ntroduction Electric Utility’s View In the era of electric utility

advertisement

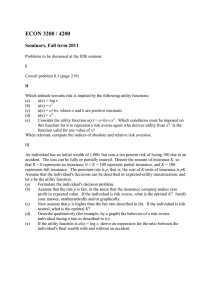

Systems Engineering Group The Economics of Distribution System Reliability by Martin T. Bishop, Supervisor Reliability Improvement Studies, Cooper Power Systems Chris A. McCarthy, Power Systems Engineer, Cooper Power Systems Virgil G. Rose, Rose Consulting I ntroduction In the era of electric utility deregulation and competition, reliability of service to the customer has become a critical issue. Cost control is also an important element in the competitive mix. In addition to customers demanding better service at lower cost, regulators are entering the picture in some situations with rate decisions tied to service reliability. The challenge for utility engineers and managers is deciding how resources should be spent on reliability to provide the customer the service that they demand, at a price that the customer is willing to pay. Historically, electric utilities defined service reliability based upon recorded system data. The feasibility of new expenditures on the system was based on the measured service reliability data, ignoring momentary outages and other short duration events. The values for reliability were reported as system average values, which may say nothing about an individual customer’s experiences. Some short term events, which may be very important to the performance of loads in the customer facilities, were not even counted in the measurement index. The perception of adequate reliability varies among customers served by the electric utility. Customers have a variety of needs, and demand different levels of service. As a result, some electric utilities are trying to develop a more customer-focused definition of reliability. The economic question can be considered through three different perspectives: the electric utility’s viewpoint, the customer’s viewpoint, and the regulator’s viewpoint. Each will yield a different set of conclusions regarding expenditures on system reliability. Electric Utility’s View From the electric utility’s point of view, the economics includes an expenditure of resources to improve reliability in order to generate increased kWh sales or customer loyalty, which translates into increased profits. However, there may or may not be a difference in the rate paid by the customer for service with higher reliability. In addition to the quantitative measures there are additional benefits such as decreased customer complaints, better public relations, and decreased pressure from the local regulators. The problem with the economic analysis considering the added revenue from improved reliability is the fact that the benefit is small. For a typical customer consuming an average of 1kW of power, the utility gets less than $1 of extra revenues from each customer by increasing the availability of electrical service from 0.999 to 1.000. To make matters worse, increased revenue does not equal increased profit. A generous estimate of the additional profit would be about 10% of increased revenues. Thus, the additional capital available to improve the system from 0.999 availability to 1.000 without reducing profits is only about $0.10 per customer each year. The task of increasing the service availability to 1.000, even if possible, would certainly require a large expenditure for little return, hardly a formula for keeping a business healthy. Another utility point of view might include an economic analysis of reliability improvement expense versus the total revenue stream to the utility from an important customer. This could be justified if the reliability improvement expenditures are needed in order to keep the customer from purchasing power from a competitor. Although one could make the argument that the competitor would still use the same electric transmission and distribution system, customers will still be persuaded to switch energy suppliers when current reliability is poor. By comparison, the automobile manufacturers in the U.S. over the past decade have improved the reliability of their products in order to retain existing customers, maintain revenues, attract new customers, etc. Utilities may be in a very similar situation, forced by the marketplace to expend resources on reliability improvement in the face of new competition. Customer’s View From a customer’s point of view, the cost of an outage may be far greater than the utility’s cost. Service interruptions, either momentary or sustained, can disturb industrial client processes resulting in lost production, scrapped material, and perhaps additional equipment cleanup and repairs. A recent IEEE IAS paper titled, “Power Interruption Costs to Industrial and Commercial Consumers of Electricity”, summarized the costs in the following table based on a survey of 210 large commercial and industrial customers: Outage Scenario Cost 4 Hr Outage With No Notice $74,835 1Hr Outage With No Notice $39,459 1Hr Outage With Notice 10-20% Voltage Sag 2 Sec. Momentary Outage $22,973 $7,694 $11,027 Table 1 Outage Costs The table gives some indication that there is a significant cost to an industrial customer when power is disturbed or interrupted. Although a momentary outage is indicated as a lesser cost per incident, momentary outages may occur 10-20 times in a year. Similar cost estimates can be developed for smaller commercial and even residential classes of customers. Regulator’s View Performance Based Ratemaking (PBR) seeks to establish an environment that stimulates the monopoly service provider to improve efficiency and keep prices in line with inflation or less. Unfortunately, this can provide an environment where maintenance and other costs can be slashed in order to make money. In the distribution environment customers