From: AAAI Technical Report SS-94-04. Compilation copyright © 1994, AAAI (www.aaai.org). All rights reserved.

Two Years On-line:

a Dynamic Scheduler for a Hot Steel Mill.

Virginio

Chiodini

GensymCorporation

125 Cambridge Park Drive

Cambridge, MA02140

Abstract

have a very high efficiency, capable of

dynamically switching their operating modes

betweencontinuous, intermittent, and batch. The

layout of the plant is shownin Fig.1.

This paper describes the development,and

installation of the 5 Mill Scheduler, a dynamic

schedulingapplication for a hot steel mill. The

mainobjective of the scheduler is to dynamically

generate,and revise schedules,,and makeeffective

use of the resources of the phant, while satisfying

a complexset of constraints dealing with the

dynamicbehavior of the resources and the material

processingspecifications. The design of the

system evolved from a knowledge-basedapproach,

,as suggestedby the user, to a constraint-based

reasoning approach embeddinguser supplied

heuristics to prunethe search space. The

constraint-based approachprovedto significantly

outperform a pure knowledge-basedapproach. The

goal of the scheduler wasto operate on-line,

closely linked to monitoringdevices. The

installation of the scheduler required some

refinements of the design to cope with imprecise

data and with the needto providegreater flexibility

to the operators in dealing with resource

constraints. The scheduler was installed in

February 1992 and has been continuously

operating on-line since that date.

1. The application

Eachpiece of material has to arrive at the mill at a

precise time to ensure proper material

compositionof the steel and to keep the roiling

mill fully utilized. A sophisticated SCADA

systemmonitors each individual piece, from the

momentit is loaded into one of the furnaces to the

momentit exits the roiling mill. At Number5

Mill, schedulingthe furnaces is a mission-critical

task. The complexityof the problemis defined by

the numberof constraints and the frequencyof rescheduling. Manytimes a day, neworders ,are

entered and the current schedulesmust be revised

within the constraints imposedby the ongoing

implementationof the current schedules.

2. The Design of the 5 Mill Scheduler.

The scheduling probleminvolves scheduling a set

of jobs J=(J1.... ,Jn) on a set of resources

RES=(R

1 ..... Rm).Eachjob Ji, originated by ,an

order, consists of a set of tasks

TK=(TK

1 ..... TKw),one for each operation in the

process plan of the ordered product.

domain.

Number5 Mill is a hot rolling mill. It heats

billets and ingots to required temperatures,

accordingto specific heating cycles, and then runs

themthrough rolls to reduce the cross-section

,areas of the material to customerspecification.

Twoalternative problem solving approaches were

considered: a heuristic dispatching (knowledgebased) approachand a conslraint-directed search

approach.

The knowledge-basedapproach solves the

scheduling problemby iterating over each resource

,and deciding whichtasks amongthose still to be

scheduled should be processed next by the resource

itself. The decision is basedeither on heuristic

knowledge,usually encodedin the form of rules,

derived from domainexperts or from Operations

Researchheuristics. The scheduling process is

monotonicand is able to produceschedules fairly

quickly. However,its absolute reli,ance on

heuristics ,and its inability to evaluate,alternative

The Number5 Mill is a multi-faceted operation

with a wide product range:

50 different heating cycles covering 350 grades of

steel, with processing temperatures ranging from

1500°F to 2425°F.

16 furnacesof four different types, with a variety

of dymuniccharacteristics ,and throughputrates,

feed two hot rolling mills. Someof the furnaces

27

decisions maygenerate poor schedules.

Furthermore, heuristic knowledgeis context

dependent,and mayrequire extensive revision

wheneverthe structure ,and dyn,’unicsof the

production process change.

The Constraint-directed search approachto

schedulingis describedin [1, 2, 3, 4, 5, 6, 8, 9].

Usingthis approach,a task is described ,as a vector

of the followingvariables:

¯

Theset of different resources

(R=(R1..... Rk)}requested to performthe

operation associated with the task.

¯

Theset of time-intervals

{T=(T1

..... Tk)} during which each one of

the required resources is demanded.

Wepreferred a constraint-search approachversus a

heuristic dispatching approach, because we

estimatedthat a constraint-directed search process

could generate better schedulesand that user

supplied heuristics could effectively be used to

guide the search-process.

