From: AAAI Technical Report FS-96-03. Compilation copyright © 1996, AAAI (www.aaai.org). All rights reserved.

AN AGENT ARCHITECTURE AND ALGORITHM FOR SOLVING

DISTRIBUTED CONFIGURATION-DESIGN PROBLEMS

Timothy P. Darr (timd@eecs.umich.edu)

http://ai.eecs.umich.edu/people/timd/timd.html

William P. Birmingham(wpb@eecs.umich.edu)

http://ai.eecs.umich.edu/people/wpb/home.html

AdvancedTechnologies Lab

The University of Michigan

AnnArbor, M148109

Fax: (313)763-1260

1.

INTRODUCTION

Configurationdesign is a type of design problemin whichparts are selected from catalogs

and connectedto meet the following problemrequirements:functionality, specifications, and

constraints [7-9, 12]. Functionality defines whatthe design is supposedto do, specifications

define optimality goals, and constraints def’methe feasibility relationships that mustbe satisfied for

the designto operate correctly. A designis a collection of parts evaluatedwith respect to the

problemrequirements(functionality, specifications and constraints). A design that meets these

requirementsis a solution to the problem.Configurationdesign is a ubiquitous and economically

important task, playing a prominentrole in complexproducts such as automobiles, airplanes or

computersystemsthat contain millions of parts, including resistors, light bulbs, screws,

microprocessors and engines.

Parts are described by attributes and implementone or morefunctions. Configuration

design is difficult becauseparts can implementmanyfunctions (the multi-function part problem)

[7, 8], functions can be implementedby manyparts, parts maydependon other parts for their

correct operation (the supportfunction problem)[9], and constraints and specifications defined

over part attributes restrict the allowedconfigurations, introducinghorizoneffects. Thereexist

several techniques to reducethe numberof designs to explore. If the functionality requirementis

decomposed

into required functions that individual parts implement,designs are constructed by

selecting parts that implementeach required function. Heuristics based on design experienceor

properties of the design problemcan be used to reduce the search space by ruling out certain part

selections.

Large-scale configuration design problemsthat consist of thousandsof required functions

and millions of parts are too complexfor a single agent1 or small group of agents to manage.Such

problemsare recursively decomposed

into sub-problems,until they are manageable.At this level,

parts are selected to implementa small numberof required functions, subject to constraints on the

selected parts. However,manyof these constraints are shared amongsub-problems, the agents

responsible for solving the sub-problemsare often geographicallydistributed, and the catalogs

from whichparts are selected often reside outside the organization. Thus, solving large-scale

problemsrequires communicationamongagents, and algorithms to resolve constraint violations on

the shared constraints that link the sub-problems.Computernetworks,such as the Internet,

facilitate communication

amongagents makingalgorithms possible to resolve constraint violations,

and provide a wayto makethe contents of part catalogs outside the design organization available to

design agents.

This paper describes the AutomatedConfiguration-Design Service (ACDS)[1-3], a system

for solving large-scale configuration design problemsusing a networkof design agents that

1 In this work,an agentis a human

or computer

processpossessing

designknowledge

withthe capabilityto

communicate

withotheragents.ACDS

agentsare computational

processesthat reside ontheir owncomputer

host,

communicating

with other agentsby passingmessages.

84

represent part catalogs and design constraints. TheACDS

algorithm is guaranteedto terminate,

with a solution if one exists. ACDS

agents communicateusing design protocols and an attributespace representation that boundsthe space of all possible designs. ACDS

agents concurrently

shrink the space by applying local knowledge,properties of the domain,and heuristics, until a

solution is found.

Thecontributions of this workare divided into three areas: (a) distributed design algorithms

and networks,(b) distributed design representations, (c) distributed design agents, and

distributed configuration design problemrepresentations. Eachof these contributions is described

briefly below,and in detail in the followingchapters.

2.

ACDS ALGORITHM AND NETWORK

The ACDS

algorithm is executed by a network of computational design agents to solve

configuration design problems.There are four basic ACDS

agents: catalog agents, that represent

part catalogs; constraint agents, that represent feasibility constraints; the systemagent, that

represents a user interface to the ACDS

network;and the search-control agent, that monitorsthe

algorithmto assist the networkin recovering fromdead-endsand to ensure that a solution will be

found, if one exists. In an ACDS

network, a communicationlink exists betweena catalog agent

and constraint agent if the feasibility constraint representedby the constraint agent restricts the

selection of parts fromthe catalog represented by the catalog agent.

