From: Proceedings of the AI and Manufacturing Research Planning Workshop. Copyright © 1996, AAAI (www.aaai.org). All rights reserved.

Tabu Search With Target Analysis To The Assembly Line Balancing

Problems - An Artificial Intelligence Approach

Wen-ChyuanChiang

Departmentof Quantitative Methodsand Management

Information System

Collegeof BusinessAdministration,Universityof Tulsa

Tulsa, OK74104

qm_wc@centum.utulsa.edn

Abstract

Thispaperdescribesthe application

of tabusearch,a recent

heuristictechnique

for combinatorial

optimization

problems,

to

the assembly

line balancingproblems.Computational

experiments

withdifferentsearchstrategieshavebeen

performed

for someassembly

line problems

fromliterature.

Computational

resultsshowthat exceptfor fewcasestabusearch

always

findsoptimalsolutions.

Introduction

Thereare two types of assemblyline balancingproblems.

A TypeI problemis to determinethe minimum

numberof

workstations required to meet the specified production

requirements. AT)~e II problemis to allocate tasks to

workstations in such a way that the maximumtime

required for assemblyat any given station is minimal

across all feasible stations (Master1970). In this paper,

we examine the T)~ I problem and apply tabu search

schema

to solveit.

The assembly line Balancing problem was first

published in a mathematicalform by Salveson in 1955.

Sincethen it has beena hot topic for researchers. Master

(Master1966) evaluated the performanceof 10 heuristic

decision rules by iteratively employingeach of the

evaluated techniques, increasing the cycle time in one

percent incrementsabovethe lowerboundcycle time until

a balance wasachievedfor the specified numberof work

stations. Dar-El(Dar-Ei 1975)investigated 12 heuristic

decision rules of Type II problems. Dar-El developed

MALB

Oar-El1973) as a heuristic variant of his earlier

optimal-seekingiterative procedure(Dar-El 1964). DarEl’s general conclusionis that MALB

gives consistently

superior results to the Arcus(Arcus1963) or the other

techniques investigated. Johnson (Johnson 1988), and

Berger et al. (Berger, Bourjolly & Laporte 1992)

investigated a branchand boundalgorithmto solve TypeI

problems. Anderson (Anderson 1994), and Leu and

Matheson 0-,¢u & Matheson 1994) combined genetic

algorithmsandheuristic criteria to solve the assembly

line

balancingproblem.Easton (Easton 1990) applied dynamic

programming

approach and used upper boundsin solving

30

AI & ManufacturingWorkshop

assemblyline balancing. Carraway(Carraway1989) used

dynamic programmingapproach to solve stochastic

assembly line balancing problems. Surcsh and Sahu

(Suresh Sahu1994) used simulated annealing to solve

stochastic assemblyline balancing problems. Shin and

Min(Shin &Min1991) im’estigated stochastic assembly

line balancingproblemin just-in-time environment.

In this paper, tabu search is applied to solve type I

assembly line balancing problems. Tabu search was

introduced by Glover (Glover 1989) as a technique

overcomelocal optimality. The underlying idea is to

forbid somesearch directions at a present iteration in

orderto avoidcycling,but to be able to escapefroma local

optimal point. This strategy can makeuse of any local

improvementtechniques. There arc manyproblemsthat

are successfully solved using tabu search (Skorin-Kapov

1990,Knox1994). In this paper, the application of tabu

searchto assemblyline balancingproblemis discussed.

