Condition-Based Monitoring of Motor-Pump Systems Using Model-Based Reasoning

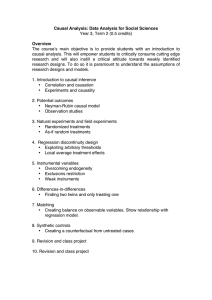

advertisement

From: AAAI Technical Report SS-99-04. Compilation copyright © 1999, AAAI (www.aaai.org). All rights reserved.

Condition-Based Monitoring of Motor-Pump Systems

Using Model-Based Reasoning

Yi-Liang Chen and Gregory Provan

Rockwell Science Center

1049 Camino Dos Rios

Thousand Oaks, California 91360

{ylchen, gmprovan}@rsc.rockwell.com

Abstract

This article presents a system-level, model-based framework for

machinery diagnosis that combines the signal processing and

domain knowledge. Based on causal network diagnosis, this

framework provides an integrated, condition-based monitoring

system with full machinery prediction capabilities. We describe

in detail a preliminary diagnostic model of a motor-pump system

in this framework.

1. Introduction

Current systems for machinery monitoring and fault

diagnosis are labor intensive and machine specific.

Furthermore, they only diagnose the local condition of a

machine and do not treat it as part of a system. In this

paper we describe an approach aimed at developing an

integrated, condition-based monitoring system based on

open systems technology that provides full machinery

prediction capabilities to allow the accurate and reliable

determination of the remaining useful life of equipment.

The primary focus of this effort will be to fuse disparate

data and information types within an open architecture for

machinery prognostics, and to validate the prognostics

system. This will be done by combining the signal

processing and domain knowledge within a system-level,

model-based framework for machinery mechanics.

We base our knowledge-integration mechanism on a set of

tools for constructing causal networks, which provide an

excellent platform for knowledge fusion. Because of the

rigorous framework in which the causal model is

constructed, completeness of the knowledge fusion is

guaranteed, essentially providing automatic inclusion of all

the possible combinations of fault conditions without the

necessity of their explicit identification [Darwiche, 1995].

Research supported in part by The Office of Naval Research under

contract number N00014-98-3-0012.

Copyright © 1999, American Association for Artificial Intelligence

(www.aaai.org). All rights reserved.

This article presents a diagnostic model of a motor-pump

system, which is modeled in terms of dynamic causal

networks. The main focus of this preliminary model is to

replicate the diagnoses of certain faults when some

peculiar vibration signatures are observed, as described in

various places in the literature [Bloch & Geitner 1997,

Eshleman 1998, Sohre 1980, TAC 1994, Wang 1997,

Wowk 1991]. This approach thus relies on constructing

system models, which replace the role rules would play in

a traditional approach. These models can integrate the

output from several sensors, and if the system is altered the

models can be altered to reflect the changes, such that the

diagnostics computed are automatically updated. The

majority of faults modeled thus far are bearing faults.

Physical descriptions/properties of the system are modeled

only when they are critical for the diagnostic purpose and

at a minimal detail. We plan to expand this model later

with more detailed physical descriptions/properties for

more accurate diagnoses and/or broader coverage of faults.

We first briefly explain our modeling mechanism that will

be followed by a description of key aspects of the motorpump system. We then present the details of this

preliminary model. Diagnostic results generated by our

model through simulation will also be shown.

2. Software Architecture

The key software novelty, as compared to approaches that

use a single sensor output to compute diagnostics/

prognostics for a device (pure signal-processing-based

methods), is that we employ a system-level model to drive

the diagnostic and prognostic reasoning. This approach

specifies a model for the device or set of devices, and can

incorporate any number of sensors, actuators, etc. This

model then can fuse the outputs of all the sensors to obtain

a more detailed and accurate prediction of component

health and expected lifetime. Our system-level model uses

the causal network model-based approach [Darwiche

1998], which has been under development for over a

decade, and has successfully been applied to conditionbased monitoring, as well as diagnosis of systems ranging

Diagnosis

from factory automation, avionics systems to the Space

Shuttle [Darwiche & Provan 1996, El Fattah & Provan

1997].