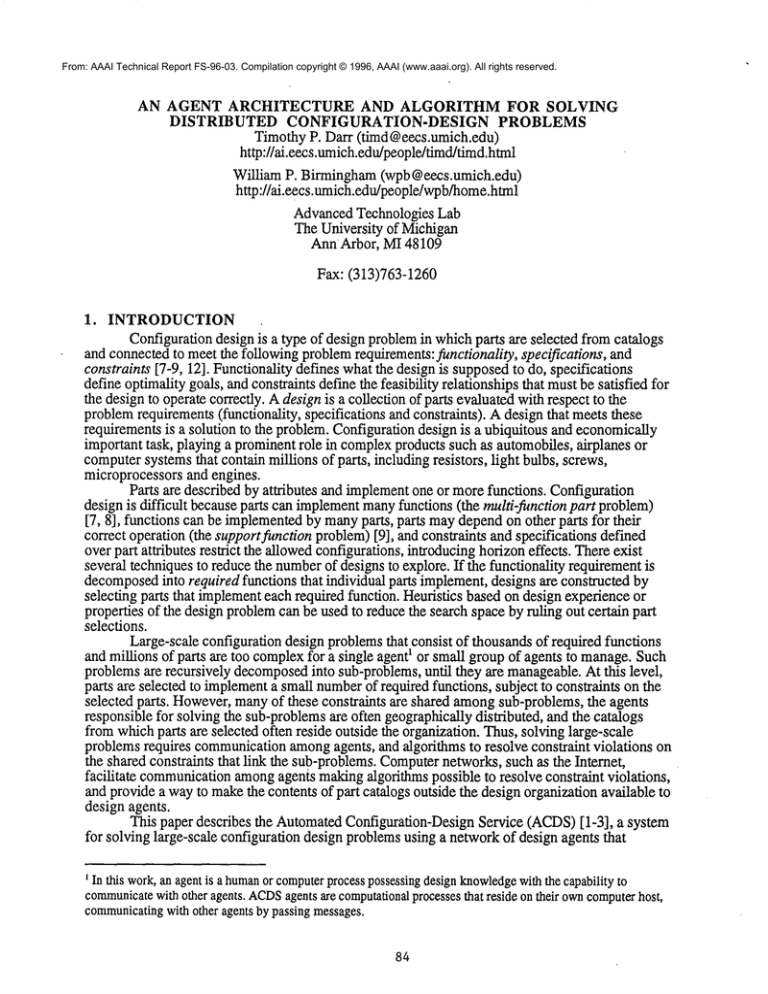

Figure 1 showsan ACDS

network for an exampleelevator configuration design problem.

In this examplenetwork, there are two catalog agents and two constraint agents. Thecatalog agents

represent sets of motors and machineunits. Themachine-unitis an assemblythat houses the motor

that drives the elevator cab up and downthe elevator shaft. Theconstraint agents represent

feasibility constraints betweenthe motorhorsepowerand machine-unit allowed horsepower, and a

feasibility constraint specifying the maximum

total weight. Asolution to the problemis a selection

of a motorand machine-unitsatisfying the constraints that the horsepowervalue of the selected

motor must lie within the minimumand maximum

allowed horsepowervalues of the selected

machine-unit, and that the total weightbe no morethan 2760lbs. Theseconstraints are represented

by the expressions:

¯ machine-unit.min_hp < motor.hp,

¯ motor.hp < machine-unit.max_hp,

¯ machine-unit.weight ÷ motor.weight < 2760.

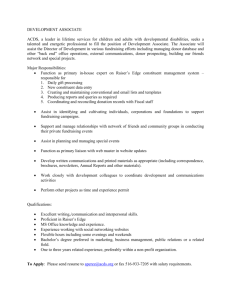

Figure 2 showsthe set of parts for each catalog.

