From: AAAI Technical Report SS-94-04. Compilation copyright © 1994, AAAI (www.aaai.org). All rights reserved.

Error Recovery in Automation - An Overview

Peter Loborg

Department of Computer and information Science

LinkSping University,

S-581 83 Link~3ping, SWEDEN

Phone: (+46) 13 282494 E-mail: plo@ida.liu.se

Abstract

This paper attemptsto providean overviewof techniques

andapproachesto error recovery,both in automationandin

other fields (such as autonomous

robotics) whereanalogousproblemsoccur. Theterm’error recovery’is often

usedas a common

namefor the three sub areas error/fault

detection, error/fault diagnose,andrecoveryfromthe

resultingfailure. All three areas will be covered.

Ratherthan presentingdifferent systemsand approaches

in-depth, different types of systemsandapproacheswill be

presented and compared.

Terminology

Thefirst observationmadeis that there is a lack of common

terminology,e.g. the worderror is sometimes

used to

denote the original reason whysomethingwentwrong,

whereas

in other casesit is usedto denotethe effects in the

computersystemdue to someunforeseenevent.

However,

in the ’reliable computing’community

there is

an emerging

standard[Laprie, 1992].Althoughthey are primarilyinterested in problems

internal to a computer

andits

software, the terminologyis applicablewhentalking about

problemsin a ’real world’controlled by a computer,problemswhichmaymanifest themselvesas discrepancies betweenthe actual state in the real worldandwhatthe computer ’think’ is the actualstate. Thefollowing

definitionswill

be usedthroughoutthis paper:.

fault the original source of any problem,such as a

brokenair pressurevalveor assemblypart out of

tolerances, whichmayled to an error directly or

indirectly.

error is a differencebetweenwhatis specifiedand

whatis actuallythere. It maybe latent (the systemhas not recognizedit as such)or detectedby

a detection mechanism

(often called monitor).

Thus,in a control system,an error is an observable discrepancybetweenthe actual state (the

state in the controlledsystem)andthe internal

representationof the intendedstate.

94

failure occurswhenan error affect the service delivered

froma systemin anyway,e.g. the robot is unable to continuethe graspingoperationsince

someonehaveremovedthe object in question.

Finally,(completing

the chainof effects) if the

component

that experiencea failure is a part of a

systemof components,

the result is a fault in the

systemwhichcontains the falling component.

Usingthis terminology,it is evidentthat whatis commonly

describedas error recovery(such as catchinga signal on

divisionby zero) is really failure recovery,althoughit

wouldbe desirable to handlethe problembefore it manifests itself as a failure, i.e. to havetrue error recovery

(detect the presenceof a zero anddo something

about it

beforeit is usedin a division). Systems

whichare able to

handlean error withoutaffectingthe service deliveredare

called fault tolerantsystems.

Thefield of error recoveryis often dividedin three subfields:

detection techniquesfor (or the processof) observing

the actual state of the controlledsystemand

comparing

it withspecificationsin order to find

discrepanciesas early as possible.

diagnosetechniquesfor finding the original fault which

causedthe error.

recoveryapplyingthe propercorrective actions in order

to preventa possiblefuture error or reachan

error free state.

In eachof these subfieldsthere are severalprinciplesfor

howto achievethese objectives,as well as different methods for representingthe informationneeded.

Classification

Thefollowingclassification parameterswill serve as a

frameworkfor the comparisonof approachesand techniques. Although

it is not alwayspossible, subjective

parametershas beenavoidedas far as possible. Thusno

approachwill be classified as beingthe ’best’, since such

an evaluationis dependenton the applicationandthe motivationfor usinga specific approachin that application.

When

presentingdifferent approachesof error recovery,

a basic categorisationis whethera forwardor backward

error recoveryapproachis used.Thedefinitionfor these terms

are ([Laprie,1992;Noreils,1990]):

backwarderror recovery:Find an earlier (previously

passed)error free state of the systemandreturn

there, by ’undoing’whathas beendonesince.

Examples

of general techniquesusing this

approachare recovery blocks [Kimand Welch,

1989]and transactions [Harderand Reuter,

1983].

forwarderror recovery:Findan error free state that the

systemis supposedto eventuallyreach, andperformactionsto reachthat state. This is often

doneusingpredefinedalternative actions or

replanningof whatactions to use to achievethe

’goal’ [Chenand Trivedi, 1991;Noreils, 1990].

Othercriteria whichhaveimplicationson the systemperformance

as wellas its flexibility are:

Knowledgesources: The information (or knowledge)

used mayoriginate fromseveral knowledge

sources, suchas fromthe original code, froma

descriptionof whatto perform,fromstatistically

aquiredinformationabout relations between

error causesandeffects in the systemas well as

the propercorrective action. This knowledge

mayalso be manuallyspecified after analysis of

the system.

Application dependence: The knowledgeas such may

be moreor less application dependent,which

haveimplicationsfor the reusability of the

knowledge.