Sensor

This paper describes our initial efforts towards the

construction of models for a complete pump loop that

consists of motor, pump, tank and pipes, with sensors for

measuring pump/motor vibration, fluid flow, fluid pressure

and temperature. This “redundant” sensor suite facilitates

higher-fidelity diagnosis/prognosis, plus the ability to

identify existing or potential faults in all key aspects of the

pump loop.

1xMag

Discrete

Indicators

Causal Networks

S/N

For this application, we are developing an openarchitecture, distributed diagnostics and prognostics

system, as shown in Figure 1. This modular system is

Figure 2: Stages of processing for typical sensor data

Middleware communications channel

Satcom

Sensor

Collection

Module

Centralized

Diagnostic

Engine

Presenter

Remote

Maint..

Interface

PMAT

RF from

distributed

smart

wireless

sensors

Figure 1: Distributed condition-based monitoring system

planned to consist of a number of components that are

connected via CORBA/COM middleware (which can be

run over the system’s communications channel as shown in

Figure 1). The components are as follows:

• smart wireless sensors: collect data and perform

signal processing on the data;

• sensor collection module: collect the processed

sensor data and send it on the middleware

communications channel;

• centralized diagnostics engine: perform sensor

fusion and, using a model of the system, compute

high-fidelity

diagnostics

and

prognostics

information based on the processed sensor data;

• diagnostics and prognostics user interface (or

presenter): transmit the diagnostics and

prognostics information to the user and provide

the user an easy tool to modify/reconfigure the

system model;

• remote maintenance interface: send the

diagnostics and prognostics information to remote

control center (or logistics/maintenance base), so

that maintenance operations can be planned and

prepared in advance.

Figure 2 shows the type of data processing typical in our

approach. The sensing unit, such as an accelerometer, of a

smart wireless sensor will transmit data to the digital signal

processing (DSP) unit of the sensor. The DSP unit

computes a set of discrete diagnostic indicators based on

analyses such as measurements of amplitude peaks at

particular frequencies in the spectra and signal-to-noise

ratio. Through the middleware communication channel,

these indicators will then be sent as inputs to the

centralized diagnostic engine. The diagnostic engine uses

the causal network model and the input indicators to

compute the most likely broken components of the system,

if any such failures are indicated.

In this document we focus on the diagnostics aspects of

this architecture. We have implemented the middleware,

Centralized Diagnostics Engine and Presenter; we are

developing smart wireless sensors that perform basic

signal-processing tasks within the sensor, sending

“diagnostic indicators”, discrete-valued representations

necessary to determining fault conditions, along the

middleware channel.

3. Overview of Causal Networks and Modelbased Diagnosis

This section introduces an example that we use to describe

our approach, and the representation that we adopt for

modeling, causal networks [Darwiche 1997]. The example

we will describe is a simple control hardware system, since

it is one of the simplest systems to describe. Note that the

causal network modeling language allows discrete

specifications of any physical system, including digital

systems and mechanical systems such as a pump or motor,

in addition to functional systems, such as software

systems.

those faults, which variables can be observed, such as

variables for sensors, etc. In this report we focus on

symbolic causal networks.

3.1 Causal Network Representation

A causal network is a graph-based representation that is

used for diagnosing failures of a system. Causal networks

provide probabilistic, order of magnitude, and symbolic

representations. They also have predictable scaling

properties for the eventual embedded runtime diagnostic

system.

To specify a causal network model we need to define:

1. the variables in the model, which represent the

components, e.g., Tx, Act1, Act2, Act3, and Act4

from Figure 4;

2. the values for the variables, which represent the data

that flows through various parts of the system;

3. the assumables, which are the variables that describe

the operating characteristics of the components, such

as ok or broken;

4. the quantifications, which relate the variables and

assumables;

5. the evidence variables, which are the variables that can

be observed, typically the system sensors; and

6. the weights for the assumables, which specify the

likelihood or relative ranking of the assumable fault

modes.