Machine-Unit

Min

Horse

Power

~

~ machine-unit

k

I k

klf

.eight

_<

l \~\ L

f Machine-Unit Max Horse Power

~ motor blO < machine-unit

max-hp

I

motor

/-~’’"~"~

~

~

Legend

~--~

Catalog

Agent

~--~

Constraint

Communication Link

Agent

Figure 1: ACDSNetwork

The ACDS

algorithm is based on the concurrent engineering (CE) design paradigm.

transformsthe design process froma serial to a parallel one by concurrentlyapplyingall relevant

knowledgeto the problem. Theresult of this methodis the shortening of the product development

85

cycle. The ACDS

algorithm and network of distributed agents achieves concurrency through

constraint-based decomposition.In constraint-based decomposition,constraint agents define

problemdecompositionsand use properties of the domainand heuristics to concurrently eliminate

designs fromconsiderationthat do not satisfy their constraint.

part_name

modell8

model28

model38

model58

min_hp

i0

15

20

40

max_hp

15

20

40

40

weight

ii00

1700

2400

2750

part_name

hp

weigh t

10HP

15HP

20HP

25HP

30HP

i0

15

20

25

30

374

473

534

680

715

(b) motorcatalog

(a) machine-unitcatalog

Figure 2: ExampleConfiguration Design Catalogs

The ACDS

algorithm operates on spaces of designs. ACDS

agents use operations to shrink

this space until a set of solutions are found. TheACDS

algorithmconsists of concurrentcatalogagent operations to construct the space from the agent’s individual parts, followedby concurrent

constraint-agent operations to shrink the space, followedby concurrentcatalog-agent operations to

removeparts that lie outside the constraint-agent generatedspaces. This cycle is repeated until a

solution or set of solutions is found.

3.

ACDS DESIGN REPRESENTATION

Thesolution to a configuration design problemis described as an assignmentof values to a

set of design attributes. In the examplepresentedin Section 2, the attributes that describe the

design are {motor horsepower,total-weight}. Thus, one possible design is { 10, 1474}

({modell8, 10HP}).ACDS

represents the design as an attribute space. The attribute-space

representationis a set of intervals that compactlyrepresent the spaceof all possible designs[1-3].

In this representation, eachdesign attribute is an interval. Thecompleteset of intervals is an

abstract, m-dimensionalspace, wheremis the numberof attributes that describe the design. As the

following exampleshows, the attribute space representation has several desirable properties when

applied to problemswhoseconstraints are monotonicand part attributes can be partially ordered.

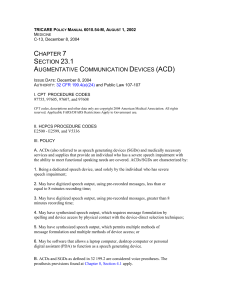

Figure 3 showsall possible designs for the exampleas points, and the attribute-space as a

rectangle, given by {motorhorsepower= [10 30], total-weight = [14743465]}, that encloses the

points. Clearly, someof the designs in the attribute space exceedthe weightconstraint. The

attribute-space representation is also usedto represent the possible part selections fromthe catalogs

shownin Figure 2. For example,the possible choices for the machine-unitcatalog are given by the

attribute space {min_hp= [10 40], max_hp- [15 40], weight = [1100 2750] }. The first advantage

of the attribute-spacerepresentationis that it is a compactrepresentationof a potentially large

numberof designs. Eventhough there are only a small numberof possible configurations m

Figure 3, the attribute space as shownencompassesany design within its boundaries.

Thesecondadvantageof the attribute-space representationis that it facilitates certain

inferences. Assuming

that the constraints are monotonicand the part attributes can be ordered, sets

of parts that cannotbe in any solution (inconsistent parts) can be identified and eliminated.

Considerthe total-weight constraint. Solving for each term yields the equivalent expressions:

¯ machine-unit weight < 2760 - motor weight

¯ motor weight < 2760 - machine-unit weight

Theseexpressions restrict the allowed assignmentsto machine-unit weight and motor

weight, respectively, giventhe set of assignmentsto the other attribute. Usingthe attribute-space

representationfor the weightattributes of eachcatalog, and interval arithmetic to evaluate the

expressions, sets of infeasible weightscan be eliminated. For example,[374 715] is the set of

86

possible assignmentsfor the motorweightattribute. Inserting this value into the expression for

machine-unitweight yields:

¯ machine-unit weight < 2760 - [374 715]

< [2045 2386]

Attribute Space (machine-unit, motorexample)

400O

..o.,,o°°O.-,,o,..,,,,,Oo°.,°,,.,,,,,,,,.%,,,o-,~

¯ :.:-:.:.:.:ik:.:.:.:.:~..:.:.:.’.;.:.:.:.:.:.