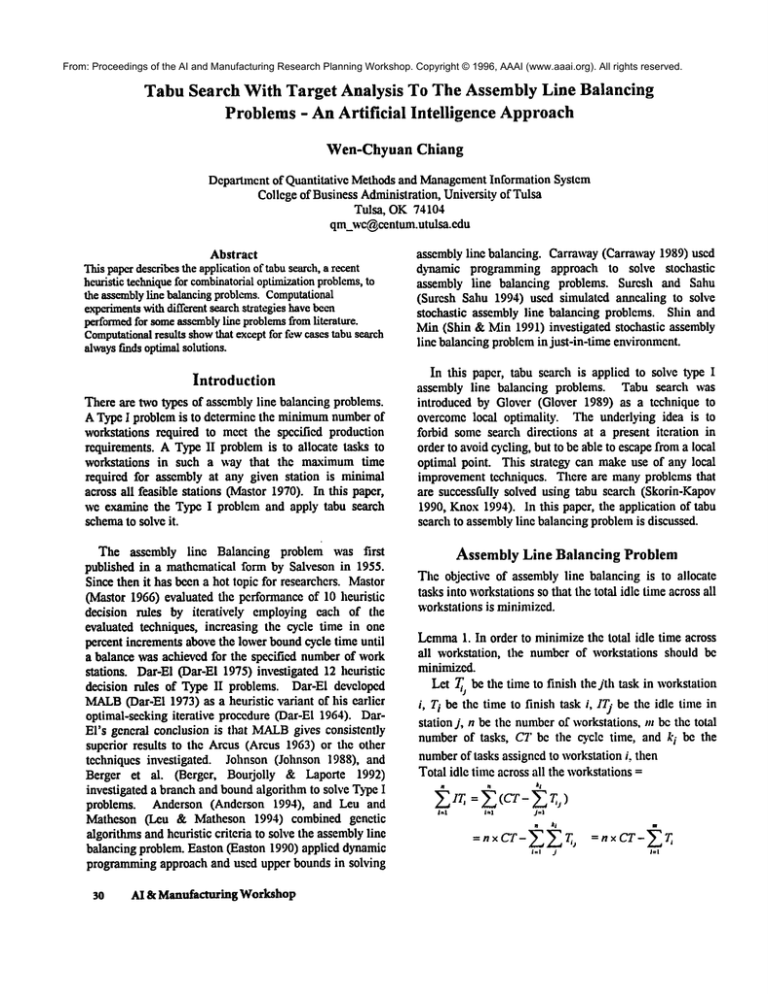

AssemblyLine Balancing Problem

Theobjective of assemblyline balancingis to allocate

tasks into workstations

so that the total idle timeacrossall

workstationsis minimized.

Lemma

1. In order to minimizethe total idle time across

all workstation, the numberof workstations should be

minimized.

Let T~jbe the time to finish the jth task in workstation

i, Ti be tile timeto finish task i, I~ be tile idle time in

station j, n be the numberof workstations,mbe the total

numberof tasks, CTbe the cycle time, and ki be the

number

of tasks assignedto workstationi, then

Total idle timeacross all the workstations=

n

n

kl

i=l

l~l

J=l

= n x CTi:l

j

T,, = n × CT- T,

l:l

From: Proceedings of the AI and Manufacturing Research Planning Workshop. Copyright © 1996, AAAI (www.aaai.org). All rights reserved.

From the above formula, wc can see that CTand

max

~T~are constant. Thereforein order to minimizetotal

I-I Jffii

subjectto

I-I

idle time across all workstations,

workstationsmust be minimized.

the number of

tj

In order to encourageas manytasks as possible to be

conglomerated

into a big workstationwith less idle time, a

nonlinear objective function is used. The objective

functioncan be written as:

a

tl

t-!

J=|

max (Z

ZJ-ITjj < CTwherek, is the nmnberof tasks

in workstationi andCTis cycle time

Tjj ;~Tj, if i ;~ k orj;~l

~

where

,, is thenumber

ofworkstationsk, = m

wheremis the numberof tasks to

be assigned

andki is the number

of tasks in workstationi.

Lemma

2. The objective function can be maximizedby

movingjobs from workstations with less total time to

workstationswith larger total time.

Thereare two cases. Case1, twoworkstationsst ands2

can be combinedinto one workstation. Let ST1 and

2 ST

be the total timein workstations

st andsz,

TheObjectivefunction after combination

~

-- (~ +sr~)" =~" +st: +2~s~>~2+sr~

= Objectivefunction before combination.

