From: AAAI Technical Report SS-94-04. Compilation copyright © 1994, AAAI (www.aaai.org). All rights reserved.

Active Rescheduling for Goal Maintenancein

DynamicManufacturing- Systems

ArneF. Claassen, RubyD. Lathon, Daniel M. Rochowiak,

Leslie D. Interrante

Intelligent SystemsLaboratory

University of Alabama

in Huntsville

intert@ebs330.eb.uah.edu

Abstract

organizationbeginsto crumbleas the tasks at hand

begin to pull frommultiplebureaucratic agencies,

The manufacturingplant is viewedas a group of

and the abstract organizational plan meets

interacting subsystems.Theresearch describedin

recalcitrant realities. The constantly changing

this paperis aimedat characterizingthe subsystem workplacecreates demandson the most immediate

interactions such that an intelligent systemcan

bureauto changeits plans, if there is to be hopeof

makeappropriatedecisionsin the face of shopfloor

meetingits goal. Further, the demands

of multiple

contingencies.Thegoal of such decision makingis

bureaucraticagenciesintersect in the workplace,

to insure the meetingof global productiongoals by and the multiple demandswill often, but not

makingreal-time tradeoffs at the level of local

always,require that onebureaucraticagencyinteract

subsystem goals. Manufacturing subsystems

withanother,if either agencyis to achieveits goal

include receiving, shipping, production lines,

(BondandGasser,1988;Durfeeet al., 1989).

maintenance,and material handling. It is assumed

that subsysteminteractions can be captured as B. The Challenge

scheduleinteractions. Activereschedulingis the use

of manufacturing parameters as "cues" for

The constant tension between the a priori

triggering subsystemrescheduling. A distributed

bureaucraticstructure and the a posteriori needto

agent system is described, in which an agent

adapt to newand unforeseencircumstancesleads to

represents a subsystemscheduler. Twoagendasare

a collision of organizational structure and work

employed:onefor the posting of proposedschedule place dynamism

that is especially apparent in the

revisions anda secondagendafor the processingof

manufacturingindustry. Thechallenge is to build

contingencies which must be resolved before

an architecture that represents both the

proposedschedulerevisionscan be accepted.

organization’sstatic structure andthe workplace’s

dynamism.Theorganization’s static structure is

I. Goal Maintenance in a Dynamic

encapsulatedin the agencygivento its bureaucratic

Environment

units. Its units havethe powerto respondto certain

changesthroughprescribed rules used to maintain

A. The Issue

goal states. However, work place events may

requirethat a unit negotiatewith other units in the

The modern world has created numerous

effort to maintainits goal state. In suchcases, the

bureaucraciesto carry out specific local goals that

rules of the agentare not sufficient withinits scope

are believedto contribute to the satisfaction of a

of agencyto handle the situation (Hewitt, 1986;

global goal. Atypical organizationis dividedinto

Star, 1989).

bureausthat are eachchargedwith a particular task.

Wepropose an architecture in whichmultiple

Eachbureau has a specific goal and its actions

agents participate in a hierarchy, havea degreeof

focus on the satisfaction of that goal. Fromthe

autonomyin taking local actions to satisfy local

organization’spoint of view, the satisfaction of

goals, respond to changing conditions, can

eachbureau’sgoal will producethe satisfaction of

negotiatewith other agentsin attemptingto satisfy

the global goal. This authoritarianstructure can be

their local goals, andare subject to the judgments

repeated as manytimes as necessaryto create an

of the agentthat is focusedon the satisfaction of

enterprise where the satisfaction of the most global goals. For our purposes,an agent represents

specific goals will producethe satisfaction of the

the agencyof a unit in an organization.It receives

most global goal. Eachbureausets morespecific

informationandcan vary its operationby reasoning

demandson the bureaus that fall under it by

about the current state and its goal. Further, the

creatingincreasinglyspecific goals.

