2409.26b,60 Page 1 of 29 FOREST SERVICE HANDBOOK

advertisement

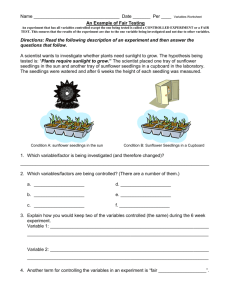

2409.26b,60 Page 1 of 29 FOREST SERVICE HANDBOOK PORTLAND, OREGON 2409.26b - REFORESTATION HANDBOOK R-6 Amendment No. 2409.26b-92-2 Effective February 7, 1992 POSTING NOTICE. Amendments to this handbook are numbered consecutively. Check the last transmittal sheet received for this handbook to see that the above amendment number is in sequence. If not, obtain intervening amendment(s) at once from the Information Center. Do not post this amendment until the missing one(s) is received and posted. After posting, place the transmittal at the front of the title and retain until the first transmittal of the next calendar year is received. The last amendment to this handbook was 2409.26b-92-1 (2409.26b,30). Document Name Superseded New (Number of Sheets) 60 2409.26b,60 29 29 Digest: This is a Technical Amendment to change the Document Name. CONTENT HAS NOT BEEN CHANGED. JOHN F. BUTRUILLE Regional Forester R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 2 of 29 FSH 2409.26b - REFORESTATION HANDBOOK R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 CHAPTER 60 - SEEDLINGS 60 SEEDLINGS 60.1 Critical Dates For Reforestation Program Coordination 61 SEED 62 ORDERING TREE SEEDLINGS 62.1 62.11 62.2 62.21 62.22 62.23 Sowing Requests SOWREQ Requires the Following Information Selection of Stock Species Selection Type of Planting Stock Matching Stock and Site 63 NURSERY 63.1 63.2 63.21 63.22 63.3 63.31 63.32 63.33 63.34 Nursery Visits Seedling Inventories 1-0 Inventory 2-0 Inventory Nursery Grading Standards Specifications Caliper and Height Root System Stem Vigor 64 LIFTING REQUESTS (INVORD) 65 CARE AND HANDLING OF SEEDLINGS 65.1 65.2 65.3 65.31 65.32 65.33 65.34 65.35 65.4 65.41 65.42 Lifting Grading, Bundling, and Packing General Requirements For Seedlings After Lifting Dormancy Temperature Humidity Root Exposure to Light Exposure to Toxic Substances. Freezer Storage Seedling Condition Necessary for Freezer Storage Freezer Storage Guidelines R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 3 of 29 65.43 65.44 65.45 65.46 Post-thaw Options Handling of Frozen Seedlings Transportation of Frozen Seedlings Freezer Storage References 66 SHIPPING SEEDLINGS FROM NURSERIES 67 RESPONSIBILITIES OF DISTRICT ON RECEIPT OF TREE SEEDLINGS 67.1 67.2 67.3 67.4 67.5 Stock Condition Temperature of Delivered Stock Assessment of Violation Other Than Temperatures Bareroot Stock Container Stock 68 LOCAL STORAGE AND SHIPMENT TO THE FIELD 68.1 68.11 68.2 68.21 68.22 68.3 68.4 68.5 Storage Tree Storage Standards Shipment to Planting Site Acclimatization Transport of Seedlings Storage of Seedlings at Planting Site Root Pruning in the Field Care of Seedlings By the Planters 69 SPECIAL CONSIDERATIONS FOR CARING FOR PLANTING STOCK 69.1 69.11 69.12 69.13 69.2 69.21 69.22 69.23 Suspension of Planting Soil Moisture Atmospheric Moisture Demand Frost and Snow Special Packaging of Seedlings Jelly Rolling Root Dipping Insulated Planting Bags APPENDIX A REFERENCE LIST B JELLY-ROLLING SEEDLINGS R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 4 of 29 60 - SEEDLINGS. The purpose of this chapter is to provide an overview of the seedling production and care process from tree seed inventory planning and nursery sowing request formulation to planting the seedling. Cross references to the Seed Handbook (FSH 2409.26f R-6) are provided for language pertaining to seed and cones. 60.1 - Critical Dates for Reforestation Program Coordination. The following table contains the schedule of paperwork events which must be completed to efficiently conduct the business of reforestation. These dates will not be repeated elsewhere in this handbook. Reforestation Document Due Dates: Item Seed Inventory Review (Excess/Unusable) Excess Seedling Report Seed Disposal List (Unserv.) Seed/Cone Procurement Plan Review Approval Sowing Schedules Fall 2/ Spring Seedling Inventory 4/ Lifting Request Fall Spring Excess Seedling List Lifting Confirmation Fall Spring Destination Nursery Origin S.O. R.O. Nursery RO 1/ 6/15 - 6/15 9/30 9/30 Nursery - 12/1 - RO 4/1 - 4/1 SO - - 7/10 Nursery RO 8/1 7/20 - 8/1 SO RO 3/ SO RO 3/ Nursery 8/10 1/10 - 8/1 11/20 9/1 8/1 8/10 11/20 12/31 9/1 SO SO SO - - 9/1 11/15 11/15 Nursery 12/1 RO distribute to potential customers by 12/15 - Nursery Nursery - 9/10 12/10 - R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 5 of 29 1/Review 2/Include container and transplants, all producers. 3/Approval 4/All producers, all age classes. 61 - SEED. Information pertaining to collection, extraction, identification, care, and shipping of tree seed and cones is contained in FSH 2409.26 R-6. 62 - ORDERING TREE SEEDLINGS. Tree seedlings, as well as any product Forests wish to have nurseries produce, for example, bitterbrush, willow, elderberry, are ordered through the use of the electronic database systems SOWREQ and INVORD. This system will be used for requesting sowing seedlings to all nurseries; federal and private. It is the responsibility of the Forest Supervisor to ensure the use of the most current update of the SOWREQ and INVORD databases. These database/reporting systems are available in the Data General electronic mail system, so no paper copies are needed until completed requests are printed out in the Regional Office. Detailed instructions on the use of these databases are generated, maintained, and stored at the J. Herbert Stone Nursery. Questions regarding the use of these systems should be directed to the System Operator at the J. Herbert Stone Nursery. Seedling size specifications necessary for ordering are found in subsection 63.31. 62.1 - Sowing Requests. The seedling production request originates at the Ranger District through the use of the SOWREQ database. The Forest Supervisor combines the Districts' plans into a Forest plan, also in SOWREQ. The consolidated datafile is electronically sent to the Regional Office, and each Nursery receives it's own individual datafile. Refer to Table in subsection 60.1 for due dates. Requests from Forests will be consolidated by the Regional Office to be used as a Nursery sowing schedule. The approved summarized Nursery Sowing request will be sent to each Nursery and Forest Supervisor. The distribution of the approved nursery sowing request will authorize the shipment of the tree seed to the appropriate nursery and the reimbursement voucher for seed cost. Seed cost will be paid when seed is withdrawn from storage and not included in seedling cost. No seed will be disbursed from storage without prior approval of the Forest Supervisor of the Forest of seed source. 62.11 - SOWREQ Requires the Following Information. 1. Species R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 6 of 29 2. Seed lots to be sown. 3. Number of seedlings. 4. Caliper of seedling. 5. Height of seedling. 6. Shoot-root ratio. 7. Special instruction (top pruning, and so forth). 8. Nursery to be grown at. 9. Forest Service Nursery or contract grower. 10. Seed bank location. 11. Seed bank identification code. 12. Sowing year (calendar year). 13. Production age (seedling age at time of lifting). 14. Production year (fiscal year to be lifted). 62.2 - Selection of Stock. Classifying the planting site environment is important, in the long term, for selecting species and seed source and, in the short term, for determining morphological and physiological seedling characteristics. Using the correct species and seed source will ensure that seedlings are adapted to infrequent climatic extremes or diseases which could affect plantation performance in the future but go unnoticed during establishment. Seedlings with the correct morphological and physiological characteristics are better adapted to meet initial threats to survival and optimal growth, such as animals, lodging of cured vegetation, or heavy brush competition. MORPHOLOGICAL TABLE 1/ SITE CONDITION SPECIFICATION Douglas-fir Height Caliper T/R cm mm Droughty 2/ 15-25 5-6 1.0-1.5 Brush 30-40 4-6 1.0-2.0 Deer-Elk 30-40 4-6 1.0-2.0 20-30 5-6 1.0-2.0 Steep2/ Other(NurStd > 15 >4 1.0-3.0 SPECIES Noble Fir Height Caliper cm mm 10-15 5-6 20-25 4-6 20-25 4-6 15-20 5-6 > 15 >4 T/R 1.0-1.5 1.0-2.0 1.0-2.0 1.0-2.0 1.0-3.0 Ponderosa Pine HT CAL T/R CM MM RATIO 15-30 5-6 1.0-1.5 20-35 4-6 1.0-2.0 20-35 4-6 1.0-2.0 15-30 5-6 1.0-2.0 >15 >4 1.0-3.0 R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 7 of 29 1/Exhibit derived from Mt Baker-Snoqualmie NF, White River RD Planting Stock Size Standards. 