Title:

advertisement

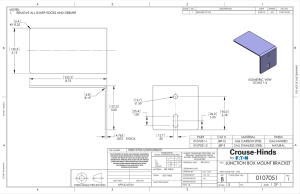

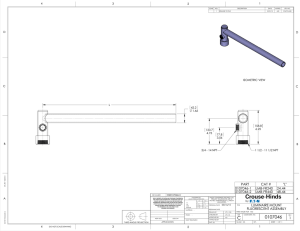

Cooper Industries Crouse-Hinds Division Crouse-Hinds Airport Lighting Products 1200 Kennedy Road Windsor, CT 06095 860 683-4300 Fax 860 683-4354 Title: DOCUMENT 9525 December 20, 2007 Revision P INSTRUCTION MANUAL L-828 & L-829 CONSTANT CURRENT REGULATOR OIL FILLED SERIES 82860-W(L-828,60HZ); 82960-W(L-829,60HZ) SERIES 82850-W(L-828,50HZ); 82950-W(L-829,50HZ) 10 KW, 6.6A; 15, 20, 30 KW, 6.6 & 20A; 37.5, 50, 70 KW, 20A 10 KW, 6.6A; 15, 20, 30 KW, 6.6 & 20A; 50 KW, 20A Copyright © 2007 Cooper Technologies Company 9525 Rev. P CONFIGURATION RECORD The following information is specific to the equipment described herein as shipped from the factory and should be retained. It should be provided when contacting the factory about this equipment for any reason. Constant Current Regulator, FAA Type Manufacturer’s Part Number Serial Number Date of Manufacture Factory Installed Options: DESCRIPTION OPTION/PART NUMBER ii 9525 Rev. P REV. A REVISIONS DESCRIPTION Revised pictorials & related items due to physical change to regulator & added additional clarifications and made corrections as warranted before actual production of this unit LTR. A96261 DATE 5/10/96 APVL PG B Pg. 44, 51, 57 & 62, Item 25 P/N 31505-2 was 31505-3; Pg. 2 & 4, added note on 10 KW qualification; Pg. 3, added A96496- 9/25/96 JAS C Deleted 2.1.5.3 on Pg. 7; 31879-3L was 31879-1L, Deleted 31879-2l, P/N 32277-1 was 31984-1 on Pg. 48; P/N 32323 was 32042-X-Y-6H, P/N 31879-3L was 31879-2L, P/N 32277-1 was 31984-1 on Pg. 53; P/N 32323 was 32042-X-Y-5H, P/N 31879-3L was 31879-2L, P/N 32277-1 was 31984-1 on Pg. 59. A97211 4/15/97 JAS D 1) Revised wiring diagram Figure 4-4, secondary of A97T20 was 12,6,0 327 6/5/97 JAS E 1) Pg. 40, Fig.4-4, re-routed wire 13 to T20. 7/10/97 JAS 8/22/97 JAS 6/1/98 RBM 1/11/99 JAS 11/27/01 DCW 10/1/02 GFR 8/10/06 PG 10-06/06 PG F G H J K L A97385 1) Pg. 19, Fig. 3-1, revised schematic to show rerouting of wire 13 to T20, Added P/N 32330, A97Safety notice, moved warning label to accomodate; 479 2) Pg. 20, Fig. 3-2, revised sheetmetal behind control cabinet; 3) Pg. 21, Fig. 3-3, flipped bolts on hold down channel for easier assembly; 4) Pg. 44, Fig. 51, rotated TB1 90 deg. to avoid interference with door; 5) Pg. 46, Fig. 5-3, flipped bolts on hold down channel for easier assembly; 6) Pg. 47, Fig. 4-7, revised sheetmetal behind control cabinet; 7) Pg. 49, Fig. 5-6, rotated top half of K1 label 90 deg. Sheet 39.1, S2, S3 & S4 was S2-S4 A98071 Changed notes on Figure 4-3c, Sheet 39.1 A98395 Added pilot relay (K2) and related data to 2400v A201Version 274 Revised graphics to agree with latest manufacturing; A202revised Figure 4-5 (cont) T3 part number was 30190; 233 updated parts lists to agree with latest manufacturing; Item 14 fuse F1 10053-307 was 10047-1205 1.2.3.1, Specification 150/5345-10F was 10E; cover A206page, revised copyright 260 iii M Pg 51, item 19 P/N for 480V was 31675; Fig 4-5, A206- 9525 Rev. P N P revised 480V, 60 HZ connections 377 Pg 41, 208V , 60 Hz, SEE FIG-5b was 4-5a & 220V, A20760 Hz, SEE FIG 4-5c was 4-5b and added SEE FIG 221 4-5c to 240V, 60 Hz and SEE FIG 4-5d to 480V, 60 Hz and deleted SEE FIG 4-5a from 208V, 50 Hz and SEE FIG 4-5d from 220V, 50 Hz; Pg 41.1, added Figures 4-5b thru d; Pg 51, added item 19 T3 P/N 10047-2424 and 10047-1444 usage was 480V and 31675 usage was 208-240V Table 3-1, revised input current ratings A207318 iii.1 8-2-07 PG 12/20/07 PG 9525 Rev. P LIMITED PRODUCT WARRANTY THE FOLLOWING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT BY WAY OF LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. Crouse-Hinds Airport Lighting Products (the “Company”) warrants to each original Buyer of Products manufactured by the Company that such Products are, at the time of delivery to the Buyer, free of material and workmanship defects, provided that no warranty is made with respect to: a) any Product which has been repaired or altered in such a way, in Company’s judgment, as to affect the Product adversely; b) any Product which has, in Company’s judgment, been subject to negligence, accident or improper storage; c) any Product which has not been operated and maintained in accordance with normal practice and in conformity with recommendations and published specification of Company; and, d) any Product, component parts or accessories supplied by Company (any claims should be manufacturer thereof). manufactured by others submitted directly to but the Crouse-Hinds Airport Lighting Product’s obligation under this warranty is limited to use reasonable effects to repair or, at its option, replace, during normal business hours at any authorized service facility of Company, any Products which in its judgment proved not to be as warranted within the applicable warranty period. All costs of transportation of Products claimed not to be as warranted and of repaired or replacement Products to or from such service facility shall be borne by Purchaser. Company may require the return of any Product claimed not to be as warranted to one of its facilities as designed by Company, transportation prepaid by Purchaser, to establish a claim under this warranty. The cost of labor for installing a repaired or replacement product shall be borne by Purchaser. Replacement parts provided under the terms of this warranty are warranted for the remained of the warranty period of the Products upon which they are installed to the same extent as if such parts were original components thereof. Warranty services provided under the Agreement do not assure uninterrupted operations of Products; Company does not assume any liability for damages caused by any delays involving warranty service. The warranty period for the Products is 24 months from date of shipment or 12 months from date of first use whichever occurs first. iv 9525 Rev. P SAFETY NOTICES This equipment is normally used or connected to circuits that may employ voltages which are dangerous and may be fatal if accidentally contact by operating or maintenance personnel. Extreme caution should be exercised when working with this equipment. While practical safety precautions have been incorporated in this equipment, the following rules must be strictly observed. KEEP AWAY FROM LIVE CIRCUITS Operating and maintenance personnel must at all times observe all safety regulations. Do not perform maintenance on internal components or re-lamp with power ON. RESUSCITATION Maintenance personnel should familiarize themselves with the technique for resuscitation found in widely published manuals of first aid instructions. v 9525 Rev. P Title Page . . . . . . . Configuration Record. . . Revisions . . . . . . . List of Effective Pages . Limited Product Warranty Safety Notices . . . . . Table of Contents . . . . SECTION 1.1 1.2 1.3 1.4 SECTION 2.1 . . . . . . . TABLE OF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1. GENERAL INFORMATION Introduction . . . . . . . Equipment Description . . . Installation Requirements . Warning Notice. . . . . . . 2. TECHNICAL DESCRIPTION Theory of Operation . . . . CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i . ii . iii . iv . v . vi . vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1 3 3 . . . . . . . . . . . . . . 5 . . . . SECTION 3. INSTALLATION AND OPERATION 3.1 Installation . . . . . . . . . . . . . . . . . . . . . 10 3.2 Operation . . . . . . . . . . . . . . . . . . . . . . . 14 SECTION 4. MAINTENANCE 4.1 Periodic Maintenance . . . . . . . . . . . . . . . . . 24 4.2 Corrective Maintenance . . .. . . . . . . . . . . . . . 25 4.3 Problem Solving Guide . . . . . . . . . . . . . . . . . 25 SECTION 5. PARTS LIST 5.1 Scope . . . . . . . . . . . . . 5.2 Arrangement . . . . . . . . . . 5.3 Reference Designation . . . . .. 5.4 Option Parts . . . . . . . . . . 5.5 Recommended Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 43 43 43 62 Catalog Number Breakdown . . . . . . . . . . Mechanical Dimensions, Front . . . . . . . . Mechanical Dimensions, Side . . . . . . . . 