S800-64-1 OEM Equipment Sectionalizing Switch Installation Instructions

advertisement

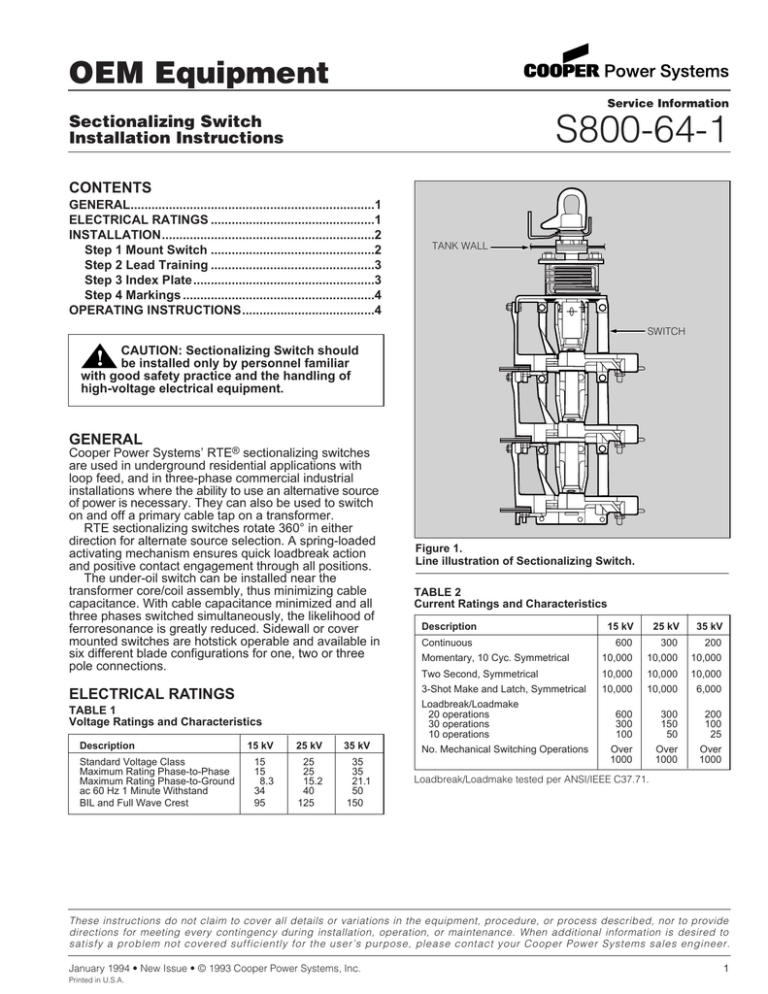

OEM Equipment Service Information Sectionalizing Switch Installation Instructions S800-64-1 CONTENTS GENERAL......................................................................1 ELECTRICAL RATINGS ...............................................1 INSTALLATION.............................................................2 Step 1 Mount Switch ...............................................2 Step 2 Lead Training ...............................................3 Step 3 Index Plate....................................................3 Step 4 Markings .......................................................4 OPERATING INSTRUCTIONS......................................4 TANK WALL SWITCH CAUTION: Sectionalizing Switch should be installed only by personnel familiar with good safety practice and the handling of high-voltage electrical equipment. ! GENERAL Cooper Power Systems’ RTE® sectionalizing switches are used in underground residential applications with loop feed, and in three-phase commercial industrial installations where the ability to use an alternative source of power is necessary. They can also be used to switch on and off a primary cable tap on a transformer. RTE sectionalizing switches rotate 360° in either direction for alternate source selection. A spring-loaded activating mechanism ensures quick loadbreak action and positive contact engagement through all positions. The under-oil switch can be installed near the transformer core/coil assembly, thus minimizing cable capacitance. With cable capacitance minimized and all three phases switched simultaneously, the likelihood of ferroresonance is greatly reduced. Sidewall or cover mounted switches are hotstick operable and available in six different blade configurations for one, two or three pole connections. ELECTRICAL RATINGS TABLE 1 Voltage Ratings and Characteristics Description Standard Voltage Class Maximum Rating Phase-to-Phase Maximum Rating Phase-to-Ground ac 60 Hz 1 Minute Withstand BIL and Full Wave Crest 15 kV 25 kV 35 kV 15 15 8.3 34 95 25 25 15.2 40 125 35 35 21.1 50 150 Figure 1. Line illustration of Sectionalizing Switch. TABLE 2 Current Ratings and Characteristics Description 15 kV 25 kV 35 kV Continuous Momentary, 10 Cyc. Symmetrical 600 10,000 300 10,000 200 10,000 Two Second, Symmetrical 3-Shot Make and Latch, Symmetrical Loadbreak/Loadmake 20 operations 30 operations 10 operations No. Mechanical Switching Operations 10,000 10,000 10,000 10,000 10,000 6,000 600 300 100 Over 1000 300 150 50 Over 1000 200 100 25 Over 1000 Loadbreak/Loadmake tested per ANSI/IEEE C37.71. These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide directions for meeting every contingency during installation, operation, or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for the user’s purpose, please contact your Cooper Power Systems sales engineer. January 1994 • New Issue • © 1993 Cooper Power Systems, Inc. Printed in U.S.A. 1 Sectionalizing