-:

~’":’:-".’.-’.:.":-:-:.:.’.:.:.’".’.:.’.:.:0

3000

2

.:.:.;.;.;.:~.:.:.:.:.:~.:.:.:.:.:.;.:.:.:.:.:.:

~ii!!iiiii:::!!iiiii~i:!:iiiiiii~ii!iiiiiiiiiii!i:"

¯ ....°,°°o,.°.....°°.Oo%.,.o.°..o.°,,,o.

°

iiiiiiiiiii:~iiiiii:ii~iii:i:i:iiiiiiiii:i:K

~:::::::::.:======================================

:::::::::::::::::::::::::::::::::::::::::::::::::

~

. 2000

+

1000

o

I

Horsepower

(motorI-IP)

Figure 3: ExampleAttribute Space

This result indicates that givenany possible motorselection, the mostthat the machine-unit

can weigh is 2386 lbs Fromthis, the parts model38and model58can be eliminated from

consideration withoutlosing any solutions, since if either model38or model58is selected, there is

no motorlight enoughto satisfy the total-weight constraint Notethat this inference waspossible

without knowinginformation about specific parts In fact, any machine-unitwhoseweight is in the

range 2386 < machine-unitweight < 2750, whichcould be a large numberof parts, is not

consistent and should be removedAnattribute space that contains only consistent parts is a

consistent attribute space [1-3, 10, 11, 16, 17]

Figure 4 showsthe samecatalogs in Figure 2 with inconsistent parts removed.Any

configurationof the remainingparts satisfies the weightconstraint, but there are still configurations

that violate the constraint betweenthe minimum

and maximum

allowed horsepowerof the selected

machine-unit and the horsepowerof the selected motor (for example, {modell8, 20HP}).The

attribute-space representationsuggestsa heuristic for further eliminatingparts to identify a set of

solutions. Anattribute space that contains only solutions is a decomposable

space.

partname

modell81

model2B

I

minhp

i0

15

max_hp

weight

[5

20

II00

1700

part_name

10HP

15HP

20HP

(a) machine-unitcatalog

hp

i0

15

20

weight

374

473

534

(b) motorcatalog

Figure 4: Catalogswithout Inconsistent Parts

87

To illustrate the heuristic for fmdinga decomposable

space, consider the constraints

between the machine-unit minimumand maximumhorsepower and the motor horsepower shown

below:

¯ machine-unit.min_hp_< motor.hp,

¯ motor.hp _< machine-unit.max_hp,

Replacingthe terms in the In’st expressionwith their interval values yields the expression:

¯ machine-unit.min_hp < motor.hp,

¯

[10 15] <[1020]

In a decomposable

space, every value in the interval on the left-hand side of this expression

must be less than or equal to every value on the right-hand side. Byexamination,the space is not

decomposable,since there exists an assignmentthat violates the constraint, namelymachineunit.min_hp= 15 and motor.hp= 10. Thus, to satisfy this constraint, an effective heuristic is to

removethe machine-unit with value min_hp= 15 and the motor with value hp = 10. Removing

infeasible designs using this heuristic movesthe attribute-space towarda decomposable

space.

4.

ACDS DESIGN AGENTS

ACDS

agents possess a set of operations to navigate attribute spaces. Catalog agent

operations mapfrom the catalog agent’s parts, to an attribute space representation; and mapfrom

an attribute spaceto a set of parts that lie within that space. Constraintagent operationstransform

one attribute spaceinto a smaller attribute spacewith certain properties. This section outlines the

agent properties and operations.

Catalogagents havethe capability to:

¯ identify parts that implementrequired functions,

¯ create an attribute-space representationof the parts in its catalog,

¯ communicate

its attribute space to constraint agents to achievedesign goals,

¯ apply an attribute spaceto its catalog to removeparts.