Knowledgerepresentation: The knowledgeused may

be representedin several different formalisms,

suchas rules, alternativecodeor pieces of plans

to use, graphsdescribingdecisiontrees etc.

Notablehere is that several of these formalisms

maybe combined,or translated fromone form

into another.

Techniques for error recovery

In this sectiondifferentaspectsof error recoverywill be

presentedanddiscussed.Firstly, techniquesfor the detection of a fault is discussed,followedby diagnoseand

recoverytechniques.

ble, since the degreeof observabilityof a systemmaynot

correspondto the richness in the modelof the system.The

followingtechniquesaddressthis problem.

Sensorysignatureis a termusedby[Leeet. al., 1983]to

denotea collection of parameterswhichspecifythe limits of

acceptabilityof a sensedsignal duringa specific task phase.

Theresult is that sensormonitoringis guidedby currentaction, not onlyin a binaryfashion(shouldit be monitored

or

not) but also qualitatively(howtight are the limits, howoften shouldtheybe verified).

Gini ([Gini, 1893])uses a worldmodelto representthe

activity in a robot system.This worldmodeland the operations on it is generatedfromthe original robotprogram,and

for eachoperationexecutedin the robot a corresponding

semanticoperationis executedin the worldmodel.If the resuits differ (the worldmodelcontainingthe expectedoutcomecompared

to the sensedstate of the world)there is an

error. Whatsensors to use is guidedby expectedchangesas

well as expectedlack of changes.

In [Hayes-Roth,1990], BarbaraHeyes-Roth

uses a focus

of attentionprinciplein a life supportandmonitoring

system to discriminate betweenwhichparametersto monitor

moreclosely andnot. This focusis guidedby rules according to whattask is performed,current loadin the system,

andmayalso (in case of overflowof sensordata) imposefiltering strategies on sensorchannels.Theknowledge

usedis

currently’hard-wired’,applicationdependenta priori

knowledge.

ObservationsThesethree examplesshowsthat there exists feasible techniquesfor detection,providedthat there is

a goodobservabilityof the system,that is that thereare sensors enoughto monitormostof the tasks. Notableis that the

knowledge

used to guide the monitoringin Gini’s approach

is extracted from the program,knowledgewhichthe user

mustsupplyexplicitly in the other twoapproaches.In Lee’s

approach,the knowledgeis input twice (althoughin somewhatdifferent forms)- bothin the ’original’ programandin

the monitoringsystem.

Guidingthe monitoringtask in planningsystemsis often

a variant of Gini’sapproach,andis thus not includedhere.

Omittedin this presentationis also techniquesfor howto

implement

monitoringof different types of signals, since

this is out of the scopeof this paper.However,

an overview

can be foundin [Iserman,1984]and[Frank, 1990].

Diagnose

Detection

In orderto avoidcostlyfailures, it is desirableto detectthe

presenceof faults as early as possible.Theconstantverification of absenceof errors is costly andnot alwayspossi-

95

Diagnose

is the processof identifyingthe causeof the error

(or failure). Theidentifcationstarts byverifyingthe presenceor absenceof selected sensordata values,often called

features. Theresult of the diagnosisis a set of explanations

for the error, i.e. a set of possiblefaults.

Failuretree [Srinivas, 1977;Srinivas, 1978]:Earlywork

by Srinivas presents a methodwherepredefinedknowledge

aboutpossiblefaults for eachaction(rules testing sensors

andfacts trying to explainwhythe action failed) andthe

currentstate of executionis usedto build a decisiontree of

tests for ’features’upona failure. Thistree is thenusedto

diagnosethe situation. Themethodalso uses the information availablein the interruptedexecutionto trace situations

wherethe error couldbe a result of a previousor parallel action. This is accomplished

by examingthe preconditionsof

all interrupted actions. Depending

on the outcomeof that

examination,the corresponding

error rules are also included.

Since Srinivas methodis computationallyexpensive,it

wouldbe favourableto ’remember’

the errors that actually

occuredin an applicationandtheir cause, andstore themin

a computationallymoreefficient form. Thetechniquefor

doing so has beentermed machinelearningI [Changand

DiCesare,1989;Changet. al., 1990a;Changet. al., 21990b]

andis usedto produceheuristic rules whichgivena failed

action, tests for the presenceandabsenceof certain features

knownto discriminate betweenpossible explanations. The

techniqueis basedon an initial knowledge

about possible

errors for an action, andfor eacherror bothprobableand

definite featuresfor that error. In the casewhenthe system

finds multipleexplanations,it produces

a tentative heuristic

rule that maybe confirmedor ruled out whenmoreknowledgeis acquired"fromexperiments,modelsor other sources".

