From: AAAI Technical Report FS-94-01. Compilation copyright © 1994, AAAI (www.aaai.org). All rights reserved.

Applying a General-Purpose Planning and Learning Architecture

to Process Planning*

Yolanda Gil

InformationSciencesInstitute

Universityof SouthernCalifornia

Marinadel Rey, CA90292

gil~isi,edu

M. Alida P4rez

School of ComputerScience

CarnegieMellonUniversity

Pittsburgh, PA15213

aperez@cs,

cmu. edu

Abstract

Processplanningposessignificantcomputational

requirementsdueto the varietyof alternativeprocesses,

their complexity,andtheir interactions.General-purpose

plannersare

generallynot considered

a practicalapproach,

andmostcurrent researchfocusesonspecial-purpose

planningsystems.

Researchwithinthe PRODIGY

framework aimsto provide

expressivegeneral-purpose

plannerstogetherwithlearning

algorithms

that canimprove

their efficiency,the accuracy

of

their domain

model,andthe qualityof their plans.Process

planningis oneof the large-scalecomplex

domains

that we

haveimplemented

in PRODIGY

to demonslrate

the feasibility

of our approach.Ourcurrentmodelof processplanningis

still far fromcomprehensive

andis limitedin manyways,

butit reflectsmany

of the complexities

involved

in the task.

This paperdescribeshowPRODIGY

learns control knowledge,acquiresdomain

knowledge,

andimproves

the quality

of its plansfor this application

domain

usinggeneral-purpose

planning

andlearningalgorithms.

Introduction

Currentresearch on automationof manufacturing

processes

includes CAD

aids, assemblyautomation,andprocessplanning tools. Theautomation

of processplanningin particular

is becoming

a seriousneedin industry,dueto the increasing

scarcity of expertson technologythat is rapidly changing,

the needfor loweringmanufacturing

costs, and the desire

to makecustomizedproductswidelyavailable. Thevariety

of alternative processes,their complexity,andtheir inter°

actions makethe planningtask very complex.In addition,

a goodprocess plan minimizesresource consumptionand

executiontime. Theseissues are part of the researchagenda

of the AI planningcommunity.

However,the automationof

*We

would

like to thankall the members

of the PRODIGY

group

for manyyearsof collaborations

anddiscussions.Thisresearch

waspartially sponsored

by the WrightLaboratory,

Aeronautical

SystemsCenter, Air ForceMaterielCommand,

USAF,

and the

Advanced

ResearchProjects Agency(ARPA)

undergrant numbers F33615-90-C-1465

and F33615-93-1-1330.

Viewsand conclusionscontained

in this document

are thoseof the authorsand

shouldnotbeinterpreted

as necessarily

representing

officialpolicies or endorsements,

either expressed

or implied,of Wright

Laboratoryor the UnitedStatesGovernment.

Thesecondauthorholds

a scholarship

fromthe Minis

t erie deEducaci6n

y Ciencia

of Spain.

48

different aspects of processplanning (see (Chang& Wysk

1985)for an overview)has focusedon special-purposesystemsthat address the complexityof the task with mechanismsspecific to processplanning. Someof these systems

useAItechniques (Hayes1990; Descotte &Latombe1985a;

Nan1987), and there are approachesthat use generalpurposeproblemsolvers coupledwith special-purposesysterns (Kambhampati

et al. 1993).All this bodyof worksuggests that general-purposeAI planningtechniquescannot

handlethe complexityinherentto processplanningtasks.

Researchwithin the PRODIGY

framework

alms to provide

expressivegeneral-purposeplannerstogether with learning

algorithmsthat canimprovetheir efficiency,the accuracyof

their domainmodel,andthe quality of their plans. Process

planningis one of the large-scale complexdomainsthat we

have implemented

in PRODIGY

as a useful testbed for our

planningandlearningresearch.

Ourcurrent modelof process planningI represents machining, joining, and finishing operations. Althoughthis

modelis still far fromcomprehensive

andis limitedin many

ways,it reflects manyof the complexitiesinvolvedin the

task. Weasked an expert job shopmachinistto assist in

the constructionof the domainso it wouldbe as accurate

as possible. Themachinistalso helpedwith the description

of a real machineshop andsampleparts for constructing

problems.For someproblemsweused actual requests that

weresubmittedto the job shopthat serves the Mechanical

EngineeringDepartmentof CarnegieMellonUniversity.