Case 2, two workstationsst and sz cannot be combined

into one workstationbecauseof cycle time constraint, ff

total timein s2 is greaterthantotal timein st, wecanstill

improvethe solution by movingsometasks from st to s2

andtherefore reducethe size of st and increasethe chance

of combiningst with other workstations and get rid of

workstationst. Supposeprocessing time A is movedfrom

st to s~, total time for these two workstationsafter the

moveis

S’/~’ =S’~-A, ST2’=ST:+A

,

Objectivefunction after combination

The search of solution for assemblyline balancing

problem consists of two stages: initial solution

constructionwhichgenerates a feasible initial solution,

and tabu search improvementwhich takes an initial

solution andimprovesit.

Relational

Matrix and Warshall Algorithm

There are precedence relationship amongtasks, which

specifies the order in whichthe tasks mustbe performed

in the assemblyprocess. Certain tasks must be finished

before other tasks can be done. Immediateprecedence

relationship amongtasks can be represented by a

relational matrix M= {Me} where

if task i mustbe finished immediately

before taskj

10 otherwise

Precedencerelationship betweenany pair of tasks i and

j can be definedas task i mustbe finished(not necessarily

immediately)

beforetaskj can start. Taski is prior to task

j if either

= ~"+ st,’~ = (~ - A)’+ (~ +

=~

~ -2~, +t: +~? +2~ +A

= ~’ +sr~’+ 2A(A+ (sr~ -~)) >~+sr~"

1. i is immediately

beforetask j, i.e. M

u = 1, or

2. Thereexists a task k, i is prior to k andk is imlnediately

beforetaskj.

= Objectivefunctionbeforecombination,

Precedencerelationship can also be represented by a

matrix M7"= {MT~}where

Therefore to maximize ~ ~’

is the sameas to

I-I 3’-I

Aft# = {10ofllenvise

if task i mustbe finishedbeforetaskj

minimizenumberof workstations.

Assembly

line balancingproblemcan be written as

In fact, precedence

relationshipis the transitive closure

of immediateprecedence relationship M= {M

U }. From

graph theory weknowthat MT

o = 1 if and only if there

Chiang

31

From:

Proceedings

the AItask

and Manufacturing

Planning

Workshop. Copyright

© 1996,

(www.aaai.org).

All rights

exists

a pathof from

i to task j. Research

Warshall

(Warshall

is reduced

to AAAI

0, job

i is allowed

to reserved.

move back

1962) developeda very efficient algorithm for calculating

transitive closure matrix. Let n be the numberof tasks, M

be the matrix representing

immediate precedence

relationship, and ll,ff = {Affa}be the matrix representing

precedence relationship. The Warshall algorithm can be

represented as follows:

Step 1. Copymatrix Mto matrix Aft.

Step 2. For i from1 to n do step 3 to 5

Step 3. Forj from 1 to n do step 4 to 5

Step 4. If Mj, -- I then do step 5, otherwise continue

step3

Step 5. For k from 1to n

set ~ff~ to be Af/’~ ¯ Aff,~

where the behavior of operator ~ can be represented by

the followin$table

0

non zero

0

0

1

non zero

1

1

Matrix MTcan be very useful to determine the feasibility

of a solution.

Tabu Search (TS)

The developmentof Tabu Search can be traced back to the

late 1960s and early 1970s. Its contemporaryversion was

proposed by Glover in (Glarer 1989). The basic idea

TS is to improve a solution using memory-guidedrules to

obtain goodsolutions.

TS introduces

penalizes certain

visited solution.

flexible memory

is

a memorystructure that forbids or

movesthat would return to a recently

In assemblyline balancing problem, the

defined as follows:

