Dimensioning of Electric Propulsion Motors for War-Ships Using Finite Element Method Abstract

advertisement

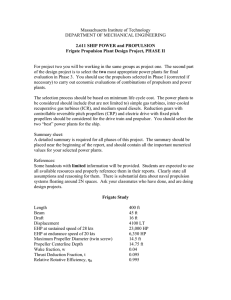

Journal of Computations & Modelling, vol.3, no.4, 2013, 11-24 ISSN: 1792-7625 (print), 1792-8850 (online) Scienpress Ltd, 2013 Dimensioning of Electric Propulsion Motors for War-Ships Using Finite Element Method Angelos P. Moschoudis 1, Miltiades C. Filippou 2, George J. Tsekouras 3 and Antonios G. Kladas 4 Abstract The electrification of war-ship propulsion system is a very attractive solution, as it provides increased safety, survivability, maneuverability, precise and smooth speed control, reduced machinery space, low operation and maintenance costs, low noise and low pollutant emission levels. In this paper the basic principles of dimensioning for warships electric propulsion motors using finite element method are presented. The respective example which will be shown synoptically is a low rotational salient pole synchronous motor connected to the propeller axis directly (without gearbox). Keywords: Electric propulsion, finite element method, synchronous motor, warship power system. 1 School of Electrical & Computer Engineering, National Technical University of Athens, 9 Iroon Polytechniou Street, 15780 Athens, Greece. E-mail: moshoudi@central.ntua.gr. 2 Mobile Communications Department, EURECOM, 06410 BIOT, France. E-mail: filippou@eurecom.fr. 3 Hellenic Naval Academy, Terma Hatzikiriaku, Piraeus, GR-18539 Greece. E-mail: tsekouras@snd.edu.gr. 4 School of Electrical & Computer Engineering, National Technical University of Athens, 9 Iroon Polytechniou Street, 15780 Athens, Greece. E-mail: kladasel@central.ntua.gr. Article Info: Received : July 1, 2013. Revised : August 30, 2013. Published online : December 1, 2013. 12 Dimensioning of Electric Propulsion Motors for War-Ships 1 Introduction to the Electrification of War-Ship Propulsion System Warships propulsion electrification offers significant anticipated benefits for war ships in terms of reducing ship life cycle cost, increasing ship stealthiness, payload, survivability and power available for non propulsion-uses, and taking advantage of a strong electrical power technological and industrial base. Potential disadvantages include higher near-term costs, increased technical risk, increased system complexity, and less efficiency in full power operations ([1]). In a ship with a mechanical-drive system, (see Fig. 1), the power-producing capability of the ship's propulsion engines typically represents 75 percent to 85 percent of the ship's total power-producing capability. This power-producing capability is devoted exclusively to ship propulsion and is not available for nonpropulsion uses, even when the ship is stationary or traveling at low speed. Prime Power Conversion and Distribution Generator Main Switch Prime Non Propulsion Electrical Loads Generator Prime Prime Reduction Gear Generator Prime Prime Reduction Gear Prime Figure 1: Basic war ship mechanical drive system Electric drive technology would change the way that war ships transmit power from their engines to their propellers, as well as the way they manage and Ang. Moschoudis, Milt. Filippou, G.J. Tsekouras and Ant. G. Kladas 13 distribute electrical power to both propulsion and non-propulsion systems. Ships with an electric drive system can be designed so that a single set of engines produces a common pool of electricity that is used for both ship propulsion and the ship’s non-propulsion electrical loads (see Figure 2). Such a system is known as an integrated electric-drive (IED) system or integrated power system (IPS). IPS consists of the following set of modules: Power generation, propulsion motor, power distribution, power conversion, power control, energy storage and load. The above mentioned sets of modules and the IPS architecture combined together provide the basis for designing, procuring, and supporting marine power systems applicable over a broad range of commercial and war ship types ([2]). Auxiliary Prime Movers PM Gen PM Gen Power Conversion and Distribution Main Prime Movers Non Propulsion Electrical Loads Switch Motor Drive Motor Switch Motor Drive Motor Main Switch Prime Prime Generator Generator Figure 2: Basic integrated electric drive system In ships with integrated electric drive, the electricity produced by the engines and generators is sent by cable to an electric switchboard that divides the electricity into two flows one for the ship's propulsion needs, and one for the ship's other electrical loads (see Figure 3). The switchboard can alter the distribution of power between these two uses on a moment to moment basis, as needed, to meet the ship's propulsion and non propulsion needs. 