2/Low Nursery Density - 17-21 live seedlings/square feet. HEIGHT - Short top reduces transpirational surface. Tall top requires larger caliper. Tall top is a liability on a steep slope. CALIPER- 5-6 mm for large root system. Stout caliper usually assures matching root system. Up to 6 mm for tall tops. GREATER THAN 6 mm DIFFICULT FOR NURSERY MANAGER. Greater than 6 mm on steep slopes does not provide enough additional resistance to be economically feasible. T/R - Ratio lower than 1.0 is too low. Ratio 1.0-2.0 good for most problem area. Up to 3.0 good for normal sites. Ratio 1.0-2.0 good for dry sites. We should not be too particular with the Nursery Managers because the range of characteristics we are working with is quite narrow. 62.21 - Species Selection. Each species will be best adapted to a given range of environmental conditions. Proper species selection may require more than just surveying native tree species and their relative frequency in the previous stand. Some may be better adapted to the environments created by harvesting or other site disturbances. A generally accepted rule is that the seral or pioneer species will survive better and grow faster on clearcuts and burned areas than the climax species. Other site factors also are important in selecting species. Using certain species is risky because of their vulnerability to insects and diseases. Management objectives may influence preferred species to be grown for timber production on certain sites or for recreational purposes, but species conversions must be approached with caution. 62.22 - Type of Planting Stock. Size and type of planting stock is an important controllable factor. Assuming the stock is in good physiological condition, then stem caliper is more important than height. Stock with 4-6 mm caliper and root systems 25-30 cm (10"12") long will out-perform tall, spindly stock. In general, severe site on slopes with south and west exposures will require a minimum caliper of 4 mm unless artificial shade is provided at the stem groundline. Container grown and 1-0 stock should R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 8 of 29 not be planted on harsh sites without shading. Small caliper seedlings are also very suspectible to small animal damage. Container grown stock is usually more expensive than bareroot and offers no appreciable survival advantages under proper planting conditions on most sites. However, container stock gives the program flexibility and is recommended for: 1. Planting high elevation sites that are difficult to access in the spring due to snow plowing requirements. These sites can be planted early in the fall with container stock. Container stock may also be used to extend planting season. 2. Planting extremely rocky sites where it is difficult to open a hole properly for bareroot stock. 3. Planting areas where site preparation would be lost if the area had to wait for bareroot stock to be produced. Container stock has the advantage in that it can be ordered in January and shipped the next fall or the spring of the following year. Container stock is often used to make up shortages from bareroot nurseries or first year failures in the field. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 9 of 29 62.23 - Matching Stock and Site. A wide range of planting conditions exists on some Forests or Ranger Districts. Close attention to the details can improve survival and growth of planted trees. For these areas, prescribe for the most limiting condition and use the stock everywhere. Nursery stock can be tailored to specific planting sites by careful use of nursery cultural practices. Among the site conditions which can be ameliorated by manipulation of stock characteristics are physical planting difficulty, high transpiration demand, droughty soils, animal pressures, overtopping vegetation, and topography. In general, gentle north slopes have few problems amenable to morphological solutions. Steep south slopes have many problems which may be ameliorated by morphological solutions. South slopes have ravel, freeze-thaw, and heat. Animals also visit south slopes first because these slopes are usually first to emerge from snow and first to green up in the spring. 1. Soil. Planting difficulty (rocks) may call for containerized trees. Shallow soil may call for short bushy, fibrous root systems. 2. Drought. Short stubby trees are needed to reduce transpirational surfaces. Large caliper will also generally assure a good root system. 3. Animals. This depends on the animal. Pressure from clipping animals requires larger caliper. For browsing animals, prescribe a woody top with good lateral branches. For cattle grazing, possibly a bareroot transplant or plug-1 is best, particularly if trees cannot be protected. 4. Overtopping vegetation. A large tree is needed here. It must be tall enough to get above brush and have large caliper to resist rabbits. In the Coast Range root systems can be small because moisture should not be a problem. In the Cascades and on the east side root systems must also be large. 5. South slopes. Generally, large caliper is needed to protect against ravel, thick bark for heat resistance, and a bushy top to provide shade for the stem and the ground line. Moisture demand will be high so an adequate root system is essential. 63 - NURSERY. The intent of this section is to provide guidance to Forest personnel in understanding the nursery's role and standards in the reforestation process. 63.1 - Nursery Visits. Plans should be made to visit the nurseries where seedlings are being grown at least on an annual basis so the client and nursery personnel have a common understanding of specific needs and the capability of the nursery to meet those needs. September or October is a good time to make these visits. Annual visits will provide an opportunity to see the stock, which will aid clients in discussing cultural treatments with the Nursery Manager for their stock, make adjustments in future sowing or lifting requests, and establishment of all cull rules. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 10 of 29 This interaction between seedling users and producers is very important. Each must respect the other's professional judgement. 63.2 - Seedling Inventories. 63.21 - 1-0 Inventory. The nurseries will prepare a 1-0 inventory for Forests showing the quantity of seedlings by September 1 of each year. The 1-0 inventory will be reported as a gross (all seedlings present) figure. Forest will review 1-0 inventory. 63.22 - 2-0 Inventory. The nurseries will prepare a 2-0 and older inventory sending copies electronically to the Regional Office and the Forests by September 1 of each year. The inventory will include the height, caliper, shoot-root ratio measurements and quantity. 2-0 inventories are net plantable seedlings. 63.3 - Nursery Grading Standards Specifications. These nursery standards are to be used as guidelines. They are nursery goals and not cull rules. Cull rules must be agreed upon in consultation between silviculturists and Nursery Managers as referred to under 63.1, Nursery Visits. 63.31 - Caliper and Height. SPECIES Douglas-fir AGE CLASS 2-0 1-1 1-0 Douglas-fir (East Side) 2-0 1-0 True Fir 2-0 3-0 2-1 Ponderosa Pine 2-0 1-0 Lodgepole Pine 2-0 Engelmann Spruce and 2-0 Western Red Cedar 3-0 Western Larch 2-0 1-0 Other Species 2-0 3-0 2-1 Bedhouse 1/ Douglas-fir 1-0 Douglas-fir (East Side) 1-0 True Fir 1-0 MINIMUM CALIPER AT GROUND LEVEL 5/32" (4 mm) 5/32" (4 mm) 1/8" (3.5 mm) 5/32" (4 mm) 1/8" (3.5 mm) 5/32" (4 mm) 5/32" (4 mm) 5/32" (4 mm) 5/32" (4 mm) 1/8" (3.5 mm) 5/32" (4 mm) 5/32" (4 mm) 5/32" (4 mm) 5/32" (4 mm) 1/8" (3.5 mm) 1/8" (3.5 mm) 5/32" (4 mm) 5/32" (4 mm) MINIMUM SHOOT LENGTH TO TIP OF TERMINAL BUD 6" (15 cm) 6" (15 cm) 4" (10 cm) 4" (10 cm) 4" (10 cm) 4" (10 cm) 6" (15 cm) 6" (15 cm) 6" (15 cm) 3" (7.5 cm) 4" (10 cm) 4" (10 cm) 6" (15 cm) 6" (15 cm) 4" (10 cm) 6" (15 cm) 6" (15 cm) 4" (10 cm) 1/8" (3 mm) 1/8" (3 mm) 1/8" (3 mm) 6" (15 cm) 4" (10 cm) 4" (10 cm) R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 11 of 29 1/Wind River Nursery only. 63.32 - Root System. Root pruning will be accomplished at 12 inches, unless otherwise specified by the ordering unit. Point of reference for measuring root length commences at the cotyledon scar. Planting stock shoot-root systems should not exceed a 3:1 ratio. Planting stock root systems should have at least 1/3 to 1/2 of the smaller feeder roots intact. When the tap root is split or severed 6 inches (15 cm) or less from the ground line, the seedling is considered a cull. Any seedling exhibiting indications of root rot disease must be culled. 