A causal network encodes the causal relations of a system;

e.g., in Figure 3, the controller/transmitter in Tx causes

Actuators Act1 through Act4 to turn on. A causal network

is thus a good way of representing the flow of data in such

systems, and hence reasoning about the root causes of data

flow. Figure 3 shows the causal network structure for this

simple example. Conversely, if data is not flowing as

intended, the causal network can help track down the

reason for the “breakdowns” of correct data flow; e.g., Tx

could be the root cause of Act1 through Act4 not turning

on. We call this diagnosing the faults in the system.

Tx

Act1

Tx

Act2

Act1

Act2

Act3

Act4

Act3

Figure 4: Causal structure for the

simple hardware system

Act4

The assumable associated with a variable characterizes the

ways the component works under an exhaustive set of

scenarios. Act1 has an associated assumable, Act1-mode,

with two possible values, ok and broken, and a

quantification as follows: if [Act1-mode = ok], Act1

receives data from Tx, but if [Act1-mode=broken]

receives no data and the actuator will not activate. In

propositional logic, we might write this as:

Figure 3: A simple hardware system

More formally, a causal network specifies the causal

relationships among a set V of variables by encoding each

variable in V with a node, and encoding the causal

influence of V1 on V2 by a directed arc from V1 to V2.

Hence a causal network is a directed graph (N,A) of nodes

N and directed arcs A.

⇒ [Act1 = on]

[Act1-mode = ok] ∧ [Tx = transmit]

[Act1-mode = broken] ∨ [Tx = not-transmit] ⇒ [Act1 = off].

3.2 Causal Network Specification Language

A causal network can encode much more than just the

cause and effect relationships among a set of variables. It

can encode the nature of these relationships, such as

probabilistic or symbolic/logical (using a multi-valued

propositional logic), static or temporal relationships, faults

that may occur in the system and the relative frequency of

If Act1-mode=OK and Tx=transmit

then Act1=on

If Act1-mode=broken or Tx=not-transmit

Act2-mode

then Act1=off

Figure 5 shows the causal network model for the simple

hardware example with the assumables and quantification

defined.

Note that the causal network representation can describe

not only deterministic systems as in the above example,

Tx-mode

Tx

If Tx-mode=OK then Tx=transmit

If Tx-mode=broken then Tx=not-transmit

Act3-mode

Act4-mode

Act1-mode

Act1

If Act2-mode=OK and Tx=transmit

then Act2=on

If Act2-mode=broken or Tx=not-transmit

then Act2=off

If Act4-mode=OK and Tx=transmit

then Act4=on

If Act4-mode=broken or Tx=not-transmit

If Act3-mode=OK and Tx=transmit

then Act4=off

then Act3=on

If Act3-mode=broken or Tx=not-transmit

then Act3=off

Act2

Act3

Act4

Figure 5: Causal network model for the simple hardware system

Tx-mode

Act2-mode

Tx

Act4-mode

Act3-mode

Act1-mode

Act1

Act2

Act3

Act41

Act42

Act43

Act44

Figure 6: Temporal causal network for hardware system with time-dependent actuator Act4,

shown for time steps t=1,2,3.

but also stochastic systems (using probabilities and orderof-magnitude probabilities (OMP) [Darwiche 1998]), and

discrete-event systems [Cassandra 1993].

3.3 Dynamic Causal Networks

We have extended the static causal networks just described

to handle dynamic systems [Darwiche & Provan 1996, El

Fattah & Provan 1997]. In such an extension, we assign a

temporal index to each causal network variable, and

describe the evolution of the variables over time.

Consider an extension of the hardware example, in which

Act4 displays time-dependent behavior: the value of Act4

depends on Tx and on the previous value of Act4.