Thepaperbeginswith a brief overviewof PRODIGY,

followedby a presentationof our modelof processplanning.

Finally, wedescribe howthe learning mechanisms

applied

to this process planningdomainimprovePRODIGY’S

performancein several respects.

Planning and Learning in PRODIGY

The PRODIGY

system (Mintonet al. 1989a; Veloso1989;

Carbonell et al. 1992) is an evolving general-purpose

problem

solvingarchitecturethat integratesseverallearning

mechanismsto improve performance. Domainknowledge

is representedin a set of operatorsandinferencerules, and

i Thedomain

is described

in detailin (Gil1991), andis available

uponrequest fromprodigyOcs,cmu.edu.

a type hierarchy for the objects in the domain.The operators are modelsof the available actions and they specify the

effects of the actions under different conditions. Inference

rules are used to deduce additional information from the

state. A problemis given by an internal state, representing

the current state of the world, and a goal state. PRODIGY

searches for a solution using a casual commitment

strategy

for every decision in the search process. Decisions include

choosing a goal, choosing an operator, selecting bindings

to instantiate an operator, and deciding whetherto subgoal

or apply an operator whoseconditions are satisfied. Search

control rules that express definitive selections or heuristic

recommendationsare applied at each decision point. The

problem solver has a very powerful language to express

both domainand control knowledge.

Learning Control Knowledge

Control rules can be learned automatically by the system

by static analysis of the domainoperators (Etzioni 1990),

analysis of problem-solving traces (Minton1988; Borrajo

&Veloso 1994), or a combinationof both (P6rez &Etzioni

1992).

In addition to learning control rules, PRODIGY

can also

control the search using derivationai analogy with similar previously solved problems(Veloso & Carbonell 1993).

Searchis also moreefficient whenPRODIGY

is used as a hierarchical problem

solver

thatlearns

tostructure

thesearch

in

multiple

abstraction

levels

automatically

(Knoblock

1991).

diverge, learning is triggered. Whenthere are several possible modifications of the domainknowledgethat could

potentially fix the problem, PRODIGY

designs and executes

experiments to discern which modification is appropriate.

The experimentationprocess is efficiently carried out with

to a set of domain-independent

hypothesis-selection heuristics that are available to the learning system.

Domainknowledgecan also be acquired directly from a

domainexpert. PRODIGY

Can engage in an apprentice-like

dialogue (Joseph 1992), or learn from observing the expert

solving problems (Wang1994).

Process

Planning

in PRODIGY

In this domain, PRODIGY

generates plans to produce parts

given a request that specifies the material, the shape(rectangular or cylindrical), the size along each dimension,the surface quality (roughness), the surface finish (metal coatings

and polishing), and the features (holes that can be reamed,

tapped, counterbored, etc). This specification forms the

goal state. A description of a shop with machines, tools,

and parts formsthe initial state of any problem.Parts have

six sides, and the location of a feature is determinedwith

x and y coordinates in a given side. Besides the machining operations themselves, a plan consists of operations to

secure the part with a holding device in a certain orientation, to clean metal burrs fromits surface, and to install an

appropriate tool in the machine.

Domain Knowledge

Learningto ImprovePlan Quality

In our model, most operators correspond to machining,joining, and finishing actions, as well as to the steps to prepare

the part and tool set-ups. Consider,for example,an operator

for face milling a part. Weneed to represent the fact that

if we use a milling cutter on a milling machinethe size of

the part will changealong a dimensioncorrespondingto the

part side facing up, that the part must be held by a holding

device in such a waythat the desired dimensioncan be machined, and that the newsize of the part must be smaller

than the current size. Also, any surface properties of the

side being machinedwill disappear, and the part will have

dirtandburrs.