63.33 - Stem. When mechanical damage into the stem or root exceeds more than 33 percent of the stem and 3/4 inch (1.9 cm) in length, the seedling must be culled. All gradeable seedlings must have at least one-third of the stem capable of photosynthesis. Needle mottling, chlorotic needles, needle cast, disease, insects, spindliness, mechanical damage, or other defects lessening the vigor and ability of a seedling to survive and grow must be considered when establishing cull rules. Seedlings infected with Botrytis cinerea will not be culled unless requested by the receiving unit. 63.34 - Vigor. All grading of stock must be accomplished within an hour of the time the stock is pulled from the seedling bed unless stock is stored in the precooler at 90 percent relative humidity and 1o-2oC (33o-36oF) temperature. The stock will be given maximum attention to prevent deterioration of vigor by various desiccating effects from time of lifting through planting. Pressure chambers will be employed to determine plant moisture stress during lifting and packing operations, and to trigger any subsequent mitigating actions to reduce the stress. 64 - LIFTING REQUESTS (INVORD). Utilizing the INVORD database, Ranger Districts will prepare lifting requests and send them to the Forest Supervisor for consolidation. The consolidated lifting requests will be sent directly to the nursery producing the stock. The Forest is automatically allocated the trees that were ordered sown providing they are on the inventory. Forests are not obligated to take overages in one lot to make up for shortage in another lot. However, if the Forest requests the overages, the Forest becomes financially obligated for these seedlings. The Forests will send the lifting requests directly to comply with the dates in subsection 60.1. Lifting requests will include: 1. Species codes. 2. Root lengths. 3. Number of seedlings. 4. Tentative delivery date. 5. Packaging type. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 12 of 29 6. Packing material needed. 7. Other special treatments. 8. Accounting data for paying for the seedlings. The Nursery will notify the Forest of lifting confirmation, agreement with the lifting request, to comply with the dates listed in 60.1. 65 - CARE AND HANDLING OF SEEDLINGS. Of the factors that influence the survival of planted seedlings, the greatest control is over care and handling. The manner in which seedlings are handled will influence final results to a significant degree. All those connected with the planting program share the responsibility for exercising extreme care in the lifting, pulling, sorting, packing, transporting, storing, handling, and planting of seedlings. 65.1 - Lifting. The intent of this section is to help Forest personnel understand the importance of proper timing and protection during harvesting of seedlings. Lifting (loosening of seedlings in the soil) should be done during the period when Root-Growth Capacity (RGC) peaks. Root-growth capacity of Douglas-fir seedlings rises steadily from September to a peak during the period from January to March and is followed by a rapid decline to the September level. Most temperate zone species follow this general pattern. However, much variation may be present among species or for different seed sources with species. Seedlings lifted when completely dormant have higher resistance to damage or stress imposed during handling. Lifting window studies are necessary to best determine lifting dates for specific seed sources. Once identified, lifting windows can be assumed to be relatively constant for the specific nursery tested. Annual climatic variations may influence the window, but generally not to any great degree. A word of caution for lifting window study participants: Lifting window study outplantings for spring lift dates must include storage periods comparable to those likely to be required for operational outplantings. Seedlings should be lifted within the established lifting windows for the particular species and nursery. Seedling dormancy and RGC are physiological factors which affect lifting windows. Though precise lifting windows are not known for all species produced at all nurseries, Nursery Managers become familiar with the requirements of specific seed sources. Field foresters should respect the Nursery Managers' professional judgement on matters relating to lifting, if specific lifting windows are not known. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 13 of 29 The best time to lift seedlings, within the window, is when Plant Moisture Stress (PMS) is low. This occurs early in the morning, or when the weather is cool and humid. These conditions also favor lifting because they minimize the potential harmful rise in PMS during field handling. To reduce mechanical damage, lifting should be restricted to occasions when the ground is not frozen or the soil is not saturated. The degree of damage resulting from lifting can be assessed by the number of stripped or broken roots. Desiccation of seedlings during lifting can be reduced by protecting lifted seedlings from direct exposure to the sun, reducing the time required to transfer lifted seedlings to field containers, misting seedlings in the field immediately after lifting, and limiting lifting operations to times the evaporatranspiration rates are low. Tree seedling roots, especially the fine roots, can become desiccated rapidly when exposed to air. Lifted seedlings should, therefore, be placed in a field container and covered as soon as possible to prevent moisture loss. Plant moisture stress of seedlings should generally not exceed -20 bars immediately prior to lifting and should trend down shortly after pulling. Again, the professional judgement of the Nursery Manager must be recognized, and mitigation efforts will allow certain instances of lifting to continue in those infrequent instances when the plant moisture stress does slightly exceed -20 bars. On days of high atmospheric moisture demand, seedling pullers should follow closely behind the lifting machine. A distinction should be drawn between desiccation of root surfaces and PMS. For instance, short exposure of tender root surfaces to dry air may cause root damage without a corresponding increase in PMS. Since root surfaces have no way of controlling moisture loss as needles have, these cells can be killed quickly without a corresponding increase in PMS. Conversely, PMS can increase dramatically in the xylary plumbing of the plant without killing root or other cells when these cells are not subject to evaporation. Therefore, root damage from drying may occur at low PMS and not at high PMS. Solar heating of tree seedlings in field containers can be rapid. Field containers should, therefore, be hauled to the packing shed as soon as seedlings have been lifted, and be placed in refrigerated storage as soon as they arrive from the field. If there is a delay in storage it should not exceed 1 hour. 65.2 - Grading, Bundling, and Packing. Once the seedling is lifted, its condition can change rapidly as a result of desiccation, molding, metabolic activity, or developmental processes. Success in minimizing the deterioration of stored seedlings depends primarily on controlling plant water content and temperature. Prepacking cooling of seedlings can greatly minimize the deterioration as temperature is a major contributing factor. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 14 of 29 Grading, bundling, and packing of seedlings should be done in a cool, humid environment to protect the root system from desiccation. Space heaters, directed toward the grading table, should not be used in the packing shed. During the grading process, seedlings should be individually separated (singulated). This allows for the culling of seedlings which may be damaged during the lifting operation, and for the separation of the entangled root masses. The time a seedling is on the grading table (belt) should be kept to a minimum consistent with maintaining PMS at the 5 bar level. Grading standards used for each seedling lot should be based on the local site need. Such standards must be established by consultation between Nursery Managers and field foresters, both at the Nursery and on the planting sites as time and travel schedules permit. Seedlings are often tied into bundles of a standard number, such as 50, which aids in determining the number of seedlings per storage container and lot. CAUTION: Bundling of seedlings may cause some damage to the seedlings if the bundles are tied too tightly or when the bundling material is removed incorrectly. Pruning of root systems should be done in a manner which minimizes the stripping of roots, and provides a clean cut surface. 