ProbabilityVectors[TaylorandTaylor, 1988;Tayloret.

al., 1990]is an alternativetechniquewherestatistical a priori knowledge

aboutthe systemis used. Eachpossible fault

is associatedwith the probabilityof its occurence,and

storedin a vector.Thisis repeatedfor all possibleeffects

(errors), all modelparametersandall sensors,resulting

four vectors containingprobability estimations.Connection

matricesdescribesa weightedrelationship betweenfaults

and errors, errors andparameters,parametersand sensors.

Usingthis information,it is possibleto compute

a set of

probablecausesfor a givenerror, whatsensorsto use to verify an error as wellas (at least in theory)guidingthe process

of instrumentinga workcell with sensorsto achieverelevant observability.

Alternativeapproachesto diagnosecan be foundin other

domains(such as AI in Medicine,e.g. see [Zhang,1993]).

Theyare often called modelbasedor consistencybased,

since theycontaina qualitative descriptionof the system.

This description, or model,expressedin somelogical forrealism, describes each components

normalbahaviourand

howmodulesinteract. If an observationof an actual system

1. Should not be mixed up with ’true’ machinelearning such as

neural nets.

2. Extends and complementsprevious work such as [Changet. aL,

1989] and [Pazzani, 1986; Pazzani, 1987].

96

state is addedto the descriptionsuchthat the descriptionbecomesinconsistent,there is an error present. Byidentifying

whichcomponent

(or components)

that in conjunctionwith

the observationresults in a contradiction,the set of explanations (faulty components)

havebeenfound. Theexpalnation

is complete,the diagnosecan handlemultiplefaults and

mayevenreviel previously unknown

faults [deKleerand

Williams,1987;Reiter, 1987]. However,it mightsometimes proposeawkward

explanationssince it lacks knowledgeaboutpossibleerrors, or rather, causalrelations.

Addingfaultmodels

[deKleer and Williams,1989; Struss

andDressier, 1990]to the descriptionimprovesthe explanation, but the explanationis nolonger guarantiedto be complete. Thesystemmaynowlabel components

as faulty, correct or either - meaning

it can not decidewhich.

Observations The techniques for diagnose presented is

just a smallsampleof whatcan be foundin the literature.

Characteristicfor the first examples

(failure trees withmodifications andprobabilityvectors) is that the knowledge

is

shallow,that is it is composed

of ’rules of the thumb’or statistics aboutthe system,andthat it is not complete.If the

systemis reconfigured,large parts of the knowledge

has to

be updated.In the failure tree basedapproaches,this could

be handledby specifyingthe diagnoseknowledge

separately for eachmodulein an assemblycell. In a specific configuration, most of the knowledgewouldthen be collected

fromits components,

andonly a smallpart wouldhaveto be

addeddescribingthe current configuration.However,

specifying all diagnosticknowledge

for each moduleis probably

not feasible,andthus theywill still be incomplete

- i.e. does

not coverall failure situations.

In the modelbasedapproach,the knowledge

stored is often called deepknowledge

since it coversthe normalstructure andfunctionof the system.This approachrequires that

the knowledgeis complete, emphasingthe sameproblems

of uppdatingthe systemas with the shallowtechniques.Althoughthis is an even moremorecomputationallyexpensiveapproach,it has gainedinterest sinceit is better suited

for modulardescriptionthan the diagnosticrules above

(e.g., see [Lee,1986]).

Recovery

Theterm(error) recoveryis usedin a moreversatile fashion thanthe twoabove.Essentially,it is the processof ’correcting an error’, i.e. changethe state of the controlled

systemto be consistentwith specifications. If a module

accomplishes

this withoutfailure (i.e. the systemwhich

uses this module/service

nevernotices any error), the module is said to be fault tolerant. If the module

reportsthe

error to someother part of the systemresponsiblefor taking correctiveactions, the systemas a wholeachieveserror

recovery.

Thefollowingsections reviewssomeof the approaches:

placingthe original(failed) part or as a correctivecontinuation of it, andthe programexecutionis then continuedby

Programming

languageconstructs A first step to structhe interpreterin its currentcontext.Thisapproach

is often

ture the handlingof exceptionalsituations in a programming calledplanrepair - andthe idea is to ’remember’

the correclanguageis to introduce a newprogramming

construct, oftion by altering the plan/program.

ten called an exceptionhandler.Uponan error, the control

Delchambre

et. al. presents a backward

error recovery

is transferred to the properexceptionhandler, whichwill

approach[Delchambre

and Coupetz,1988;Gaspartet. al.,

then executecorrective actions. However,in somelanguag1989].It usesa ’flat’ (nonhierarchical)plan representation

es not eventhis supportexists, andthe constructsof the lanwith framelikestructuresrepresentingparts andtheir feaguage has to be used to trap errors and accomplish

tures, and rules describinggeneral assemblyknowledge.

dispatchersfor correctiveactions or default actionst [Cox,

Theplan describesthe assemblytask and is givenby the

1988; Cox1989].