agent can enter into negotiationwith other agents,

Opposed

to this hierarchicalbureaucraticstrategy if it is unableto maintainits goal state through

is the reality of the workplace. Theworkplace is

local changes commensuratewith its agency. In

constantly changing and placing demandson the

this sense, agents represent organizationalagency

immediate bureaucracy which is attempting to

and not the psychologicalagencyof the human.

satisfy its goal. In the workplace,the bureaucratic

33

Agentsembodyknowledgeand have resources for

communication and negotiation. The latter

characteristic separates themfrom a traditional

knowledge-basedsystem. Each agent has its own

information and knowledge which guides its

actions. Each agent can inform other agents or

request resources. For any particular agent, the

sensors, databases, and actions of other agents

constitute the external world.Theagent’sinternal

world is constituted by the knowledge and

understanding

that it has of its particular task. The

spectrumof organizational modelsof agents in a

systemspans two poles, fromstrictly hierarchical

(agent results reported to a higher level where

authority exists to makedecisions)to planar (agent

results reportedto all other agents; all haveequal

authority). Ourintelligent systemattemptsto avoid

the excesses of these poles. Unlike the focus of

attention in a hierarchical system, agents do take

accountof the rest of the world.Unlikethe focusof

attention in planar systems,agents are constrained

in the actions that they maytake. In brief,

intelligent focusof attention requiresthat agentsbe

awareof their ownresources,goals, andconstraints

in the effort to solve a problemthat potentially

affects the entire collectionof agents(Interrante et

al, 1993a).

C.

Agents and Schedules in Manufacture

Achievement

of the global goals of manufacturing

requires an understandingof interacting schedules

and tradeoffs. Manufacturing

research has produced

manyanalytic techniquesfor generatingindividual

schedules. Typically, however,interactions with

other schedules(with the exceptionof the master

production schedule) are handled by making

assumptionsthat create boundaries.Thescheduleof

interest is thus separated from the schedulesof

other agents andthe dynamism

of the shopfloor.

A scheduler agent views the plant as a closed,

idealized world,in whichcause-and-effectanalysis

across organizational units is ignored. Bounding

assumptions keep the plans and schedules in

relative isolation, and embodyassumptionsabout

the abilities of neighboring subsystems. The

application of rigorous analytical techniques is

normallytightly constrainedby these assumptions

and problemsoccur whenshopfloor events violate

them.

Theconflict of agents is a result of the closedworld assumption that any knowledge not

explicitly representedin the agent nor inferable

from such knowledgeis irrelevant to the agent’s

activity. The closed world assumption can be

mitigatedby providinghigher-orderrepresentations

and reasoningto moderateconflicts amonglowerlevel agents. The closed world is openedto some

34

degree by allowing more heuristic styles of

reasoni-~gto moderateconflicts andviolations of

the boundaries.Suchheuristic techniquesare also

subject to the closed world assumption,but when

combined

with the analytical techniquesin a multiagentsystema "larger" closedworldis created.

II. Negotiating Schedules: An

Architecture

A. Agents

1. Description

The architecture described in this section in

designed to capture manufacturing subsystem

interactions such that appropriatedecisionscan be

madein the face of shop floor contingencies.

Subsysteminteractions are viewedas schedule

interactions for our purposes. Toaid intelligent

rescheduling the rescheduling actions should be

performedin reaction to systemparameters(Smith

et al. 1991)and the schedulingmodelshouldadhere

to the physical modelof the plant (McKay,1993).

Our system includes intelligent,

autonomous

agentsthat negotiateschedulechangesaffecting the

entire system. This design is similar to one

discussedby Burkeand Prosser (1991). In the case

that a proposedschedulechangehas no real "cost"

in termsof inhibiting the goalsof other agents, the

change is implemented with no need for

negotiation. Otherwise,negotiation amongagents

occurs to determine whether a proposedschedule

changeis appropriatein light of its contributionto

the global masterproductionscheduleand its cost

in terms of the effect on related subsystem

capabilities. Unlike bidding schemes, which

attemptto quantifysuchcontributionsand/orcosts,

an overseeing agent employsheuristic schedule

interaction knowledgeto determine whether a

proposedschedule changeshould be implemented.