65.3 - General Requirements For Seedlings After Lifting. From the time seedlings are lifted until they are outplanted, safeguards must be taken to control dormancy temperature, humidity, root exposure to light, and exposure to toxic substances. 65.31 - Dormancy. Trees must be kept in a dormant state to prevent stress and loss of vigor. Trees that have broken dormancy deteriorate rapidly even under the best storage conditions. Survival and growth of outplanted trees decreases rapidly as storage time increases for trees that have prematurely broken dormancy. Trees break dormancy due to a change in their environment, such as heat. Root growth and other physiological processes begin before bud burst is evident. Storage temperatures must be low enough to prevent this activity. Dormancy release is often shown by the softening and enlargement of buds, and the upturning and/or elongation of terminal or lateral candles on seedlings stored horizontally. Root growth is not an indicator of dormancy release as root tips do not become dormant. They simply stop growing when temperatures drop below approximately 35oF. (This is species dependant.) An occasional white root tip on stored seedlings is not cause for alarm. 65.32 - Temperature. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 15 of 29 1. Heat. Respiration and micro-organism activities increase within tree packages when temperature rises above 2oC (36oF). This physiological activity raises temperatures even higher. Stored food (carbohydrate) reserves are depleted at a fast rate. 2. Cold. Mechanical injury, such as broken twigs and roots, may be caused by handling frozen trees. Frozen trees should be thawed slowly at temperatures below 10oC (50oF) and in an area protected from wind and direct sun. Thawing time will vary depending on many factors, particularly packaging. A generally acceptable range is 1-15 days. 3. Temperature Fluctuations. Significant temperature changes adversely affect seedlings in transit and storage. Transpired water vapor condenses on inner bag surfaces and collects on bag bottoms drying trees and forming a mold hazard. 65.33 - Humidity. Trees in storage have a limited water supply. Much of the tree's ability to absorb moisture has been lost when roots were left in frozen soil and when they were pruned at the nursery during lifting and prior to packaging. High storage humidities are essential to prevent water loss from needles and roots. If plant moisture stress measures six (6) or more, roots should be watered. 65.34 - Root Exposure to Light. The full effect of exposing seedling roots to direct or diffused light is not known, but it is contrary to their natural environment. Tree roots are normally shielded from light by soil. Light intensities and solar heating are more serious at high elevations where atmospheric protection is less. 65.35 - Exposure to Toxic Substances. Substances, such as pesticides, petroleum products, and chemicals are lethal to seedlings. Gas and oil for planting augers and saws must not be transported in contact with seedlings. Also, seedlings should not be stored with fruit as the production of ethylene gas also is detrimental to seedling performance. 65.4 - Freezer Storage. Freezer storage (storage below 0oC) is an alternative to storing seedlings at temperatures just above freezing. There are a number of advantages to freezer storage including: 1. Storage time can be extended. 2. Storage molds are better controlled. 3. Respiration, loss of dry weight and loss of carbohydrate reserves are reduced. 4. Dormancy release is delayed. 5. Winter losses in nursery and field are reduced. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 16 of 29 6. Earlier and more accurate inventories can be made. 7. Nursery workload is better balanced. 8. Shipping to early opening planting sites can occur. Both containerized and bareroot seedlings may be stored frozen. Freezer storage is appropriate for fall-lifted seedlings, winter-lifted seedlings, and early spring-lifted seedlings, especially when the anticipated storage period is greater than 2 months. 65.41 - Seedling Condition Necessary for Freezer Storage. Prior to placement in freezer storage, seedlings must be sufficiently dormant to withstand freezer storage temperatures. Seedlings must be entering dormancy rather than exiting dormancy. If seedlings are exiting dormancy, they will be less cold hardy and tissue can be damaged by below-freezing temperatures. With increasing dormancy, the seedling can withstand increasing amounts of cold without freezing the intracellular contents. Chilling requirements will be met in freezer storage; seedlings will be ready to grow when warmed. Refrigerated storage must be used to keep product temperatures (seedlings) below 35oF during and after thawing if seedlings are not planted immediately. After thawing it is possible to maintain seedlings in refrigerated storage for a considerable length of time without any expected deterioration. Seedlings should be hardy to -5oC prior to freezer storage (Hee, 1987). Hardiness and appropriate lift dates will vary from year to year, depending on frost hardiness and chilling hours received. Frost hardiness tests, as well as monitoring accumulated chilling hours may be used to determine when seedlings can be lifted and freezer stored. 65.42 - Freezer Storage Guidelines. 1. Freezer facilities. (a) Temperature capability: (1) Range: 26o-50oF (for freezer and cooler capability). (2) Ability to regulate within 2oF. (3) Air temperature off coils not more than 3o-5oF below minimum temperature. (4) Freezer set point: 28o-30oF (5) Alarm points: 27oF, 31oF (b) Humidity: Humidification is not necessary with freezer storage. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 17 of 29 (c) Types of systems: (1) Direct Expansion (DX): With DX system, air off coils is below thermostat setting, allowing for temperature variation throughout the box. Inside bag temperatures will be more stable than ambient box temperature, but monitoring inside bag temperatures must be done to ensure that "warm spots" and "cold spots" fall within desired temperature range. (2) Glycol: With glycol system, air off coils will be the same temperature as the thermostat temperature so that there is minimum variation in temperatures within the box. 2. Freezing Procedure. a. Temperature: CAUTION: Seedling temperature refers to the inside bag temperature of the seedlings. It does not refer to the ambient temperature of the cooler. Bring seedling temperature down to 32o-34oF as quickly as possible after packing, or when frost hardiness tests indicate that seedlings are hardy to 28oF or below. Seedlings may be held at 32o-34oF for 4 weeks to enhance cold hardiness. (Pre-cooling the freezer to 28oF is an effective means of initially cooling down seedlings to 32o-34oF.) Lower seedling temperature to 28o-30oF slowly by lowering ambient 1oF every 4 days. Hold seedlings at 28oF until thawing/shipping. Many seedlings can be frozen at temperatures much lower than 28 oF, but 28oF is specified as minimum to prevent damage to seedlings or species which are not fully dormant or are not as hardy. b. Humidity: commences. Humidification should be turned off when freezing c. Duration: Seedlings of some species (lodgepole pine, noble fir, western hemlock, Douglas-fir, ponderosa pine) have been kept in freezer storage for up to 6 months with no significant effects on survival or growth. Most species can be effectively frozen for 6 months. 3. Packaging. Seedlings in frozen storage must be provided with an adequate moisture barrier to prevent desiccation. Either polyethylene bags placed in a packing box or a 3-ply polyethylene coating inner ply bag will provide adequate moisture barriers. In either case, the bags must be sealed. If bags or boxes are punctured during storage or transport, the opening should be mended and resealed. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 18 of 29 4. Seedling moisture. Seedlings should be moist, but not wet, prior to frozen storage. Dipping roots in water prior to freezing is not recommended. 5. Packing materials. Use of packing materials, such as peat or vermiculite around the roots is optional. Consistent benefit from using these materials has not been demonstrated. Additional thawing time is required if additional materials are placed around the roots. 