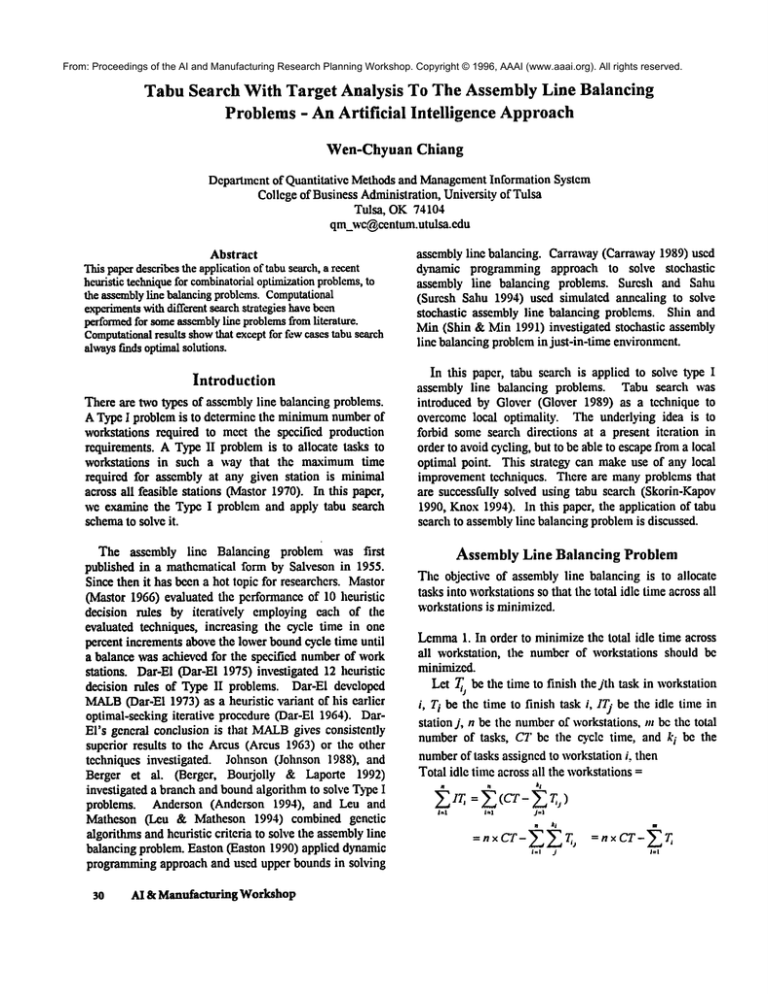

The following example can be helpful to understand

this flexible memory.Supposethere are 6 jobs assigned to

3 workstations:

jobs 1 and 2 are in workstation 1

jobs 3 and 4 are in workstation 2

jobs 5 and 6 are in workstation 3

Theinitial values of all entries in tabuare all set to be 0

and tabu size is 3. In iteration 1, it is decidedto exchange

jobs 1 and 3. Figure 1 shows the flexible memorytabu

after the exchange. Both tabu[l][1] and tabu[3][21are set

to be 3 because job 1 cannot go back to workstation 1 and

job 3 cannot go back to workstation 2 in the next 3

iterations.

Solution

Workstation

1

2

3

Jobs

2.3

1,4

5,6

tab u

Job

I

2

3

4

5

6

1

3

0

0

0

0

0

WorkStation

3

2

0

0

0

0

3

0

0

0

0

0

0

0

Figure 1 Solution and tabu memory

after iteration 1

Supposein iteration 2, it is decided to movejob 2 to

workstation 3, tabu[2][1] are set to be 3 because job 2

cannot go back to workstation 1 in the next 3 iterations.

After iteration 2, tabu[l][1] and tabu[3][2] arc reduced by

1 which means that job 1 cannot return to workstation 1

and job 3 cannot return to workstation 2 in the next 2

iterations. Solution and tabu memoryafter iteration 2 are

shownin Figure 2.

int tabu[MAX_JOBS][MAX_STATIONS]

int tabusize

The above two dimensional array tabu is used to check

if a movefrom a solution to its neighborhoodis allowed.

Iftabu[i][s] is 0, then job i is free to movefrom its current

workstation to another workstation s. Otherwise, say

tabu[ills] is 6, job i cannot moveto workstation s in the

next 6 iterations. After a job i movedfrom workstation s

to another workstation, the value of tabu[i][s] is assigned

to a value called tabu size, which meansthat job i cannot

go back to workstations in the next tabusize iterations.