The scheduling engine performs the constraintdirected search by iterating over the following

cycle:

Eachvariable mayassumea finite (discrete or

continuous) domainof vaiues.

Ri:[ rkl ..... rin }, Tj: { Tj1 -- Tj2}.

A dech’trative hanguagebased on consistency

techniquesoffers substantial advantagesover a

heuristic approach:

¯

Constraints can be formulated in

symbolic manner, enabling a more

intuitive and natural formulation of the

problem.

¯

Applications,are easily modifiedand

extended, due to the separation of the

definition of constraints from the wayriley

,are applied.

¯

Control of knowledgecan be stated in a

declarative form, enablinga fast

tailoring of scheduling,algorithms to

specific problems.

heuristics is to select for a specific variable a

value that leaves the largest numberof solutions

opento the variables still to be processed.

Conflict resolution strategies are activated

wheneverthe constraint-directed search is unable

to find a vulue to assign to a specific variable.

Conflict resolution strategies performan

intelligent backtracking, changingthe sequencein

whichvariables ,am processed and/or the values

assignedto the v,’u-iables

1.

Select a task to be scheduledapplying

variable orderingheuristics.

2.

Applybackwardconsistency enforcing

procedures.

3.

If no reservation is available for any of the

requested resources then

3.1 relax constraints and/or

select a conflict

resolution method.

3.2 go to 1,

.

Becausethe scheduling problem is an NPcompleteproblem,a constraint-directed search

could take exponential time in the worst case.

However,both experimental and empirical studies

indicate that, on the average, the ,amountof

searchingrequired to find a solution can be

significantly reducedby judiciously selecting the

order in whichvariables ,are processed(variable

orderingheuristics), the values that are assigned to

the variables (value orderingheuristics), ,and the

conflict-resolution method(repair method)to

used wheneverthe search process encounters a

de’d-end.

Select the reservations for the task

(resource and time interv,’d) applyingvalue

orderingheuristics.

5.

Applyforward consistency enforcing

procedures.

6.

If a dead-endis detectedthen

6.1 relax constraints and/or select a

conflict resolution method.

6.2 go to 1.

.

Create a new search skate by adding the new

reservation assigmnentto the current partial

schedule.

Backwardconsistency checks the availability of

values to be assigned to a variable, checkingthe

constraints against the variables already processed.

Forwardconsistency checks the availability of

values for the variables still to be processed,

Variable ordering heuristics alwaysfocus on the

variables that are the mostdifficult to process, to

avoid building partial solutions that cannot be

completedlater on. The goal of the value ordering

28

checkingthe constraints against the value selected

for the variable being processed.

Constraints relaxation simply reformulates part of

the scheduling problem,increasing the size of the

solution space by relaxing soft constraints.

Constraints,are relaxed accordingto a priority that

takes into accounttheir cost ,and the probability of

m~kingthe search process converge toward a

satisfactory solution. For examplein the 5 Mill

application possible constraint relaxations

included:

The Process Modeldescribes the structure,

behavior, products, ,and goals of the m,’mufacturing

system to be scheduled. The Process Modelis

definedby selecting ,and extendinga predef’med

library of object classes. Followingthe

representation schemedescribed in [7], the main

predefinedobject classes are:

States: defining the fin,’d products of the

manufacturingprocess (for example: FinishedSteel) and the intermediate stages through which

the process must proceedto reach a final product

(for example:Hot-steel).

- Increasing the nominalcapacity of some

Operations:defining the activities required to

performtransitions betweentwo states. For

examplethe Rolling operation transforms Hotsteel into Finished-steel. The graph of operations

required to performall the state transitions

necessaryto reach a product is called a "process

plan",

reSOUrCeS

- Extendingthe conditions under which tasks are

allowedto be batched together.

The 5 Mill Scheduler applies two conflict

resolution methods:

- ResoUrcePermutation.

- Push Forward

The Resource Permutation methodsaves the

current status of the search process,and iteratively

identifies conflicting set of tasks, selects a task in

the conflict set for whichalternative resource

selections are possible and ch,angesthe resource

,assignment. The iterating process terminates when

the original dead-endis removed,or a user defined

time period assigned to the conflict resolution

methodexpires, or ,an infeasibility conditionis

identified.