6. Monitoring. Temperatures in the freezer (ambient and within bag, if possible) should be monitored daily. A hygrothermograph or other monitoring device should be used to continuously monitor and provide a record of temperatures. Freezers should be equipped with an alarm which is activated when temperatures rise above or fall below the set temperature. 7. Thawing Procedure. a. Temperature: (1) Ambient: >35oF (QUICK THAW): Seedlings thawed at temperatures >35oF will thaw relatively quickly. Bareroot seedlings will thaw more quickly than extracted containerized seedlings (3-5 days at 40o-50oF for former; 2-3 weeks at 40o-50oF for later). Thawing should be accomplished under controlled and/or monitored conditions. It is preferred that thawing be done in buildings where temperature fluctuations are not sufficient to cause re-freezing at night and rethawing during the day. Seedlings should not be thawed in the open where sunlight can cause over-heating. (2) Cooler: 33o-35oF (SLOW THAW): Seedlings thawed in conventional cooler, 33o-35oF, will thaw much more slowly (about 3 weeks for bareroot seedlings). Thawing should be done gradually by raising ambient setting 1oF every four days until the AMBIENT cooler temperature reaches 33o-35oF. As SEEDLING temperatures reach 33o35oF, reset COOLER AMBIENT temperature to 32.5oF and hold there until shipment. Thawing will be more uniform at lower temperatures. b. Air circulation: Uniform, rapid thawing requires good air circulation around containers. Placing boxes or bags on pallets and spreading out boxes or bags will improve air circulation around them. If space is limited and containers can not be spread out, rotation of grouped containers where inside containers are moved to outside and vice versa will facilitate uniform thawing. c. Species: Some species, such as pine, thaw more rapidly than others. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 19 of 29 65.43 - Post-thaw Options. Planting: Unless seedlings are returned or maintained at 33o-35oF, planting must occur immediately after thawing. Further Storage: If seedlings are not planted immediately after thawing, they must be kept in cooler storage until they are planted. Temperature should be at the conventional storage temp of 33o-35oF. Thawed seedlings may be successfully kept in cooler storage for a period of 4 to 8 weeks (Emerson, 1986; Hee, 1987; Myers, 1990). The length of time will depend on the species and the rapidity with which various lots begin to break dormancy in storage. Seedlings should be planted as soon as possible after thawing so that the physiological advantage gained by early lifting and freezer storage is not lost (Eklund, p. 19). 65.44 - Handling of Frozen Seedlings. Frozen tissue is much more brittle than nonfrozen tissue. Frozen stock should be handled carefully and minimally to prevent tissue damage. Handling damage can be minimized by packaging seedlings in bags which are then placed in cardboard boxes. Use of pallets and racks in storage can be used if pallets/racks are not moved until seedlings are thawed (that is, thawing is done in the freezer by converting to cooler). However, cardboard boxes are not necessary for a successful frozen seedling storage program. 65.45 - Transportation of Frozen Seedlings. Seedlings can either be thawed prior to transporting to field or shipped frozen with thawing at field location. The potential for damaging frozen stock will be minimized if seedlings are thawed at the Nursery before they are shipped to the District or field. Nursery thawing conditions are consistent and well-monitored. The recommended treatment is for Nursery thawing of frozen Stock. Seedlings may be transported frozen, stored frozen at the District site, and then thawed at the District or field site. If seedlings are PLANNED to be shipped frozen, they should be packaged in bags within boxes to minimize handling and damage. 65.46 - Freezer Storage References. Ekland, R. 1988. Frozen storage tree seedling study on the Winthrop and Twisp Ranger Districts, Okanogan National Forest- A comparison of survival and growth of fall lifted and frozen seedlings with conventional spring lifted seedlings. USDA Forest Service, Silviculture Certification Paper, Pacific Northwest Region. Emerson, T. 1986. Unpublished data James W. Toumey Nursery files. Watersmeet, MI. Hee, S.M. 1987. Freezer storage practices at Weyerhaeuser nurseries. Tree Planters Notes 38(3):7-10. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 20 of 29 McDonald, S.E., R.J. Boyd and D.E. Sears. 1983. Lifting, storage, planting practices influence growth of conifer seedlings in the Northern Rockies, USDA, Forest Service, Intermountain Forest and Range Experiment Station, Ogden, UT, Research Paper INT-300, 12 p. Morby, F.E. and R.A. Ryker. 1979. Fall-lifted conifers successfully spring planted in southwest Idaho. Tree Planters Notes 30(3):27-29. Myers, J. 1979. Fall lifting and frozen stock storage at the Coeur d'Alene Nursery. Poster presented at 1987 Region 6 Silviculture Business Meeting, Portland, OR. Myers, J. 1990. Unpublished data. Couer d'Alene Nursery files. Coeur d'Alene, ID. Mullin, R.E. 1980. Water dipping and frozen over-winter storage of red and white pine. Tree Planters Notes 31(3):25-28. Mullin, R.E. and J.D. Parker. 1976. Provisional guidelines for fall lifting for frozen overwinter storage of nursery stock. The Forestry Chronicle 52(1):22-25. Ritchie, G.A. 1987. Some effects of cold storage on seedling physiology. Tree Planters Notes 38(2):11-15. 66 - SHIPPING SEEDLINGS FROM NURSERIES. The shipping packaging must protect seedlings from desiccation by maintaining high relative humidity, and from physical damage by shielding them from crushing pressure and hard blows. Seedlings are quite vulnerable during shipping. Shipping vehicles must contain seedling racks and be able to maintain appropriate short term seedling storage environment. The standards are the same as those which must be maintained in nursery storage. Humidity must be in the 90-95 percent range to ensure that the seedlings do not become desiccated. Temperature must be in the 1o-2oC (34o-36oF) range to ensure a low level of physiological activity and maintenance of dormancy. 67 - RESPONSIBILITIES OF DISTRICT ON RECEIPT OF TREE SEEDLINGS. Regional standards for stock quality are published in section 63.3. Districts should report stock quality received from Forest Service Nurseries or Contract Nurseries. When stock quality problems occur with Contract Nurseries, the Contracting Officers Representative (COR) should be notified. Call the Forest Service Nursery immediately if substandard conditions are detected. 67.1 - Stock Condition. If the stock is of poor quality, for example, excessive temperatures, moldy, insufficient root, or root lengths beyond specified allowances, a report shall be made immediately to the Nursery with a copy to the Regional Reforestation Specialist. Notification of poor quality stock is normally channeled R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 21 of 29 through the Forest stock coordinator. However, if the stock coordinator is unavailable, Districts should contact the Forest Silviculturist before contacting the Nursery and Reforestation Specialist directly. The following indications of poor stock quality (as detailed in the next section) must be reported within 7 days after receipt of seedlings: 1. Product temperature violations. 2. All dormancy violations. 3. Excessive mold in boxes. 4. Dry trees or roots. 5. Damaged packages. 6. Dead roots. 7. Discolored tops. If the trees are received frozen, items 4, 6, and 7 can be reported with the violations listed below. Some tree quality criteria cannot be assessed until the trees are being processed for planting. These criteria, explained in detail in the next section, can be reported when discovered at the time of processing. Items that can be reported when the trees are processed are: 1. Root lengths. 2. Height and caliper standards. 3. Tree counts. 4. Inadequate root mass in container plugs. 67.2 - Temperature of Delivered Stock. The temperature of the delivered stock is the first concern of the District. The shipper must maintain an air temperature of 0o-4oC (32o-39oF) in the shipping compartment of bareroot stock. The product temperature of bareroot stock (inside box) should not exceed 2oC (36oF) at any time during shipment. Above this temperature the heat of respiration begins to increase at an exponential rate, and it may be difficult to stop the process in snow caches or ice houses. If the temperature of the stock is between 2oC (36oF) and 4oC (39oF) the District should contact the Nursery and should sample the seedlings to determine the condition of shipment. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 22 of 29 Sample the loads using soil type or digital electronic probe thermometers. Sample as many containers as feasible up to 2 percent with an absolute minimum of three containers. Insert thermometers into center containers (fully surrounded) and leave for 2-3 minutes or until temperature equilibrates with inside box temperature. Be sure the thermometer has been calibrated for accuracy by checking it against a good mercury thermometer or placing in a glass of ice water, 0oC (32oF). Be sure to include samples from the top of the load. If you find trees with inside box temperatures of over 2oC (36oF) notify the Nursery's COR immediately; then: 1. Determine accurately how many boxes of trees are involved. All boxes exceeding minimum standards may be rejected. If a 10 percent of the load has been sampled and it has been determined that more than 70 percent of the sample exceeds 4oC (39oF), the whole load may be rejected. The District is not responsible for any costs associated with trees in the rejected boxes. 2. Warm trees may be saved by rapid temperature drawdown. Send the trees back to the nursery. If cooled promptly, they will suffer no appreciable damage and can be reshipped and planted. The District is responsible for only the original tree costs. No additional charges are assessed. If spoiled trees are received, return them to the Nursery by the truck they came on. Coordinate this with Nursery COR. Warm trees should not be put in snow caches or ice houses as they may cause problems to trees already in storage. For container stock the storage compartment shall be held between 2o-24oC (36o-75oF). Violations of these conditions, or any damage to stock, should be reported immediately to the Nursery. 67.3 - Assessment of Violation Other Than Temperatures. Nursery stock, in general, is in good condition when delivered to the Districts. However, there is always a risk of receiving poor stock and, therefore, stock should be checked for quality when received. Before checking for stock quality carefully read the Regional guide for Planting Stock Standards found in section 53.3. 67.4 - Bareroot Stock. 1. Root Length. Length of primary or tip roots should be 12 inches, or some other requested root length. 2. Live roots. Check for live versus dead roots by simply stripping the outer layers of cork and bark from the roots with a pocket knife or finger nail to expose the steele. This tissue is white in healthy roots and brown to yellow tan in dead R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 23 of 29 roots. The brownish color is due to oxidation similar to that of a cut apple which has been left exposed. Tree boxes can be checked by taking a tree from the top, center, and bottom of the box. Do not be alarmed to find the roots have died back half an inch or so from the cut ends. This is normal. Also, in some species (especially Douglas-fir) a portion of the root system may die with no apparent adverse effect to the tree. However, if more than 10 percent of the roots are dead more than 15 percent of their length on more than 5 percent of the trees, this should be reported. 3. Root Activity. Check roots for the presence of white growing tips. Usually, few will be present because soils are relatively cold at lifting time (late winter or early spring) and tender growing tips may be left behind in the beds. Storage temperatures are too low for root growth on all but a few species (larch, lodgepole and true firs, for instance). However, roots do not experience dormancy as top terminals do, so some activity may occur in storage. Root activity in storage is not as frightening as top activity is. Tops should be less than 1/2 centimeter in length and not numerous, although white buttons or elongations on root ends may be very numerous without causing alarm. 4. Top Caliper and Height. Nursery grading standards for both top height and caliper are listed in section 63.3. At least 95 percent of the stock packed should meet these standards or the requested specifications on Lifting Request. 5. Color. The foliage of healthy stock is green. A purple cast is acceptable in lodgepole pine. Western larch is deciduous and whatever needles are retained are last year's and are dead or soon will be. In other species red or brown colors or spotting is indicative of unhealthy stock. Needles may be shaded toward yellow green without causing alarm. All discoloration except the purple tinge should be reported if more than 15 percent of the trees appear red or brown or with red-brown mottling. 6. Lammas Growth. Lammas growth (abnormal late season growth by terminal or lateral buds) has normally been a problem only in lodgepole pine, and to a lesser extent, in ponderosa pine. This late season growth may cause two problems with nursery stock. The late formed growth may be succulent and not hardened off properly. Perhaps even worse, trees in this condition may not store well at temperatures above 1o-2oC (34o-36oF). Field experience has shown that lodgepole pine with lammas growth will break dormancy and/or spoil under storage conditions suitable for other species. Three types of lammas growth are of primary concern here. a. Lammas shoots. Shoots which develop by bursting and elongation of the current year terminal bud. This will result in 2-0 stock having the appearance of 3-0 with the last growth whorl in varying degrees of hardening off. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 24 of 29 b. In long buds the current year terminal elongates with no corresponding bud burst. Elongation may be from a few millimeters to 4 or 5 inches. The result may be a long, slender, succulent terminal with a soft unhardened terminal. c. Proleptic shoots. buds. Shoots that emerge from current year's lateral While the classes are clearly defined, lammas will vary in gradation and some trees will exhibit growth that is a mixture of the classes. Lots with green succulent growth and soft buds in more than 5 percent of the trees should be reported on the tree quality assessment form. 7. Dormancy. Dormancy release is revealed usually by candle extension and softening in pines, and by bud enlargement and softening in most other commonly planted species. Dormant buds usually appear dark while active buds will be lighter because bud scale edges hidden in firm dormant buds will become exposed when swelling begins. Species which candle give unmistakable evidence of dormancy release. As candles begin to grow on seedlings stored in a horizontal position, new growth will turn upward at a 90o angle in response to geotropism. If new green needles appear, dormancy is unquestionably broken. However, if buds are visibly active, physiological awakening has progressed to the point where storage life of seedlings is drastically reduced. Dormancy release is an indication of serious tree quality problems and should be reported immediately. It means either that trees were lifted after the lifting window closed or that storage or shipping temperature became too high for too long a period. If trees cannot be planted immediately when terminal activity becomes apparent, they probably should be discarded. 8. Packing Material. The packing material and roots should feel cool, moist, and pliable to the touch. Roots that feel stiff and dry may be damaged. If dry roots are suspected, cambium condition should be checked. Plant moisture stress should also be checked if a pressure bomb is available. A PMS of 5 bars (atmospheres) or less is preferable and trees with stresses over 10 bars should be reported immediately. Trees with stresses up to 10 bars should recover within hours after dipping and burlap wrapping to stresses of below 5 bars. Trees stresses over 15 bars have a high risk of suffering permanent physiological damage. Trees that feel dry and show any evidence of damage due to drying should be reported as not meeting standards. 9. Mold or Fungus Mycelium. The presence of visible mycelium (white or black threads on strands of fungal tissue) may be cause for some concern. However, most molds are either saprophytic (living on dead substances) or mycorrhizal on the roots. Mats of mycelium on the foliage are of major concern. Fungi associated with strong odors, brown cambial tissues in roots or stem, or spotting of needles are of R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 25 of 29 major concern. Fine strands or tufts in the roots without the other symptoms are not usually harmful. 