30 KW, 50 HZ & 37.5 KW, 70 KW Oil Tank . . . Controls and Indicators . . . . . . . . . . Calibration Flow Chart . . . . . . . . . . . Control System Connector Operation . . . . . Standard Model Diagnostic Indicators . . . . Remote Control Connections . . . . . . . . . Remote Control Jumper Connections . . . . . Dip Switch Configurations . . . . . . . . . System Wiring Diagram . . . . . . . . . . . K2 Relay Wiring Diagram, 2400v . . . . . . . Control Transformer Wiring Details . . . . . Monitor Wiring . . . . . . . . . . . . . . . Front View Part I.D. . . . . . . . . . . . . Front View Part 1.D., 2400v. . . . . . . . . Top View Part I.D . . . . . . . . . . . . . 10 KW-20 KW & 30 KW, 60 HZ Oil Tank . . . . Regulator Left Side View . . . . . . . . . . Control Box Circuit Card Identification. . . 2400V K1 & Lightning Arrestor Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 19 20 21 22 23 30 31 39 39.1 39.2 40 40.1 41 42 44 44.1 45 46 47 48 49 FIGURES Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure Figure 1-1 3-1 3-2 3-3 3-4 3-5 4-1 4-2 4-3 4-3c 4-3d 4-4 4-4a 4-5 4-6 5-1 5-1a 5-2 5-3 5-4 5-5 5-6 - vi 9525 Rev. P TABLE OF CONTENTS Cont'd TABLES AND CHARTS Table 3-1 Power Requirements . Display Messages and What They Mean Quick Problem Solving Checklist . . Power Supply Problem Checklist . . . Protection Problem Checklist . . . . Regulation Problem Checklist . . . . Local Control Problem Checklist. . . Remote Control Problem Checklist . . Digital Problem Checklist. . . . . . Display Problem Checklist. . . . . . Parts List - 60 Hz . . . . . . . . . Parts List - 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 27 28 32 33 34 35 36 37 38 50 56 9525 Rev. P SECTION I. 1.1 INTRODUCTION 1.1.1 Purpose GENERAL INFORMATION This instruction manual provides information for installing and maintaining oil-cooled (wet) FAA Type L-828 & L-829 Constant Current Regulators manufactured by Crouse-Hinds Airport Lighting Products, Windsor, Connecticut 06095, U.S.A. 1.1.2 Applicability Only 10 - 70 KW regulators bearing Crouse-Hinds catalog number series 82860-W, 82960-W, 82850-W, & 82950-W are covered by this manual. Refer to Figure 1-1 for complete part number information. Instructions for standard options are provided as supplements to this manual. 1.2 EQUIPMENT DESCRIPTION 1.2.1 Features The Constant Current Regulator is a power supply designed for precision operation of airfield lighting. The output current is regulated within +/-1% at any load and for line voltages form +10% to -5% of nominal. The three or five discrete brightness steps conform to FAA standards. The regulator may be controlled both locally and from a remote location. Protective circuits are provided to sense an overcurrent or an open circuit in the series lighting loop and shutdown the regulator. The front panel display alerts maintenance personnel to the nature of the shutdown. The protective circuitry can be reset by setting the regulator control switch to off for 1 second. Provided no fault condition remains, setting the control switch to the desired brightness step will restore operation. The regulator may be connected directly to an FAA approved load switching device. No regulator malfunction or damage to the series lighting loop will occur. 1.2.2 Options This regulator can be factory supplied with various options. Contact Crouse-Hinds Airport Lighting Products for a current list of options. 1 9525 Rev. P 1.2.3 1.2.3.1 Specification FAA Classification Specification: Constant Current Regulator manufactured and qualified to FAA Advisory Circular 150/5345-10F Type: L-828 Regulator L-829 Regulator (with monitoring) Class: 1 - 6.6 amperes output current (10KW*, 15KW, 20KW, 30KW) 2 - 20 amperes output current (15KW, 20KW, 30KW, 37.5KW, 50KW, 70KW Style: 1 - 3 Brightness Steps: 4.8, 5.5, 6.6 amperes or 14.5, 16.7, 20.0 amperes 2 - 5 Brightness Steps: 2.8, 3.4, 4.1, 5.2, 6.6 amperes or 8.5, 10.3, 12.4, 15.8, 20.0 amperes Ratings: Sizes - 10KW*, 15KW, 20KW, 30KW, 37.5KW, 50KW, 70KW Voltages - 208, 220, 240, 480, 2400V; 60 Hz 208, 220, 230, 240, 380, 400 & 415; 50 Hz *10KW NOT FAA QUALIFIED. 1.2.3.2 Electrical Characteristics Primary Power: Refer to Table 3-1 for ampacity information based on regulator size and line voltage. Remote Control Power: 1.2.3.3 (a) Internal Supply - 120 VAC, standard (Other voltages optional) (b) External Supply - 120 VAC, Standard (Other voltages optional Physical Characteristics Dimensions: Refer to Outline Drawings, Figures 3-1 and 3-2. Weight: 10 15 20 30 KW KW KW KW - 1575 1700 1825 2000 lbs. lbs. lbs. lbs. 2 37.5 KW - 2400 lbs. 50 KW - 2600 lbs. 70 KW - 3000 lbs. 9525 Rev. P Mechanical: The regulator has a vented sheet steel enclosure painted blue with light gray accents. A removable cover provides access to line and load connections. The electronic controls are housed in a hinged compartment which provides access to the remote control terminals when open. Removable covers and panels allows easy access to other customer serviceable parts. The Main Transformer is immersed in an oil (No PCB’S) filled tank. The tank contains between 85-90 U.S. Gallons of electrical insulating Oil. Environmental: 1.3 Temperature: -40 degrees C to + 55 degrees C (-40 degrees F to +131 degrees F) Relative Humidity: 10 percent to 95 percent Altitude: Zero to 6,600 feet (2000 m) Installation Requirements The regulator is shipped from the factory complete and ready to install. The agency responsible for installation must supply all necessary connectors, wire and conduit. The regulator is for indoor use only. It must be floor mounted. 1.4 WARNING NOTICE Exterior metal surfaces may exceed 120° (49°C) when regulator is operated at full power for more than 10 hours. Radiator temperature and oil tank may exceed 150°F (66°C). 3 9525 Rev. P Figure 1-1 4 9525 Rev. P SECTION 2. 2.1 TECHNICAL DESCRIPTION THEORY OF OPERATION (BASIC REGULATOR) The information presented here applies to a standard model Constant Current Regulator (CCR). Regulators supplied with options may have minor operating differences, but the basic operation is the same for all units. Many functions in the CCR are controlled by a custom programmed electronic circuit. This device performs brightness step and digital display control, open circuit and over-current sensing, and handles system fault conditions. Several optional features also use the programmed circuit to reduce the amount of additional circuitry required. Each of the standard functions is discussed in detail in the following paragraphs. Optional functions are discussed in Supplemental sections of this manual. 2.1.1 Current Regulation A ferro-resonant transformer is conjunction with a pair of silicon controlled rectifiers (SCR) is used for current regulation. This design provides precise control regardless of the load size or line voltage. For very low loads or low brightness settings, the SCR conduction angle will be large. At increased loads or higher brightness settings, the conduction angle will be smaller. The SCR gating signal is controlled using closed-loop electronic feedback control. Load current is sensed by a current transformer which generates an analog signal. The signal is processed by an electronic circuit and compared to a predetermined reference. The result is a time delayed SCR control signal. This control signal is applied to a pulse transformer to generate a gating signal for the SCR’s. 2.1.2 Brightness Control Each brightness step has a specific digital reference value stored in electronic memory. When the desired step is selected on the keypad, the proper memory value is converted to an analog signal. This signal is the reference used for comparison as discussed in paragraph 2.1.1. Refer to Section 3.2 for keypad operation. All remote brightness connections are electrically isolated form the control electronics by opto-couplers for transient protection. 