Catalog agents use operations to mapfrom parts to the attribute-space representation and

back. To illustrate, wereturn to the examplepresented in Section 2. Themachine-unitcatalog agent

constructs the initial attribute-space representation by mappingfrom the parts shownin Figure 2 to

the space {min_hp= [10 40], max_hp= [15 40], weight = [1100 2750]}, which bounds all

possible part selections. To removeinconsistent parts identified by the consistencyoperation

illustrated in Section 3, the machine-unitcatalog agent mapsfrom the constraint-agent generated

space weight = [1100 2386] to the set of parts {model18,model28} by removingthe parts

{model38,model58} since their weights exceed2386 lbs. Oncethe inconsistent parts are

removed,the newmachine-unit catalog attribute space is {min_hp= [10 15], max_hp= [15 20],

weight = [1100 1700]}.

Constraint agents havecapability to:

¯ construct a consistent attribute space,

¯ movean attribute space toward a decomposablespace.

Theconstraint agents use operations to create a consistent space, and create a space that

movesin the direction of a decomposablespace. Theseoperations are implementedusing interval

techniquesdescribedin Section 3. This section illustrates these operations graphically as spaceshrinking operations.

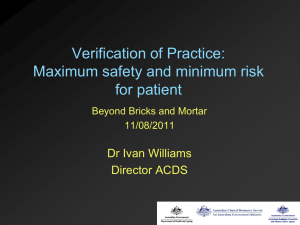

Figure 5 illustrates the constraint-agent operations for the constraint betweenthe machineunit minimum

horsepowerand the motorhorsepower.Theinitial attribute space for the constraint

in Figure 5: is {motorhp = [10 30], machine-unitmin_hp= [10 40] }.

Viewedas a projection onto the feasible space, there are slices along each dimensionof the

initial attribute spacethat do not intersect the feasible space. In particular, the slice alongthe

machine-unitmin_hpdimensionjust greater than 30 up to the value 40 does not intersect the

feasible region at all, so any machine-unitwhoseminimum

required horsepowerlies within this

88

slice can be removedas they are not consistent. Theconsistent space {motorhp = [10 30],

machine-unitmin_hp= [10 30] } is shown.Theupdated space after the catalog-agent operations

have been applied is {motor hp = [10 30], machine-unit min_hp= [10 20]}, shownas the space

boundedby dotted lines. Eventhough this space intersects the feasible space along each

dimension,it is not enclosedby the feasible space.

Constraint Agent Shrinking Operation

35

3o

::::::::::.:.:.:.’

25

iiiiiii.iiiiiiil

Legend

Current Space

Consistent Space

Updated Space

Feasible Space

Figure 5: Constraint-Agent Shrinking Operations

Tofurther shrink the spaceso that it is enclosedwithin the feasible space, a second

constraint-agent operation using the space-shrinkingheuristic described aboveis used. This

operation directs the attribute space towardthe feasible region by examiningthe boundsof the

current attribute space. In this example,the comerof the current attribute space defined by {motor

horsepower= 10, machine-unitmin_hp= 20} lies outside the feasible space. To direct the space

towardthe feasible space, the boundsthat define this comerare tightened by creating the space

{motor hp = (10 30], machine-unit min_hp= [10 20)}, where the interval motor hp = (10

meansthe horsepowermust be greater than 10 and less than or equal to 30.

Thesystemagent represents the user interface to ACDS,

and has the capability to:

* collect and broadcast design requirements,

¯ identify whenthe design process is complete.

Thesearch-control agent monitorsthe design process, and has the capability to:

¯ detect dead-endconditions whenbacktracking is necessary,

direct the agents to a newattribute spaceto explore,

¯ guarantee complete coverage,

¯ identify whenno solution exists.

ACDS

agents communicatethrough design protocols to achieve design goals. These

protocols specify the format of messagessent and received, and the sequenceof messagesused

within the protocol. For example,consistency and feasibility protocols allow catalog and constraint

agents to achieve consistent and decomposablespaces by sending messagesfrom the catalog

agents to the constraint agents to define the current space. Theconstraint agents use this spaceto

construct newspaces whichare sent backto the catalog agents, whoremoveparts that lie outside

the space.

89

5.

ACDS DESIGN PROBLEM REPRESENTATION

ACDS

includes a precise definition of the configuration design problem, whichis mapped

to a distributed, dynamic,multi-attribute domain,interval constraint-satisfaction problem(CSP)

computationalmodel[14, 15]. ACSPis a general problem-solvingrepresentation given by a set of

variables, a set of domainvalues for the variables and a set of constraints that restrict the possible

assignment of values to variables. The ACDS

CSPcomputational modelhas the following

additional properties:

1. the variables and constraints havepreconditions that specify whenthey are active

(dynamic CSP),

2. each variable or constraint is a separate computationalprocess that communicate

by

sending messages (distributed CSP),

3. the domainelementsare described by an attribute tuple (multi-attribute domainCSP),

4. constraints are evaluated over interval-valued variables (interval CSP).