10. Mud or Dirt in Boxes. Trees packed in boxes should be relatively clean. Excess mud and dirt will promote fungal problems and foliage discoloration. 11. Free Moisture. Mold growth will be favored by free moisture in the storage containers. Presence of free moisture on the seedlings or in the bottoms of containers should be reported on the seedling quality assessment form. 12. Damaged Packages. Packages should not be torn or broken to the point where seedlings are exposed to outside air. 67.5 - Container Stock. 1. Adequate Root Mass. The root mass should be developed to the point the plug can be extracted from the container and still retain its original form. Excessive root development and resultant pot binding may be damaging to containerized seedlings. To check this, shake the plug until the media pulls away from the roots. Most of the roots should be pointed downward with the lateral horizontal roots smaller and not circling the plug. If the horizontal roots are thick and flattened and the plug stays in a thick net the shape of the original plug, the tree is suffering from pot binding. 2. Root Media Moist. Roots and plug should be moist when seedlings arrive. Moisture stress should be below 10 bars. 3. Live Roots. Roots can be checked for live tissue using the same technique as described previously for bareroot stock. 5. Caliper and Height. The bareroot direction for caliper and height are appropriate for container stock as well. 5. Sturdy, Standing Erect. Individual trees must be capable of standing erect individually. 6. Dormancy. For fall delivery, terminal buds should be evident. growth is permissible. Root For spring delivery, ideally, stock should be dormant with tight buds and little or no new root growth. The main disadvantage with nondormant container stock is that the new top growth is easily broken off. However, since root systems are essentially intact, will be minimally disturbed, and do not have to be regenerated, the container seedling survival is not affected as is bareroot stock. 7. Color. The color standards described for bareroot stock are applicable to container also. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 26 of 29 8. Mold Absent. Any signs of strands or threads of mycelium on the tree foliage or buds should be noted. Gray mold (Botrytis sp.) is of major concern. Check carefully for myceliums on the foliage. 68 - LOCAL STORAGE AND SHIPMENT TO THE FIELD. The local storage and shipment of seedlings to the field are critical in assuring reforestation success. 68.1 - Storage. Temperature should be held between 1o and 2oC (34o and 36oF) and relative humidity greater than 90 percent within seedling packages so that seedlings do not break dormancy or become desiccated. The critical area for seedling environment is within the storage packages, not in the ambient spaces of the tree coolers. Coolers with ambient temperatures of -1o-0oC (30o-32oF) can be expected to maintain seedling packages at 1o-2oC (34o-36oF). Even though cooler space may be -1oC (30oF), within packages temperatures as high as 4oC (39oF) have been measured when inadequate racking systems or closely stacked boxes have prevented air circulation. Root-mass temperatures 8oC (46oF) above ambient temperature have been reported under conditions of poor air circulation. Stored seedlings should be monitored to assure the PMS is maintained below 5 bars. Stresses higher than 5 bars indicate a problem requiring immediate correction. Humidities of 90 percent in packages should be adequate to maintain storage PMS below 5 bars. 68.11 - Tree Storage Standards. When storing bareroot stock on the District, the following standards must be met: 1. The product temperature (inside package temperature) must be kept below 2oC (36oF) at all times. This will require facilities that allow for ambient temperature settings of -2o-1oC (28o-34oF). Ideal product temperature is 0-1oC (32o-34oF) and it is better to drop to -2oC (28oF) than to go above 2oC (36oF). 2. Relative humidity in the storage compartment must be kept at 90 percent. Humidity less than this can dry seedlings out when stored over a period of several weeks. 3. Tree packages must be racked and spaced to allow for air flow between the packages. 68.2 - Shipment to Planting Site. Keep seedlings cool and moist at all times. Delicate root surfaces may be damaged in seconds by exposure to wind and low humidities. Warm temperatures will cause seedlings to use up their food reserves rapidly and induce dormancy release. Never allow seedling packages to be shipped in direct sunlight. Inside package temperature must never rise over 4oC (39oF). 68.21 - Acclimatization. This is the process of slowly bringing seedlings from a dormant state to an active state. This process is thought to allow time for seedlings to adjust to the more harsh field conditions without being stressed. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 27 of 29 Seedlings that are planted while in a dormant state are immediately exposed to a hostile environment. Needles warm up from solar heating or dry out from wind movement. They begin to transpire moisture before roots are ready to replace it. Shoot desiccation may occur. While in storage, seedlings have been slowly depleting food reserves in the tops and roots. This food reserve is further reduced after planting, unless seedling shoots are fully photosynthetically active. There is general disagreement among scientists on the mechanisms or the need for acclimatization of seedlings. It has not been shown to be be beneficial. However, neither has it been shown to be detrimental. Current acclimatization methods are associated with Jelly Rolling (section 69.21). Seedlings are left up to 24 hours in shelters (usually tents) at planting sites to permit them to gradually come up to the ambient temperature of the site. This process is not recommended nor is it discouraged. If it is used, duration should not be longer than 24 hours, and seedlings must not be allowed to freeze as they are coming out of dormancy, and the probability of damage would be high. ACCLIMATIZATION OF STOCK IS NOT REQUIRED BUT IS OFFERED ONLY AS A METHOD OF REDUCING PLANTING SHOCK TO SEEDLINGS. 68.22 - Transport of Seedlings. Seedlings must be protected constantly from extremes of temperature and moisture stress. Closed canopied vehicles are the preferred method of transporting seedlings to the field if kept at 4 oC (39oF). If open-bed vehicles are used, seedlings SHALL BE covered with space blankets or reflective mylar tarps. Canvas tarps are WORSE than nothing. The cover should allow some air circulation to prevent heat buildup or self-heating by seedlings. CAUTION: The beds of vehicles heat up thus the seedlings should be insulated from the bed to prevent heating. 68.3 - Storage of Seedlings at Planting Site. At the planting site, seedlings should be kept in a cool, shaded, and well-ventilated location until they are used. Trees, logs, and canvas shelters other than tarps can be used to provide shade. Seedlings should be protected from freezing when left out in cold weather. Bags or boxes of seedlings should not be stacked more than two or three high to prevent both crushing and heat buildup in the center of the piles. To avoid damaging the seedlings, planters must not be allowed to throw, handle carelessly, sit, or walk on bags or boxes of seedlings. Normally, seedlings that arrive first should be planted first. However, seedlings in torn packages should be given priority if excessive dryness is indicated. Tears in packages should be repaired when they occur! 68.4 - Root Pruning in the Field. As a general principle, root pruning on the planting site is an emergency measure, to be avoided if at all possible. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 28 of 29 ROOTS MUST NOT BE TORN OR PULLED OFF! Root pruning by the Districts should be minimized as much as possible. Pruning just prior to planting is detrimental because root ends do not have time to callus over and generate new growing centers prior to planting. Some Districts avoid pruning completely. Long laterals are just stuffed in the planting hole. As long as only one or two laterals are involved and are not wrapped around the root systems, this may be a better practice than pruning. If this option is chosen, it may require a planting contract amendment. If selective pruning is chosen, it should be kept at an absolute minimum. Do not cut off one-half to an inch of roots. Only seedlings with excessively long roots should be pruned. Pruning must be done at the time of wrapping or placement in planting bag, NEVER BY THE PLANTER. Scissors or paper cutters are recommended for root trimming while the seedlings are laid flat. 68.5 - Care of Seedlings by the Planters. Planters handling seedlings must take the following precautions: 1. Tree seedlings must be protected at all times from drying, heating, smothering, freezing, crushing, drowning, abrasion, rapid temperature fluctuations, or contact with injurious substances. 