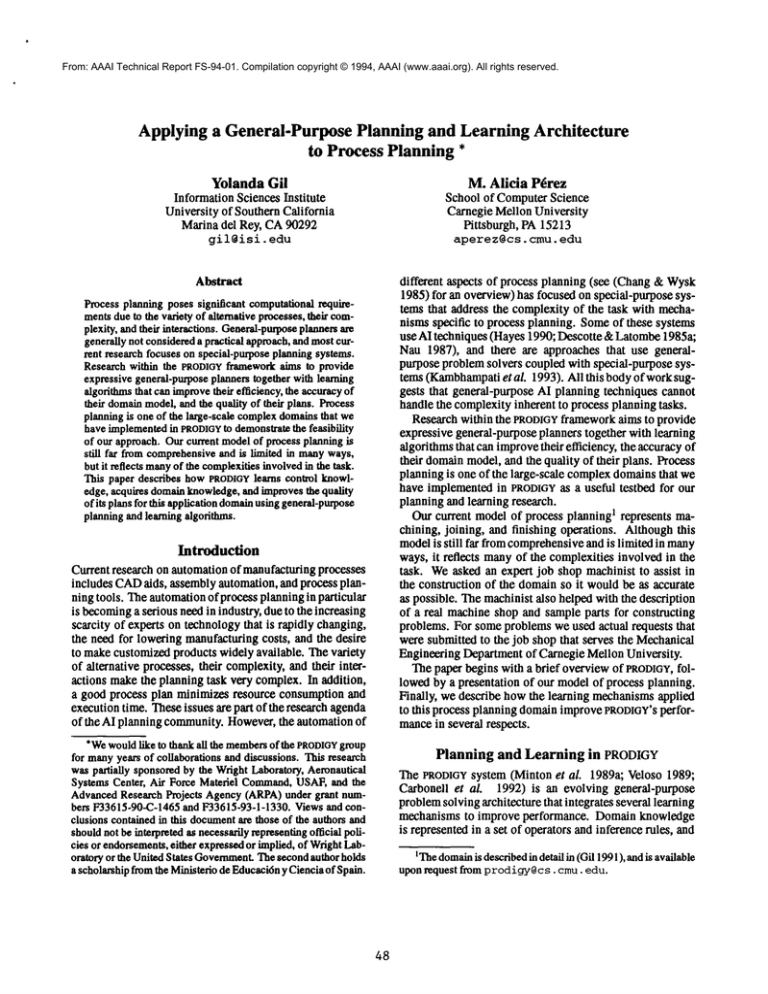

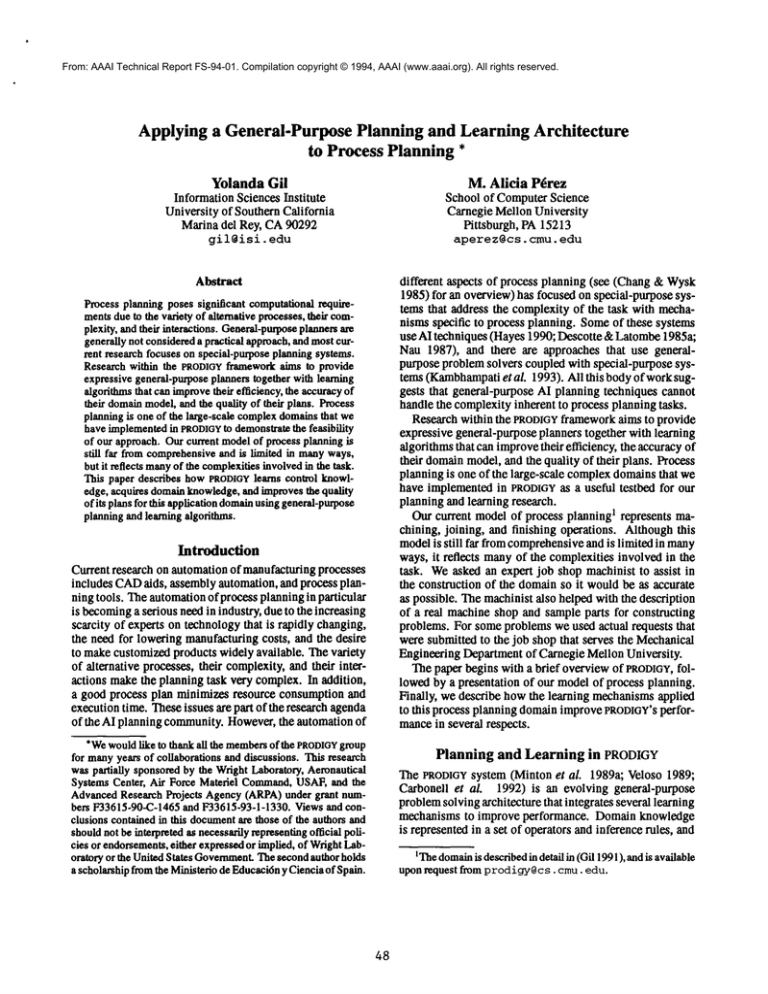

Figure

I showsthecorresponding

operator.Thenotation

means

thatifthepreconditions

aretruein

the current state then we can performthe milling operation,

whichchangesthe state accordingto the effects listed.