14 Dimensioning of Electric Propulsion Motors for War-Ships Electric drive technology offers significant anticipated benefits in terms of reducing ship life cycle cost, increasing ship stealthiness, payload, survivability, and power available for non-propulsion uses, and taking advantage of a strong electrical-power technological and industrial base ([3]). Depending on the kind of ship in question and its operating profile (the amount of time that the ship spends traveling at various speeds), a war ship with an integrated electric drive system may consume 10 percent to 25 percent less fuel than a similar ship with a mechanical drive system. Electric propulsion makes possible the use of new propeller/stern configurations, such as a podded propulsor, that can reduce ship fuel consumption further due to their improved hydrodynamic efficiency, depending on the ship type and the exact propeller/stern configuration used ([4]). Due to their design electric drive systems can be highly automated and self monitoring. Consequently reductions in maintenance and crew size would further reduce war ship life cycle cost. Electric propulsion promises to be significantly quieter acoustically than mechanical drive. Since acoustic noise is an important component of a war ship's overall detectability, ships equipped with electric drive promise to be less detectible than ships equipped with mechanical drive technology. In a surface combatant, electric drive's reduced fuel consumption can be translated into a reduction in the amount of space aboard ship required for fuel storage. In addition, by eliminating the need in a mechanical drive system, to install the engines, reduction gears, shafts, and propellers in a long line running along the bottom of the ship electric drive makes it possible to install the various parts of a surface combatant's drive system in positions that may use space aboard ship in a more efficient manner. In both these ways, electric drive may free up space that can be used to carry additional payload (e.g., weapons or sensors). But electric drives have also potential disadvantages in terms of higher near term costs, increased program risk, increased system complexity, and less efficiency in full-power Ang. Moschoudis, Milt. Filippou, G.J. Tsekouras and Ant. G. Kladas 15 operations. However, warships typically spend only a small fraction of their time at full power. Impedance G Main Generators G G M Filter Electric G Medium Voltage Busbar M M M M ~ M ~ G G Auxiliary Low Voltage Busbar 440 V Low Voltage Loads Emergency Loads Back Up Battery Low Voltage Generator Busbar G Shore Emergency Low Voltage Busbar Low Voltage Loads Low Voltage Loads 115 V Low Voltage Emergency Loads Busbar 440 V Low Voltage Emergency Loads 440 V Low Voltage Emergency Loads 115 V Figure 3: Analytical representation of a fully electrified war ship’s electric power System Much of the debate over electric drive concerns electric motors. The five basic types in question synchronous motors, induction motors, permanent magnet motors, superconducting synchronous motors, and superconducting homopolar motors differ in terms of their technological maturity, power density, and potential applicability to different war ships. 16 Dimensioning of Electric Propulsion Motors for War-Ships The synchronous motor can be considered the most mature technologically in application to warships. In this paper the basic principles of dimensioning for warships synchronous propulsion motors using finite element method are presented. Additionally, for this reason an under scale synchronous salient pole motor design is analytically presented. 2 Introduction to Synchronous Propulsion Motor Design In the electrification of war ship propulsion system considered, the synchronous motor is the most mature technologically application. In such applications low rotational speed salient pole synchronous motor connected to the propeller shaft directly (without gear box) are used. Also the voltage and the frequency of the electricity supply needed to be modified by a motor drive in order the proper motor’s operation at the desired speed to be achieved. Here, a novel two step design procedure for the design of a reliable multi-pole salient pole low rotational speed synchronous propulsion motor is presented. Engine Generator Switchboard Motor Drive Motor Electrical power for non propulsion electrical loads Figure 4: Block diagram representation