The use of the Resource Permutation methodwas

promptedby the diversity in the structure ,and

dyn,’unicsof the resourcesavailable for ,an

operation. A changein the resource selected to

perform,an operation maydramatically,affect the

search process, improvingthe global utilization of

the resources beyondthe capability of the value

orderingheuristics.

Whenthe Resource Permutation fails to remove

the dead-end situation, the Push Forwardmethod

is invoked. The Push Forwardmethoditeratively

shifts the scheduleof conflicting sets of tasks, ,and

possibly the schedule of their downstreamtasks,

forward in time. The possible outcomeof this

methodis a set of delays forced in the requested

flow of the mill, ,and therefore a lowerquality

schedule.

3. The Modeling Scheme.

29

Resources:defining the physical entities

required to perform an operation. Examples

include machines, manpower,,and tools. Each

operation mayrequire multiple resoUrcesand each

resource maybe requested by operations belonging

to different process plans.

Orders:requesting the creation of instances of

specific states (order’s final state). Ordersmay

directly request the instantiation of the final state

of a process plan or of any one of its intermediate

states. Ordersmayspecify a due-time, a releasetime (the earliest time at whichoperations

requestedfor the order maystart) and a priority.

Constraints: providing a set of declarative

assertions defining the dynamicbehavior and

constraints of the process to be scheduled.

Constraints are logically divided into unary

constraints that unconditionallyrestrict the

domainthat a scheduling variable mayassume(for

example:the set of furnaces allowed to process a

certain grade), and binary constraints expressing

mutual dependencies between the domainsof two

variables (for examplethe set-up time betweenthe

rolling of two different grades of steel). Someof

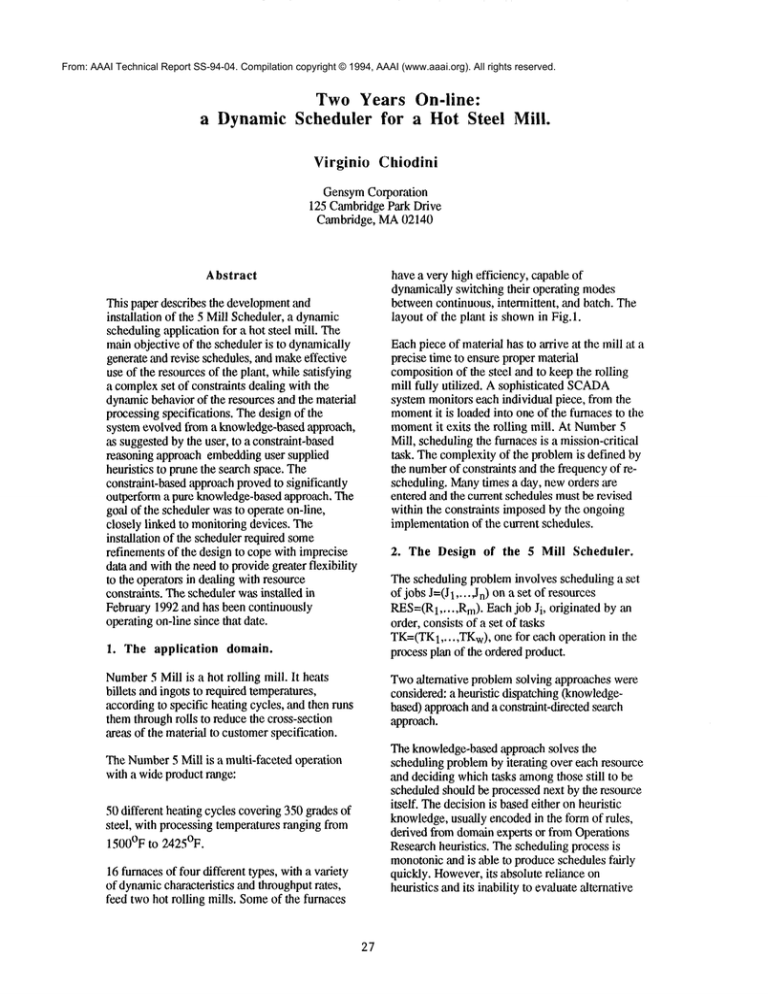

the constraints used by the 5 Mill Schedulerare

shownin Fig. 2.