Figure 6 shows the causal relationships for this temporal

t

model. If we denote the temporal variable as Act4 , where t

denotes the time, then for such a system we may have

some temporal equations including the generic relations:

∀ t ([Act4-mode=ok] ∧ [Tx=transmit] ∧ [Act4 =on]

t

⇒ [Act4 =on]);

∀ t (([Act4-mode=broken] ∨ [Tx=not-transmit]) ∧

t-1

t

[Act4 =on] ⇒ [Act4 =off]);

t-1

∀ t ([Act4-mode=ok] ∧ [Tx=transmit] ∧ [Act4 =nott

on] ⇒ [Act4 =off]) .

t-1

Note that in the ensuing motor-pump modeling, we

describe only the static structure for the system. The

temporal expansion of our model will not be described, due

to the limitation of the space.

4. Key Aspects of the Motor-Pump System

Figure 7 shows a generic motor-pump system that we

model. The system components are horizontally mounted.

We assume that the motor is a three-phase AC induction

motor and the pump is a centrifugal pump. The motor and

the pump are rigidly coupled.

Figure 7: A motor-pump system

Two sets of bi-axial accelerometers are mounted onto the

housing of the driving end bearing of the motor and the

housing of the pump bearings, respectively. The bi-axial

accelerometers are oriented to measure the axial and radial

vibrations. Note that, for simplicity, we do not measure the

vibrations from the motor bearing at the free end. Such

measurements could be added later on for more extended

and/or more accurate diagnoses.

As mentioned previously, we focus mainly on the

modeling and diagnosis of bearing faults for this

preliminary model. We describe the types of faults

modeled thus far as follows. For motor/pump bearings, we

are interested in the misalignment, mechanical looseness,

and wearing of the bearings. Four types of wearing are

covered: inner race, outer race, balls, and cage. For the

motor, only the imbalance of the rotor is of interest for

now. Similarly, for the pump, our concern is only the

imbalance of the pump shaft. For the coupling, we focus on

the misalignment problem, both angular and parallel.

Please note that, as we expand the model with more

physical descriptions/properties, we will extend our

coverage to most of the motor and pump faults.

5. Dynamic Causal Network Model for the

Motor-Pump System

In this section, we present our preliminary model for the

motor-pump system in a hierarchical manner. We divide

the system into seven subsystems/components: motor,

pump, shaft/coupling, motor bearing (at the driving end),

pump bearings, and the signals from accelerometers on

housings of both motor and pump bearings. Note that we

do not model the motor bearing at the free end thus far.

Figure 8 depicts a high-level causal structure of the system.

This figure shows the causal relationships among the

subsystems. For example, the rotation of the motor rotor

and the condition/health of the motor affect the rotation of

the shaft/coupling. The rotation of the shaft/coupling then

drives the pump and affects the condition of motor and

pump bearings and their housings. Meanwhile, the

condition of the pump can also affect the rotation of

shaft/coupling.

Motor

Observed that the quantizations of the variable values are

coarse. We will change to finer quantizations, if necessary,

when we expand the model.

Pump

Shaft/Coupling

Motor Bearing

Pump Bearing

Sensors at

Motor Bearing

Sensors at

Pump Bearing

There is only one assumable in Figure 9 as indicated by a

solid shade of the node:

•

Figure 8: High level causal structure

of the system

The subsystems are also modeled in terms of dynamic

causal networks. These dynamic causal network models

are implemented in both Rockwell’s CNETS [Darwiche

1992] system (textual) and CDMB [Provan & Chen 1998]

user interface (graphical) formats. Note that the interface

between related subsystems can contain multiple nodes in

their causal structures. We present the detail causal

structures of these subsystems in the following

subsections.

MRotorBalMode; {ok, unbal}; balance mode of

motor rotor, ok or unbalanced.

Note that the assumable MRotorBalMode represents

whether the motor rotor is balanced or not while the

unobservable MRotorBalCond, which is speed dependent,

serves as a ramification of the rotor balance situation to the

other subsystem, i.e., shaft/coupling.