5 9525 Rev. P 2.1.3 Remote Control Operation The regulator can operate remotely using external switches connected to the remote control terminal block TB1. The exact wiring of these switches depends upon whether control power is obtained from the regulator internal supply or from an external source. The regulator turns on to brightness B1 (or B10) when control power is applied to terminals CC and B1 (B10). To get a higher brightness, control power is applied to terminal B2, B3, B4 or B5. (For threestep regulators, apply control power to B30 or B100, for one-step regulators, apply control power to on). Only the terminal for the desired step and CC require control power. If two or more steps are energized together, the regulator will operate at the highest brightness step selected. 2.1.4 Digital Display A multi-purpose Digital Display provides system operation data. Under normal conditions, the display shows the output current being supplied by the CCR. Under power-up and system fault conditions, it displays specific CCR status data (refer to paragraph 2.1.6). 2.1.5 Protective System 2.1.5.1 Overcurrent Protection Overcurrent protection is triggered by comparison of the value of the feedback signal to predetermined limits. In the event of a minor overcurrent (between 5% and 25% above rated output), the control system responds within 5 seconds. If a major overcurrent (greater than 25% above rated output) occurs, the control system responds immediately. The response consists of de-energizing the load by opening the main contactor and providing status data to the digital display. To reset and re-energize the CCR, the keypad or remote brightness control switch must be set to OFF for at least one second. 2.1.5.2 Open-Circuited Load Protection This protection is triggered by comparison of the value of the feedback signal to a minimum current level. If the current remains below 2 amps for about 2 seconds, the control system performs the same shutdown sequence as for overcurrent protection. 6 9525 Rev. P 2.1.5.3 Not Used 2.1.5.4 Fuses There are two fuses in the regulator for internal power supply protection. Fuse F1 protects the internal 120 VAC supply. Fuse F2 protects the remote control system supply. 2.1.5.5 Transient Protection Protection against transients from lightning or other sources is provided. Lightning arrester LA1 protects the regulator power lines. Arresters LA2 and LA3 protect the regulator load lines. Varistors are provided on the control system assembly to protect it from transients on the power and control lines. The lightning protection provided exceeds the requirements of the applicable Advisory Circular. Lightning is a naturally occurring phenomenon that varies in intensity and frequency based upon geographic location. Therefore, each installation should be evaluated to determine the need for additional lightning protection. 2.1.6 System Status Information The CCR Digital Display is used during power-up and fault conditions to provide data regarding system status. 2.1.6.1 Power-Up When power is applied to the CCR and when resetting from a latched fault mode, the control electronics performs a series of internal checks. If these are completed without incident, the control program number will be displayed for one second. The display will then begin to indicate CCR output current. If any check is not successfully completed, the system will "lock-up" preventing further operation. 2.1.6.2 Fault Status Messages If the CCR control circuits detect an abnormal system shutdown, a message will automatically scroll across the display. When two or more fault conditions exist, the most recent occurrence is displayed. Messages are cleared when the system is reset or conditions return to normal. Refer to the Operation and Maintenance Sections for information on specific messages. 7 9525 Rev. P 2.1.7 Monitoring (L-829 Only) The monitor circuitry utilizes runway circuit and regulator signals to perform its function. The runway circuit current and voltage are applied to current and potential transformers which perform isolation and step-down functions. The outputs of these transformers are applied to the electronic circuitry for processing. Also, the regulator brightness step signals are used by the monitor circuit. 2.1.7.1 Calibration (L-829 Only) The calibration function is used to initialize the monitor. Upon selection of this mode, the operator is prompted for information on the specific load circuit and the desired alarm levels. When all the information has been entered, the monitor turns on the regulator and automatically adjusts itself for each brightness step. When this adjustment period is completed (usually within 2 minutes), the regulator is returned to the off state. 2.1.7.2 Normal Operation (L-829 Only) The monitor continuously checks the runway circuit for faults. If no system faults have been detected, the monitor relay is in the energized state, the lampout warning and alarm relays are in the deenergized state, and the digital display functions as a true-RMS ammeter. 2.1.7.3 Regulator Power Fault (L-829 Only) Any removal of input power will de-energize immediately, thereby signaling a regulator fault. 2.1.7.4 the monitor relay Protective Circuit Faults In the event of an open circuit or overcurrent shutdown (see section 2.1.5), the monitor relay will be de-energized, signaling a regulator fault. In addition, the display will indicate what fault was encountered. 2.1.7.5 Brightness Step Fault (L-829 Only) The monitor continuously checks the load current. This current value is compared with reference values selected by information from the brightness step control inputs. If the fault is continuously present for a five second period, the monitor relay is de-energized. A star (*) will appear to the right of the current reading on the digital display to indicate an alarm. This fault condition will reset when (1) the current returns to an in-tolerance value, (2) another properly operating brightness step is selected, (3) the regulator is set to the off position. 8 9525 Rev. P 2.1.7.6 Ten Percent Drop in Load Volt-Amperes (L-829 Only) When a large change in load volt-amperes occurs, it is an indication that there are either two ground paths in the runway circuit or that there are many lamp burned out in the circuit. After a five second delay, the monitor relay is energized and a star (*) appears on the digital display to indicate an alarm. The fault condition remains until the situation is corrected. Connection of a runway circuit selector between the monitor and the loads will affect monitor performance. 2.1.7.7 Lamp Failure Detection (L-829 Only) The lamp failure detection feature of the monitor is performed in essentially the same manner as the monitoring of volt-amperes discussed in paragraph 2.1.7.6. It is important to note that because of the method used to detect lampouts, it is not necessary to eliminate lamp shorting devices commonly used in some lighting circuits. If the number of lampouts exceeds the warning level entered by the user, the lampout warning relay will energize. If the number of lampouts exceed the alarm level entered by the user, the lampout alarm relay will energize as well, and the monitor relay will deenergize. 2.1.8 Elapsed Time Meter The regulator is equipped with an electronic elapsed time meter. It records the total on-time of the regulator as well as the individual brightness steps. It will record up to 9999.9 hours of operation before starting at zero hours again. It can be viewed by entering the appropriate command at the regulator keypad. The total or individual brightness step on-time may be viewed while the regulator is in the on or off state. 