Informally, such negotiation can be viewedas a

combinationof "taking the easy road" and "doing

the right thing". Eachagent is autonomous

in that

it attempts to protects its beliefs about howits

schedulesshould be organizedand executed. Each

agent represents a manufacturing

system(receiving,

material handling, productionlines, maintenance,

andshipping) and has its ownset of schedulesand

schedulingstrategies for performingthe necessary

rescheduling. In this way, an agent is a selfcontained scheduling unit with the capability of

communicating with the other agents. As in

Zlotkin and Rosenschein

(1991)the negotiation can

result in either one of the agents involvedin the

conflict yielding to the other agent, or a

compromiseof the agent’s goals to promote a

global goal. Unlike Zlotkin and Rosenscheinthis

system utilizes a Superagent to oversee this

stochastic simulation is used as a knowledge

process.

acquisition tool for the schedulingagents, similar

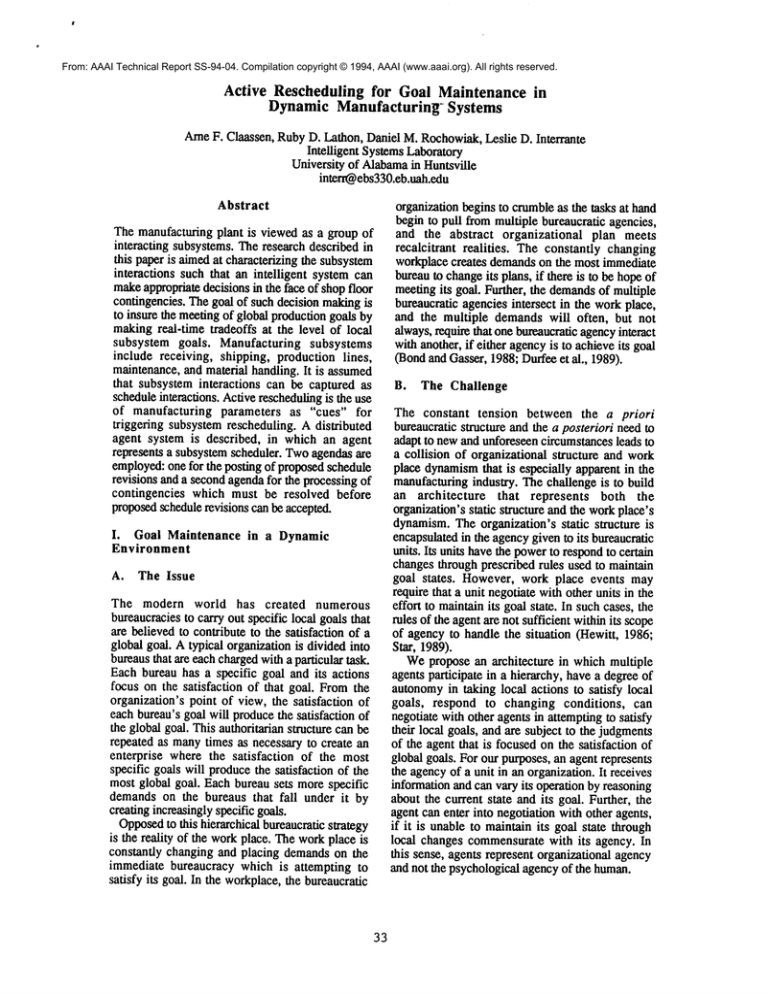

TheSuperagentis similar to the other agents in

to the approachof Nakasukaand Yoshida(1992).

that it contains a schedule and a scheduling

Theschedulingsystemis dividedinto three parts as

strategy, but it is uniquein that its scheduleis the

illustrated below: 1. a Superagent monitoring

masterproductionschedulewhichis preeminentand interactions and analyzing shop floor data, 2. a

embodies the global system goals. It has

committee of subagents that represent the

knowledge

of agent interactions and the ability to

production system and 3. a shop-floor database

adjudicateconflicts among

agents. Adiscrete-event, providing both with necessary state data.

