stacking fault tetrahedron. Philosophical Magazine, 89: 821-841.

Li D, Zbib H, Garmestani H, Sun X, Khaleel M. 2011. Modeling of irradiation hardening of polycrystalline

materials. Computational Materials Science, 50: 2496-2501.

Li J C M. 1963. Petch relation and grain boundary sources. Transactions of the Metallurgical Society of

Aime, 227: 239.

Li W, Sun L, Xue J, Wang J, Duan H. 2013. Influence of ion irradiation induced defects on mechanical

properties of copper nanowires. Nuclear Instruments & Methods in Physics Research Section B-Beam

Interactions with Materials and Atoms, 307: 158-164.

Li W N, Xue J M, Wang J X, Duan H L. 2014. Mechanical properties of self-irradiated single-crystal copper.

Chinese Physics B, 23: 036101.

Lu K, Lu L, Suresh S. 2009. Strengthening materials by engineering coherent internal boundaries at the

nanoscale. Science, 324: 349-352.

Lucas G E. 1993. The evolution of mechanical property change in irradiated austenitic stainless-steels.

Journal of Nuclear Materials, 206: 287-305.

Luppo M I, Bailat C, Schaublin R, Victoria M. 2000. Tensile properties and microstructure of 590 MeV

proton-irradiated pure Fe and a Fe-Cr alloy. Journal of Nuclear Materials, 283: 483-487.

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

33

Mansur L K. 1979. Irradiation creep by climb-enable glide of dislocations resulting from preferred absorption of point-defects. Philosophical Magazine a-Physics of Condensed Matter Structure Defects and

Mechanical Properties, 39: 497-506.

Matsukawa Y, Osetsky Y N, Stoller R E, Zinkle S J. 2006. Destruction processes of large stacking fault

tetrahedra induced by direct interaction with gliding dislocations. Journal of Nuclear Materials, 351:

285-294.

Matsukawa Y, Osetsky Y N, Stoller R E, Zinkle S J. 2008. Mechanisms of stacking fault tetrahedra destruction by gliding dislocations in quenched gold. Philosophical Magazine, 88: 581-597.

Matsukawa Y, Zinkle S J. 2004. Dynamic observation of the collapse process of a stacking fault tetrahedron

by moving dislocations. Journal of Nuclear Materials, 329: 919-923.

Matsuoka H, Yamasaki T, Zheng Y J, Mitamura T, Terasawa M, Fukami T. 2007. Microstructure and mechanical properties of neutron-irradiated ultra-fine-grained SUS316L stainless steels and electrodeposited

nanocrystalline Ni and Ni-W alloys. Materials Science and Engineering a-Structural Materials Properties

Microstructure and Processing, 449: 790-793.

Matthews J R, Finnis M W. 1988. Irradiation creep models—An overview. Journal of Nuclear Materials,

159: 257-285.

Mecking H, Kocks U F. 1981. Kinetics of flow and strain-hardening. Acta Metallurgica, 29: 1865-1875.

Nita N, Schaeublin R, Victoria M. 2004. Impact of irradiation on the microstructure of nanocrystalline

materials. Journal of Nuclear Materials, 329-333: 953-957.

Nita N, Schaeublin R, Victoria M, Valiev R Z. 2005. Effects of irradiation on the microstructure and

mechanical properties of nanostructured materials. Philosophical Magazine, 85: 723-735.

Nogaret T, Robertson C, Rodney D. 2007. Atomic-scale plasticity in the presence of Frank loops. Philosophical Magazine, 87, 945-966.

Odette G R, Alinger M J, Wirth B D. 2008. Recent developments in irradiation-resistant steels. Annual

Review of Materials Research, 38: 471-503.

Odette G R, Frey D. 1979. Development of mechanical property correlation methodology for fusion environments. Journal of Nuclear Materials, 85-6: 817-822.

Odette G R, Lucas G E. 2001. Embrittlement of nuclear reactor pressure vessels. Jom-Journal of the

Minerals Metals & Materials Society, 53: 18-22.

Orowan E. 1942. A type of plastic deformation new in metals. Nature, 149: 643-644.

