57 A FIELD PLOT SPRINKLER IREGATOR Riley J. W. Wolfe

advertisement

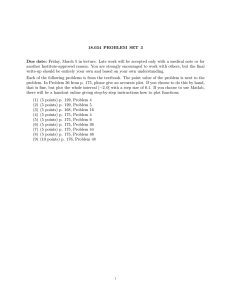

57 A FIELD PLOT SPRINKLER IREGATOR J. P. Riley J. W. Wolfe Miscellaneous Paper No. 57 September 1958 Agricultural Experiment Station Oregon State College Corvallis The research reported in this manuscript was sponsored in part by Western Regional Research Project W-28, eleven Western States, Hawaii, and U. S. Department of Agriculture, cooperating. A FIELD PLOT SPRINKLER IRRIGATOR by J. P. Riley and J. W. Wolfe* Introduction Moisture control and evaporation is one of the most difficult variables to control in irrigation research. This difficulty has resulted from the usual methods and techniques of applying irrigation water to field experimental plots. These methods have usually employed conventional farm equipment of rotary sprinklers or perforated pipe. These are satisfactory at the farm level where precise amounts of water applied are not critical, and inequalities of distribution are not apparent in the over-all yield. In experimental purposes, where close control of the variables is necessary, these methods have many disadvantages. Uniformity of water application by rotary sprinklers or perforated pipe is not ideal for experimental work. This uniformity is further affected when the rate of application exceeds the soil infiltration rate and puddling results, or the pattern of distribution is altered by winds. Also, these methods require large experimental plots or they must be spaced at great distances apart. The first alternative requires a split-plot experimental design, while under, the second the soil variability between plots is increased. Because of the obvious need in irrigation research for a tool which would apply a precise amount of water at a given rate and at a high degree of uniformity to a small, rectangular, experimental plot, the project described in this bulletin was initiated in 1954. Objectives Basic requirements of the proposed plot were: 1. To apply water uniformly to a small plot. 2. To apply water at a rate of 0.20 inches per hour or less. 3. To apply water uniformly to the edges of a rectangular plot with no spillover onto the adjacent plot. *Research Assistant and Associate Agricultural Engineer, respectively, Oregon Agricultural Experiment Station -2- 4. To apply a precise amount of water. To be portable and easily moved from plot to plot and site to site. 6. To be adaptable or readily modified in accordance with both the height of the crop and the dimensions of the plot as required by other factors. 7. To have a relatively low construction cost. Review of previous work Previous work in the development of a plot irrigator is limited. The first plot irrigator of this kind built in this country was developed at Pennsylvania State College (1). This machine was later modified and used for irrigation research in Georgia (2). Both irrigators employed the principle of a traversing boom mounted on rails. An air-cooled gasoline engine produced the traverse movement of the boom. Water from nozzles mounted on the boom sprayed down over the crop. A third precision plot irrigator has been developed in England by the National Institute of Agricultural Engineers (3). This irrigator also was equipped with a traversing boom with mounted low pressure drip nozzles. Each of these three machines satisfied many of the requirements listed in the previous section. However, work at Oregon State College was initiated in the hope of finding a simpler, less costly design that met all of the requirements. Irrigator design Oscillating boom The first step in the design of the irrigator was the testing of several commercially-built lawn and agricultural sprinklers. White Showers and Skinner oscillating sprinklers satisfied requirements most closely. Primary disadvantages were insufficient uniformity of application for experimental work, lack of precise boundary control, and lack of independent control between area of coverage and rate of application. From modifications of these units, various models of irrigators were designed based on the principle of an oscillating boom mounted in one position at a height of 8 to 10 feet over the center of the plot. Complete coverage of the plot was achieved by moving the nozzles through