The domainimplementation makes use of PRODIGY’S

ability to represent infinite types and to do arbitrary Lisp

function calls. Infinite types, i.e. types withinfinitely many

instances, are used to represent numericquantities, such as

Learning Domain Knowledge

part sizes, hole depths, diameters, and angles. Functions

PRODIGYCan acquirenew domainknowledge

by intercan be used to denote facts that never changein the state,

actionwiththeenvironment

andexperimentation

(Gil

as generators for the infinite types, and to performnumeric

1992).

Given

aninitial

description

ofthedomain

operators, calculations. In the FACE-MIIJ.operator, the function

PRODIGY

Can acquire additional

preconditions

andeffects

smal 1 or represents the restriction that the part size never

autonomously

byexecuting

theplans

thatitbuilds

withthe

increases after milling. Inference rules are used to specify

currently

available

knowledge.

Thesystem

hasexpectations the availability of machines,parts, tools, tool holders, and

thatemerge

fromitscurrent

knowledge.

Planexecution

is

holding devices. They are also used to determine which

monitored,

andwhentheexpectations

andtheobservations sides should be used to hold a part.

PRODIGY

Canlearntoimprove

thequality

oftheplansit

generates

(P6rez& Carbonell

1994).Givena domaindependent

objective

function

thatcanevaluate

thequality

of

plans,

thelearning

algorithm

compares

thesearch

trace

for

theplanner

solution

giventhecurrent

control

knowledge,

andanother

search

tracecorresponding

to a better

solution(better

according

totheevaluation

function).

Thelatter

trace

isobtained

byletting

theproblem

solver

search

further

until

a better

solution

isfound,

orbyasking

a human

expert

formodifications

onthefirst

solution

ora completely

new

one,andthenbuilding

a corresponding

search

trace.

The

algorithm

explains

whyonesolution

isbetter

thantheother

anditsoutput

issearch

control

knowledge

thatleads

future

problem

solving

towards

better

quality

plans.

Thelearning

algorithm

iseffectively

operationaiizing

theobjective

functionintoknowledge

thattheplanner

canuseduring

plan

generation

bytransforming

itintocontrol

rules.

49

(Operator FACE-MILL

(params <machine> <part> <cutter> <hold-dev>

<side> <side-palr> <dim> <value-old> <value>)

(preconds

((<machine> MILLING-MACHINE) (<cutter> MILLING-C~ER)

(<hold-dev> (or 4-JAW-CHUCK VISE COLLET-CHUCK TOE-CLAMP))

(<part> Part)

(<dim> Dimension)

(<side-pair> Side-Pair)

(<side> side)

(<value-old>

(and Size (gen-from-pred (slze-of <part> <dim> <value-old>})))

(<value> (and Size (smaller <value> <value-old>))))

(and (shape-of <part> RECTANGULAR)

(side-up-for-machining <dim> <side>)

(sides-for-holding-devlce <side> <side-palr>)

(holdlng-tool <machine> <cutter>)

(holding <machine> <hold-dev> <part> <side> <slde-pair>)))

(effects ((<surface-coatlng> SURFACE-COATING)

(<surface-flnlsh> SURFACE-FINISH))

((del (Is-clean <part>))

(add (has-burrs <pert>))

(del (surface-coating-slde <part> <side> <surface-coating>))

(del (surface-finish-side <part> <side> <surface-flnish>))

(add (surface-flnlsh-slde <part> <side> RO~H-MILL})

(add (size-of <part> <dim> <value>))

(del (slze-of <pert> <dim> <value-old>)))))

Figure I: The FACE-MILL

operator.

Somequalitative and quantitative measuresof the complexity of this domainare:

¯ The effects of most operators are not reversible.

¯ The precondition expression ofsorne operators and inference rules includes negations, disjunctions and universal

quantification. Someof the preconditions correspond to

predicates derived by inference rules.

¯ There are context-dependenteffects of operators.

¯ Thereare 117rules, that include 73 operatorsand 44 in ference rules. 38 of the operators correspond to machining

operations, and 35 to set-ups.

¯ The average numberof parameters for an operator is 7,

the average numberof preconditions is 5, and the average

numberof effects is 3.

¯ Thereare 41 different predicates. 7 of themare static (i.e.,

do not changeduring problemsolving). 11 Lisp functions

are used to perform numericalcomputationsand constrain

variable values.