5.2 Pump

Figure 10 shows the causal structure of the preliminary

pump model. Similar to the motor model, the pump model

is much simplified and will be expanded in the future.

PumpRPM

PImpelBalMode

LoadTorque

PImpelBalCond

5.1 Motor

The causal structure of our preliminary motor model is

illustrated in Figure 9. This is a much-simplified model

where we only model the motor torque and rotor balance

condition. As mentioned previously, in future work we will

expand the model with more physical descriptions of the

motor and cover more motor faults.

Figure 10: Causal structure for pump

Two unobservable that were not previously described are:

•

ElectricTorque

LoadTorque

•

DynamicTorque

MRotorBalMode

MotorRPM

MRotorBalCond

Figure 9: Causal structure for motor

There are six nodes in the causal structure of the motor.

Five of them are unobservables whose names, possible

values, and descriptions are listed below:

•

•

•

•

•

ElectricTorque; {0, pos}; electrical torque

generated by the motor, zero or positive;

LoadTorque; {0, pos}; torque generated by the

loading (from pump), zero or positive; an

interface node to pump

DynamicTorque; {neg, 0, pos}; net dynamic

torque; negative, zero, or positive;

MotorRpm; {0, 1, 2}; rotor rotation speed; an

interface node to shaft/coupling;

MRotorBalCond; {ok, unbal}; balance condition

of motor rotor, ok or unbalanced; an interface

node to shaft/coupling.

PumpRpm; {0, 1, 2}; rotation speed of pump

shaft; an interface to shaft/coupling;

PImpelBalCond; {ok, unbal}; balance condition

of the pump impeller, ok or unbalanced; an

interface to shaft/coupling.

And the only assumable is:

•

PImpelBalMode; {ok, unbal}; balance mode of

the pump impeller, ok or unbalanced.

5.3 Shaft/Coupling

The causal structure of the shaft/coupling is shown in

Figure 11. Note that causal structure is not connected. This

indicates that there are some attributes of the

shaft/coupling that are not causally related.

We list the new unobservables in the following:

•

•

•

MBRpm; {0, 1, 2}; rotation speed of the shaft

felt by the motor bearing; an interface to the

motor bearing;

PBRpm; {0, 1, 2}; rotation speed of the shaft felt

by the pump bearing; an interface to the pump

bearing;

MBBalCond; {ok, m, p, mp}; balance condition

felt by the motor bearing, ok, motor unbalanced,

•

•

pump unbalanced, or motor and pump

unbalanced; an interface to the motor bearing;

PBBalCond; {ok, m, p, mp}; balance condition

felt by the pump bearing, ok, motor unbalanced,

pump unbalanced, or motor and pump

unbalanced; an interface to the pump bearing;

SAliCond; {ok, misali-a, misali-p, misali-ap};

alignment condition of the coupling, ok, angularly

misaligned, parallely misaligned, or angularly and

parallely misaligned; an interface to both the

motor bearing and the pump bearing.

MotorRPM

PumpRPM

SAliMode

MBRPM

PBRPM

SAliCond

MRotorBalCond

PImpelBalCond

MBBalCond

PBBalCond

Figure 11: Causal structure for

shaft/coupling

threshold. Sensor nodes of this type include:

The only assumable in the shaft/coupling model is:

•

•

SAliMode; {ok, misali-a, misali-p, misali-ap};

alignment mode of the coupling, ok, angularly

misaligned, parallely misaligned, or angularly and

parallely misaligned.

Observe that, although the unobservable SAliCond looks

identical to the assumable SAliMode, it is necessary to

have such an unobservable for technical reasons. This is

because, in our modeling mechanism, an assumable node

cannot

have

any

parent

nodes

while

an

observable/unobservable can have multiple parent nodes.

Hence, the unobservable SAliCond serves as an extension

of SAliMode in order to interface with nodes in both

motor bearing and pump bearing models.