Osetsky Y N, Bacon D J. 2001. Defect cluster formation in displacement cascades in copper. Nuclear

Instruments & Methods in Physics Research Section B-Beam Interactions with Materials and Atoms,

180: 85-90.

Osetsky Y N, Bacon D J. 2003. Atomic-scale modelling of primary damage and properties of radiation

defects in metals. Nuclear Instruments & Methods in Physics Research Section B-Beam Interactions

with Materials and Atoms, 202: 31-43.

Osetsky Y N, Bacon D J, Serra A, Singh B N, Golubov S I. 2000. Stability and mobility of defect clusters

and dislocation loops in metals. Journal of Nuclear Materials, 276: 65-77.

Osetsky Y N, Rodney D, Bacon D J. 2006. Atomic-scale study of dislocation-stacking fault tetrahedron

interactions. Part I: mechanisms. Philosophical Magazine, 86: 2295-2313.

Osetsky Y N, Stoller R E, Rodney D, Bacon D J. 2005. Atomic-scale details of dislocation-stacking fault

tetrahedra interaction. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, 400: 370-373.

৯

34

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

Paquin A, Berbenni S, Favier V, Lemoine X, Berveiller M. 2001. Micromechanical modeling of the elasticviscoplastic behavior of polycrystalline steels. International Journal of Plasticity, 17: 1267-1302.

Paquin A, Sabar H, Berveiller M. 1999. Integral formulation and self-consistent modelling of elastoviscoplastic behavior of heterogeneous materials. Archive of Applied Mechanics, 69: 14-35.

Patra A, McDowell D L. 2012. Crystal plasticity-based constitutive modelling of irradiated bcc structures.

Philosophical Magazine, 92: 861-887.

Patra A, McDowell D L. 2013. Continuum modeling of localized deformation in irradiated bcc materials.

Journal of Nuclear Materials, 432: 414-427.

Peirce D, Asaro R J, Needleman A. 1982. An analysis of nonuniform and localized deformation in ductile

single-crystals. Acta Metallurgica, 30: 1087-1119.

Perez-Perez F J, Smith R. 2000. Structural changes at grain boundaries in bcc iron induced by atomic collisions. Nuclear Instruments & Methods in Physics Research Section B-Beam Interactions with Materials

and Atoms, 164: 487-494.

Petch N J. 1953. The cleavage strength of polycrystals. Journal of the Iron and Steel Institute, 174: 25-28.

Rhee M, Zbib H M, Hirth J P, Huang H, de la Rubia T. 1998. Models for long-/short-range interactions

and cross slip in 3D dislocation simulation of BCC single crystals. Modelling and Simulation in Materials

Science and Engineering, 6: 467-492.

Robach J S, Robertson I M, Lee H J, Wirth B D. 2006. Dynamic observations and atomistic simulations of

dislocation-defect interactions in rapidly quenched copper and gold. Acta Materialia, 54: 1679-1690.

Robach J S, Robertson I M, Wirth B D, Arsenlis A. 2003. In-situ transmission electron microscopy observations and molecular dynamics simulations of dislocation-defect interactions in ion-irradiated copper.

Philosophical Magazine, 83: 955-967.

Rose M, Balogh A G, Hahn H. 1997. Instability of irradiation induced defects in nanostructured materials.

Nuclear Instruments & Methods in Physics Research Section B-Beam Interactions with Materials and

Atoms, 127: 119-122.

Sabar H, Berveiller M, Favier V, Berbenni S. 2002. A new class of micro-macro models for elastic-viscoplastic

heterogeneous materials. International Journal of Solids and Structures, 39: 3257-3276.

Saintoyant L, Lee H J, Wirth B D. 2007. Molecular dynamics study of the interactions between dislocation

and imperfect stacking fault tetrahedron in Cu. Journal of Nuclear Materials, 361: 206-217.

Samaras M, Derlet P M, Van Swygenhoven H, Victoria M. 2002. Computer simulation of displacement

cascades in nanocrystalline Ni. Physical Review Letters, 88: 125505.

Samaras M, Derlet P M, Van Swygenhoven H, Victoria M. 2003. Radiation damage near grain boundaries.