Superagent

ContingencyAgenda

Agenda Controller

(list

of suspended

contingencies

to i~e processed)

(contains knowledge

of muter production

Proposed

Schedule

Agenda

interactions)

(ilsl of suspended

proposed

schedul~s)

¯

4

~

Cue8

nro~r~

edule

Posting

of proposed

schedules

with

contingencies

I

Approval

or

Disapproval

of proposed

schedule

I

Response

to

negotiation

Contingencies

proposed

to

the individual

agents

w

System

Input

Database

(Cues

Floor

Sensors)

Request

for

detailed

data

Detailed

floor

data

Receiving Agent

Shipping Agent

Maintenance Agent

Line 1 Agent

Materials Handling

Agent

¯ ¯ ¯ Line

n Agent

ProductionSystemAgents

~

~(outpuO

Schedule & Strategy changes

Factory floor

(inpu0

Superagent

are entered by a sorting algorithmand pulled fxom

the top of the list one at a time for processing.A

The Superagent "watches" the system and has a

contingency is the result of a newly-proposed

controllingrole in that it triggers reschedulingof

scheduled event; it is a changewhichmust take

the subsystemsand has detailed knowledgeof the

place in a related subsystem(e.g., release of

master productionschedule. It embodiesknowledge committedresource) to accept the proposed new

of the global goals of the productionsystem, the

schedule. A proposedschedule mayhave a number

local goals of the subsystems and how the

of contingencies associated with it. All

subsystemsinterconnect. This knowledge

is used to

contingenciesrelated to a proposedschedulemust

decidewhichlocal goals are moreimportantat any be approved by the affected agent(s) or via

given time to preserve the master production

negotiation before the proposedschedule can be

scheduleif a reschedule

createsa local goalconflict.

implemented.

To manage rescheduling, the Superagent

Negotiation is performedwhena contingency

monitorscue data received fromthe shopfloor to

creates a conflict, whichmaycause a proposed

determineif any of the cue values are critical,

scheduleto be rejected. Robustrepresentation and

indicatinga possibleneedto rescheduleoneor more processingof the contingenciesis vital to improve

subsystems.

When

sucha critical level is identified, the reliability

of the rescheduled system

a messageis sent to the affected subsystemagents. (Drummond,

et al 1993). If a contingencycannot

This messageis a request to reviewthe needfor a

be approvedby the affected agent(s), the Superagent

strategy and/or schedulechangeto return the cue has to use its knowledgebase to resolve the

parameterto an acceptable level. Therequest may scheduling conflict. To preserve the master

cause a revised schedule to be proposedby one or

productiongoals either one of the subsystemswill

more subsystems. If a proposed schedule is in

have to yield its goals or both will have to

conflict with the local goals of related subsystem compromise and change to an intermediate

agents, negotiation is performedwith the help of

schedule.In somecases, neither a single agent or a

two agendas: one for keepingschedules proposed multiple agent compromisecan be reached, in

by the subsystems and one for processing the

whichcase the master productionschedulemust be

contingenciesthat these proposedschedulescreate.

compromised.

Anagendain this context is a queuewhereitems

.

35

3. Committee of Subagents

Each agent contains a variety of scheduling

strategies and a scheduling mechanism. The

schedulingstrategy determinesthe techniqueusedto

schedule subsystemtasks (may be analytical or

heuristic), while the schedulingmechanism

builds

time-basedevent scheduleaccordingthe strategy.

Theagent strives to maintainits local goals when

altering the schedulealoneor both the scheduleand

the strategy.

AGENT

STRUCTURE

SUPERAGENT

BOUNDING ASSUMPTIONS

Schedule

Clu~e 7

strategy

AND/OR Change ?