a certain arc. Trajectories of the streams from these nozzles were required to be long enough to reach the extreme ends of the plot, a horizontal distance of approximately 15 feet from the stand on which the nozzles were mounted. The oscillating motion was imparted to the nozzle boom by means of a double-acting water cylinder. Water passed from the supply line to the cylinder and from the cylinder to the nozzles. The final model of this type can be characterized by two essential features: 1. The linear velocity of the water driven piston was transformed into angular velocity of the boom by means of a cam. The shape of this cam determined the rate of angular rotation at any point in the wetting arc. Thus, the rate of jet travel along the ground surface could be regulated at any point along the length of the plot by an adjustment of the cam shape. For a given height of sprinkler above the ground surface and a given nozzle size and operating pressure a cam shape could be designed by test methods which would yield good uniformity of application along the line of the jet. 2. Through a ratchet drive mechanism the movement of the water piston was utilized to impart lateral motion to the boom. The boom was equipped with 0.10 gpm high velocity jet nozzles spaced at a distance of 2I. inches. This spacing was selected in order to produce a precipitation rate within the desired range of 0.15 to 0.20 inches per hour. The 0.10 gpm nozzles were found to be the minimum size necessary for the spray to reach the extreme ends of the plot and to avoid excessive wind n drift. 11 Because of the lateral movement of the boom, dry spots between the nozzles were eliminated and uniformity of application across the plot was thus considerably improved. Tests were conducted on this irrigator under still-air conditions in the laboratory. Variables involved in these tests were the nozzle size, pressure, spacing, maximum angle from the vertical, and height above the ground surface. Data from these tests were obtained for the rate of precipitation, maximum horizontal distance of jet travel, and uniformity of coverage. In order to determine mechanical reliability of the machine and the influence of wind upon the distribution pattern, extended tests were also conducted in the field. These tests indicated several disadvantages in the oscillating boom type of irrigator: 1. Streams of water issuing from the nozzles tended to destroy structure of exposed surface soil. When the irrigator was first proposed * it was-to be used only on close growing crops such as pasture; however, the need developed to irrigate small experimental plots on which inter-tilled crops such as beans were being grawn. Under these conditions, particularly in the area directly beneath the boom, force of the water from jets or nozzles tended to break up surface soil structure. A more gentle stream of water would not have reached the ends of the plot. 2. Because of the long trajectories from the nozzles, wind considerably influenced the uniformity of distribution, particularly toward the ends of the plot. 3. The irrigator permitted very little variation in the type and intensity of spray. It was felt that it would be an advantage to be able to vary the intensity of spray (and so the intensity of application) from almost a fog to a heavy rain. 4. The area of coverage could not be varied without changing the uniformity of application. 5. It was mechanically complicated and unreliable. However, this situation could have been improved. Traversing boom Although the principle of the oscillating boom sprinkler appeared good, the machine contained several disadvantages. A new type of design, now referred to as the Oregon Plot Irrigator, was proposed, based upon the traversing boom principle. A line drawing illustrating the various parts of this irrigator is shown in figure 1. The design of the pilot model was based upon a plot size of 20 by 25 feet. The following is a brief description of basic components of the machine: 1. Boom: Water is sprayed vertically downward from nozzles mounted on a boom which traverses the entire length of the plot (figure 2). The 20-foot boom is of 3/1-inch outside diameter aluminum pipe fitted with commerciallYavailable tee jet nozzles spaced at 15 inches. The tee jet nozzles may readily be changed to vary the intensity and type of spray as required. (Those selected discharged water in a fan-shaped spray.) For a given nozzle size, rate of application can be varied somewhat by changing the regulated pressure to the boom. Two gay wires consisting of 3/32-inch airplane cable anchored to the carriage supports the boom ends. 2. Carriage: The boom is slung from a 4-wheeled carriage which traverses two cylindrical tracks (figure 3). Wheels are cast aluminum. Rims are shaped to conform to the outside diameter of the tracks. 