user. Anexample

of a feature definedfor a part is the ’handAttemptshavebeenmadeto introduce a notion of recovability coefficient’,describinghow’easy’it is for the robot

erypoints(or blocks)in a program,specifyinga legal and

to handlethat part. Anexampleof an assemblyknowledge

consistentstate to return to in caseof errors. This maybe

rule is that if a sub-assembly

is to be pickedup, the system

viewedas a weakerversionof the conceptof transactionsas

shouldfocusthe pickingoperationto the part of the sub-asused in the data base community

[Harderand Reuter, 1983],

semblywith the best handabilitycoefficient. Theresponse

andthere is ongoingworkstudyingthe usability of these

to an error is to disassemble

the faulty part (i.e. onlyerrors

conceptsin the automationarea [Schmidt,1992].

causedby faulty parts are handled)by generatinga sequence

In the data base community,

the notion of SAGAS

or

of actions (a plan) to accomplish

this.

nested SAGAS

[Gareia-Molinaand Salem, 1987; GarciaMeijeret. al. presentsa hierarchicalsystemin whichthe

Molinaet. aL, 1991] has beendevelopedand proposedfor

objectsusedin the (a priori given)planis called ’knowledge

modelling

parallel, nestedactivities in a corporationas a

areas’ (KA’s)[MeijerandHerzberger,1988;Meijeret. al.,

data base application. Examples

of suchactivities are re1991]. EachKAis responsiblefor someaction suchas callceivingorders, billing the customerwhileupdatingthe ining a partially orderedset of other KA’sor performingsome

ventory,andso on. In principle,it is a scheme

for specifying

primitivesensingor acting. For eachKAthere is an invocacompensating

activities to be usedin case of an abortionof

tion specification,specifyingwhatgoalsit will fulfill and/or

an ongoingactivity, and to specifyhowthe abortionof one

whatfacts needto existsin orderto use it. If it is a primitive

activitythat is a part of a nestedstructureof activitiesshould

KA,monitorconditionsmaybe specified, as well as a set of

affect the other activities. Thereare nomeansto describe

exceptionhandlingstrategies. Sincethese strategies are

that somealternative activity shouldbe performedwhenan

themselvesrepresentedas KA’s,they contain invocation

activityaborts.

specificationsguidingthe systemto whatrecoverystrategy

Knowledgebased systems The term knowledge based

to use whenthe monitoringconditionssignal an error.

systems is commonly

used to denote any system wherethe

Ahierarchical, framebased approachis proposedby

knowledge

usedis separatedfromthe programthat uses it.

[ChertandTrivedi,1991], whereframesrepresentplanskelThesesystemare often also called rule basedor framebased

etonsof different abstractionlevels. The’planning’consists

systems,accordingto howthe knowledge

is represented.

of selectingappropriate’frames’and’instantiating’ subIn twoearly proposals([Leeet. al., 1983;Gini, 1983])

plans(frames)refiningthe planuntil all leavesare primitive

conventionalrobot system wasextendedby a "knowledge

actionsor perceptions.In this approach,the majordifferand reasoningmodule".Error recoverywasachievedby usencebetweengeneratingthe original plan for an assembly

ing the failure tree produced

in the diagnoseprocess,andby

task andgeneratingan error recoveryplanis that the overall

goalfor the plan is onlyconsideredin the first case. During

augmenting

the explanationswith corrective actions/proceplanningfor error recovery,the maingoal is to achieveany

dures. These’corrections’weredesignedto restore the controlled system(the application)to either a previouslyvisited

errorfree state.

Themaindifferences in the approachestaken by Meijer

state or a state further downthe original program.In both

these approachesthe original robot programis interrupted

andChenis that in the first case exceptionhandlingstrateandthe recoveryis performedby downloading

newinstrucgies are predefinedfor eachprimitiveaction, albeit as more

tions to the robot.

or less generalplans, whilein Chen’sapproachthese plans

In Noreilset. aL [NoreilsandChatila, 1989;Noreils,

are generateduponan error situation usingavailableactions

1990]proposesa variant of the solutionabove.Herethe corandsubplans,but with a somewhat

different goal state than

rectiveactionis insertedinto the originalprogram,

either reduringthe original planning.

I. Examples

are ’longjump’

in Candstructureduse of methods

in

C++.

Graphbased approachesWhenthe task description is

basedon somegraphformalismsuch as a Petri Net or Finite

97

State Machines,somerestricted variants of the approaches

described above apply. In the following, only Petri Net

basedapproacheswill be presentedsince alternative formalismsare often compilable

into a Petri Net.

Petri Nets(PN)is a static description(’basedplaces

and transitions betweenthem,whereaction normallytake

place duringa transition) withoutany exceptionhandling

constructs as can be foundin programming

languages.Thus,

if error handlingis to be usedin a PNbasedapproach,it

mustbe modelledas a part of the normaloperation,andonce

the PNis constructedit can not be arbitrarily modified.Using PN’s,there are four constructsthat canbe usedto encode exceptionhandling [Zhouand DiCesare,1989]:

Input Condition:Whenseveral transitions leaves a

place, it is customary

to select arbitrarily

betweenthem. However,the transitions maybe

augmented

with a condition,whichif satisfied

will favourthe selectionof that transition, and

otherwisereject that transition.