4

SCHEDULING

MECHANISM

~ Dc t tiled Shop

Floor

Information

SYSTEM

]

DATABASE

H

SCHEDUHNG

STRATEGY

A

B

C

Propmed

Schedule with

Contingencies[

Oursystem contains agents whichrepresent the

Automated Guided Vehicle (AGV) system,

production lines, receiving, shipping, and

maintenance. For agents that contain multiple

schedulingstrategies to choosefrom,a requestfor a

schedulechangemayinvolvea different strategy, a

different scheduleor a combinationof both, as in

the accompanyingfigure depicting a subsystem

agent. Eachagent maintainsa time-basedschedule

for its manufacturing

subsystem.

The Superagent sends the subsystem agent a

request for reschedule based on cue parameters,

along with the cue values. Theagent then solicits

relevant detailed informationfrom the shopfloor

databaseto determinewhethera schedulechangeis

warranted. The agent determinesif a scheduling

change,a strategy change,or both needto be made.

The choice of scheduling strategy is based on a

comparison

of state conditionswith eachstrategy’s

bounding assumptions, and on knowledgeof the

conditionsunderwhicheach strategy performsbesL

Theappropriate schedulingstrategy is determined

and the scheduling mechanism develops the

scheduleaccordingly.Relatedcontingenciesarise in

two ways: the agent’s knowledgeof howcertain

36

changes in its subsystem propagate to related

subsysi’dmsand notification of an inability to

achieve prior commitmentsto other subsystems

because of the proposedchange(s). The proposed

schedule, along with any contingencies,is sent to

the Superagent,whichwill then acceptor reject the

schedule in the mannerdescribed in the previous

section. If the schedule is accepted, it will be

carried out as planned, otherwise the agent will

revise its schedule and resubmit it to the

Superagent. Ourpast research has focused on the

material handling (AGV) subsystem. The

remainingagents are currently underdevelopment.

The AGV

agent’s structure is comprisedof two

sections: the AGV

strategy selector and the AGV

scheduler. The strategy selector is designed to

dynamically adjust the AGVdispatching and

mutingstrategy in real time suchthat eachstrategy

is used whenit is most effective, resulting in

improvedpart throughputand reducedAGV

arrival

time. The AGVagent’s rule-based reasoning

utilizes output data from a series of empirical

simulationexperiments(Interrante et al, 1993b).

new strategy will be considered whenever a

significant changein a parameterassociated with

AGV

performanceis detected (a cue parameter),

such as a consistently low utilization value. The

AGV

scheduler handles the rescheduling of events

becauseof contingencies imposedby other agents

andminorinefficiencies, such as a productionline

not receivingorderedparts.

Thestrategy selector is a five-level structure

whichis constructedas a decisiontree. Theswategy

selector is triggered wheneverthe Superagent

informs the AGVagent that there is a problem

with a "cue" parameter.Thecue parametersinclude

AGV

utilization, AGV

arrival time, localized line

prioritization, localized order amount(to create

congestion), level of backorders, AGV

breakdown

rate, production line breakdown

rate, and overall

order volume. The AGVagent then retrieves

detailed informationon all of the cue parameters

fromthe systemdatabaseanduses it as input to the

decision tree. The parameters are analyzed and

propagateddownthe tree basedupona set of rules

and information drawn from the simulation

experiments. Oncepropagationis complete, a new

strategy is selected. This newly-cbosenstrategy

will perform best under the current shop floor

conditions.

The AGVscheduler is triggered wheneverthe

AGV

agent receives a request for reschedule or a

contingencyimposedby other agents. The agent

accesses its database and checksthe AGV

schedule

and the availability

of the AGVs.The AGV

agent’s scheduleis reactionary andbased uponthe

orders currentlyplacedfor part delivery.It is only

madefor a short period of time. The schedule

B. Reasoning Processes

of cuesreachescritical levels, the Super’agent

sends

out re~fiests for rescheduling to the affected

subsystems.Thecritical level for each cue depends

on whether it occurs in combinationwith other

critical cue values and is based on knowledge

acquiredfromexperiencedmanufacturers(Interrante

et al, 1993a).Therequest for reschedulingtells

subsystemagentto evaluate its current performance

and determinewhetheritsschedulingstrategy, its

schedule,or both needsto be adjusted.