9 9525 Rev. P SECTION 3. INSTALLATION AND OPERATION WARNING INSTALLATION, SERVICE, MAINTENANCE OR OPERATION SHOULD BE PERFORMED BY QUALIFIED PERSONNEL ONLY. 3.1 INSTALLATION The Constant Current Regulator is supplied ready for operation with all ordered options installed. When properly connected, no electrical adjustments other than noted in this section should be necessary before use. 3.1.1 Location The regulator is designed for indoor locations meeting the environment specified in Section 1.2.3.3. The area should be clean and dry, protected from rain, snow, dust, etc., and have adequate ventilation. The equipment should be accessible to qualified personnel only. 3.1.2 Installation Drawings Typical details and dimensions are provided in Figures 3-1, 3-2, 3-3 and 5-3. 3.1.3 Power Requirements Table 3-1 lists the line current requirements for the different CCR power and voltage ratings. It is recommended that the distribution circuit breaker or fuses be sized to carry 125% of the rated circuit. TABLE 3-1 POWER REQUIREMENTS RATED INPUT VOLTAGE 208 220 230 240 380 400 415 480 2400 10KW 15KW 53 50 48 46 29 28 27 23 5 80 75 72 69 43 41 40 35 7 RATED INPUT CURRENT (RMS AMPERES) 20KW 30KW 37.5KW 106 100 96 92 58 55 53 46 9 159 150 143 138 87 83 80 68 14 10 ------172 ------86 17 50KW 70KW --------145 138 133 115 23 --------------160 32 9525 Rev. P 3.1.4 Cable and Conduit Do not locate line and load cables near sensitive control, radar, or communications lines. For suggested cable entrance locations, see Figures 3-2 and 3-3. 3.1.5 3.1.5.1 3.1.5.2 Installation Check List (1) Read these instructions before attempting installation. Improper installation can damage this regulator and may void the warranty! If the equipment fails to perform properly at any step of this procedure, consult the troubleshooting guide in Section 4. Call Crouse-Hinds Airport Lighting Products (860) 683-4300 if further information is required during installation. (2) Instructions for each equipment option included should also be read before proceeding with installation. (3) SUGGESTION: To stay organized, make a check mark next to each step as it is completed. Mechanical Installation 1. Unpack the Constant Current Regulator, and check for shipping damage. any 2. For handling, a 2” fork-lift clearance is provided underneath the unit and 4 lifting lugs are provided. The regulator cover should be in place before lifting. 3. Refer to Figures 3-1 through 3-3 and 5-3 for mechanical installation details. Adequate clearance should be left around the regulator for access and cooling. 4. Level the transformer so that the degrees off of vertical. Check the The oil level should be visible in gauge at 25 degrees C (77 degrees F) operating temperature. tank is not more than 5 oil level in sight gage. the lower portion of the and will rise somewhat at Power Wiring and Checkout 1. Connect the ground conductor to the equipment ground terminal. It is located on the lower right side toward the front of the regulator. CAUTION: DO NOT connect counterpoise system to this terminal. 2. Verify that the lien voltage is the same as the regulator nameplate voltage rating. This is very important. CONNECTION TO THE WRONG LINE VOLTAGE MAY VOID THE WARRANTY. 3. Make required conduit holes as suggested in Figures 3-2 and 3-3. 11 9525 Rev. P 4. Connect the line voltage source to the input terminals. On 2400 volt WYE unites, the phase wire connects to the left terminal (LA1A) and the neutral connects to the right terminal (LA1B). Do not rely on the ground wire as a neutral conductor. 5. Connect the series lighting circuit to the output terminals. CAUTION: DO NOT MEGGER test the series lighting load while it is connected to the regulator. 6. Before connecting remote control lines, check regulator operation using the front panel control switch. Follow steps AC below. NOTICE: The regulator is equipped with a safety interlock. Be sure the control module is in its normal operating position before operating. (A) Apply main power to the regulator. (B) Operate the regulator at all brightness steps and check that the load current levels are correct. See regulator nameplate for load current levels. (See Section 3.2 for keypad operation.) Only a True RMS instrument can accurately IMPORTANT: measure the regulator output externally. Other instruments will provide improper readings. (C) 3.1.5.3 Shut off main power to the regulator. Control Wiring and Checkout 1. Connect remote control lines to terminal block TB1 using the appropriate wiring diagram. Refer to Figure 4-3. Units which are shipped without an internal primary contactor (Option 92) must use 120Vac external control. See the instructions in the Option 92 Supplement for connection data. Incorrect wiring can cause malfunction or damage to CAUTION: the control system and possibly void the equipment warranty. Re-check these connections before operating. 12 9525 Rev. P 2. Make a final operation check using local and remote Steps A-C below. 3.1.5.4 modes. (A) Apply main power to the regulator. (B) Operate the regulator in the local mode at all rightness steps and check for correct current levels. (See Section 3.2 for keypad operation.) (C) Operate the regulator in the Remote mode at all rightness steps and check for correct current levels. Monitor Wiring (L-829 Only) This regulator is equipped with monitor relay, and a warning and alarm lampout relay. Connect the relay contacts to the monitor and lampout circuits per Figure 4-6. Each relay is rated for 120 VAC, 2 AMPS resistive load. relays are protected by 2 AMP fuses on the P.C. board. 3.1.5.5 The lampout Final Installation Steps 1. Make any option related connections discussed in the Supplements. option 2. Check that all cables an wiring are dressed within the Reinstall all covers. cabinet. 13 9525 Rev. P 3.2 OPERATION Figure 3-4 shows the standard controls and indicators on the front control panel. 3.2.1 Local Control Keypad The local control keypad in conjunction with the digital display acts as an interactive control terminal for entering many different operational commands into the regulator. All keypad entries are echoed to the display for a period of five seconds for operator verification. In all instances, with two exceptions, the command sequence ends with the “E” key ( for Enter). The two exceptions are the “ABORT” command - which erases any un-entered command, and the “OFF” command - which will immediately turn off the regulator. To select an operating brightness step, simply press according to the following list: (Remember - If you make a mistake, press “A” for ABORT.) To select OFF - Press “OFF” (no Enter required) or Press “BO (Enter)” or Press “0 (Enter)” To select Remote - Press “BB (Enter)” For 1 step regulators: To select ON - Press “B1 (Enter)” For 3 step regulators: To select B10 - Press “B10 (Enter)” or Press “B1 (Enter)” To select B30 - Press “B30 (Enter)” or Press “B2 (Enter)” To select B100 - Press “B100 (Enter)” or Press “B3 (Enter)” Entering B4 or B5 will result in an “ERROR” message. 14 the keys 9525 Rev. P For 5 step regulators: To select B1 - Press “B1 (Enter)” To select B2 - Press “B2 (Enter)” To select B3 - Press “B3 (Enter)” To select B4 - Press “B4 (Enter)” To select B5 - Press “B5 (Enter)” Entering B10, B30 or B100 will result in an “ERROR” message. The brightness step command is stored in what is called ‘non-volatile’ electronic memory which is reliable for at least 10 years without power applied. This enables the regulator to immediately return to the selected brightness after a power interruption without operator intervention - just as if a rotary switch were used for brightness control. 3.2.2 Digital Display During normal operation, the digital display functions as a True RMS ammeter, displaying the regulator load current. during power-up, under system fault conditions and when the keypad is in use, the display performs other functions. When these other functions are finished using the display, it automatically returns to reading load current. If the display is echoing keypad entries and no new entry is made within 5 seconds, the display returns to reading load current. They key entries are not lost. When power is initially applied to the regulator, the computer performs checks for valid operation. If these checks are completed successfully, the display will read “VER. X.X.”, where X.X is the software program version number, for a period of 1 second. Then normal display activity will begin. If the regulator should shut down due to system fault, a message will immediately begin to scroll across the display to explain the reason for the shut down. See Section 3.2.4 for further information. L-829 only If a lamp out monitor or brightness step monitor fault is detected, the display will continue to read current, but a “*” will appear to the right of the current reading. See Section 3.2.4 for further information. 