Switch Installation Instructions A .78 (20 mm) C B D E .470" (11.9 mm) DIA. HOLE ALL LINE CONNECTIONS 8.35" (212 mm) 4.376" (111.2 mm) 5.153" (130.9 mm) .438" (11.1 mm) DIA. MTG. HOLES TANK SEALING GLAND FURNISHED WITH SWITCH 5.400" (137.2 mm) TYP. SEE NOTE 2 AND 3 2.75" (69.9 mm) 8.346" (212 mm) Figure 2. Line illustration with dimensions of sectionalizing switch. Note: 1. Dimensions given in Figure 2 and Table 3 are for reference only. 2. Handle can be used on 14 GA. (.075/1.9 mm) to .25 (6.4 mm) thick frontplate. 14 gage shown. 3. Optional padlock handle is available, but not shown. 4. See catalog section 800-64 for switch types, number of phases, and catalog numbers. TABLE 3 Dimensional Information for Figure 2 NO. OF DECKS/ PHASES A SIDEWALL MOUNT 15 & 25 kV 35 kV D COVER MOUNT 15 & 25 kV 35 kV E B C SIDEWALL MOUNT 15 & 25 kV 35 kV COVER MOUNT 15 & 25 kV 35 kV SIDEWALL MOUNT COVER MOUNT — — 7.0 8.0 12.25 13.25 .745 6.0 (177.8 mm) (203.2 mm) (311.2 mm) (336.6 mm) (19.05 mm) (152.4 mm) — 7.0 8.0 12.25 13.25 .75 6.0 (177.8 mm) (203.2 mm) (311.2 mm) (336.6 mm) (19.05 mm) (152.4 mm) 1 7.75 8.75 13.0 14.00 (196.9 mm) (222.3 mm) (330.2 mm) (355.6 mm) 2 11.813 12.813 17.063 18.063 4.063 (300.0 mm) (325.5 mm) (433.4 mm) (458.8 mm) (103.2 mm) 3 15.875 16.875 21.125 22.125 4.063 4.063 7.0 8.0 12.25 13.25 .75 6.0 (403.2 mm) (428.6 mm) (536.6 mm) (561.9 mm) (103.2 mm) (103.2 mm) (177.8 mm) (203.2 mm) (311.2 mm) (336.6 mm) (19.05 mm) (152.4 mm) INSTALLATION ■ ■ Sectionalizing switches are sidewall or cover-mounted in a 1.325" diameter hole with the internal electrical switch components completely immersed under transformer oil or equivalent. Refer to Figure 2 for dimensional information. All parts should be inspected for damage before using. If there is evidence of physical damage, the unit should not be installed unless approved by your Cooper Power Systems representative. Step 1. MOUNT SWITCH ■ Switch should be mounted to four (4) couplings on inside of tank (refer to Figure 3 for coupling pattern) before tightening locking nut to sealing gland. Failure to do this may increase operating torque of switch or cause damage. 2 ■ ■ Sealing is accomplished with O-rings on operating shaft and gasketed sealing gland secured on outside of tank with locking nut. Switch should be located to ensure recommended clearances in Table 4 are maintained. TABLE 4 Recommended Clearances Mechanical External handle clear of obstruction. Clearances also required for hook-stick operation. Dielectric (Under Oil) Minimum of 4 inches on all sides of the switch. 1.325" (34 mm) DIA. HOLE 1.5" (38.1 mm) TYP. 2.187" (56 mm) TYP. 1.375" (35 mm) TYP. .662" (17 mm) 2.750" (70 mm) 1.5" (38.1 mm) TYP. .140" (4 mm) RAD. ON INSIDE WALL: COUPLING WITH 3/8-16 TAPPED THREAD X .75 LG (19.1 mm) 4.375" (111 mm) ON OUTSIDE WALL: .312" Dia. x 625" Long (7.9 mm) (15.9 mm) WELD PIN Figure 3. Mounting hole and coupling placement. NOTES: 1. Weld pins, couplings and position designations not included with switch. Pre-welded coupling pin plates available-cat. no. 2037424C02M. 2. All couplings and pins to be welded flat within an angularity tolerance of ± 30’. 