2. Seedlings stored in shipping containers must not be exposed to direct sunlight. Punctured or torn containers must be promptly resealed. Containers of seedlings shall be separated to provide free air movement. 3. Seedlings shall not be removed from shipping containers until needed for preparation for planting. 4. Tree seedlings are to be planted or prepared as received without further root or top pruning or culling. If pruning or culling appears necessary, or if mold, dry roots, evidence of injury or dying is seen, the condition shall immediately be reported to the individual in charge of the planting project. 5. Seedlings that are frozen shall not be handled until completely thawed. 6. Seedlings in planting bags shall have only their tops exposed. Burlap wrapped seedlings shall have the wrapping loosened, just prior to planting, to allow easy extraction of seedlings from the roll. 7. NO SEEDLING SHALL BE REMOVED FROM PLANTING BAGS UNTIL IMMEDIATELY BEFORE PLANTING IN A PREPARED HOLE. 8. Seedlings shall be gently removed, one at a time, to prevent stripping or other injury, and quickly and gently inserted into the planting hole. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 29 of 29 9. Seedlings carried in planting bags or trays shall not exceed the amount that can be carried and removed without injury, or which can be planted before critical heating or drying occur. Trees placed in bags will be planted and not returned to storage. 10. Separate seedlings to be planted by shaking the roots loose in the shipping container, taking care not to strip them. 11. Use planting bags that are not holed or torn. 69 - SPECIAL CONSIDERATIONS FOR CARING FOR PLANTING STOCK. 69.1 - Suspension of Planting. Planting under certain weather conditions may be a waste of time, funds, and seedlings. These conditions will vary depending on the species being planted and the subregional area where the planting is being done. Factors to consider are soil moisture and temperature, air temperature, relative humidity, and wind speed. Several references exist to help make decisions on when to and conversely when not to plant seedlings. Local administrative units must supplement this handbook material with details applicable to local conditions. 69.11 - Soil Moisture. Soil moisture will usually be adequate during the planting season if site preparation has been adequate. If no or limited vegetation is present moisture will not be pumped out. Several computer programs have been written using local climatic history and soil moisture retention curves which can be adapted for localized conditions. See Appendix A for references. 69.12 - Atmospheric Moisture Demand. High moisture demand in the atmosphere can be very damaging to exposed seedling roots. Three things which contribute to high demand, a humidity index, wind speed, and temperature have been incorporated into a pair of tables to identify combinations which may be particularly damaging. These tables should be used to alert oneself to marginal conditions when a damaging combination occurs, and remedial measures to protect roots should be used. For instance, insulated planting bags should be used. Also, root systems should be dipped in water or a vermiculite or peat moss slurry. If conditions are deep in the hazard zone of the table, it may be wise to delay planting until late in the day and plant until dark when trees are then entering a recovery period. 69.13 - Frost and Snow. Planting should be suspended if the ground cannot be scalped free of frost crystals or snow. Planters must be instructed not to use snow or frozen soil to back fill planted trees. The adverse consequences of planting in frozen ground can be reduced by planting south facing slopes first until the ground has warmed up on other aspects. 69.2 - Special Packaging of Seedlings. 69.21 - Jelly Rolling. Seedlings are rolled into a water-saturated burlap sheet, with tops exposed and roots enclosed. A moisture-holding medium, such as sphagnum, peat moss, or horticultural grade vermiculite is packed around roots for additional R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 30 of 29 protection. This "jelly roll" of seedlings is slipped into the planter's bag, and the seedlings are extracted one at a time for planting. R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 31 of 29 The burlap used in "jelly rolling" must be at least 18" X 30" in size to accommodate seedlings properly. If new burlap is used it should be soaked for a minimum of 24 hours before using. If new burlap is used without soaking this period it will wick moisture from the roots. 69.22 - Root Dipping. Dipping roots in aqueous solutions of various moistureretaining products or in plain water immediately before seedlings are bagged for planting helps protect roots from desiccation during the short time they are exposed before planting. Horticultural grade vermiculite or peat moss are the two most frequently used materials. Insulation grade vermiculite MUST BE avoided because it is waterproof. 69.23 - Insulated Planting Bags. Planting bags insulated with polyurethane foam or similar materials can be used to protect seedling roots when climatic conditions become warm and dry. Waterproof bags with foam linings are particularly effective in keeping seedlings moist and cool during the hours required to plant the number of seedlings they contain. APPENDIX A - REFERENCE LIST. Baumgartner, D. M. and R. J. Boyd, eds. 1976. Tree Planting in the Inland Northwest. Washington State Univer.,Coop. Ext. Serv., Pullman, Wash. 311p. Cleary, B.D., R.D. Greaves, and R.K. Hermann, eds. 1978. Regenerating Oregon's Forests. Oregon State Univ. Ext. Serv., Corvallis. 287p. Cleary, B.D., and D.R. DeYoe. 1982. Seedling Care and Handling. Oregon State Univ. Ext. Serv., Corvallis. Ext. Circular 1095. 4p. Dobbs, R.C., D.G. Edwards, J. Konishi, and D. Wallinger. 1976. Guidelines to Collecting Cones of British Columbia Conifers. British Columbia For. Serv./Canadian For. Serv., Victoria, B.C., Joint Rep. No. 3. 98p. Duryea, M.L. and T.D. Landis, eds. 1984. Forest Nursery Manual Production of Bareroot Seedlings. Oregon State Univ. Forestry Res. Lab., Corvallis. 386p. Duryea, M.L., ed. 1985. Evaluating Seedling Quality: Principles, Procedures, and Predictive Abilities of Major Tests. Oregon State Univ., Forest Res. Lab., Corvallis. 143 p. Hedlin, A.F., H.O. Yates III, D.C. Tovar, B.H. Ebel, T.W. Koeber, and E.P. Merkel. 1980. Cone and Seed Insects of North American Conifers, Canadian For. Serv., U.S.D.A. For. Serv. and Secretaria de Agricultura y Recursos Hidraulicos, Mexico. Hermann, R.K., D.P. Lavender, and J.B. Zaerr. 1977. Lifting and Storing R-6 AMENDMENT 2409.26b-92-2 EFFECTIVE 2/7/92 2409.26b,60 Page 32 of 29 Western Conifer Seedlings. Oregon State Univer., Forest Res. Lab., Corvallis. Res. Paper 17. 8p. Hocking, D.A. and R.D. Nyland. 1971. Cold storage of coniferous seedlings, a review. Applied Forestry Res. Institute, State Univ., New York, Coll Forestry, Syracuse. Res. Rep. 6. 70p. Hopkins, J.C. 1975. A review of moulding of forest nursery seedlings in cold storage. Can. Forestry Serv., Pacific Forest Res. Centre, Victoria, B.C. Rep. BC-X-128. 16p. Lopushinsky, W. and T. Beebe. 1976. Relationship of Shoot-Root Ratio to survival and growth of outplanted Douglas-fir and Ponderosa pine seedlings. U.S.D.A. Forest Serv., Pacific NW Forest and Range Exp. Sta., Portland, Oregon. Res. Note PNW-274. 7p. Lopushinsky, W. 1986. Jelly Rolling. McDonald, S.E., R.J. Boyd, and D.E. Sears. 1983. Lifting, storage, planting practices influence growth of conifer seedlings in Northern Rockies. U.S.D.A. Forest Serv., Intermountain Forest and Range Exp. Sta., Ogden, Utah. Res. Paper INT-300. 12p. Navratil, S. 1973. Pathological and physiological deterioration of planting stock in cold storage (Silviculture review). Timber Seminar. Thunder Bay District, Thunder Bay, Ontario. Unpubl. rep. 27p.