15 9525 Rev. P 3.2.3 Monitor Calibration (L-829 only) Calibrating the monitor does not require any tools. All that you need to know is the number of lamps in the circuit and at what number of lamp burn outs you want the warning and alarm functions to activate. If you wish, you may elect to calibrate the monitor in percentage rather than lamp count. This is recommended when there are different lamp wattages, very few lamps, many lighted signs or more than 200 lamps on the circuit. Complete instructions are provided below. A flow chart is also provided in Figure 3-5. TO CALIBRATE THE MONITOR: BEFORE CALIBRATING THE MONITOR, BE SURE ALL THE LAMPS ARE OPERATING PROPERLY. IF SOME ARE BURNED OUT, THEY WILL BE IGNORED BY THE MONITOR!!. (Remember - Press “A” to ABORT if you make a mistake.) Press “CC(Enter)” - This enters the calibrate mode. The CCR will turn off and the prompt LMPS = XXX where XXX equals the number of lamps previously entered (100 if in percent mode) will appear on the display. If you wish to use the lamp mode: Press the keys for the number of lamps in the load, followed by All future prompts will refer to number of “E” for Enter. lamps. If you wish to use the percent mode: Press “C” for “Change” - the display will now prompt “PERCENT?”. If you change your mind and want to go back to lamp mode, press “C” again. If you are sure you want percent mode press The number of lamps is not important in percent “(Enter)”. mode. All future prompts will refer to percentage of the total load. The next prompt in either monitor mode is “WARN = XX”. Where “XX” = the lamps or percent previously entered. Press the keys for the number or percentage of lamps at which the warning signal is to be If you are not using the activated, followed by “E” for Enter. warning signal, enter any number (a number must be entered). At the prompt NORM = XX, WHERE “XX” equals the lamps or percent previously entered, press the keys for the number or percentage of lamps at which the Primary Alarm signal should activate, followed by “E” for Enter. In the FAA Advisory Circular this is called the Normal operation mode. 16 9525 Rev. P The last data entry is at the DEGR = “XX” where XX equals the lamps or percent previously entered prompt. Press the keys for the number or percentage of lamps at which the Secondary Alarm signal should activate followed by “E” for Enter. In the FAA Advisory Circular this is called the degraded operation mode. This entry must be higher than the Primary Alarm entry or an error message will appear. At this point the monitor will ask permission to perform automatic calibration with the prompt “AUTOCAL?”. Check to be sure the load circuit is connected and no personnel are working on it. When you are sure of these things, press “E” (for Enter). The monitor now will assume control of the regulator, turning it on to the highest brightness step. The monitor will automatically adjust for the load circuit and then proceed to the lower steps. For a 5 step CCR, it will do B2-B5, A 1 or 3 step will be monitored at every step. This normally takes about 5 minutes. You can check on the progress of this calibration by watching the starts (“*”) on the display. Each time a step change take place, one star will go out. When the calibration procedure is finished, the display will read “COMPLETE” for about one second and then normal display operation will resume. If the regulator was in remote control mode before calibration, it must be reset to remote by pressing “BB(Enter)”. If the load is less than 50% of the regulator’s capacity, the regulator will shut off and the display will read “Load Too Small.” The regulator must be loaded to 50% or more of its capacity to use the lamp-out monitor. 3.2.4 Monitor Operation (L-829 only) After calibration the monitor will continuously operate in both local and remote control modes. The lamp-out monitor always begins in the Primary Alarm (Normal) mode. To switch to the Secondary Alarm To return to (Degraded) mode, press “CD(Enter)” on the keypad. Primary Alarm mode, press “CB(Enter)” on the keypad. If a regulator shutdown occurs you can find out what happened by reading the display: “HIGH LOAD CURRENT” - Over current protection trip. “OPEN LOAD CURRENT” - Open Load protection trip. “LOW INPUT LINE” Low line voltage trip. - 17 9525 Rev. P Other monitor alarms, which do not result from complete regulator shutdown, are indicated by one star (“*”) to the right of the load current reading on the display. To find out exactly what is One of the following happening, press “CF(Enter)” on the keypad. messages will scroll across the display. “10% LOAD OUT” - More than 10 percent of the load is not operating, typically the indication of a ‘double ground’ on the load circuit. “STEP CURRENT OUT OF SPEC.” - The brightness step which is selected is not operating within the FAA Advisory Circular limits. WARNING “XXX” LAMPS OUT or “XXX% LAMPS OUT The actual number or percentage of lamps out, only if the alarm limit has been exceeded. - “NO WARNINGS OR ALARMS”” 3.2.5 Self-explanatory. Elapsed Time Meter Operation To display the elapsed operating time of the brightness step, press “DB” followed by the selected step. (1-3 for a three step regulator, 1 for a one step regulator, or 1-5 for a five step regulator) Press “E” for Enter on the keypad. To display the total elapsed operating time of the regulator, press “DBO(Enter)”. 18 9525 Rev. P 19 9525 Rev. P 20 9525 Rev. P 21 9525 Rev. P 22 9525 Rev. P 23 9525 Rev. P MAINTENANCE WARNING INSTALLATION, SERVICE, MAINTENANCE, OR OPERATION SHOULD BE PERFORMED BY QUALIFIED PERSONNEL ONLY. 4.1 PERIODIC MAINTENANCE The Constant Current Regulator should be inspected periodically as shown below: INTERVAL PROCEDURE 6 months (1) Remove main power from the regulator. (2) Remove the front access control box compartment. (3) Check all wiring connections for loose or missing screws. (4) Check for broken or damaged wires and parts. (5) Remove dust build-up. (6) Inspect housing for rush or chipped paint. and touch up with paint as required. (7) Check the oil level. The oil level should be visible in the lower portion of the gauge at 25 degrees C (77 degrees F). Add oil if necessary (Crouse-Hinds P/N 10053-25). (8) Secure control box and re-install access panel. (9) Restore primary power to the regulator. Operate the regulator at all brightness steps, first by local control, then by remote control. Check for proper load currents. 24 panel and open the Clean 9525 Rev. P 4.2 CORRECTIVE MAINTENANCE Corrective maintenance is required when the regulator does not work properly. This usually requires the replacement of parts or subassemblies. The use of easily removable subassemblies make repair a simple task. The removal and replacement method should be obvious to qualified maintenance personnel. WARNING VOLTAGES ABOVE 1000 VOLTS ARE PRESENT WHEN THE REGULATOR IS OPERATING. DO NOT REPAIR OR SERVICE WITHOUT FIRST REMOVING POWER FROM THE REGULATOR. THE USE OF LOCK-OUT DEVICES IS RECOMMENDED. The control assembly contains parts which can be replaced in the field by a service person. If properly trained personnel are not available, replace the entire control assembly. Improper removal and handling can cause damage to the equipment. Particular areas of concern are: 4.3 (A) Remove power from the regulator before disconnecting the connector plug from the control compartment. (B) Depress the serrated release on the connector to remove it from the control compartment. DO NOT try to remove by pulling on the wire harness. See Figure 4-1 for operation of the connector. (C) CAUTION: The circuit cards within the control assembly are STATIC SENSITIVE. Do not remove or handle them without an static control wrist strap. PROBLEM SOLVING GUIDE This guide will assist qualified airport maintenance personnel in locating and correcting equipment failures. Problems associated with option functions are addressed in the specific option Supplement. If further assistance is required, contact the Customer Service Department at Crouse-Hinds Airport Lighting Products, Windsor, Connecticut. 