3. Alternate method: weld 3/8 – 16 x 1.25 L studs in place of couplings and use .75 long spacers over studs. ■ Torque requirements as defined in Table 5 shall be maintained. TABLE 5 Recommended Torque Mounting Bolts: 3/ " diameter mounting bolts to be 8 torqued 60-100 in-lbs To Seal (Gland): 60-120 in-lbs Step 2 LEAD TRAINING ■ Cantilever Strength of Assembly: Sufficient to support one 500MCM Cu lead per contact. ■ Switch contacts are pre-gauged at factory and will have some rotation in same plane as switch blade. Leads attached to switch contacts must not restrict this rotation. The nuts holding the contacts should not be tightened. Leads can be bolted to rear of contact and care should be taken to minimize mechanical stress on the contacts. Standard dielectric dimensions for lead separation should be followed. Tight lead training may cause excess cantilever force and difficulty in switch operation. Step 3. INDEX PLATE ■ An externally installed optional limit plate prevents rotation to positions other than the one desired. Refer to Figure 4. WELD PINS (4) (FOR LOCATING LIMIT PLATE) LINES A&B LINE A ONLY LINE B ONLY OPEN NOTE: Typical position configuration shown for some “V” blade switches. See catalog section 800-64 for other switch layouts and schematics. Position labeling provided by equipment manufacturer. Figure 4. View of tank front with optional limit plate positioned over pin. NOTE: With limit plate positioned securely as shown, switch can be operated only counterclockwise to “line A only” position and no further. 3 Sectionalizing Switch Installation Instructions Step 4. MARKINGS ■ Appropriate markings and/or stops should be included on tank wall to meet customer specifications. CAUTION: Enclosed decal (Cooper P/N 1109699A) should be displayed at or near operating handle of switch as a warning to service personnel. Failure to do so will constitute a waiver of all warranty and indemnity obligations which may be attributable to Cooper Power Systems. ! OPERATING INSTRUCTIONS ■ ■ ■ ■ The switch can be operated 360° in either clockwise or counter-clockwise direction. When switching (with hotstick) from one position to the next, (for example: position “A” to position “B”), the limit plate should be located on the pin location just beyond the position being turned to. Turn hotstick until switch has fully indexed into the next position. If for any reason, the switching operation cannot be completed with a single motion, it is acceptable to relax, regrip the hotstick and complete the operation by moving the switch handle in the same direction as the original effort. NOTE: Do not reverse the direction of the switching operation before completing the rotation. If the handle stops (jams) in a position between the designated (marked) positions, stop switching operation and consult the factory prior to reattempting operation of the switch. RTE® is a registered trademark of Cooper Power Systems, Inc. #5000050062 Rev. 02 4 P.O. Box 1640 Waukesha, WI 53187