¯ Thereare 85 different types and subtypesof objects in the

type hierarchy, 5 of whichare infinite type,.

¯ The length of manysolutions is over one hundred rules

(including operators and inference rules).

¯ The initial state that represents the machineshop includes

morethan 500 facts.

Control Knowledge for Process Planning

[earned or handwritten control rules guide the search for

solutions along the more promising paths. For example,

the rule in Figure2 rejects certain kinds of cutting fluid for

somemachiningoperators according to the material of the

part.

Plan Quality in Process Planning

Plan quality is crucial in process planning to minimizeboth

resource consumption and execution time (Doyle 1969;

Descotte &Latombe1985a). For instance: it maybe advantageous to execute several cuts on the same machine

with the samefixing to reduce the time spent setting up the

50

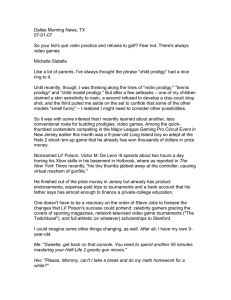

(control-rule DONT-USE-MINERAL-OIL

(if (and (current-goal-first-arg <part>)

(current-ops (DRILL-WITH-HIGH-HELIX-DRILL

DRILL-WITH-GUN-DRILL REAM

ROUGH-GRIND FINISH-GRIND

CUT-WITH-CIRCULAR-FRICTION-SAW ...))

(or (known (materlal-of <part> STEEL))

(known (material-of <part> ALUMINUM)))

(type-of-object <f> mineral-oil)))

(then reject bindings ((<fluid> . <f>))))

Figure 2: Control rule that rejects bindings for the cutting

fluid dependingon the part’s material.

work on the machines; or, if a hole HI opens into another

hole//2, then/-/2 should be machinedbefore Ht in order to

avoid the risk of damagingthe drill.

Sharing parts of the set-ups amongoperations on one or

moreparts usually reduces the total plan cost. Plan length

is usually not an accuratemetric of plan quality, as different

operators have different costs. For example,a tool can be

switched automatically but holding the part requires human

assistance (Hayes1990). Therefore plans that share set-ups

are cheaper than plans that share tools. The next section

describes howquality-enhancing control knowledgecan be

acquired automatically.

Learning

to Improve Performance in Process

Planning

This section describes howPRODIGY’S

learning techniques

described in the secondsection can be used to improvethe

planner’s performancein our process planning domain.

Efficient Process Planning through Learning

There are two mainapproachesto building process planning

systems (Chang & Wysk 1985). Generative approaches

combine elementary process planning operations to produce the final plan. Variant approaches retrieve complete

plans from a plan library and adapt themto suit the needsof

the current problem. In the implementationjust described,

PRODIGY

finds solutions for process planning problemsin a

generative fashion, i.e., by constructing plans given a set of

possible operators. PRODIGY’S

analogical

engine (Veloso

Carbonell 1993) could be used to implementa variant approach using predefined planning episodes associated with

families of parts, modifying themfor the particular part

wanted.

Abstraction planning has been applied to process planning and scheduling domains successfully (Fox & Smith

1984; Nan 1987). PRODIGY’S

domain-independent techniques (Knoblock1991) should provide useful abstractions

to handle the interactions within subproblemsin a process

planning application.

PRODIGY

currently uses manycontrol rules to guide the

search in the process planning domain. These control rules

are hand-coded, and continue to grow in number as we

continue to understandhowto control the search complexity

of the domain. Someof the work on automatically learning

control knowledgein PRODIGY’$

has been applied to the

process planning domain(Borrajo & Veloso 1994).

Learning to Generate Process Plans of Good

Quality

The performance of the planner can also be improved by

learning newrules to guide the search towards better quality solutions. The mechanismto learn quality-enhancing

control knowledgedescribed previously has been applied to

the process planning domain. The following simple example illustrates the learning process. The domain-dependent

quality metric used is additive on the cost of the individual operators and the operations to set-up the part on the

machineare moreexpensive than those to switch the tool.

Supposethe goal is to reduce the height of a part and

have a spot hole at certain coordinates, and the planner

choosesthe drill press to drill the spot hole. Adomainexpert

mayinput modifications to improvethat solution so that it

uses the milling machineto drill the spot-hole, and shares

the same set-up (orientation, machineand holding device)

for the drill and mill operations. The learning mechanism

comes up with the control rule in Hgure 3 and a similar

bindings preference rule. Goal preferences are also learned

from other problems.