4.3.1 FAULT ISOLATION The first step in fault isolation is the preliminary evaluation. Start by checking for disconnected wires, switches in the wrong position, blown or missing fuses, etc. Determine if other equipment on the same circuit is operating properly. Be sure that the equipment is being used properly by checking the operation instructions. Finally, if the digital display is working, use the displayed message to localize the problem. 25 9525 Rev. P If these checks do not pinpoint the problem, try operating the regulator with a short across the load terminals. OPERATING INTO A SHORT WILL NOT HARM THE REGULATOR. This is the best way to find out if the problem is with the regulator or the load circuit. Once these checks have been made, refer to the checklist for further instructions. 26 9525 Rev. P DISPLAY MESSAGES AND WHAT THEY MEAN DISPLAY MESSAGE WHAT IT MEANS ‘VER.X.X’ (where X.X is a number like 1.1) This is the indication that all power-up checks are OK. The number is the program version. This should appear for 1 second. The line voltage supplied to the regulator is too low for proper operation. Check to be sure the supply voltage is the same as the regulator nameplate. If OK then see section on power supply problems. The regulator has tripped off-line due to an over current condition. See the section on protection problems to fix. The regulator has tripped off-line due to an open circuit condition. Try operating the regulator into a short circuit. If it doesn’t trip again, check the field wiring for an open. If no open is found, or the unit trips even with a short circuit see the section on protection problems. See the option supplement to find out what the message means. See the section on display problems. ‘LOW INPUT LINE’ ‘HIGH LOAD CURRENT’ ‘OPEN LOAD CIRCUIT’ Display shows some other readable message. Display shows a bunch of funny things or garbage. 27 9525 Rev. P QUICK PROBLEM SOLVING CHECKLIST SYMPTOM WHAT TO DO System will not turn on. (1) Check power source turned on. (2) Check for 120VAC across X1 to X2 on transformer T3. It is probably bad. Control display OFF. (3) Check F1. If good, see the section on power supply problems. (1) If display reads ‘0.00A’ see the section on local control problem. (2) See section on digital problems. (1) See section on local control problems. (2) See section on remote control problems. (3) If supplied with Option 92, contact Crouse-Hinds Airport Lighting Products. (1) If display reads ‘Open in load circuit’ or “High load current’ see section on protection problems. (2) See section on digital problems. (1) See section on remote control problems. (1) Check for overload. (2) If problem is only in remote see section on remote control problems. (3) Otherwise, see section on regulation problems. (1) See section on display problems. System will not turn on. display ON. Control System will not turn off. System turn on for 1 to 5 seconds, then trips out. System works find in Local but does not work in Remote. Wrong current levels in any or all steps. Regulator works but display is out or showing ‘funny’ data. Monitoring Problems (L-829 only) (1) Check load circuit. (2) Re-calibrate (Section 3.2.3 (3) See section on monitor problems. 28 9525 Rev. P 4.3.2 DETAIL PROBLEM SOLVING GUIDE On the next few pages are detail problem solving guides. These guides make use of the digital display and the indicators on the control box circuit cards to speed repair. 4.3.2.1 OPENING THE CONTROL BOX TURN OFF MAIN POWER TO THE REGULATOR BEFORE STARTING: To open the control box, swing it away from the cabinet and unplug the connector. Then use a screw driver to remove the top cover screws. Be careful to keep screws from falling into the box, as they could short out components inside. Plug the connector back in. Default the interlock switch by pulling the interlock switch actuator out. Turn on main power to regulator to begin trouble-shooting. DANGER; BE CAREFUL! THE CIRCUITS INSIDE THE CONTROL BOX ARE LIVE AND CONTAIN DANGEROUS CURRENT LEVELS. 4.3.2.2 CIRCUIT CARD INDICATORS Before doing any problem solving, take a few minutes to become familiar with the circuit card indicators. They are provided as an aid in deciding what part or subassembly to change. A diagram showing the indicators is shown in Figure 4-2. Now go to the detail checklist for the problem being addressed. 29 9525 Rev. P 30 9525 Rev. P 31 9525 Rev. P POWER SUPPLY PROBLEM CHECKLIST SYMPTOM WHAT TO DO All board indicators are OFF. (1) Remove the power supply board an check fuse F1. If blown, replace it. If not blown, replace the power supply board. (2) If the fuse blows again right away, replace the power supply board. (3) If the indicators light, but the regulator still does not work, go to the next symptom. (1) Remove all boards except the power supply and display. If the problem is still there, replace the power supply board. If the problem goes away, install one board at a time until it reappears. Replace the faulty board. One power supply board indicator is OFF or it is very dim. For further help contact Crouse-Hinds Airport Lighting Products. 32 9525 Rev. P 9525 PROTECTION PROBLEM CHECKLIST PLEASE REMEMBER TO TURN OFF MAIN AND CONTROL POWER BEFORE REMOVING OR INSTALLING CIRCUIT CARDS: SYMPTOMS WHAT TO DO Display reads ‘OPEN LOAD CIRCUIT.’ (1) Observe feedback indicator on the Regulation Circuit Card before shutdown. If OFF, check T2 for an open winding. If T2 is OK, replace Regulation Circuit Card. (2) Observe both SCR drive indicators. If both are off, replace Regulation Circuit Card. If both are on, replace SCRs Q1 and Q2. (1) If regulator operates on lower steps but currents are high, replace Regulation Circuit Card. (2) If regulator trips right away, regardless of step, observe SCR drive indicators. They should be dim before out. If they are, then replace SCRs Q1 an Q2. Otherwise, replace Regulation Circuit Card. (1) Observe +12V power supply indicator. If dim, see section on power supply problems. If OK, replace Regulation Circuit Card. Display reads ‘HIGH LOAD CURRENT.’ Display reads ‘LO INPUT LINE.’ For further help contact Crouse-Hinds Airport Lighting Products. 33 9525 Rev. P REGULATION PROBLEM CHECKLIST PLEASE REMEMBER TO TURN OFF MAIN AND CONTROL POWER BEFORE REMOVING OR INSTALLING CIRCUIT CARDS! SYMPTOM WHAT TO DO All currents low. (1) Observe SCR Drive indicators. They should go from dim to bright when the unit is turned on. If one or both stay dim all the time, replace Regulation Circuit Card. If OK, replace SCRs Q1 and Q2. High steps OK, but low steps are high. (1) Observe SCR Drive indicators. They should change brightness together. If they don’t then replace Regulation Circuit Card. If OK, replace SCRs Q1 and Q2. (1) If in local and remote control replace Control Interface card. (2) See section on Remote Control problems. (1) Run regulator in a short. If OK, regulator is over-loaded. (2) Observe Control indicator with local switch in OFF. If it is OFF, replace Regulation Circuit Card. If it is ON, replace Control Interface Card. (1) Observe +12V indicator. If it blinks, then be sure area temperature is below 130 degrees F. If it is OK, replace the Regulation Circuit Card. One step high or low. Low steps OK, but high steps are low. Current fluctuates over a wide range. For further help contact Crouse-Hinds Airport Lighting Products. 