of the war ship electric propulsion system 3 First-Step: Preliminary Design The synchronous motor’s main dimensions are derived by using classical formulae. These are calculated after the selection of motor’s parameters such as Ang. Moschoudis, Milt. Filippou, G.J. Tsekouras and Ant. G. Kladas 17 nominal power, rotational speed, specific magnetic loading in the various parts, and electric loading in the windings. Additionally the temperature rise and the motor’s performance are calculated. The preliminary design is presented in the flowchart of Figure 5. Starting of Motors Preliminary Design ϕ, Nph , Stators Slots, τs, Iline , Sconductor Calculation Construction of magnetization curve Motors Selection Design Parameters ωr, B, q, KW , f, S Calculation of Stators Slots Teeth Core Depth Dimensions Excitations full load ampereturns per pole calculation Motors Poles Calculation, Stators D L li, Pole Pitch τp Vph , j Selection Calculation of Copper, Stray, Eddy Current and Stators Core Power Losses Air gap, Drotors, Rotors pole characteristics Calculation Design of field coil Field winding and Stator temperature rise calculation Motors efficiency calculation Figure 5: Flow chart used for synchronous motor’s main dimensions calculation (preliminary design) 4 Second Step: Final Design – Numerical Simulation Using Finite Element Modelling The finite element model used in this application involves the solution of some limiting cases of Maxwell’s partial differential equations. The magnetic problems are those that can be considered as "low frequency problems", in which displacement currents can be ignored. Displacement currents are typically relevant to magnetics problems only at radio frequencies ([5]). 18 Dimensioning of Electric Propulsion Motors for War-Ships Magnetostatic problems are problems in which the fields are time-invariant. In this case, the field intensity H and flux density B must obey the following equations: ∇×𝐻 =𝐽 (1) ∇∙𝐵 =0 (2) 𝐵 =𝜇∙𝐻 (3) subject to a constitutive relationship between 𝐵 and 𝐻 for each material: If a material is nonlinear (e.g. saturating iron, or alnico magnets), the permeability, 𝜇 is actually a function of 𝐵: 𝐵 𝜇 = 𝐻(𝐵) (4) Finite element method goes about finding a field that satisfies equations (1)(3) via a magnetic vector potential approach. Flux density is written in terms of the vector potential, 𝐴, as: 𝐵 = ∇×𝐴 ( 5) Now this definition of 𝐵 always satisfies equation (2). Then equation, (1) can be rewritten as ([5], [6]): 1 ∇ × �𝜇(𝐵) ∇ × 𝐴� = 𝐽 (6) Finite element method retains the form of equation (6), so that magnetostatic problems with a non-linear B-H relationship can be solved. In the general 3D case A is a vector with three components. However, in the 2 D planar and axisymmetric cases, two of these three components are zero, leaving just the component in the "out of the page" direction. The advantage of using the vector potential formulation is that all the conditions to be satisfied have been combined to a single equation. The use of machines full geometry could have been applied in this problem but this method is extremely time consuming due to the large number of nodes and elements of the triangular mesh. In such cases, symmetry can be employed to analyze only a fraction than the entire machine. Ang. Moschoudis, Milt. Filippou, G.J. Tsekouras and Ant. G. Kladas 19 Generally, the number of rotor poles and stator slots can be divided by their greatest common denominator in order the smallest region that can be analyzed to be obtained. If the number of rotor poles to be analyzed is odd numbered, the ends of the motor should be joined by anti-periodic (anti-symmetric) boundary conditions. If the number of rotor poles were even periodic (symmetric) boundary conditions would have been used instead. The design which will be presented has 32 salient rotor poles and a stator with 96 slots. Consequently the motor’s basic structure consists of one pole and three stator slots. For the above mentioned reasons the simulation of one motor’s pole has been adopted. Once the motor’s basic structure has been determined the next step of the design is performed with the application of the boundary conditions. In order to improve the accuracy of the results the air-gap division in four parts has been adopted. Air-gap Limits Rotor Anti-periodic B5 Stator Anti-periodic B4 Anti-periodic B10 Anti-periodic B6 Anti-periodic B7 Anti-periodic B8 Anti-periodic B9 Figure 6: Application of anti-periodic boundary conditions to the split motor in the air gap 20 Dimensioning of Electric Propulsion Motors for War-Ships Anti-periodic B9 Anti-periodic B4 Prescribed A (Dirichlet) Anti-periodic B3 Anti-periodic B1 Anti-periodic B2 Anti-periodic B4 Anti-periodic B1 Anti-periodic B2 Anti-periodic B9 Anti-periodic B3 Figure 7: Application of anti-periodic boundary conditions to the split motor in rotor and stator Dirichlet-type boundary condition A = 0, is defined on the boundary (stators external diameter) in order magnetic flux to be kept from crossing the boundary. The use of a finite element model will verify the preliminary results of the classical design. 