After each iteration, all nonzero values in flexible

memorytabu are reduced by 1. Whenan entry tabu[i][s]

32

AI & Manufacturing Workshop

to

workstation s again.

Solution

Workstation

Jobs

1

3

2

1, 4

3

5,6,2

tabu

Job

1

2

3

4

5

6

1

2

3

0

0

0

0

WorkStation

2

3

0

0

0

0

2

0

0

0

0

0

0

0

Figure 2 Solution and tabu memory,after iteration 2

From:

Proceedings

of the AI3,

andifManufacturing

Research

©line

1996,

AAAI (www.aaai.org).

All rights

reserved.

Suppose

in iteration

wecould move

job 1Planning

from Workshop.

In Copyright

assembly

balancing,

the idea is

to allocate

as

workstation2 to workstation1, wecould get a solution

that is better than the best solution wehadfoundso far.

Howeveraccordingto tabu flexible memory,job 1 cannot

go to workstation1 for the next two iterations. If we

strictly followtabu search methodology,

wecould miss an

optimalsolution. Anadditional rule called aspiration can

solve this problem.

Aspiration Criterion

Whena movecan lead to a solution better than the best

solution obtainedso far, this moveis allowedevenff it is

in tabu. This rule is called an aspiration criterion (Glover

1989).In the abovesituation, job 1 is allowedto moveto

workstation1 evenff this moveis still in tabu. Solution

andtabu memory

after iteration 3 are shownin Figure3.

Solution

Workstation Jobs

1

1,3

2

4

3

5,6,2

tabu [ WorkStation

Job

1

2

3

1

3

0

0

2

2

0

0

1

0

3

0

4

0

0

0

0

5

O

O

6

0

0

0

Figure3 Solutionandtabu memory

after iteration 3

Aspiration criterion is a very importantrule in tabu

search, It allows a moveto get out of tabu status

temporarily and therefore makesthe quality of result

solution less dependenton tabu size. Usuallythe greater

the tabu size is, the less chancefor solution to be trapped

in local optima. Howeverusing greater tabu size could

also eliminatemanyopportunitiesto find better solution if

aspiration criterion werenot used.

Intensification and Diversification

Besides the above described components,tabu search

requires someadditional rules to makeit moreintelligent

to find better solutions. Theuse of flexible memory

has

beenlimited to a short termhorizon, i.e. to remember

the

mostrecent movesto avoid beingtrappedto local optima.

The intensification schemein Tabusearch uses long

term memory

to guide its search of solutions. Accordingto

Glover (Glover 1989), it can be used to encourage

solutions to satisfy such properties and discourage

solutions that violate them. Wewouldlike to narrowthe

neighborhood

in the searchprocessto favor solutions with

properties that occurredoften in goodsolutionspreviously

visited.

manyjobs as possible to each workstation so that the

numberof workstations can be minimized. The rule of

intensification in the case of assemblyline balancing

problemcan be stated as follows:

Whena job j movesto workstation s and

makess to reach its full capacity, this moveis

believed to be good and job j is fixed to

workstations in the next fewiterations, unless a

solution whichis better than the best solution

found so far can be found by movingjob j to

anotherworkstation.

Thediversification schemeis anotherstrategic pursuit

of solutionswith varyingcharacteristics whichprovidesan

essential counterbalanceto the intensification component

of tabu search. (Glover1989)In assemblyline balancing

problem,diversification can be achievedby introducinga

penaltyfunctioninto the objectivefunction. Let switch(/)

be the number of times job j switches from one

workstationto another. Thepenalty function for moving

jobj to workstations can be definedas

0 if the movecan improve

[

penally function = ~ current solution

[switch(j)* 10 otherwise

Thechangeof objective function

= newobjective function value - old objective function

value- penaltyfunction

Since in assemblyline balancing, weare trying to

maximizeobjective function, in each improvement

step,

wesearch the neighborhoodto find a movewhichhas the

maximal change of objective function. Whena job

switchedtoo manytimes, its chanceto he selected as next

moveis reduceandthereforethe chancesfor other jobs are

increasedso that the searchregionis forcedto those areas

that havenot beensearchedbefore.