1. Active Rescheduling

2. Negotiation & Conflict Resolution

contains knowledgeabout the assignmentsof each

AGV.

Withthis information, the agent determines

its ability to carry out the request. It thensendits

response to the Superagent,whichwill be one of

the following:"yes, I can makethe change,""no, I

cannot makethe changedueto lack of a particular

resourceor a scheduleconflict," or "yes, I canmake

the changeff a particular contingency

is met."

Thenew, as yet unaccepted,scheduledevelopedby

Theterm "active rescheduling"is motivatedby the

workof Swain,Bailard, and others (Swain,1991; a subsystemagent is sent to the scheduleagendaof

BaUard,1991)in active vision, whereby"cues" are

the Superagent. Theschedule is accompanied

by a

identified and used to enhanceperformancein the

set of the previously-scheduledevents that were

movedin rescheduling (which mayaffect other

recognition of objects from visual images.

Reschedulingis a non-value-addingactivity and agents). Suchchangesmaybe the result of the need

shouldbe minimized.Yetthe reschcdulingfunction for a resource for an alternate purposethat its

original intent. Theseevents are the contingencies

is essential because of the dynamics of

manufacturingsystems. Weemploymanufacturing that are mutedto the contingency agenda. Each

contingencyis stampeduponreceipt to identify the

parameters as cues to trigger a reschedule for

time of receipt and the schedulewith whichit is

particular subsystems.This approachsimplifies

the process of deciding whichsubsystemneeds to

associated. Theagendaprocessingmechanism

sorts

contingenciesby their id stamp,temporallocation

be rescheduled based on current shop floor

conditions. Onceit is determinedthat a reschedule and priority of the contingency.Contingenciesare

is required,the actual reschedulingprocessinvolves removedfromthe stack one at the time, starting

with the top-most contingencyat the time of the

manymoremanufacturingparameters.

Tochoosethe right time for changinga schedule, next processingcycle (i.e. everytime a contingency

is finished processing,the current top-mostitem is

the Superagent continuously monitors the cue

parameters(Interrante et al., 1993a),an indication removedfrom the agenda)and processed. Theflow

of which subsystems are in danger of running

of information in the agenda system of the

is

depicted

below:

behindtheir schedule. Whenone or a combination Superagent

Schedule

fromLine 1

to AGVagent

1

scheduleproposal

AGV

contingency

from

from

from Line 8

1 contingency

AGV

AGV

contingency

Line 8

0

0

0

0

0

0

to Line 6 agent

_---to Maintenance

agent

agerlL

toReceiving

~ AGVagent

to Line2

8 contingency

contingency

8 contingency

to Receivingagent,~

to ShippingAgent

lab.._

O

The processing of a contingencyis performedby

proposingthe changeto the affected sub-systems.If

the change is not acceptable to one or more

subsystem agents, the Superagent proceeds by

beginning negotiation. It employsknowledgeof

37

the goals of each sub-system and the cost of

proposedchangesin light of the affected goals.

Usingthis informationthe conflict is resolved by

either forcing oneof the systemsto accept the new

eventandaccordinglyadjust the rest of its schedule

(forfeiting its goal for the goodof the moreglobal

"Intelligent

Control of AGVs:Dynamic

goal), forcing all involved systemsto reschedule

Sc’fi-eduling via Selective Attention".

the event in compromise,or relaxing the master

Proceedings of the 1993 NSF Design and

production schedule. Onceall contingenciesof a

Manufacturing Systems Conference, Volume

particular schedulehavebeenresolved,the schedule

2, 1993.

agendais given permissionto resumethe suspended Intermnte, Leslie D., Daniel M. Rochowiak,and

scheduleand return it to the senderagent as the

Ben Sumeral. "Scheduling of Automated

approvedschedule.

Guided Vehicles for Material Handling:

DynamicShop Floor Feedback". To appear in

III. Conclusion

ComputerControl of ManufacturingSystems.

1993.