5.4 Bearings and Sensors on the Bearing Housings

In this subsection, we describe the causal network model

for the bearings. We use the same model for both motor

and pump bearings. The causal structure of this model is

depicted in Figure 12. To differentiate the nodes between

two models, we usually add an M prefix and a P prefix to

the name of the nodes for motor and pump bearing models,

respectively.

There are three types of node in the causal structure:

sensors (observables), unobservables, and assumables. The

sensor nodes, denoted as shaded ovals in the figures,

represent the information obtained from the signalprocessing unit that performs FFT analysis and Cepstrum

analysis of the signals from the accelerometers. There are

two types of sensor nodes. The first type of sensor returns a

Boolean value that represents whether a particular

peak/signature in the spectrum is present or has exceed the

|1xR|

|1xA|

1xA>1xR?

|2xR| |2xA|

2xR>.5 1xR?

BBalCond

SubHar

2xA>.5 1xA?

BAliMode

1xR

1xA

2xR

2xA

RPM

LooseMode

BRPM

ORMode

SAliCond

BAliCond

LooseCond

IRMode

BPFI

BPFO

CageMode

BallMode

BSF FTF

Figure 12: Causal structure for bearing

•

•

•

•

•

•

•

•

1xA: the presence of excessive 1xRPM signal in

the Axial direction;

1xR: the presence of excessive 1xRPM signal in

the Radial direction;

2xA: the presence of excessive 2xRPM signal in

the Axial direction;

2xR: the presence of excessive 2xRPM signal in

the Radial direction;

SubHar: the presence of excessive subharmonic

signals;

BPFI: the presence of BPFI (Ball Pass Frequency

Inner) signal;

BPFO: the presence of BPFO (Ball Pass

Frequency Outer) signal;

BSF: the presence of BSF (Ball Spin Frequency)

signal; and

FTF: the presence of FTF (Fundamental Train

Frequency) signal.

The other type of sensor node shows a quantized value of

the specific signals it represents, covering:

•

•

•

•

•

RPM: the rotation speed detected;

|1xA|: the magnitude of 1xRPM Axial signal;

|1xR|: the magnitude of 1xRPM Radial signal;

|2xA|: the magnitude of 2xRPM Axial signal; and

|2xR|: the magnitude of 2xRPM Radial signal.

Note that the threshold values and the quantization of

specific signals remain context-dependent; these measures

are defined based on relative sensor values.

We list the new unobservable nodes in the bearing models

as shown below:

•

•

•

BAliCond; {ok, misali-a, misali-p, misali-ap};

alignment condition displayed at the bearing, ok,

angularly misaligned, parallely misaligned, or

angularly and parallely misaligned;

LooseCond; {ok, loose}; mechanical looseness

condition at the bearing, ok or loose;

1xA>1xR?; {true, false}; the magnitude of the

1xRPM Axial signal is larger than that of the

1xRPM Radial signal, true or false;

•

•

2xA>.51xA?; {true, false}; the magnitude of the

2xRPM Axial signal is larger than 50% of that of

the 1xRPM Axial signal, true or false; and

2xR>.51xR?; {true, false}; the magnitude of the

2xRPM Radial signal is larger than 50% of that of

the 1xRPM Radial signal, true or false.

Shaft/Coupling

Motor Bearing

Sensors at

Motor Bearing

Finally, the assumables of the bearing model are:

•

•

•

•

•

•

BAliMode; {ok, misali}; alignment mode of the

bearing, ok or misaligned;

LooseMode; {ok, loose}; mechanical looseness

mode of the bearing, ok or loose;

IRMode; {ok, worn}; wearing condition of the

inner race, ok or worn;

ORMode; {ok, worn}; wearing condition of the

outer race, ok or worn;

BallMode; {ok, worn}; wearing condition of the

rolling balls, ok or worn; and

CageMode; {ok, worn}; wearing condition of

the bearing cage, ok or worn.