are captive. They cannot leave the supplier and connect to another provider. An alternative is to include measurements of reliability in a Service Quality Index (SQI) for a distribution company subject to a PBR. The SQI will impose significant penalties on revenues if service quality deteriorates from a preset baseline performance level. The idea is to mimic the loss of revenue to the company that happens in a free market if customers leave a poor service provider to go to one with better performance. In order to create a PBR service quality index, definitions must be created for evaluation of ongoing performance. Performance levels can be utility-specific to allow for different situations. If multiple items are included in the measurement process, an SQI specific for a utility and its history can be developed. One suggested approach would establish a rule that requires all utilities to measure certain service quality indices and report the data annually. With this data, a utilityspecific SQI can be part of the rate plan that compares annual performance to baseline performance standards. The typical reliability measurements that are being adopted are SAIFI, SAIDI, and MAIFI. Pennsylvania, New York, and California have adopted these indices. Penalties are included as part of the PBR for reliability reviews to discourage deterioration in service with cuts in the budget. California and New York will be incorporating penalties in their rate plans. Rewards (higher rates) are not generally part of the plans since it is not fair to assign higher costs to customers that receive better reliability than they want. Rewards and penalties might create a situation where poor performance in one area is balanced by good performance in another area. This might remove the incentive to improve the service to the poorly performing part of the system. Reliability Improvement Initiatives An unplanned customer outage is generally caused by a fault on the utility system. Although the number of faults that occur on the system directly impacts the resulting reliability indices, the response of the overcurrent protection system can also have a large impact on the number of customers out of service and the total outage time. Figure 1 shows the relationship of both factors to the development of the reliability indices. Many utilities are focusing reliability improvement initiatives around prevention aimed at reducing the number of faults. It can be shown that investments in response initiatives, such as the design of overcurrent protection systems that sectionalize the system after a fault event, also have a major impact on reliability results. Circuit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Total Reclosers exisnew ting 1 0 0 1 2 0 0 0 2 1 1 0 2 1 1 0 0 2 0 14 2 0 2 4 6 1 0 2 2 4 3 4 1 0 2 2 1 5 2 43 Benefit savings per year $29,877 — $18,594 $102,980 $75,125 $10,839 — $28,644 $19,714 $105,225 $48,988 $43,615 $6,224 — $63,147 $14,231 $5,111 $51,568 $21,913 $645,795 Storms Animals Equipment Failures Tree Trimming System Faults Prevention Initiatives Response Initiatives OCP Response SAIFI SAIDI MAIFI Figure 1 Prevention and Response Initiative Impact Reliability Especially when considering the value of service to the customer, expenditures in the overcurrent protection system for reliability improvement can generate reasonable payback periods and rates of return. One reliability improvement study for an oil production company resulted in economic justification for installing reclosers on the primary distribution circuits Cost new/relocated reclosers $64,300 — $60,000 $124,300 $180,000 $30,000 — $60,000 $68,600 $124,300 $90,000 $120,000 $30,000 — $90,000 $60,000 $30,000 $150,000 $60,000 $1,341,500 Table 2 Recloser Placement, Economic Summary for Study Total Circuit Pay back Rate of (years) Return 2.2 — 3.2 1.4 2.4 2.8 — 2.1 3.5 1.2 1.8 2.8 4.8 — 1.4 4.2 5.9 2.9 2.7 2.1 46.3% — 30.4% 82.8% 41.5% 35.8% — 47.6% 28.0% 84.6% 54.3% 36.0% 19.3% — 70.1% 22.6% 15.0% 33.9% 36.2% 48.0% Economics of Reliability serving the pump loads. Table 2 (see page 6) displays the recloser placement and economic summaries for the 19 circuits investigated in the system reliability study. The results in the table demonstrate that for the majority of the circuits studied, reliability expenditures generate a very favorable rate of return, an average of over 50% annual return over a 15 year period. The only dilemma for the utility with this approach is that it bears the expense and the customer reaps the benefits. However, the competitive market may force electric utilities to make the system investments to maintain their present customer base. Conclusions What is the motivation for improving distribution system reliability even if it cannot be economically justified on increased kilowatt hour sales? One possibility is that the regulatory commissions will establish a minimum value for various performance indices, such as SAIDI, SAIFI, MAIFI, ASAI, etc. Penalties will be based on comparison to the performance indices. Avoiding penalty costs is one incentive to improve service reliability. Another motivation is the avoidance of negative public relations. A utility with a reputation for unreliable service cannot attract major industrial customers to its service area. Customer satisfaction may become even more critical in the future. If customers can pick their electric energy supplier, a utility with a poor reliability record will lose customers to its competitors. If a utility fails to provide highly reliable service it risks losing customers, lack of growth in kWh sold, and increasing political pressure from state regulatory agencies. THE LINE Virgil G. Rose is a former senior vicepresident with Pacific Gas and Electric. ©1998 COOPER POWER SYSTEMS • BULLETIN 03035