Alternative Path: Usingthe Input Conditionconstruct

above, an alternative path throughthe PNmay

be defined.

Backward

Error Recovery:The two constructs aboveis

used to trap an anomalyand executecorrective

actions (undoingthe problem),returning to

previouslyvisited place in the PN.

ForwardError Recovery: Analogousto Backward

Error Recovery,

but the correctiveaction will

directly solve the problemandreturn control to

the sameplace as wherethe error originated(or

wasdetected).

Petri Nets with backtracking:In [CaoandSanderson,1992]

a systemis presentedwhichgeneratesa PNcontroller from

an assemblydescription representedas an AND/OR

tree. At

eachplace reachedby a transition wherethe transition/operation mayfail, a forwarderror recoveryaction is defined

whichwill try to correct the failure. If the PNstill fails, a

backtrackingapproachis used basedon the augmentation

of

the PNwith inverse transitions (brother transition in [Cao

and Sanderson, 1992]) allowing the system to backtrack

(disassemblingparts) to a previousstate. In the assembly

context, dependingof the parts disassembled,the system

maychooseto redo the assembleoperation with partially

newmaterialas a strategyto correct the originalerror. This

augmentation

of the PNis doneas a part of the generation

of the PNfrom the AND/OR

graph, and can only handle a

subsetof all faults that mayoccurin an assembly

cell. Also,

whenexpandingthe PNwith newplaces and transitions for

handlinganomalies,the resulting net growslarge and complex.

LayeredPetri Nets (LPN)is used to modularizea

98

controlleras severalPN’sresponsiblefor different functionality or modesof operation.In a LPN

a place maybe defined

to be a completePNin itself, defininga complex

action to

be performedwhenthe token reachesthat place. In [Hasegawaet. al., 1990]LPN’sis usedto define separatenets for

normaloperation (an auto-modenet) for exceptionhandling, manualoperationetc., and howto switchbetween

these modes.This maybe viewedas a moregeneral and

structured versionof the exceptionhandlerconstruct mentioned above,since it also handles’manualmode’and any

other modeof operationdesirable.

ModifiableLayeredPetri Nets: In [Zhouand DiCesare,

1 usingthe four error

1989;ZhouandDiCesare,1993]a LPN

recoverymethodsdescribedabovein cooperationwith an

Error Diagnoseand RecoveryPlanning module(EDRP)

presented. Whenan anomalyappears during ’execution’ of

the LPNwhichhas previouslynot beenplannedfor, the

EDPR

moduleextends the original LPNby transforming

parts of it (using the four constructsdescribedabove)

handlethe situation. This maybe viewedas on line ’patching’ of the code,but the authorsclaimthat all propertiesof

the original net (suchas avoidingdeadlocksor buffer over2.