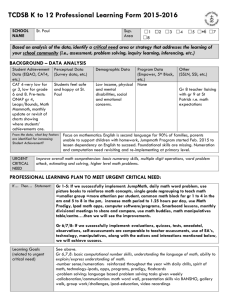

Problemset

(10 probsper set)

!# problemswith

!improvement

3

9i

3

Withoutlearned

control knowledge107 2O2 190

’Withlearned

control knowledge 91 132 166

Cost decrease

44% 48% 33%

10

10

4

9

431 362 442 732

350 220 409 665

24% 47% 17% 8%

Table 1: Improvementon the quality of the plans obtained

for 70 randomly-generated problems in the process planning domain. The third and fourth rows showsolution cost

according to the evaluation function.

initially given to the system(Gil 1992). Table 2 presents

some results obtained when PRODIGY

learns preconditions

that are missingfromits initially givenspecification of the

process planning domain. The tests were run in domains

with 10%and 30%incompleteness using two training sets

and twotest sets.

(control-rule

pre f-dril l-with-spot-drl i i- in-mi I i Ing-machlne30

(if (and

(current-goal (has-spot <pert> <hole> <side> <loc-x> <loc-y>}

( l~ndi ng-goa

(holding <mach> <holdlng-dev> <park> <side> <slde-palr>}

(type-of-object<msch> mllllng-machlne))

(then prefer operator drill-wlth-spot-drill-ln-milling-mechlne

drill-wlth-spot-drill)

Conclusion

Process planning is often considered too complexto be handled by general-purpose mechanisms.The work presented

here illustrates our work on applying PRODIGY’S

generalpurpose planner augmentedwith learning techniques that

improveits performancein a process planning domainalong

several dimensions.

Figure 3: Search control rule learned from the example

problem.

As the explanation is built from a single exampleand

does not consider all possible hypothetical scenarios, it may

be incomplete and the learned rules maybe overgeneral.

Uponunexpected failures the system refines the learned

knowledgeincrementally adding new rules if needed, and

mayset priorities amongrules.

Table I showsthe effect of the learned knowledgeon the

solution cost over 70 randomly-generated problems. Each

columncorresponds to a set of 10 problems with common

parameters: numberand type of goals, parts, etc. The training set consisted of 60 randomlygenerated problems with

the sameparametersthan for sets I to 6 in the table. In many

of the training and test problemsthe planner did not require

control knowledgeto obtain a good solution. Consequently

for each problemset we have only recorded those for which

the solution was actually improved. The numberof nodes

and total CPUtime was also reduced due to shorter solution

lengths. Howeverwe plan to further analyze the possible

tradeoff betweenthe learned-knowledgematching cost and

the savings obtained by using it. Weare exploring the effect

of this learning mechanismon other domainsand on other

types of evaluation functions.

References

Borrajo,D., andVeloso,M.1994.Incrementallearningof control

knowledge

for nonlinearproblemsolving. In Proceedingsof the

EuropeanConferenceon MachineLearning, ECML94.

Sicily,

Italy: SpringerVerlag.

CarbonelLJ. G.; the PRODIGY

Research Group: Jim Blythe,

a.; Etzioni, O.; GiLY.; Joseph, R.; Kahn,D.; Knoblock,C.;

Minton,S.; (editor), A.P.; Reilly, S.; Veloso,M.;andWang,

1992. PRODIGY4.0:

Themanualand tutorial. TechnicalReport

CMU-CS-92-150,

Schoolof ComputerScience, CarnegieMellon

University.

Chang,T. C., and Wysk,R.A. 1985. AnIntroduction to AutomatedProcessPlanningSystems.Englewood

Cliffs, NJ: Prentice

Hall.

Descotte, Y., and Latombe,J.-C. 1985b. Makingcompromises

among

antagonistconstraintsin a planner.Artificial Intelligence

27:183-217.

Doyle,L. E. 1969. Manufacturing

ProcessesandMaterialsfor

Engineers.Englewood

Cliffs, NJ: Prentice-Hall,secondedition.

Etzioni, O. 1990. A Structural Theoryof Explanation-Based

Learning. Ph.D. Dissertation, CarnegieMellonUniversity,

Schoolof Computer

Science. Alsoappearedas TechnicalReport

CMU-CS-90-185.