Muchresearch remains, including the development Law, Averil M. and W.David Kelton. Simulation

of additional subsystemagents, the controlling of

Modeling & Analysis. NewYork, McGrawpropagationof contingenciesand schedulechanges

Hill, 1991.

and the handling of contingency and schedule

McKay,KennethN., "The Factory from Hell - A

satisfaction in time. Boththe scheduleagendaand

ModelingBenchmark",Intelligent, Dynamic

the contingency agenda must be dynamically

Scheduling for Manufacturing Systems

updatedto reflect the fact that the processingof an

Workshop,1993.

agendaitem will alter the validity of someof the

Nakasuka, Shiniehi and Taketoshi Yoshida,

remainingitems.

"Dynamic

scheduling system utilizing machine

Wehave described an architecture which is

learning as a knowledgeacquisition tool",

intended to model subsystem interactions in

International Journalof ProductionResearch,

manufacturingsuch that shop floor contingencies

Vol. 30, No. 2, 1992.

can be appropriately handled by an intelligent

Romero,Iv(m S. and Nilda R. Romero."Chrysler

schedulingsystem.Ourapproachaddressesthe need

Acustar Simulation Model Development"

to balancethe a priori bureaucraticstructure andthe

Technical report, University of Alabamain

a posteriori need to adapt to newand unforeseen

Huntsville, Intelligent SystemsLaboratory,

circumstancesin manufacturing.

1993.

Smith, Stephen F., MarkS. Fox and Peng Si Ow,

References

"Constructing and Maintaining Detailed

AutoSimulations, Inc. AutoModUser’s Manual

ProductionPlans", A/Magazine,Fall 1986.

and Lesson’s Manual.

Star, S. L. "The structure of ill-structured

Ballard, D. "Animate Vision," Artificial

solutions: boundaryobjects and heterogeneous

Intelligence, Vol48, 57-86, 1991.

distributed problemsolving." In Gasser,L and

BondandGasser,DistributedArtificial Intelligence.

Huhns, M. (eds) Distributed artificial

MorganKaufman,1988.

intelligence Vol 2, London:Pitman, 37-53,

Burke, P. and P. Prosser, "A distributed

1989.

asynchronous

systemfor predictive andreactive Swain, M. Proceedingsof the NSFActive Vision

scheduling", Artificial Intelligence in

Workshop,Chicago, IL, August, 1991.

Engineering,Vol. 6, No.3, 1991.

Wemer,E. "Cooperatingagents: A unified theory

Drummond,

Mark, John Bresina, Keith Swanson,

of communication and social structure."

"Contingent Scheduling: Opportunities and

Research notes in Artificial Intelligence,

Issues", Intelligent, Dynamic

Schedulingfor

Distributed Artificial Intelligence, Morgan

ManufacturingSystems Workshop,1993.

Kaufman,1989.

Durfee, E., Lesser, V. and Corkill, D. "Trendsin

Wilson, Carlton M., ThomJ. Hodgson, and

cooperativedistributed problemsolving," IEEE

Russell E. King, "A Note on Incorporation of

Transactions on Knowledge and Data

Improved Information in the Control of

EngineeringI, 63-83, 1989.

Multiple Vehicle AGVSystems". NCSU

Egbelu, Pius J., and Jose" M. A. Tanchoco.

TechnicalReport#90-14,North CarolinaState

"Characterizationof AutomaticGuidedVehicle

University, 1991.

Dispatching Rules". International Journal Zlotkin, Gilad and Jeffrey S. Rosenschein,

Production Research, Volume22, Number3,

"Cooperation and Conflict Resolution via

359-374,1984.

Negotiation AmongAutonomousAgents in

Hewitt, C. "Offices are open systems." A CM

NoncooperativeDomains",IEEETransactions

Transactionson Office Information Systems,

on Systems, Man,and Cybernetics, Vol. 21,

Vol 4, No3, 271-287,1986.

No. 6, November/December

1991.

Interrante, Leslie D. Daniel M. Rochowiak,John

S. Rogers, and Lysle E. Shields III.

38