3. Tracks: Three-inch aluminum irrigation pipe in 30-foot lengths forms the twin tracks (figure 2). Besides being light and readily available, this pipe is effective in beam action. Two clamps at each end of the pipe secure it to a frame consisting of welded steel conduit and pipe (figures 3 and 4). Sag in the tracks is eliminated by a cable supported truss stand placed at the middle of the pipe (figure 2). The 3/32-inch airplane cable is anchored to the frame at either end of the irrigator. The aluminum pipe is not drilled or otherwise damaged in any way. 4. Prime mover: A double-acting water cylinder produces the movement of the carriage and boom (figure 5). The reciprocating motion of this cylinder is converted to rotational motion by means of two overrunning clutches mounted on the same shaft. Since this arrangement produces rotation of the shaft for both the forward and backward strokes of the water piston, the rotational motion is nearly continuous. Drive mechanism: A sprocket wheel mounted on the shaft rotated by the water cylinder drives a number 48 roller chain which in turn transmits the motion to the boom carriage (figure 5). The chain is supported only at its two extrane ends. The idler sprocket at the end of the chain farthest from the water cylinder is adjustable to enaDle tdfLhtening of the chain (figures 3 and 4). The carriage is connected to the chain by means of a pivot and sliding linkage which permits a reversal of the boom travel at the ends of the plot (figures 3 and 5). 6. Water supply: Water under pressure from a source of supply passes through a shut-off valve to the doubleacting cylinder (figure 5). From the exhaust of this cylinder the water flows through a pressure regulator valve and then is conveyed to the boom by means of a light-weight 3/8-inch plastic garden hose (figures 2 and 5). This hose is suspended from a taut cable by means of swivel snap hooks and is coiled and extended by the reciprocating motion of the carriage. There is no ftwaste n water. The boom pressure is adjusted and held constant by means of the pressure regulator valve which is also equipped with a pressure gage (figure 5). Since the water cylinder is a positive displacement mechanism, the speed of boom travel for a given plot size is a function of the nozzle discharge rate. For an application rate of 0.20 inches per hour and a plot size of 20 by 25 feet the time required for the carriage to travel the entire length of the plot is 9 minutes. 7. Standards: The entire irrigator mechanism and frame is supported on four standards or legs consisting of 2-inch steel tubing (figures 3, 4, and 5). Position of the frame on these legs is adjustable so that, depending upon the type and stage of crop growth, the boom height can be varied in a range from the ground surface to a distance of 8 feet above the ground. A slight lateral adjustment is also provided for the legs in order to accommodate different row spacings. At one end of the irrigator the legs are equipped with 3-inch square metal ground pads, while attached to the remaining two legs are wide-rimmed cast aluminum wheels 16 inches in diameter. To facilitate moving from one plot to another, Wheels can be adjusted to turn in a direction either lengthwise or crosswise with the plot. By carrying the pad equipped legs two men can negotiate the irrigator from plot to plot as required without difficulty. In order to transport the irrigator from one experimental site to another the aluminum ground wheels are exchanged for rubber-tired wheelbarrow wheels. One end of the irrigator is placed on the back of a truck, while the wheeled end is permitted to trail. The carriage and boom are removed during this operation. The total weight of the irrigator (25 foot model) is approximately 250 pounds. Performance tests on the traversing-boom irrigator The uniformity of application was evaluated for four different tee jet nozzle sizes--80015, 80020, 80030, and 800140. Each size was operated at three different pressures--6, 8, and 10 pounds per square inch. For the larger nozzles tests were conducted for approximately two hours while for the smaller nozzles the length of test was approximately five hours. Water was caught in 46ounce cans spaced 7 1/2 inches in rows parallel to the boom and 5 feet perpendicular to the boom. Each test included a total of 84 can readings. The boom height during the tests was 6 feet. Tests covered rates of application ranging from 0.15 inches per hour to 0.37 inches per hour. These rates were based on a plot size of 20 by 25 feet. For a given nozzle size and pressure an increase or decrease in the length of plot would produce a converse change in the rate of application. A typical test result is shown by figure 6. (Table 1 summarizes the results of all the tests. Each entry in the table is the mean of duplicate trials.) The smaller nozzles operating at 10 pounds per square inch and applying 0.20 inches per hour gave the highest uniformity of application at 92.4%. Based on a total of 84 can readings, the amount of water applied was measured to an accuracy of plus or -7- minus 0.0033 inches per hour. The large nozzles operating at the lowest pressure of six pounds per square inch, and applying water at 0.30 inches per hour gave the lowest uniformity obtained at 81.1%. Here the amount of water applied was accurately measured to an accuracy of plus or minus 0.0124 inches per hour. These figures indicate that the irrigator was able to apply a required quantity of water with a considerable degree of accuracy. Tests indicated that wind caused drift of the spray and somewhat lowered the uniformity of application. It was found however, that this problem was not so serious in actual field operation as in the test area because of the protection from air movement afforded by the crop foliage. After a thorough testing in the laboratory, the irrigator was extensively operated under actual field conditions (figure 7). As the result of these tests several mechanical difficulties were detected and eliminated. A total of four machines were then built and used during the entire irrigation season of 1957. Figure 8 shows these in operation on sweet corn plots on one of the college farms. During the season they irrigated a total of 30 plots which were in two separate projects about three miles apart. A total of 112 plot irrigations were applied, or 28 per irrigator. Amount of water applied at each irrigation ranged from 1 to 6 inches. At a precipitation rate of 0.20 inches per hour a 6-inch irrigation required 30 hours to apply. Operation of the plot irrigators was very successful. They were permitted to run unattended during the night with relatively little difficulty. Temporary equipment failure occurred, however, during 8 of the 112 irrigations. In each instance the design of the equipment was modified to prevent a reoccurring stoppage of each respective type. By the end of the season there were very few stoppages. The irrigator is now being used in connection with several irrigation research projects in Oregon and is functioning very satisfactorily. For one of these projects at Hillsboro, Oregon, the length of the irrigator was increased from 25 to 30 feet. This change required that the 3-inch aluminum pipe tracks be substituted by 4-inch aluminum pipe, and also necessitated a slight increase in the size of some of the members of the frame. Complete working drawings are now available from the Department of Agricultural Engineering, Oregon State College, for either the 25-foot or the 30-foot model. Conclusions The traversing boom irrigator described in this bulletin has met he basic reuirements of an irrigation research tool to apply water to field experimental plots. 