Philosophical Magazine, 83: 3599-3607.

Sharma G, Mukherjee P, Chatterjee A, Gayathri N, Sarkar A, Chakravartty J K. 2013. Study of the effect of

alpha irradiation on the microstructure and mechanical properties of nanocrystalline Ni. Acta Materialia,

61: 3257-3266.

Sharma G, Sarkar A, Varshney J, Ramamurty U, Kumar A, Gupta S K, Chakravartty J K. 2011. Effect of

irradiation on the microstructure and mechanical behavior of nanocrystalline nickel. Scripta Materialia,

65: 727-730.

Sharp J V, Makin, M J. 1965. Microstrain in neutron irradiated copper crystals. Philosophical Magazine,

12: 427.

Shimada M, Campbell D J, Mukhovatov, V, Fujiwara, M, Kirneva, N, Lackner, K, Nagami, M, Pustovitov,

V.D, Uckan N, Wesley J, Asakura N, Costley A E, Donne A J H, Doyle E J, Fasoli A, Gormezano C,

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

35

Gribov Y, Gruber O, Hender T C, Houlberg W, Ide S, Kamada Y, Leonard A, Lipschultz B, Loarte A,

Miyamoto K, Osborne T H, Polevoi A, Sipps A C C. 2007. Progress in the ITER Physics Basis - Chapter

1: Overview and summary. Nuclear Fusion, 47: S1-S17.

Singh A, Tao N R, Dao M, Suresh S. 2012. Repeated frictional sliding properties of copper containing

nanoscale twins. Scripta Materialia, 66: 849-853.

Singh B N, Edwards D J, Toft P. 2001. Effect of neutron irradiation and post-irradiation annealing on

microstructure and mechanical properties of OFHC-copper. Journal of Nuclear Materials, 299: 205-218.

Singh B N, Foreman A J E, Trinkaus H. 1997. Radiation hardening revisited: role of intracascade clustering.

Journal of Nuclear Materials, 249: 103-115.

Singh B N, Horsewell A, Toft P, Edwards D J. 1995. Temperature and dose dependencies of microstructure

and hardness of neutron-irradiated OFHC copper. Journal of Nuclear Materials, 224: 131-140.

Singh B N, Zinkle S J. 1993. Defect accumulation in pure FCC metals in the transient regime - A review.

Journal of Nuclear Materials, 206: 212-229.

Song D K, Li X G, Xue J M, Duan H L, Jin Z H. 2014. Irradiation-enhanced twin boundary migration in

BCC Fe. Philosophical Magazine Letters, 94: 361-369.

Sugio K, Shimomura Y, de la Rubia T D. 1998. Computer simulation of displacement damage cascade

formation near sigma 5 twist boundary in silver. Journal of the Physical Society of Japan, 67: 882-889.

Taylor, G I. 1938. Plastic strain in metals. Journal of the Institute of Metals, 62: 307-324.

Terentyev D, Bakaev A. 2013. Interaction of a screw dislocation with Frank loops in Fe-10Ni-20Cr alloy.

Journal of Nuclear Materials, 442: 208-217.

Terentyev D, Bakaev A, Osetsky Y N. 2013. Interaction of dislocations with Frank loops in Fe-Ni alloys and

pure Ni: An MD study. Journal of Nuclear Materials, 442: S628-S632.

Uchic M D, Shade P A, Dimiduk D M. 2009. Plasticity of micrometer-scale single crystals in compression.

Annual Review of Materials Research, 39: 361-386.

Varshni Y P. 1970. Temperature dependence of the elastic constants. Physical Review B-Solid State, 2:

3952-3958.

Victoria M, Baluc N, Bailat C, Dai Y, Luppo M I, Schaublin R, Singh B N. 2000. The microstructure and

associated tensile properties of irradiated fcc and bcc metals. Journal of Nuclear Materials, 276: 114-122.

von Blanckenhagen B, Gumbsch P, Arzt E. 2001. Dislocation sources in discrete dislocation simulations

of thin-film plasticity and the Hall-Petch relation. Modelling and Simulation in Materials Science and

Engineering, 9: 157-169.

von Blanckenhagen, B, Gumbsch, P, Arzt, E. 2003. Dislocation sources and the flow stress of polycrystalline

thin metal films. Philosophical Magazine Letters, 83: 1-8.