flows)is preserved

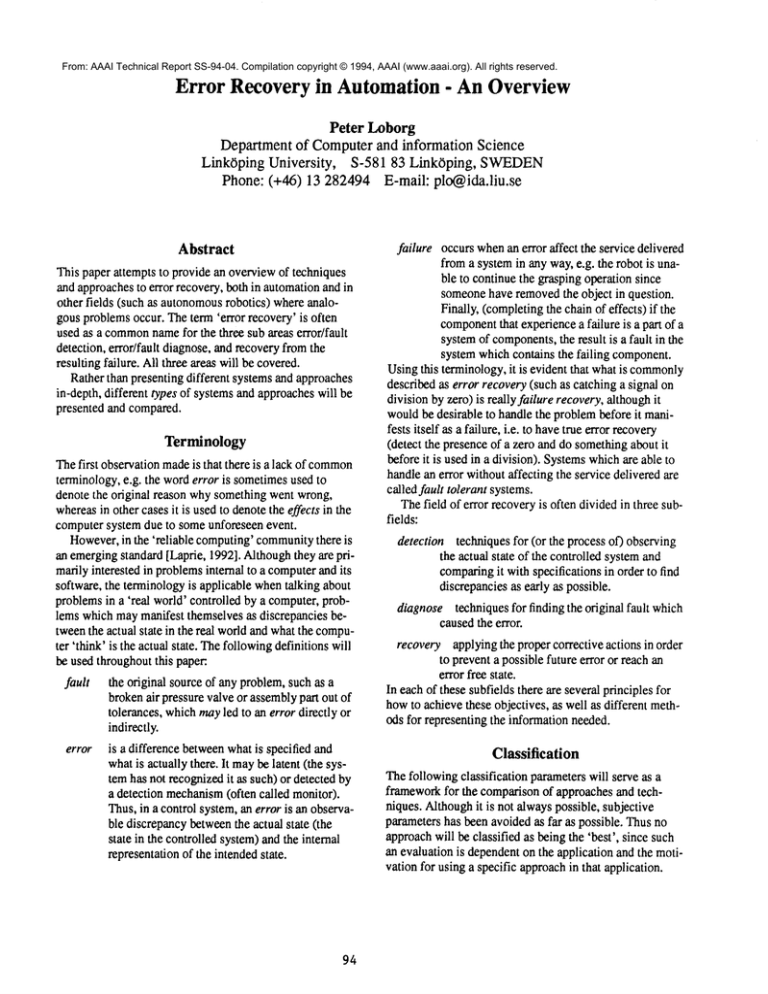

Observations

Table 1: Techniques for recovery after an error

"13qaeof

error

recover

Knowled Is knowlge

source? edgeapplication

dependent

Knowled

gerepresentationt

eehnique

Gini

any

program

Lee

any

us4~r

Not~ils.

Chatila

any

user/system

ycrJno

mles

Delchambre backward

user/system

no

roles.frames

Meijeret.a/.

any

user

?

semofrules

Chcn

any

system

no

plans

Caoet. al.

yea

mles

backward assembly

petrinet

Hasegawa

et. al.

any

user

yes

layered PN

Zhou,

DiC-

any

user/system

yes/no

layered PN,

~ale~

@.sKre

Mostof the techniquespresentedaboveprovideboth back1. Herethe authorsviewstheplaceas aa operationor ongoing

activityanda transitionas aninstantaneouschange

of state

(place).

2. Theoretical

work

supporting

thisis described

in [-Fielding

et. al.,

1988].

ward and forward error recovery. Someof the systems

combinepredefined system information with application

dependent knowledgespecified by the user (Delchambre/

Zhou), someextract it from other available sources such as

the original robot programor assemblydescription(Gini/

Cao). Notable is that very few approachesuses general

error recovery knowledgeonly. Exceptions is approaches

proposed by Delchambreand Chert, witch manageswithout

any application specific error recovery knowledge.In all

other approaches error recovery knowledgeis associated

with each action or each possible error explanation.

Techniquesfor recovery seems to evolve in two directions; techniques based on graph formalismssuch as Petri

Nets, whichhave sometractable properties of provable liveliness etc., and general, plan basedformalisms.In both cases

there are planners involved, which poses a problemsince

1most planners are knownto have problem with soundness

and/or safeness2, and to have intractable complexity(i.e.

they can’t handle large data). However,there are planners

that are safe, and in somedomainseven sound. Andby restricting the semantics of the planning problem,the complexity can be reduced. Promisingworkin this direction can

be found in [Klein, 1993].

Conclusions

In this paper different techniques proposingsolutions to

the error recovery field have been reviewed. Whatthey

share is a completely different view of what to specify and

howto do it comparedwith equipmenttraditionally used in

industry, whichmakesthemhard to integrate into existing

production plants. Although, someattempts have been made

to build industrial applications (e.g. ThornEMI[Ashtonet.

al., 1987], and LookheedAeronautical Systems Company

[Kartak, 1988]), using only the most fundamentaltechniques. As limited as they are, they are still regardedas improvementsto the alternatives given at the time.

As striving towards a moreflexible work cell equipment

yields a more complexinstruction task and a more complex

behaviour, it is essential to find suitable high-level methods

and languagesfor instructing the cell if the flexibility is not

to be lost. Simplyproviding ’hi-level’ languagesused for

programmingcomputers is not enough. The goal must be to

maximizethe expressiveness while minimizingthe specification needed, and thus only leave to the application programmerto specify what is really application dependent

knowledge, knowledgewhich can not be generated from the

design of the product. This in turn implies that different

parts of the system(abstraction levels) is to be specified/instructed by different categories of people, and thus that dif1. Just becausethe plannerdoesnot find a planthere is noguarantee that it doesn’texist one

2. Theplanneris not guaranteed

to halt if a plandoesnot exist

99

ferent languages/forms av descriptions maybe needed - as

opposite to what is suggested in [Cox, 1988].

Concludingfromthis, future research in the area ought to

be heading towards multileyered knowledgebased systems

describing limited domains, systems which is easy to adapt

to a newapplication.

References

[Ashton et. al., 1987] M. Ashton, D. A. Harding and M. I.

Micklefield. A flexible assembly system controller. In

Proceedingsof the 2nd International Conferenceon Machine

Control Systems - MACON-2,

p.165-74, IFS Publications,

Kempston,UK1987.

[Cao and Sanderson,1992]T. Caoand A. C. Sanderson.SensorbasedError Recoveryfor RoboticTaskSequencesUsingFuzzy

Petri Nets. In IEEEInternational Conferenceon Roboticsand

Automation,p.1063-9, 1992.