1. The uniformity coefficient of water application is high. For the 80015 tee jet nozzles operating at 10 p.s.i. and applying 0.20 inches per hour this coefficient was found to exceed 90 per cent. 2. The rate of application can go as low as 0.10 inches per hour with nozzles that are available commercially. This rate, however, is computed on the basis of the entire plot. Since the boom traverses fairly slowly from one end to the other, the application rate directly under the boom is considerably higher than the average application rate for the plot. 3. The border zone at the edges of the rectangular plot where the application rate tapers off to zero can be made less than two feet in width. A precise amount of water can be applied at each irrigation. No attempt has been made to measure any change in the discharge characteristics of the nozzles after they have been used. 5. The machine is relatively portable and can be moved without difficulty from plot to plot and site to site. 6. The irrigator is adaptable to varying crops and plot sizes. The height of the boom is readily adjusted. The width of coverage can be increased by extending the boom length, or decreased by plugging nozzles as required. An increase in the length. of plot requires longer track pipes and drive chain and perhaps stronger component parts, while a decrease in plot length entails only an adjustment at the track clamps and a shortening of the drive chain. 7. The cost of construction in 1958 in Ore g,on was approximately. $400. It is considered an excellent investment because it will reduce the cost of irrigation research. -9References 1. Myers, Earl A. A field plot irrigator. Ponn. State College, Progress Report No. 83. 1952. 2. Sparrow, George N. and R. L. Carter. A field plot irrigator. Paper presented at the Winter Meeting, American Society of Agricultural Engineers, Chicago, Illinois, December 11-12, 1955. (Mimeo) 3. Bean, A. G. M., E. J. Winter, and D. A. Wells. Design of a precision plot irrigator. The British Society for Research in Agricultural Engineering, National Institute of Agricultural Engineering, Report No. 30. Not dated. Appendix ...• 0 H (44 M ---.., O) gl r-.1 0 H ca r4 P-i 0 I-1 E.+ +3 ..a 0 0 * C./ +3 . +3 g 0) C-) S.4 0 fa, 4I4+ •1-1 0 o 0 (..) r4 CC1') VA cr+ • 94 ,. 0 +3 ',.... W CO 0 0 Q) +3 • e-0 A r-1 C.) Pc4 P4 0 P4 -i —..-:!........, • r-I 0 co+ n-I 0 43 (1) 8 -P • -4 M r--I f.-. Q. t:;' S-4 ..0 "--... Ca ,c 0 o 02 H 1IN ON ON H • 0 as CV N • 0 CO H rel • 0 C.4. IA c,"‘ • 0 +3 a) +3 --1- 0\ 0\ CO c.1 ON li\ CO CZ CO `43 CO --t' -.1 C-.- 0 c% cci: '8 o d d a) 2 H d (NI es, rr1 1-'4 4, +3 0 -P CO "a • r04 (1)0 8 '44 p., 4) ..4 'a 0) '.:O C...1 4.1 04 0 0 .ri 0 4-1 cn--I cD at cri 0 O CO .....„ to ,t P4 CV * • (0 N 0 Os V0 ....1 :4 00\, IA a) +rya 0 0 4i • .,9 44 to to ,r) H n0 0 tt 0 CI R -4 CO a) N1.‘"\ -S. r- 1 -P -P >a 0 +3 0 ri •0 •1-1 o A-1 4-1 4-1 (g, 6 N ..• "'• H 0 • `'' 0 -P 0 (I) 0 $.4 9 2)) o o a N •r, r co c3 UN \O H• H tr; CO 0\ an CO crl • CO H 4 CO " 4-I 44 Q) 2 r-i a) N N ..c, ,E -IS I-1 Z a 3 a) F-1 U\ Ho 0 Cm ° d d 0 0 CrN c:) I 8 d a) 0 -I-) 2 Figure 2. Traversing boom and carriage motion near the center of the tracks. Figure 3. Traversing boom and carriage approaching the idler gear mounted on an end frame. Figure 4. Closeup of the end frame secured to the two pipe tracks. Figure 5. This end frame supports the water motor, pressure control valve, shutoff valve, sliding hose, drive sprocket, and one end of the pipe tracks. Figure 6. Plot sprinkler test Tf, me 197 181 180 182 214 205 207 202 193 196 191 '182 193 . 200 18.9 196 200 196 193 196 191 195 184 190 20'2 . .204 .203 198 200 192 188 188 202 193 196 196 '200 20o 1196 198 214 226 216 218 214 220 210 217 207 212 210 216 203 202 1 1 8I 18 189 188 Boom 193 201 191 188 181 194 192 189 Total length 15 feet with 12 nozzles 206 ..-14. 213 204 '196 11 194 Z, .186 185 226 211 208 183— 19 —191 - 5 ft. -- 5 ft. 5 ft.— 223 i 1:00 am 6:00 am 5 hours Nozzles Type tee jet 80015 psi 10 Height above cans 61111 Spacing along boom 15n Plot tested 4 ze Si I 196 ! Start Stop Total (-1 I 208 211 (North to south 13I9n (East to west 1510n Boom travel —...................... Length of track time 16 min. 58 sec. Can spacing 5 1 0 n perpendicular with boom 7.5" parallel with boom Precipitation 181 Coefficient of uniformity= 94.4% Average precipitation rate = 0.1986 ..t 0.0024 in/hr Precipitation figures are in/hr X 1000 Figure 7. An Oregon Plot Irrigator applying water to an experimental sweet corn plot. Figure 8. Four Oregon Plot irrigators operating in a sweet corn experimental area.