Wang H, Wu P D, Tome C N, Huang Y. 2010a. A finite strain elastic-viscoplastic self-consistent model for

polycrystalline materials. Journal of the Mechanics and Physics of Solids, 58: 594-612.

Wang Y, Weissmuller J, Duan H L. 2010b. Mechanics of corrugated surfaces. Journal of the Mechanics and

Physics of Solids, 58: 1552-1566.

Wirth B D, Bulatov V V, de la Rubia T D. 2002. Dislocation-stacking fault tetrahedron interactions in Cu.

Journal of Engineering Materials and Technology-Transactions of the Asme, 124: 329-334.

Wirth B D, Odette G R, Marian J, Ventelon L, Young-Vandersall J A, Zepede-Ruiz L A. 2004. Multiscale

modeling of radiation damage in Fe-based alloys in the fusion environment. Journal of Nuclear Materials,

329: 103-111.

৯

36

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

Xiao X Z, Song D K, Xue J M, Chu H J, Duan H L. 2015a. A size-dependent tensorial plasticity model for

FCC singlecrystal with irradiation. International Journal of Plasticity, 65: 152-167.

Xiao X Z, Song D K, Xue J M, Chu H J, Duan H L. 2015b. A self-consistent plasticity theory for modeling

the thermo-mechanical properties of irradiated FCC metallic polycrystals. Journal of the Mechanics and

Physics of Solids, 78: 1-16.

Yu K Y, Bufford D, Sun C, Liu Y, Wang H, Kirk M A, Li M, Zhang X. 2013. Removal of stacking-fault

tetrahedra by twin boundaries in nanotwinned metals. Nature Communications, 4: 1377-1377.

Zhang H M, Dong X H, Du D P, Wang Q. 2013. A unified physically based crystal plasticity model for

FCC metals over a wide range of temperatures and strain rates. Materials Science and Engineering

a-Structural Materials Properties Microstructure and Processing, 564: 431-441.

Zinkle S J, Singh B N. 1993. Analysis of displacement damage and defect production under cascade damage

conditions. Journal of Nuclear Materials, 199: 173-191.

(ᄳщ: นഒ఼)

༰ሰ, සקএ, ԣࡹݚ, ࿏ࡹૼ, ߰؍ਪ : ࣁඋҋਘ৯࿐ྟି֥ڕᅶ႗߄ིႋ

37

Irradiation hardening for metallic materials

XIAO Xiazi1,2

SONG Dingkun1

CHU Haijian3,4

XUE Jianming2,5

DUAN Huiling1,2,†

1

State Key Laboratory for Turbulence and Complex System, Department of Mechanics and

Engineering Science, College of Engineering, Peking Universitity, Beijing 100871, China

2

HEDPS, Center for Applied Physics and Technology, Peking University,

Beijing 100871, China

3

Shanghai Institute of Applied Mathematics and Mechanics, Shanghai 200444, China

4

Department of Mechanics, College of Sciences, Shanghai 200444, China

5

Physics School of Peking University, Beijing 100871, China

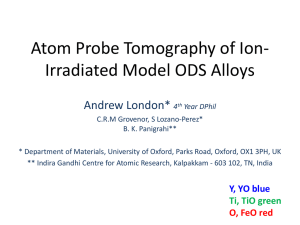

Abstract Investigations on irradiation hardening of metallic materials have much significance for the design of anti-irradiation materials and engineering applications. Both

irradiation-induced defects and gaseous impurities produced by nuclear reactions have dramatic irradiation effects on the mechanical properties of materials, which include irradiation

hardening, irradiation embrittlement and irradiation creep, etc. In this paper we are concerned with irradiation hardening, i.e., the strength of materials increases with irradiation,

under low irradiation doses and low temperatures of T < 0.3 Tm with Tm the melting temperature. Besides, other factors such as the grain size, the grain boundary and the temperature

affect mechanical behaviors of irradiated polycrystalline materials. The study of irradiation hardening of metallic materials is a multi-scale problem, for which the macroscopic

mechanical behaviors of irradiated materials are determined by both the change of interior

structures with irradiation at micro-scale and the interactions among irradiated grains at

meso-scale. This paper reviews experimental results, numerical simulations and theoretical

models for irradiation hardening of metallic materials. Some scientific problems for future

study are also presented.