Task Focus Guidelines: defining the variable

ordering heuristics. Guidelinesare cailed at the

beginningof each scheduling cycle to select the

tasks to be scheduledduring the cycle and the

sequence in whichthey should be scheduled.

Guidelines specify also whether tasks should be

scheduled Just in Timeor As Soon As Possible.

In the 5 Mill Schedulertasks are scheduledjust in

time in a sequencedefined by a fixed set of

variable orderingheuristics:

the manufacturingsystemand, in particular,

the complex dynamic behavior of some

resources could be accurately def’med,without

the simplifying descriptions and assumptions

required by the heuristic approach.

1. Tasks with ,an available numberof resources

belowa defined threshold.

2. Tasks with an available slack belowa defined

threshold.

All the other tasks ,are scheduledin ,ascendingorder

of late-finish-time.

Resource Preference Guidelines: defining

the value orderingheuristics for the resourcesto

be ,assigned to performa task.

Both constraints ,and scheduling guidelines may

include action procedures,,allowing the user to

express complexevaluation functions. In the 5

Mill Schedulerthe definition of action procedures

was facilitated by a natural languageinteractive

editor ,and by a variety of graphictools available

in G2®,the software platform used for the

development.

2) Anaccurate constraints definition increased the

domainsize of somevariables. Actually, it

becameevident that in manycases the number

of alternatives available to the operator before

the installation of the 5 Mill Schedulerwas

limited by the need to managethe complexity

of constraints, rather than by the structure ,and

dynamicsof the manufacturing process. The

SchedulingEngine, enforcing the actual

material and resource constraints, wasable to

generatea larger variety of scheduling

solutions, withoutdeteriorating the qu,’dity of

the schedules.

3) Thevariable ,and value ordering heuristics

proved to be very effective. In almost 60%of

the cases, the SchedulingEngineis capable of

finding a feasible solution without

backtracking. In 20%of the cases, constraints

relaxation and the ResourcePermutation

methodare able to improvethe schedule over

the value ordering heuristics within the time

limit ,allowed.

In the 5 Mill Scheduler, the Process Modelis

defined ,and updatedin a special ModelEditing

Session and compiledinto efficient run-time

control structures.

During the initial phase of operation, two minor

changesin the design of the application became

necessary.

4. The Installation

and Operation of the

5 Mill Scheduler.

The 5 Mill Scheduler was installed in February

1992and has been continuously operating on-line

since that date. The schedulingfunction is

automaticallyactivated whena set of orders is

released. Whena scheduleis completed,it is

revised by the operator. The operator mayfirm or

change the scheduling decisions made. When

changes,are applied, the operator resubmitsthe set

of orders to be scheduled.In this case, the firmed

scheduledecisions ,and the applied changes,are used

by the 5 Mill Scheduler,as additional constraints

to be satisfied in the search for the schedule. On

average, ulmost 5%of the schedules are manually

edited by the operators.

The installation and the operation of the scheduler

confirmedthe validity of the constraint-directed

search approachfor the specific domain.

1) A declarative constraint languageenabled

moreintuitive ,and natur,al formulationof the

problem, simplifying the knowledge

,acquisition phase. Oncethe conslxaint-based

approachwasdecided, the dyn,’unic behaviorof

3O

The first change was madeto support the schedule

editing capability. Althoughschedule editing

capabilities were provided by the 5 Mill

Scheduler,an existing interface not interacting

with the scheduler was preferred to minimize

changes to the operator’s environment.Schedule

changes,are therefore applied outside the control of

the SchedulingEngine, at times violating capacity

constraints. Constraints violations are detected

during the reschedulingphase. In this phase, the

imperative nature of the schedule changes prevents

any explorations of alternative solutions, causing

irrecoverable dead-endsin the search process.

While somemanual schedule changes ,are

consequencesof errors, other ,are forced by the

occurrence of abnormalsituations. To overcome

the problem,,an "override" attribute was addedto

the constraint object definition. Whenan override

action procedureis defined and the Scheduling

Engine encounters a constraint violation caused by

the imperativedecision of an operator, a w,’u’ning

messageis issued, and the confirmation of the

intention to violate the constraint is requested.