34 9525 Rev. P LOCAL CONTROL PROBLEM CHECKLIST PLEASE REMEMBER TO TURN OFF MAIN AND CONTROL POWER BEFORE REMOVING OR INSTALLING CIRCUIT CARDS! SYMPTOMS WHAT TO DO System will not turn on. (1) Observe Control and Contactor indicators. They should go on and off together when switching from off to a step. If they don’t then replace Microcontroller Circuit Card. (2) Check K1 coil for open. If open replace K1. If OK replace Regulation Circuit Card. (1) If system will not turn off when the interlock switch is opened, K1 may be welded closed. (2) Observe Contactor indicator. If on all the time, replace Microcontroller Circuit Card. If it turns off, replace Control Interface Card. (1) Check for damage to keypad. If found, replace. (2) Replace display card. System will not turn off. Keypad does not respond to one or more key presses. For further help contact Crouse-Hinds Airport Lighting Products. 35 9525 Rev. P REMOTE CONTROL PROBLEM CHECKLIST PLEASE REMEMBER TO TURN OFF MAIN AND CONTROL POWER BEFORE REMOVING OR INSTALLING CIRCUIT CARDS! SYMPTOM WHAT TO DO System will not turn on. (1) Check in local control. If not OK, see section on local control problems. (2) Check remote supply and wiring. If OK, replace Control Interface Card. (1) Check for control lines longer than 10,000 feet in length. (1) Check for control lines longer than 10,000 feet in length. System will not turn off. Current fluctuates up or down. For further help contact Crouse-Hinds Airport Lighting Products 36 9525 Rev. P DIGITAL PROBLEM CHECKLIST PLEASE REMEMBER TO TURN OFF MAIN AN CONTROL POWER BEFORE REMOVING OR INSTALLING CIRCUIT CARDS! SYMPTOM WHAT TO DO System will not turn on. (1) Observe Run and Halt indicators. If they are blinking, replace Regulation Circuit Card. If the Half indicator is always on, replace Microcontroller Circuit Card. If the Run indicator is on all the time, see the section on local control problems. For further help contact Crouse-Hinds Airport Lighting Products. MONITOR PROBLEM CHECKLIST (L-829 ONLY) SYMPTOM WHAT TO DO Remote indicators out. (1) Check for power source on. (2) Check fuses on load monitor board. (3) If relay indicators on monitor board switch on and off, replace K1, K2 and/or K3. (4) Replace load monitor board. (1) Try percent mode calibration (2) Replace load monitor board. (3) Replace transformer T5. (1) Re-calibrate. (2) Replace load monitor board. Unit will not calibrate. Erroneous readings or alarms. For further help contact Crouse-Hinds Airport Lighting Products. 37 9525 Rev. P DISPLAY PROBLEM CHECKLIST PLEASE REMEMBER TO TURN OFF MAIN AND CONTROL POWER BEFORE REMOVING OR INSTALLING CIRCUIT CARDS! SYMPTOM WHAT TO DO Regulator runs but no display. (1) Check for a loose cable from the display to the Control Interface Card. If OK replace Display Card. (1) Check switch settings on the Control Interface Card. (2) Replace Control Interface Card. (1) If display reads ‘VER.X.X.’ and does not change, see the section on digital problems. (2) Replace Microcontroller Circuit Card. Regulator runs but Display shows wrong current. For further help contact Crouse-Hinds Airport Lighting Products. 38 9525 Rev. P 39 9525 Rev. P 39.1 9525 Rev. P 39.2 9525 Rev. P 40 9525 Rev. P 40.1 9525 Rev. P 41 9525 Rev. P 41.1 9525 Rev. P 42 9525 Rev. P 5.1 SCOPE The Parts List provides ordering data for all replaceable parts and subassemblies. 5.2 ARRANGEMENT The Figures and Tables in this section are arranged to show each replaceable part or assembly. The parts are identified in each Figure by Index Number. The Index Number appears in the corresponding Parts List which also provides the part number and description. 5.3 REFERENCE DESIGNATION A reference designation number is assigned to each electrical part contained in the regulator. These reference designations are shown on the wiring diagram. 5.4 OPTION PARTS Parts that are option related are discussed in the respective Supplement for that Option. 43 9525 Rev. P 44 9525 Rev. P 44.1 9525 Rev. P 45 9525 Rev. P 46 9525 Rev. P 47 9525 Rev. P 48 9525 Rev. P 49 REFERENCE DESIGNATION DESCRIPTION INDEX NO. 1 2 R1 C2 Resistor Assembly Capacitor CROUSE-HINDS AIRPORT LIGHTING PART NO. 31499 10047-1051 3 4 TB1 S2 Terminal Block Assembly Interlock Safety Switch 32048 10047-1878 5 DS1 Neon Indicator 10047-938 Label, Indicator Light Standoff, 3/4” Dia 31683 10053-10 12 Warning Label Wiring Diagram Varistor Assembly Current Transformer, 6.6A Current Transformer, 20A Electrical Insulating Oil 32272 32152 31665 31374 31394 10053-25 13 Fuse Holder 10047-1660 Fuse, 1 amp Slo-Blo Fuse, 2Amp, Slo-Blo, (30KW 208/220/240V; 37.5KW 240V; 70KW 480V and 2400V) 10053-307 10047-1141 6 7 50 8 9 10 11 14 RV1 T2 F1 C.S.I. P/N 2N256T Unimax P/N 23TL604 Ledtronics PF50-CRN120VAC-T H.H. Smith 2615 or equal Exxon Univolt N61, Product Code 33183101831 Buss P/N HKPHH Buss P/N MDL-1 Buss P/N MDL-2 9525 REV P 9525 Rev. K 60 HZ PARTS MANUFACTURER PART NO. INDEX NO. REFERENCE DESIGNATION DESCRIPTION 15 F2 Fuse, 1/8 amp Slo-Blo CROUSE-HINDS AIRPORT LIGHTING PART NO. 10047-1005 16 RV2 & RV3 Varistor, 150V RMS, 20J 10047-1297 17 T20 32044 18 T5 20 E1-E6 Power Supply Transformer Subassembly Potential Transformer Potential Transformer (15KW, 20A Units only) Potential Transformer (30KW, 6.6A Units only) Transformer (208-240V, 10-20 KW & 240V, 37.5 KW & 480V, 30, 37.5 & 50 KW) Transformer (208V, 30 KW) Transformer (2400V) Transformer (220-240V, 30 KW & 480V, 70 KW) Bushing 21 E7 Standoff Insulator 10053-698 22 LA1A & LA1B Standoff Insulator (480V & Lower) 10053-696 23 24 LA1 Danger Label Lighting Arrestor (208-480V) 41222 10047-885 25 Q1 & Q2 SCR/Heatsink Assembly (10, 15 & 20 KW) SCR/Heatsink Assembly (30, 37.5, 50 & 70 KW) 31505-1 19 T3 51 Buss P/N MDL1/8 G.E. P/N V150LA20B 31436 31789 32271 31675 10047-2424 32414 10047-1444 10053-24 Porcelain Products 71118 Glastic P/N 1872-1A Glastic P/N 1603-2A G.E. P/N 9L15ECB001 31505-2 9525 REV P 60 HZ PARTS MANUFACTURER PART NO. INDEX NO. 26 27 52 REFERENCE DESIGNATION DESCRIPTION LA2 & LA3 Lightning Arrestor, 3KV (10 KW; 15 KW; 20 KW, 20A; 30 KW, 20A; 37.5 KW) LA2 & LA3 Lightning Arrestor, 6 KV (20 KW, 6.6A; 30 KW, 6.6A; 50 KW, 70 KW) 10053-351 LA1A (2400V) Lightning Arrestor, 6 KV (All KW Sizes) Contactor, 75A (15 KW, 480V; 20 KW, 480V) 10053-351 Contactor, 95A (10 KW; 15 KW, 208-240V; 30 KW, 480V) Contactor, 120A (20 KW, 208-240V) Contactor, 150A (37.5 KW, 480V; 50 KW, 480V) Contactor, 200A (30 KW, 208-240V; 37.5 KW, 240V; 70 KW, 480V) Relay, 125A, Single Pole (2400V) 32084 K1 CROUSE-HINDS AIRPORT LIGHTING PART NO. 10053-693 10047-1249 MANUFACTURER PART NO. Cooper Power UHS0303-0A0A1A1A or G.E. P/N 9L23BXX003XH Cooper Power UHS0604-0A0A1A1A or G.E. P/N 9L23BXX006XH Square DP/N 8910-DPA62-V02Y236 32085 32087 10047-2774 10047-2757 Joslyn Clark P/N CVC77U022006-76 Joslyn Clark P/N VC77U0143676 60 HZ PARTS 9525 REV P INDEX NO. 28 29 53 REFERENCE DESIGNATION DESCRIPTION C1 Capacitor (10 KW; 37.5 KW; Qty 1) Capacitor (20 KW; 50 KW, Qty 1) Capacitor (30 KW; 50 KW, Qty 1; 70 KW, Qty 1; 37.5 KW, Qty 1 Capacitor (15 KW) Capacitor (70 KW, Qty 1) Capacitor (70 KW, Qty 1) Control Assembly (insert 1, 3, or 5 in place of “X” for number of steps desired. Insert 1 for 6.6A or 2 for 20A in place of Y for current desired. The standard Control Assembly consists of the following major replaceable items: Digital Display Board Assembly Power Supply Board Assembly Control Interface Board Assembly *(1) Microcontroller Board Assembly Regulation Board Assembly Load Monitor Board Assembly *(2) (L-829 only) Keyboard, 4 x 4 Matrix *(1) If complete Control Assembly is not ordered, set dip switch on board per instructions. *(2) Specify KW rating of regulator when ordering. 