5.5 Additional nodes for sensor fusion

We have described the causal network models of the

subsystems as depicted in Figure 8. Using the

CNETS/CDMB environment and its simulation capability,

we can combine these subsystem models and generate

diagnostic results given specific observations. We will

present some of the results in the next section.

It is not necessary to have two sets of accelerometers, in

order to generate meaningful diagnostic results. In fact, if

we remove the models of pump bearing and sensors

mounted on the its housing, the remaining models can still

tell whether there is a misalignment or an imbalance

problem.

The main motivation for having two sets of accelerometers

in place is to have a finer “resolution” of diagnoses. For

example, instead of having a diagnosis like “there is a

balance problem”, it would be much better to have a

diagnosis like “there is a balance problem on the motor

rotor”. In order to achieve this objective, information

gathered from different sources needs to be properly

combined/compared (that is, “fused”). This sensor fusion

process can be easily accomplished in our approach by

employing additional “sensor fusion” nodes. Note that

these nodes are often categorized as unobservables.

Figure 13 shows the high-level causal structure of adding

such sensor fusion nodes to our model. We add one sensor

fusion node to our model:

•

1xRMB>1RPB?; {true, false}; the magnitude of

1xRPM Radial signal at motor bearing is larger

than that at pump bearing, true or false;

Pump

Motor

Pump Bearing

Sensor

Fusion

Sensors at

Pump Bearing

Figure 13: High-level causal structure with

sensor fusion

•

1xRMB<1RPB?; {true, false}; the magnitude of

1xRPM Radial signal at motor bearing is larger

than that at pump bearing, true or false.

Both of the nodes have parents from with parent nodes

from MRotorBalCond and PImpelBalCond of the

shaft/coupling model and from |1xR| nodes of both motor

and pump bearing models.

6. Simulation Results

In this section, we present some diagnostic results

generated by our preliminary models when simulated using

both CNETS and CDMB. We use three different settings

of the models. In the first setting, we use only the sensors

at the motor bearing and do not include the models for

pump bearing and sensors attached to it. In the second

setting, we add the models for pump bearing and

corresponding sensors, but there are no sensor fusion

nodes. In the third setting, we add the two sensor fusion

nodes as described in Section 5.5.

Example 1: (imbalance, first setting)

We set the following sensors to true: M1xA, M1xR, and

MRPM. All other sensors are set to false. We also set the

unobservable M1xA>1xR? to false, since the non-binary

valued sensor nodes, M|1xA| and M|1xR|, cannot be

implemented as discussed in Section 4.4. The diagnostic

result is “MRotorBalMode is unbal OR PImpelBalMode

is unbal”, which indicates either motor rotor or the pump

shaft is unbalanced.

Example 2: (imbalance, second setting)

We set sensors M1xA, M1xR, MRPM, P1xA, P1xR, and

PRPM to true and all other sensors to false. We also set

unobservables M1xA>1xR? and P1xA>1xR? to false.

The diagnostic result is the same as that of Example 1.

Example 3: (imbalance, third setting) We set sensors

M1xA, M1xR, MRPM, P1xA, P1xR, and PRPM to true

and all other sensors to false. We also set unobservables

M1xA>1xR?, P1xA>1xR?, and 1xRMB<PB? to false

and 1xRMB>PB? to true. The diagnostic result becomes

“MRotorBalMode is unbal”, which shows that the motor

rotor is unbalanced. This diagnosis is finer than the

diagnoses shown in previous two examples, which shows

the advantage of using a second set of accelerometers and

References

Figure 14: CDMB Simulation results for example 3

sensor fusion technique. Simulation results of this example

on the CDMB is shown in Figure 14.

Example 4: (angular misalignment, third setting)

We set sensors M1xA, M2xA, MRPM, P1xA, P2xA, and

PRPM to true and all other sensors to false. We also set

unobservables M2xA>.5 1xA? and P2xA>.5 1xA? to

false. The diagnosis generated is “SAliMode is misali-a”,

which indicates the angular misalignment of the coupling.