Supporting this functionality required minor

"Look-aheadTechniques for Microopportunistic Job Shop Scheduling".

PhDthesis, School of Computer

Science, Carnegie Mellon University,

March 1991.

changesto the SchedulingEngine,and to the

Process Model.

The second changewas applied to provide greater

flexibility ,and autonomyin the selection of

resources by the operators. "Constraints Filters",

interacting with the action proceduresof some

constraints, enabledthe operator to graphically

modifythe resource selection criteria based on

product attributes like grade and temperature. The

Constraints Filters enabledthe operators to

dyn,-unically changethe selection criteria, without

requiring ,any ch,’mgesto the model.

[7]

Sathi, A., Fox, M. S., Greenberg, M.,

"Representation of Activity Knowledge

for Project Management."

IEEETransaction on Pattern Analysis

and MachineIntelligence, September,

1985.

[81

Smith, S. F., Ow,P. S., Muscettola,

N., Potvin, J. V., and Matthys, D.,

"An Integrated Frameworkfor Generating

and Revising Factory Schedules",

Journal of the Operational Research

Society,41(6), June 1990.

[9]

Zweben,M., Davis, E., and Deale, M.,

"Iterative repair for Scheduling,and

Rescheduling".

Technical Report, NASAAmes Research

Center, MS244-17, Moffett Field, CA

94035, 1991.

The 5 Mill Scheduler has been developed on top

of GensymCorporation’s G2®and is operating

TM 3800. It served as a prototype for

on a VAX

TM,

DSP a G2-baseddyn,’unic scheduling product

currently under developmentat Gensym.

References.

Chiodini, V.

"SCORE:An Integrated System for

Dynamic Scheduling and Control of

High-VolumeManufacturing".

Proc. 5th IEEEConf. on Artificial

Intelligence Application (Miami), March

1989, pages 271-278.

[21

VAX

is a trade-mark of Digital

Equipment Corporation.

G2is a registered trade-mark of Gensym

Corporation.

Fox, M. S., ,and Smith, S.F.,

"ISIS: A Knowledge-BasedSystem for

Factory Scheduling",

Expert Systems, 1 (1), July 1984,

pages 25-49.

[31

Fox, M. S., Sadeh, N., Baykan, C.,

"Constrained Heuristic Search"

Proceedingof the Eleventh International

Joint Conferenceon Artifici,’d

Intelligence, 1989, pages 309-315.

[4]

OwP.S., Smith, S. F., and Thiriez, A.,

"Reactive Plan Revision",

Proceedings AAAI-88,St. Paul, MN,

1988.

[5]

Sadeh, N., Fox, M. S.,

"V,’uiable and ValueOrderingHeuristics

for Activity-based Job-shop Scheduling".

Proceedingof the Fourth International

Conference on Expert Systems in

Production ,and Operations Management,

Hilton HeadIsland, S.C., March1990,

pages 134-144.

[6]

Sadeh, N.,

DSPis a trade-mark of Gensym

Corporation.

31

Definitions

States

furnace

batch-furnace

resource

Process

Plan

continuous-furnace

mill¯

"WZ"

"H"

"MILL1"

"MILLZ"

"W3"

"W4"

"W6"

Definitions

Constraint

States

Process

Plan

"Z0-ton-flow-gap"

Resources

"20-ton-flow-delay"

"bFfinish-Lime-delay" "BFnon-overlapping"

N

H

Guidelines

"BFUtJllz. DepP. Time" "HeaLing

Processtime"

Data Interface

Displays

CloseModel

B

"zoton oul]owrate"

N

H

"a tonoutflowrate"

N

"Z0ton uLilizaLion""8 ton utilization" "4 ton utilization" "1 ton uLillzatlon"

H

N

N N H

N

N

"started-by HSM""finished-by SMMilling"

N

N

N

milling-set-up-Lime mlll-outnow-rateassert-mill-transition-task

mlll-lnl]ow-rate

N

H

N

furnace-doors-coupling

"HeaLingLot splitting" Idle-resource max-heaLing-duration

"mlHow-rate"

N

"dooruLillzation"

N

N

32

"milHlenup"

N

mlll-utillzaLion

N