[Chang and DiCesare, 1989] S.J. Changand E DiCesare. The

generation of diagnostic heuristics for automated error

recoveryin manufacturing

workstations.In IEEEInternational

Conference

on RoboticsandAutomation.p. 522-7vol.1, 1989.

[Chang, 1989] S.J. Chang, E DiCesare and G. Goldbogen.An

algorithm for constructing a failure propagation tree in

manufacturingsystems. In IEEEInternational Symposium

on

Intelligent Control,p.38-43,1989.

[Chang et. al., 1990a] S. J. Chang, G. Goldbogenand E

DiCesare.Evaluationof diagnosabilityof failure knowledge

in

manufacturingsystems. In IEEEInternational Conferenceon

RoboticsandAutomation,p.696-701vol. 1, 1990.

[Chang et. al., 1990b] S. J. Chang, G. Goldbogen and E

DiCesare. Aspects of diagnostic rules for manufacturing

systems: generation, generalization and reduction. In IEEE

International Conferenceon Systems, Manand Cybernetics,

p.78-83, 1990.

[Chert and Trivedi, 1991]C.X.Chelaand M. M.Trivedi. A task

planner for sensor-basedinspection and manipulationrobots.

In Proceedingsof the SPIE- The International Society for

OpticalEngineering,vol. 1571,p. 591-603,1991.

[Cox, 1988] I.J. Cox. C++language support for guaranteed

initialization, safe termination

anderror recoveryin robotics.In

IEEEInternational Conferenceon Robotics and Automation.

p.641-3vol.l, 1988.

[Cox, 1989] I.J. Coxand N.H. Gehani. Exception handling in

robotics. Computer,22(3):43-9, March1989.

[deKleer amdW’llliams, 1987] J. deKleer and B.C. W’dliams.

Diagnosing

MultipleFaults. Artificial Intelligence, 32(1):97130, 1987.

[deKleer and Williams, 1989] J. deKleer and B.C. V~rdliams.

Diagnosis with Behavioural Modes.In Proceedingsof the

1989’thlntenationalJoint Conference

on Artificial Intelligence

(IJCAI89),pp. 1324-1330,1989.

[Delchambreand Coupez,1988] A. Delchambreand D. Coupez.

Knowledge

based error recovery in robotized assembly.In

Proceedings of the 9th International Conference on

Developmentsin AssemblyAutomation - Japan vs Europe;

ProductDesignfor Assembly;AssemblyAutomation.p.349-66.

IFS Publications, Kempston,Bedford,UK,1988.

[Fielding et. aL, 1988] E J. Fielding, E DiCesare and O.

Golbogen. Error Recovery in Automated Manufactoring

through the Augmentation of ProgI’amrned

Processes. In

Journal

ofRobotic

Systems,

5(4),337-362,

1988.

[Meijer and Herzberger, 1988] G. R. Meijer and L. O.

Hertzberger. Off-Line Programming of Exception Handling

Strategies.

In Proceedings of IFAC Symposium on Robot

Control p.431-436, Karlsruhe 1988.

[Frank,

1990]E M. Frank.FaultDiagnosis

in Dynamic

Systems

usingAnalyticaland Knowledge

BasedRedundancy- A

Survey

onsomenewresults.

Automatica,

26(3):459-474,

1990.

[Meijer et. al., 1991] G.R. Meijer, L. O. Hertzberger, T. L. Mai,

E. Ganssens and E Arlabosse. Exception Handling System for

AutonomousRobots Based on PES. In Journal of Robotics and

AutonomousSystems. 7(2-3): 197-209, 1991.

[Garcia-Molina

and Salem,1987]H. Garcia-Molina

and K.

Salem.SAGAS.Proc.SIGMODint.conf.on Management

of

Data,pp.249-259,

May1987.

[Garcia-Molina

et.al.,1991]H.Garcia-Molina,

D. Gawlick,

J.

Klein, K. Kleissner and Kenneth Salem. Coordinating MultiTransaction Activities. Data EngineeringBulletine, 1991.

[Gaspart et. al., 1989] P. Gaspart, A. Delchambre, A. Coupez

and P. Brouillard. Rule based procedures for diagnosis and

error recovery. In Proceedings of MIV-89 . International

Workshopon Industrial Applications of MachineIntelligence

and Vision (Seiken Symposium),p.88-93, 1989.

[Gini, 1983] M. Gini. Recovering from Failures:

A New

Chalengefor Industrial Robotics. In Proceedingsof the 25"th

IEEE Computer Society

International

Conference

(COMPCON-83).

p.220-227, Arlington 1983.

[Harder and Reuter, 1983] T. Harder and A. Reuter. Principles of

Transaction Oriented Database Recovery. ACMComputing

serveys, 15(4):287-317, 1983.

[Hasegawa et. al., 1990] M. Hasegawa, M. Takata, T. Temmyo

and H. Matsuka. Modelling of exception handling in

manufacturing cell control and its application to PLC

programming. In IEEE International Conference on Robotics

and Automation, p.514-19, vol.1, 1990.