5. Variable represent parts that cover the sameset of functions.

The ACDS

CSPcomputational model provides a precise frameworkfor applying

established CSPproperties and heuristics to configuration design problems. For example,ACDS

uses arc-consistency [4, 5, 16, 17] to reduce the numberof combinationsby efficiently removing

certain configurations that violate constraints, and the forwardcheckingheuristic to propagatethe

effects of design decisions [6J. Bymappingrequired functions to CSPvariables and design

constraints and specifications to CSPconstraints, the ACDS

CSPframeworkencompassesall

types of configuration design problems,including those with multi-function parts and support

components.This workextends the class of problemsto which a CSPmodel applies by defining

the multi-attribute CSP, whichis a CSPwhosevariable domainelements are described by an

attribute tuple. In the multi-attribute CSP,parts mapdirectly to CSPdomainelements.

Anadditional property identified by the ACDS

CSPcomputational modelis the boundarypart property. This property applies to a class of configuration design problemsin whichthe parts

can be orderedfor each part attribute and in whichthe constraints that are definedover the part

attributes are monotone.This property states the conditions under whicha single part can be

selected to implementa function without losing any solutions. This property is used as a basis for

the conditions for backtrack-free search, namelya boundarypart implementseach required

function.

5"

6.

ACDS CONTRIBUTIONS

This section summarizesthe contributions of this workand describes the experimentaland

theoretical results that supportthese contributions. Thecontributions of this workfall into three

areas: distributed design algorithms and networks, distributed design problemrepresentations, and

distributed design agents.

6.1.1

Distributed Design Algorithm Contributions

Aneffective algorithmfor large-scale distributed design is guaranteedto terminate, uses

heuristics to managethe problemcomplexityand is scaleable. This workdefines a distributeddesign algorithmfor solving configuration design problemsthat is guaranteedto terminate. The

contributions are the following:

¯ ACDSAlgorithm

¯ Soundand complete,

¯ Uses heuristics for particular design domainsand classes of designs,

Scales to over 200 agents.

This workprovesa theoremthat states the properties of the search-control agent that must

hold for the algorithmto terminate, with a solution if one exists. Weshowthat for the VTelevator

9O

configuration design problem[13], the space-shrinkingheuristics reduce the time to solve the

problemover binary-search methods. Finally, we demonstrate that the ACDS

algorithm solves an

elevator design problemwhenscaled to over 200 agents, which is a limit on the numberof

computerhosts available at the University of Michigan.

6.1.2

Design Problem Representation Contributions

To incorporate domain-independent

heuristics and into design algorithms, it is necessary to

have a precise problemdefinition and a domain-independentcomputational model. This work

precisely defines the distributed configurationdesign problemand casts it as a dynamic,

distributed, interval constraint-satisfaction problem(CSP).Thecontributions are the following:

¯ Precise defmition of the distributed configuration design problem,

¯ Theattribute-space representation.

¯ Facilitates efficient reasoningfor a large class of problems,

¯ Effective for communicatinglarge design spaces.

¯ CSPmodelfor configuration design represents

¯ Multi-function parts,

¯ Support components,

¯ Multi-functioncatalogs.

¯ CSPtechniques reduce the search space using node- and arc-consistency.

This workdefines the distributed configuration design problem, and mapsit to a CSP

computationalmodel. Multi-function part, support componentand multi-function catalog design

problemsare solved using ACDS

to demonstrate that the CSPmodelcan be used to solve these

problems.Experimentsare performedto demonstratethe effectiveness of node- and arcconsistency properties in solving design problems.

Themulti-attribute domainCSPintroduces uniqueproperties that must be satisfied to

extend the class of backtrack-free search problems.This workextends the class of problemsto

whichthe basic CSPrepresentation applies to include problemswith multi-attribute variable

domainelements. Thecontributions are the following:

¯ Multi-attribute CSP:

¯ Boundaryelement property reduces the numberof domainelements to a single

elementwithout losing solutions,

¯ Precise characterization of the conditions for backtrack-free search.