Example 5: (mechanical looseness, third setting)

We set sensors MRPM, PSubHar, and PRPM to true and

all other sensors to false. We obtain the diagnosis of

“PLooseMode is loose” that shows the mechanical

looseness of the pump bearing.

7. Conclusions

We have described a model-based approach for conditionbased monitoring of pump/motor systems. We have shown

how we model these systems, and how we can use our

approach to perform sensor fusion and system-level

diagnostics for such systems. This approach offers several

advantages over traditional methods of condition-based

monitoring. The system models, which replace the role

rules would play in a traditional approach, can integrate the

output from several sensors, and if the system is altered the

models can be altered to reflect the changes, such that the

diagnostics computed are automatically updated. This

process of model updating is much simpler than rule

updating. In addition, our model-based approach provides

analytical results about completeness and soundness of

fault coverage, results that are not possible with a rulebased approach.

This paper describes our preliminary efforts on this topic,

and our future goals include extending the models to be

able to diagnose a wider range of faults, and using

additional signal-processing algorithms to extract

information from the sensors that is more indicative of the

underlying faults.

Bloch, H. P. and Geitner, F. K. 1997. Machinery Failure

rd

Analysis and Troubleshooting, Vol. II, 3 ed. Gulf

Publishing Co.

Cassandras, C. G. 1993. Discrete Event Systems: Modeling

and Performance Analysis. IRWIN Inc.

Darwiche, A. 1992. A Symbolic Generalization of

Probability Theory. Ph.D. Thesis, Department of

Computer Science, Stanford University.

Darwiche, A. 1995. Model-based diagnosis using causal

networks.” In Proceedings of IJCAI Conference, Montreal,

Canada.

Darwiche, A. 1998. Model-based diagnosis using

structured system descriptions. Journal of AI

Research, 8: 165-222, June 1998.

Darwiche, A. and Provan, G. 1996. “Exploiting system

structure in model-based diagnosis of discrete-event

systems.” In Proceedings of International Workshop on

Principles of Diagnosis, Canada, pp. 95-105.

Darwiche, A. and Provan, G. M. 1996b. Query-DAGs: a

practical paradigm for implementing belief-network

inference. Journal of AI Research.

Darwiche, A. and Provan, G. M. 1997. The effect of

observations on the complexity of model-based diagnosis.

In Proc. AAAI, 91-94.

El Fattah, Y. and Provan, G. M. 1997. Modeling temporal

behavior in the model-based diagnosis of discrete-event

systems. In Proc. 8th International Workshop on

Principles of Diagnosis (Dx’97), 43-50, Le Mont-SaintMichel, France.

Eshleman, R. L. 1998. Machinery vibration evaluation

nd

techniques. Course Notes for short course at the 52

Meeting of the Society for Machinery Failure Prevention

Technology (MFPT), Virginia Beach, VA.

Jensen, V.; Lauritzen, S. L.; and Olesen, K. G. 1990.

Bayesian updating in recursive graphical models by local

computation. Computational Statistics Quarterly, 4:269282.

Provan, G. M. and Chen, Y.-L. 1998. Component-based

modeling and diagnosis of process-control systems.

Technical Report, SCPP98-116, Rockwell Science Center.

Submitted to 1999 IEEE Intl. Symposium on ComputerAided Control System Design (CACSD’99).

Sohre, J. S. 1980. Turbomachinery problems and their

correction. Ch. 7, Sawyer Turbomachinery Maintenance

Handbook. Turbomachinery Intl. Publishers.

Technical Associates of Charlotte, Inc. 1994. Illustrated

Vibration Diagnostic Chart.

Taylor, J. I. 1994. The Vibration Analysis Handbook.

Vibration Consultants, Inc.

Wang, Y. X. 1997. A progress report of a preliminary

expert system for CBM of MUA compressor in the 12-foot

PWT. Technical Report, Research Center IC, NASA

AMES.

Wowk, V. 1991. Machinery Vibration: Measurement and

Analysis. McGraw-Hill.