Fox, M., and Smith, S. 1984. ISIS: Aknowledge-based

system

for factory scheduling.InternationalJournalof ExpertSystems

I(I).

Learning Domain Knowledge for Process

Planning

PRODIGY

acquires new preconditions by experimentation

while planningusing the process planning operators that are

51

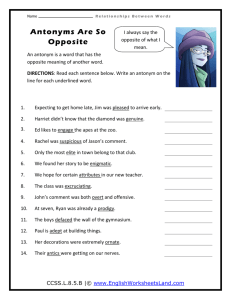

,6

I

11;

12

,C---7--7--7---7--7---

I0

,/

8

6

Train

Train

4

i

2 ~--

n 1 ~

n 2 ~--

2

0

I0 20

30 10 50 60 70

~aining Problem

80 90 i00

io 20 30 40 50 60 70 80 90

Training Proble~

IOO

(a) Cumulative number of unexpected action outcomes during training.

20

. ..........

i___L-~~ ’

1.

16

10

u

8

6

Train 1

2

10 20

30 10 50 60 70

Training

Problems

80 90 100

o

10 20

30 10 50 60 70

Training Probl em~

a0

90 100

(b) Numberof plans successfully executed in the test set.

Table 2: PRODIGY

learns new preconditions

Gil, Y. 1991. A specification of process planning for PRODIGY.

Technical Report CMU-CS-91-179,School of Computer Science, Carnegie MellonUniversity, Pittsburgh, PA.

Gil, Y. 1992. Acquiring DomainKnowledge for Planning by

Experimentation. Ph.D. Dissertation, Carnegie Mellon University, School of ComputerScience. Available as technical report

CMU-CS-92-175.

Hayes, C. 1990. MachiningPlanning: a Modelof an Expert Level

Planning Process. Ph.D. Dissertation, The Robotics Institute,

Carnegie MellonUniversity, Pittsburgh, PA.

Joseph, R. L. 1992. KnowledgeAcquisition for Visually Oriented Planning. Ph.D. Dissertation, School of ComputerScience, Carnegie MellonUniversity, Pittsburgh, PA. Available as

technical report CMU-CS-92-188.

Kambhampati,S.; Cutkosky, M. R.; Tenenbaum,J. M.; and Lee,

S.H. 1993. Integrating general purpose planners and specialized

reasoners: Case study of a hybrid planning architecture. IEEE

Transactions on Systems, Manand Cybernetics, Special Issue on

Planning, Scheduling, and Control 23(6).

Knoblock, C. 1991. Automatically Generating Abstractions for

ProblemSolving. Ph.D. Dissertation, Carnegie Mellon University, School of ComputerScience. Also appeared as Technical

Report CMU-CS-91

- 120.

Minton, S.; Carbonell, J. G.; Knoblock,C. A.; Kuokka,D. R.;

Etzioni, O.; and Gil, Y. 1989a. Explanation-based learning: A

problem-solvingperspective. Artificial Intelligence 40:63-118.

Available as technical report CMU-CS-89-103.

Minton, S. 1988. Learning Effective Search ControlKnowledge:

An Explanation-basedApproach. Ph.D. Dissertation, Carnegie

Mellon University, School of ComputerScience. Also appeared

as Technical Report CMU-CS-88-133.

52

in the process planning domain.

Nan, D. 1987. Automatedprocess planning using hierarchical

abstraction. In 1987Texas Instruments call for papers on Al for

Industrial Automation.

Ptrez, M. A., and Carbonell, J. G. 1994. Control knowledgeto

improveplan quality. In Proceedingsof the Secondlnternational

Conference on AI Planning Systems, AIPS-94.

Ptrez, M. A., and Etzioni, O. 1992. DYNAMIC:

A new role

for training problemsin EBL.In Sleeman, D., and Edwards,P.,

eds., MachineLearning: Proceedingsof the Ninth International

Conference (ML92). San Mateo, CA.: Morgan Kanfmann.

Veloso,M. M., and Carbonell, J. G. 1993. Derivational analogy in

PRODIGY:

Automatingcase acquisition, storage, and utilization.

Machine Learning 10:249-278.

Veloso, M. M. 1989. Nonlinear problemsolving using intelligent

casual-commitment Technical Report CMU-CS-89-210,School

of ComputerScience, Carnegie Mellon University.

Wang,X. 1994. Learning planning operators by observation and

practice. In Proceedingsof the Secondlnternational Conference

on AI Planning Systems, AIPS-94.