This workprecisely defines the multi-attribute CSP, and the boundaryelement property,

and proves the properties of the boundaryelement. Theconditions for backtrack-free search are

stated and a theoremproven.

6.1.3

Design Agent Contributions

To create flexible design networksfor solving a variety of design tasks, design agents must

be able to interact with other agents in well-definedwaysto achieve joint design goals. This work

describes a set of generic design agents at the knowledgelevel, and a set of design protocols these

agents use to achieve specific design goals. Thecontributions are the following:

¯ Knowledge-leveldescription of agent capabilities, design messageclasses, agent

operations for distributed design.

¯ Protocols to achievespecific design goals.

Theseagents and protocols are specialized for configuration design and incorporatedinto

the ACDS

algorithm to demonstratetheir effectiveness in solving distributed configuration design

problems.

91

7.

REFERENCES

1.

Dart, T.P. and W.P. Birmingham,AutomatedDesign for Concurrent Engineering, IEEE

Expert, 1994, Vol. 9, No. 5, p. 35-42.

2.

Darr, T.P. and W.P. Birmingham,An Attribute-Space Representation and Algorithm for

Concurrent Engineering, A/EDAM,

1996, Vol. 10, No. 1, p. 21-36.

3.

Darr, T.P., Ph.D. thesis in preparation, 1996, TheUniversity of Michigan,

4.

Mackworth,A.K., Consistency in Networksof Relations, Artificial Intelligence, February

1977, Vol. 8, No. 1, p. 99-118.

5.

Freuder, E.C., Synthesizing Constraint Expressions, Communicationsof the ACM,1978,

Vol. 21, No. 11, p. 958-966.

6.

Haralick, R.M.and G.L. Elliott, Increasing Tree Search Efficiency for Constraint

Satisfaction Problems,Artificial Intelligence, 1980, Vol. 14, No. 3, p. 263-313.

7.

Mittal, S. and F. Frayman,Towardsa generic modelof configuration tasks, Eleventh

International Joint Conferenceon Artificial Intelligence (IJCAI-89), 1989, Detroit, MI, Morgan

Kaufmann,p. 1395-1401.

8.

Haworth, M.S., W.P. Birmingham,and D.E. Haworth, Optimal Part Selection, 1EEE

Transactions on Computer-AidedDesign of Integrated Circuits and Systems, 1993, Vol. 12, No.

10, p. 1611-1617.

9.

Mittal, S. and F. Frayman, COSSACK:

A Constraints-Based Expert System for

Configuration Tasks, Proceedingsof the 2nd lnternational Conferenceon Applications of AI to

Engineering, 1987, Boston, MA.

10. Hyvt~nen,E., Constraint reasoning based on interval arithmetic: the tolerance propagation

approach, Artificial Intelligence, December1992, Vol. 58, No. 1-3, p. 71-112.

Benhamou,F., D. McAllester, and P. Van Hentenryck, CLP(Intervals) Revisited, 1994,

11.

Brown University Technical Report CS-94-18.

12. Birmingham, W.P., A.P. Gupta, and D.P. Siewiorek, Automating the Design of

ComputerSystems, 1992, Jones and Bartlett Publishers.

13. Marcus, S., J. Stout, and J. McDermott,VT: AnExpert Elevator Designer That Uses

Knowledge-basedBacktracking, AIMagazine, 1988, Vol. 9, No. 1, p. 95-112.

14. Yokoo,M., et al., Distributed Constraint Satisfaction for Formalizing Distributed Problem

Solving, Twelfth International Conference on Distributed ComputingSystems, 1992, Yokohama,

Japan, IEEEComputerSociety, Los Alamitos, CA, p. 614-621.

15. Mittal, S. and B. Falkenhainer, DynamicConstraint Satisfaction Problems, Proceedings of

the Eighth National Conferenceon Artificial Intelligence (AAM-90),1990, p. 25-32.

16. Carlson, B., S. Haridi, and S. Janson, AKL(FD)- A concurrent language for

programming,Logic Programming:1.994 International Symposium,1994, The MITPress, p.

521-535.

17. Carlson, B., M. Carlsson, and D. Diaz, Entailment of Finite DomainConstraints,

Proceedingsof the Eleventh International Conference of Logic Programming,1994, MITPress.

92