Keywords metallic materials, irradiation hardening, temperature effect, size effect, mechanical behaviors

Received: 27 November 2014; accepted: 8 April 2015; online: 14 April 2015

†

E-mail: hlduan@pku.edu.cn

Cite as: Xiao X Z, Song D K, Chu H J, et al. Irradiation hardening for metallic materials.

Advances in Mechanics, 2015, 45: 201505

c 2015 Advances in Mechanics.

°

38

৯

࿐

ࣉ

ᅚ

ֻ 45 ज : 201505

߰؍ਪ, ୯, Кࣘն࿐࿐Ѱൖ (2005), Ӊࡾ࿐ᆀหௗ࢝൱, ุܥ৯࿐Ѱൖ

ള֝ഽ; Кࣘն࿐۽࿐ჽ৯࿐ა۽ӱ॓࿐༢༢ᇶaุ࡙ܥ৯࿐࿐॓ׄᇶ

, Кࣘն࿐ “ۚିਈૡ؇ඔᆴଆ” ࢝ტ҆ᇗׄൌဒ൩ڬᇶ. ૅݓ

ࠏྀ۽ӱഽླྀ߶ (ASME) ᇶϷᄖᆽ Journal of Engineering Materials and

Technology ֥ڬᇶщaScientific Reports ֩؟۱ᄖᆽ֥щ; ᇏݓ৯࿐࿐߶

൙, ڬӉ, ੀܥᯒކህြჴ߶ჴ, ุܥ৯࿐ህြჴ߶ളҋਘ

ٟࠣളህြቆڬቆӉ, ؓຓࢌੀაކቔჴ߶ჴ. ୍࣍ট, ᄝ٤नᇉҋਘ

֥ྟ৯࿐ࠎЧ໙ีaگᄖྙષุܥі૫֥ྟં࣏ࠣંaЊଇၳ

ᇉࢲ֥ܒ৯࿐ંࠣႋႨ֩ٚ૫౼֤ਔᇗေ֥॓Ӯݔ. ᄝݓଽຓ࿐ඌᄖ

ᆽa࿐ඌ߶ၰഈؿі࿐ඌં໓ 100 Ⴥ, ఃᇏ, ॓࿐ႄ໓෬ႄ (SCI) ൬ં໓ 70 ؟, Їও Nature

Communications, Proceedings of the National Academy of Science, Advanced Materials, Physical

Review Letters, Advances in Applied Mechanics, Journal of the Mechanics and Physics of Solids,

Physical Review B, Proceedings of the Royal Society A ֩࠽ݓ௹़, SCI ં໓Фದ SCI ႄႨ 1 300

؟Ց. Ⴕ 7 ં໓ФູۚႄႨં໓ބಣׄં໓; ఃᇏႵਆં໓ೆ࿊ࠎ“ ࠽ݓЧ॓࿐ᆷѓ”(ESI)

ۚႄႨં໓, ႄनӑ ݖ180 Ց. ᄝ IUTAM Symposiumaݓଽຓ࿐ඌ߶ၰ؟ބ෮ն࿐ቓն߶Б

ۡaᇶᆻБۡބဤ౨࿐ඌБۡ؟Ց. ᇶӻࢭࡅݓԛౝ୍॓࿐ࠎࣁaყฐ෬ᇗնཛଢaࡅݓሱ

ಖ॓࿐ࠎࣁ૫ഈཛଢaಆݓႪྮѰൖ࿐໊ં໓ቔᆀህཛࠎࣁޠݓ֣ބЍࠎࣁ߶Ⴖ࣮ቆ৳ࠎކ

ࣁ֩؟ཛ॓ཛଢ; ҕࡆࡅݓሱಖ॓࿐ࠎࣁᇗׄཛଢ ބ973 ࠎࡅݓԤ࣮ؿᅚ࠹߃֩.