[Heyes-Roth, 1990] B. Hayes-Roth. Architectural Foundations

for Real-TmaePerformancein Intelligent Agents. In Journal of

Real-17meSystems, no.2, p.99-125, 1990.

[Iseremann, 1984] R. Isermann. Process Fault Detection based

on Moddeling and Estimation

Methods

A Survey.

Automatica, p.387-404, vol.20, 1984.

[Kartak, 1988] J. A. Kartak. Development of automated

workcell control software: a case study. In Proceedingsof the

18th International Symposiumon Industrial Robots, p.467-91,

1988.

[Klm and Welch, 1989] K.H. Kiln and O. H. Welch. Distributed

Execution of Recovery Blocks: an approach for uniform

treatment of hardware and software faults in real-time

applications. In IEEEtransactions on Computers, 38(5):626636, 1989.

[Klein, 1993] I. Klein. Automatic Synthesis fo Sequential

Control Schemes. PhD-theses no.305, Linktping University,

1993.

[Noreils, 1990] E R. Noreils. Integrating error recovery in a

mobile robot control system. In IEEEInternational Conference

on Robotics and Automation, p.396-401vol. 1, 1990.

[Noreils and Chatila, 1989] E R. Noreils and R. G. Chatila.

Control of mobile robot actions. In IEEE International

Conference on Robotics and Automation. p. 701-7 vol.2, 1989.

[Pazzani, 1986] M.J. Pazzani. Reflnln$ the KnowledgeBase of

a Diagnostic Expert System: AnApplication of Failure Driven

Learning. In 5’th National Conferenceon Artifical Intelligence

(AAA1-86). p.1029-35, 11-15 Aug. 1986.

[PazTarti, 1987] M.J. Pazzani. Failure-Driven Learning of Fault

Diagnosis Hheuristics. IEEE Transactions on Systems, Man

and Cybernetics, SMC-17(3),p.380-394, May/June 1987.

lReiter, 1987] R. Reiter. A Theory of Diagnose from First

Principles. Artificial Intelligence, 32(1):57-95,1987.

[Schmidt, 1992] U. Schmidt. A Frameworkfor Automated Error

Recovery in FMS.In International Conference on Automation,

Robotics and ComputerVision. p. IA.3.4.1-5, 1992.

[Srinivas, 1977] S. Srinivas. Error Recovery in Robot Systems

PhDthesis California Inst. of Tech., Pasadena,1977.

[Srinivas, 1978] S. Srinivas. Error Recovery in Robots Through

Failure ReasoningAnalysis. In Proceedingsof AFIP- National

ComputerConference, p.275-282, 1978.

[Struss and Dressier, 1989] R Struss and O. Dressier. "Physical

Negation" - Integrating Fault Models into the General

Diagnostic Engine. In International Joint Conference on

Artificial Intelligence (IJCAI89), pp. 1318-1324,1989.

[Taylor and Taylor, 1988] G. E. Taylor and P. M. Taylor.

Dynamicerror probability vectors: a framework for sensory

decision making. In IEEE International

Conference on

Robotics and Automation, p. 1096-100, 1988.

[Taylor et. al., 1990] P.M. Taylor, I. Halleron and X.K. Song.

The application of a dynamicerror frameworkto

robotic

assembly. IEEEInternational Conference on Robotics and

Automation, pp170-5, 1990.

[Zhang, 1993] T. Zhang. A Study in Diagnosis Using

Classification and Defaults. PhDthesis no. 302, LinkSping

University, 1993

[Zhou and DiCesare, 1989] M. C. Zhou and F. DiCesare.

Adaptivedesign of Petri net controllers for error recovery in

automated manufacturing systems. IEEE Transactions on

Systems, Manand Cybernetics, 19(5): 963-73, Sept. 1989.

[Laprie, 1992] J. C. Laprie. Basic Concepts and Associated

Terminology. In Dependable Computing and Fault Tolerant

Systems, Vol. 5, Springer-Verlag, WienNew-York,1992.

[Lee et. al., 1983] M. H. Lee, D.P.Bames and N.W. Hardy.

KnowledgeBased Error Recovery in Industrial Robots. In

International Joint Conference on Artificial Intelligence

(IJCAI83). pp.824-26, 1983.

[Zhou and DiCesare, 1993] M.C. Zhou and E DiCesare. Petri

Net Synthesis for Discrete Event Control of Manufactoring

Systems. ISBN0-7923-9289-2, Kluwer AcademicPub., 1993.

[Lee, 1986] M.H. Lee. Deep knowledge modelling in robotics.

In Proceedings of the Alvey IKBS Research Theme: Expert

Systems. Deep Knowledge. Workshop 3Io.2, p.44-50, Alvey

Directorate, London,UK, 1986.

100