5 Application The methodology presented has been applied to an under scale design of a 20 kVA, 120 rpm synchronous salient pole motor to be connected to a low rotational speed propeller. The behavior of the machine has been investigated by considering the use of the material M-43 for stators and rotors laminations, copper windings with electric loading below 4 A/mm2, efficiency above 84 % respectively. At the preliminary design stage the following main parameters have been calculated: an air - gap width of 1.1 mm, number of stator slots 96, stator’s internal diameter Ang. Moschoudis, Milt. Filippou, G.J. Tsekouras and Ant. G. Kladas 21 852 mm, stator’s external diameter 978 mm, rotor’s diameter 689,8 mm (without salient poles), motors stator core length 109 mm, a single layer stator winding with total slots area 464 mm2. Also all the above mentioned requirements were calculated in order to be validated by using the method of finite elements. The above mentioned machine configuration for each pole is shown in Figure 8 (during rotors rotation). Figure 9 gives the triangular mesh employed for the finite element analysis of the machine involving approximately 6714 nodes and 12865 elements. Figure 8: One pole machine design in the FEM model during rotors rotation Figure 9: Mesh implemented in the FEM model Figure 10 shows the magnetic field distribution corresponding to full load conditions, while Figure 11 shows the respective flux density plot implemented in the FEM model. 22 Dimensioning of Electric Propulsion Motors for War-Ships Figure 10: Field distribution Figure 11: Flux density plot implemented in the FEM model The air gap’s arc flux density magnitude variations, the magnetic induction’s harmonic components in the middle of the air-gap and the torque variations versus the torque angle δ are shown in Figure 12, Figure 13 and Figure 14 respectively. The requirements that were set in the preliminary design are validated (no exceeding the specific magnetic loading of 1.5 T and the specific electric loading of 4 A/mm2) and the resultant values of magnetization for the various generators parts are 1.5 T for the stators teeth, 1.1 T for stators core and 1.34 T for rotors pole respectively, while the specific electric loading of winding is not beyond 3.2 A/mm2. 1,0 0,5 0,0 0,00 0,02 0,04 0,06 0,08 Pole Pitch tp (m) Figure 12: Flux density magnitude variations 1,2 23 Torque (Nm) . B (Wb/m^2) 1,5 0,9 0,6 0,3 2500 2000 1500 1000 500 0 0 1 3 5 7 9 11 13 15 17 Fourier coefficient. Ang. Moschoudis, Milt. Filippou, G.J. Tsekouras and Ant. G. Kladas 0 Harmonic Figure 13: Magnetic induction’s harmonic components (air gap middle) 45 90 135 180 degrees Figure 14 : Torque variations versus angle δ 6 Conclusion An integrated two step methodology for the classical design of a salient pole, low r.p.m., synchronous motor for war ship electric propulsion application has been presented. This method has been validated by numerical simulation reducing the necessary number of finite element method executions and the computational time during the selection of the generator’s dimensions through the first step of classical design. References [1] R. O’ Rourke, Electric Drive Propulsion for U.S. Navy Ships : Background and Issues for Congress, The Library of Congress, Congressional Research Service, CRS Report for Congress, Order Code RL 30622, Security Classification of Report, Unclassified, 31 July 2000, p. 3. 24 Dimensioning of Electric Propulsion Motors for War-Ships [2] N. Doerry, Presentation of Designing All Electric Ships, 9th IMDC, (May 1619, 2006), 3-4. [3] McCoy and J. Timothy, Powering the 21st Century Fleet, U.S. Naval Institute Proceedings, (May 2000), 54-58. [4] K. Bonner, Naval Propulsion for the 21st Century : The Azipod System, U.S. Naval Institute Proceedings, (August, 1999), 74-76. [5] D. Meeker, Finite Element Method Magnetics: User’s Manual, (October 2010), 7-8. [6] J. Pyrhonen, T. Jokinen and V. Hrabovcova, Design of Rotating Electrical Machines, J. Wiley & Sons, p. 6-10, 2008.