60 HZ PARTS CROUSE-HINDS AIRPORT LIGHTING PART NO. 30062-01 30062-02 30062-03 MANUFACTURER PART NO. 30062-04 30956 30957 32323 Add 61 @ end for L-829 31765-1 31971 31716-1 32277-1 31879-3L 31926-1 10047-2176 9525 REV P INDEX NO. 30 54 REFERENCE DESIGNATION DESCRIPTION T1 Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, 10 10 10 10 10 15 15 15 15 15 15 15 15 15 15 20 20 20 20 20 20 20 20 20 20 KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, 6.6A, 208V 6.6A, 220V 6.6A, 240V 6.6A, 480V 6.6A,2400V 6.6A, 208V 6.6A, 220V 6.6A, 240V 6.6A, 480V 6.6A,2400V 20A, 208V 20A, 220V 20A, 240V 20A, 480V 20A, 2400V 6.6A, 208V 6.6A, 220V 6.6A, 240V 6.6A, 480V 6.6A,2400V 20A, 208V 20A, 220V 20A, 240V 20A, 480V 20A, 2400V CROUSE-HINDS AIRPORT LIGHTING PART NO. 32143-10-1 32143-10-2 32143-10-4 32143-10-8 32143-10-9 32143-15-1 32143-15-2 32143-15-4 32143-15-8 32143-15-9 32143-16-1 32143-16-2 32143-16-4 32143-16-8 32143-16-9 32143-20-1 32143-20-2 32143-20-4 32143-20-8 32143-20-9 32143-21-1 32143-21-2 32143-21-4 32143-21-8 32143-21-9 MANUFACTURER PART NO. 60 HZ PARTS 9525 REV P INDEX NO. REFERENCE DESIGNATION DESCRIPTION 30 (Cont’d) T1 32143-50-8 32143-50-9 32143-70-8 32143-70-9 10047-1898 10047-1899 (REF K2) 32 K2 Relay Octal Plug (2400V Only) 55 31 Main X’fmr Assy, 30 KW, 6.6A, 208V Main X’fmr Assy, 30 KW, 6.6A, 220V Main X’fmr Assy, 30 KW, 6.6A, 240V Main X’fmr Assy, 30 KW, 6.6A, 480V Main X’fmr Assy, 30 KW, 6.6A,2400V Main X’fmr Assy, 30 KW, 20A, 208V Main X’fmr Assy, 30 KW, 20A, 220V Main X’fmr Assy, 30 KW, 20A, 240V Main X’fmr Assy, 30 KW, 20A, 480V Main X’fmr Assy, 30 KW, 20A, 2400V Main X’fmr Assy, 37.5 KW, 20A,240V Main X’fmr Assy, 37.5 KW, 20A,480V Main X’fmr Assy, 37.5 KW, 20A, 2400V Main X’fmr Assy, 50 KW, 20A, 480V Main X’fmr Assy, 50 KW, 20A, 2400V Main X’fmr Assy, 70 KW, 20A, 480V Main X’fmr Assy, 70 KW, 20A, 2400V Socket, Octal Relay (2400V Only) CROUSE-HINDS AIRPORT LIGHTING PART NO. 32143-30-1 32143-30-2 32143-30-4 32143-30-8 32143-30-9 32143-31-1 32143-31-2 32143-31-4 32143-31-8 32143-31-9 32143-37-4 32143-37-8 32143-37-9 MANUFACTURER PART NO. Potter & Brumfield 27E122 Potter & Brumfield KRPA-5AG-120V 60 HZ PARTS 9525 REV P INDEX NO. REFERENCE DESIGNATION DESCRIPTION 1 2 R1 C2 Resistor Assembly Capacitor CROUSE-HINDS AIRPORT LIGHTING PART NO. 31499 10047-1051 3 4 TB1 S2 Terminal Block Assembly Interlock Safety Switch 32048 10047-1878 5 DS1 Neon Indicator 10047-938 Label, Indicator Light Standoff, 3/4” Dia 31683 10053-10 12 Warning Label Wiring Diagram Varistor Assembly Current Transformer, 6.6A Current Transformer, 20A Electrical Insulating Oil 32272 32152 31665 31374 31394 10053-25 13 Fuse Holder 10047-1660 F1 Fuse, 1 amp Slo-Blo 10053-307 Exxon Univolt N61, Product Code 33183101831 Buss P/N HKPHH Buss P/N MDL-1 10047-1141 Buss P/N MDL-2 F2 Fuse, 2 amp Slo-Blo (30KW 208/220/230V) Fuse, 1/8 amp Slo-Blo 10047-1005 Buss P/N MDL1/8 6 7 56 8 9 10 11 14 15 RV1 T2 MANUFACTURER PART NO. C.S.I. P/N 2N256T Unimax P/N 23TL604 Ledtronics P/N PF50-CRN120VAC-T H.H. Smith 2615 or equal 50 HZ PARTS 9525 Rev P INDEX NO. REFERENCE DESIGNATION DESCRIPTION CROUSE-HINDS AIRPORT LIGHTING PART NO. 10047-1297 16 RV2 & RV3 Varistor, 150V RMS, 20J 17 T20 18 T5 31675 10053-24 57 19 20 T3 E1-E6 Power Supply Transformer Subassembly Potential Transformer Potential Transformer (15KW, 20A Units only) Potential Transformer (30KW, 6.6A Units only) Transformer (208-415V) Bushing 21 E7 Standoff Insulator 10053-698 22 LA1A & LA1B Standoff Insulator 10053-696 23 24 LA1 Danger Label Lighting Arrestor (208-415V) 41222 10047-885 25 Q1 & Q2 SCR/Heatsink Assembly (10, 15 & 20 KW) SCR/Heatsink Assembly (30 & 50 KW) 31505-1 MANUFACTURER PART NO. G.E. P/N V150LA20B 32044 31436 31789 32271 Porcelain Products 71118 Glastic P/N 1872-1A Glastic P/N 1603-2A G.E. P/N 9L15ECB001 31505-2 50 HZ PARTS 9525 REV P INDEX NO. 26 27 REFERENCE DESIGNATION DESCRIPTION LA2 & LA3 Lightning Arrestor, 3KV (10 KW; 15 KW; 20 KW, 20A; 30 KW, 20A) K1 CROUSE-HINDS AIRPORT LIGHTING PART NO. 10053-693 58 Lightning Arrestor, 6 KV (20 KW, 6.6A; 30 KW, 6.6A; 50 KW) 10053-351 Contactor, 75A (10 KW; 15 KW, 380-415V; 20 KW, 380-415V) 10047-1249 Contactor, 95A (15 KW, 208-240V; 30 KW, 380-415V) 32084 Contactor, 120A (20 KW, 208-240V) 32085 Contactor, 150A (50 KW 380-415V) 32087 Contactor, 200A (30 KW, 208-240V) 10047-2774 MANUFACTURER PART NO. Cooper Power UHS0303-0A0A1A1A Cooper Power UHS0604-0A0A1A1A Square D P/N 8910-DPA62-V02Y236 Square D P/N DPA72V02 or Arrow-Hart P/N ACC720U20 Square D P/N DPA92V02 or Arrow-Hart P/N ACC927U20 Arrow-Hart P/N ACC1220U20 Joslyn Clark P/N CVC77U022006-76 50 HZ PARTS 9525 REV P INDEX NO. 28 29 59 REFERENCE DESIGNATION DESCRIPTION C1 Capacitor (30 KW, Qty 1) Capacitor (50 KW, Qty 1) Capacitor (20 KW; 30 KW, Qty 1; 50 KW, Qty 1) Capacitor (10 KW) Capacitor (15 KW) Control Assembly (insert 1, 3, or 5 in place of “X” for number of steps desired. Insert 1 for 6.6A or 2 for 20A in place of Y for current desired. The standard Control Assembly consists of the following major replaceable items: Digital Display Board Assembly Power Supply Board Assembly Control Interface Board Assembly *(1) Microcontroller Board Assembly Regulation Board Assembly Load Monitor Board Assembly *(2) (L-829 only) Keyboard, 4 x 4 Matrix *(1) If complete Control Assembly is not ordered, set dip switch on board per instructions. *(2) Specify KW rating of regulator when ordering. CROUSE-HINDS AIRPORT LIGHTING PART NO. 30062-01 30062-02 30062-03 MANUFACTURER PART NO. 30062-04 30062-05 32323 Add 61 @ end for L-829 31765-1 31971 31716-1 32277-1 31879-3L 31926-1 10047-2176 50 HZ PARTS 9525 Rev P INDEX NO. 30 60 REFERENCE DESIGNATION DESCRIPTION T1 Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main Main X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr X’fmr Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, Assy, 10 10 10 10 10 10 10 15 15 15 15 15 15 15 15 15 15 15 15 15 15 20 20 20 20 20 20 20 KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, KW, 6.6A, 208V 6.6A, 220V 6.6A, 230V 6.6A, 240V 6.6A, 380V 6.6A, 400V 6.6A, 415V 6.6A, 208V 6.6A, 220V 6.6A, 230V 6.6A, 240V 6.6A, 380V 6.6A, 400V 6.6A, 415V 20A, 208V 20A, 220V 20A, 230V 20A, 240V 20A, 380V 20A, 400V 20A, 415V 6.6A, 208V 6.6A, 220V 6.6A, 230V 6.6A, 240V 6.6A, 380V 6.6A, 400V 6.6A, 415V CROUSE-HINDS AIRPORT LIGHTING PART NO. 32144-10-1 32144-10-2 32144-10-3 32144-10-4 32144-10-5 32144-10-6 32144-10-7 32144-15-1 32144-15-2 32144-15-3 32144-15-4 32144-15-5 32144-15-6 32144-15-7 32144-16-1 32144-16-2 32144-16-3 32144-16-4 32144-16-5 32144-16-6 32144-16-7 32144-20-1 32144-20-2 32144-20-3 32144-20-4 32144-20-5 32144-20-6 32144-20-7 MANUFACTURER PART NO. 50 HZ PARTS 9525 REV P INDEX NO. REFERENCE DESIGNATION DESCRIPTION 30 (Cont’d) T1 (Ref K2) 32 K2 Relay Octal Plug (2400v Only) 61 31 Main X’fmr Assy, 20 Main X’fmr Assy, 20 Main X’fmr Assy, 20 Main X’fmr Assy, 20 Main X’fmr Assy, 20 Main X’fmr Assy, 20 Main X’fmr Assy, 20 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 30 Main X’fmr Assy, 50 Main X’fmr Assy, 50 Main X’fmr Assy, 50 Socket, Octal Relay KW, 20A, 208V KW, 20A, 220V KW, 20A, 230V KW, 20A, 240V KW, 20A, 380V KW, 20A, 400V KW, 20A, 415V KW, 6.6A, 208V KW, 6.6A, 220V KW, 6.6A, 230V KW, 6.6A, 240V KW, 6.6A, 380V KW, 6.6A, 400V KW, 6.6A, 415V KW, 20A, 208V KW, 20A, 220V KW, 20A, 230V KW, 20A, 240V KW, 20A, 380V KW, 20A, 400V KW, 20A, 415V KW, 20A, 380V KW, 20A, 400V KW, 20A, 415V (2400V Only) CROUSE-HINDS AIRPORT LIGHTING PART NO. 32144-21-1 32144-21-2 32144-21-3 32144-21-4 32144-21-5 32144-21-6 32144-21-7 32144-30-1 32144-30-2 32144-30-3 32144-30-4 32143-30-5 32144-30-6 32144-30-7 32144-31-1 32144-31-2 32144-31-3 32144-31-4 32144-31-5 32144-31-6 32144-31-7 32144-50-5 32144-50-6 32144-50-7 10047-1898 10047-1899 MANUFACTURER PART NO. Potter & Brumfield 27E122 Potter & Brumfield KRPA-5AG-120V 50 HZ PARTS 9525 REV P RECOMMENDED SPARES DESCRIPTION PART NUMBER Interlock Safety Switch 10047-1878 1 Fuse, 2 amp, Slo-Blo 10047-1141 5 Fuse, 1 amp, Slo-Blo 10053-307 5 Fuse, 1/8 amp, Slo-Blo 10047-1005 5 SCR/Heatsink Assembly (10, 15 & 20 KW) 31505-1 2 SCR/Heatsink Assembly (30, 37.5, 50 & 70 KW) 31505-2 2 Controller Assembly SEE ITEM 29 DESCRIPTION * *Minimum of one. NUMBER REQUIRED Consider having 1 controller for every ten CCRS. 62