References

Anderson,E. J. 1994. GeneticAlgorithmsfor

combinatorialoptimization: The assemblyLine Balancing

Problem.ORSAJournal on Computing,Vol 6, No2, 161

Arcus, A. L. 1963. Ananalysis of a ComputerMethodof

SequencingAssembly

Line Operations,Ph.D. dissertation,

Universityof California, Berkeley.

Chiang

33

Berger,

I.; Bourjolly,

J. Manufacturing

M., and Laporte,

G. 1992.

BranchManagement

Science, Vol

22, 728From:

Proceedings

of the AI and

Research

Planning

Workshop. Techniques.

Copyright © 1996,

AAAI (www.aaai.org).

All 16,

rightsNo

reserved.

and-BoundAlgorithm for the Multi-Product Assembly

Line Balancing Problem. European Journal of

Operational Research, Vol 58, No 2, 215

Carraway, R. L. 1989. A Dynamic Programming

Approachto Stochastic AssemblyLine Balancing.

ManagementScience, Vol 35, No 4, 459-471

Dar-El, E. M. 1964. AssemblyLine Balancing -- An

Improvementon tile Ranked Positional Weight

Technique. Journal of Industrial Engineering, Vol 15, No

2, 73-77

Dar-El, E. M. 1973. MALB

-- A Heuristic Technique for

Balancing Large Single-Model AssemblyLines. AIIE

Trans., Vol 5, No 4, 343-356

Dar-El, E. M. 1975. Solving Large Single-Model

Assembly Line Balancing Problems - A Comparative

Study. AHETrans., Vol 7, No 3, 1975, 302-310

Easton, F. F. 1990. A DynamicProgram with Fathoming

and DynamicUpper Bounds For the AssemblyLine

Balancing Problem. Computersand Operations Research,

Vol 17, No2, 163

Glover, F. 1989. Tabu Search, Part 1. ORS4Journal on

Computing 1:3, 190-206

Glover, F. 1989. Tabu Search, Part II. ORSAJournal on

Computing2:1, 4-32

Johnson, R. V. 1988. Optimally Balancing Large

Assembly Lines with FABLE.ManagementScience, Vol

34, No 2, 240-253

Knox,J. 1994. The Application of TabuSearch to the

SymmetricTraveling Salesman Problem. Ph.D. thesis,

Graduate School of Bnsiness, University of Colorado,

Boulder

Leu, Y. Y.; Matheson, L A. 1994. AssemblyLine

Balancing Using Genetic Algorithms with HeuristicGenerated Initial Populations and Multiple Evaluation

Criteria. Decision Science, Vol 25, No4, 581

Master,

A. A. 1966. An Experimental Investigation and

ComparativeEvaluation of Production Line Balancing

Techniques. Ph.D. dissertation, University of California,

Los Angeles.

Mastor, A. A. 1970. An Experimental Investigation and

ComparativeEvaluation of Production Line Balancing

34

AI & Manufacturing Workshop

745

Skorin-Kapov,J. 1990. Tabu Search Applied to the

Quadratic Assignment Problem. OR&4Journal on

Computing,Vol 2, No 1, 33-44

Shin, D.; and Min, H. 1991. Flexible Line Balancing

Practices in a Just-In-Time Environment.Production and

Inventory J~[anagementJournal, Vol 32, No 4, 38

Shin, D.; and Min, H. 1991. Uniform AssemblyLine

Balancing with Stochastic Task Times in Just-In-Time

Manufacturing. International Journal of Operations and

Production, Vol 11, No 8, 23

Suresh, G.; Sahu, S. 1994. Stoclmstic AssemblyLine

Balancing Using Simulated Annealing. International

Journal of Production Research, Vol 32, No 8, 1801

Warslmll, S. 1962. A Theoremof Boolean Matrix. Journal

ofACM,Voi 9, No 1, 11-12