S280-30-10 Reclosers Types VW, VWE, VWV 27kV, and VWVE 27kV

advertisement

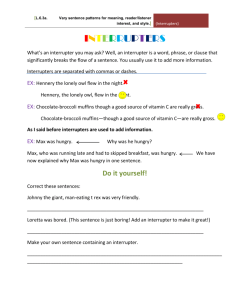

Reclosers Service Information Types VW, VWE, VWV 27kV, and VWVE 27kV KRW710V Vacuum Interrupter Replacement Kit S280-30-10 Fuse mounted above Upper Exchange Plate on Type VWE Reclosers, below on Type VW Reclosers. (High Voltage Units only) Long Bushing Lead Insulating Barrier Plate Vacuum Interrupter Nylon Wire Ties (4) Lower Double Stringers Upper Current Exchange Plate Upper Interrupter Clamp Lower Current Exchange Plate Lower Single Stringer Lower Interrupter Clamp Figure 1. Existing Vacuum Interrupter KA173VS Installation (Type VWE Recloser shown) Fuse mounted above Upper Exchange Plate on Type VWE Reclosers, below on Type VW Reclosers. (High Voltage Units only) Long Bushing Lead Insulating Barrier Plate Lower Double Stringers 101,6MM (4“) Approx. Nylon Wire Ties (4) Upper Current Exchange Plate Upper Interrupter Clamp Vacuum Interrupter Lower Single Stringer Lower Current Exchange Plate Lower Interrupter Clamp Figure 2. Replacement Vacuum Interrupter VSAM-612-1 Installation (Type VWE Recloser shown). May1997• Supersedes 9/90 Printed in USA Types VW, VWE, VWV 27kV and VWVE 27kV; KRW710V Vacuum Interrupter Replacement Kit ! SAFETY FOR LIFE ! SAFETY FOR LIFE SAFETY FOR LIFE Kyle Distribution Switchgear products meet or exceed all applicable industry standards relating to product safety. We actively promote safe practices in the use and maintenance of our products through our service literature, instructional training programs, and the continuous efforts of all Kyle employees involved in product design, manufacture, marketing, and service. We strongly urge that you always follow all locally approved safety procedures and safety instructions when working around high voltage lines and equipment and support our “Safety For Life” mission. SAFETY INFORMATION Following is important safety information. For safe installation and operation of this equipment, be sure to read and understand all cautions and warnings. Hazard Statement Definitions WARNING: Hazardous voltage. Contact with high voltage will cause death or severe personal injury. Follow all locally approved safety procedures when working around high voltage lines and equipment. G103.2 ! This manual contains two types of hazard statements: WARNING: Refers to hazards or unsafe practices which could result in severe personal injury, or death, and equipment damage. ! CAUTION: Refers to hazards or unsafe practices which could result in damage to equipment or in personal injury. ! Safety Instructions Following are general caution and warning statements that apply to this equipment. Additional statements, related to specific tasks and procedures, are located throughout the manual. WARNING: Before installing, operating, maintaining, or testing this equipment, carefully read and understand the contents of this manual. Improper operation, handling or maintenance can result in death, severe personal injury, and equipment damage. ! G101.0 WARNING: This equipment is not intended to protect human life. Follow all locally approved procedures and safety practices when installing or operating this equipment. Failure to comply may result in death, severe personal injury and equipment damage. G102.1 ! 2 WARNING: This equipment requires routine inspection and maintenance to ensure proper operation. If it is not maintained it may fail to operate properly. Improper operation can cause equipment damage and possible personal injury. G105.1 ! ! S280-30-10 SAFETY SAFETY FOR LIFE LIFE FOR Contents Safety Information ..................................................... 2 Installation ................................................................. 4 Hazard Statement Definitions ................................. 3 Description ............................................................. 4 Safety Instructions................................................... 3 Replacement Instructions........................................ 4 Product Information .................................................. 3 Removing Existing Interrupter ................................. 4 Introduction ............................................................. 3 Installing Replacement Interrupter ......................... 5 Acceptance and Initial Inspection............................ 3 Testing......................................................................... 6 Handling and Storage.............................................. 3 Dielectric Withstand Test ......................................... 6 Description ............................................................. 3 PRODUCT INFORMATION Introduction ANSI Standards Service Information S280-30-10 provides installation and operating instructions for the Types VW, VWE, VWV 27kV and VWVE 27kV KRW710V Vacuum Interrupter Replacement Kit. Before installing and operating this kit, carefully read and understand the contents of this manual. Kyle reclosers are designed and tested in accordance with ANSI standards C37.60 and C37.85 and ANSI guideline C37.61. The information contained in this manual is organized into the following major categories; Safety Information, Product Information, Kit Installation and Testing Refer to the table of contents for page numbers. Read This Manual First Quality Standards The Quality System at the Cooper Power Systems, Kyle Distribution Switchgear plant is certified to the following standards. ISO 9001, 1994 CAN/CSA ISO 9001, 1994 BS EN ISO 9001, 1994 Read and understand the contents of this manual and follow all locally approved procedures and safety practices before installing or operating this equipment. ANSI/ASQC Q9001, 1994 Additional Information Description These instructions cannot cover all details or variations in the equipment, procedures, or process described, nor provide directions for meeting every possible contingency during installation, operation, or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for the user's purpose, please contact your Cooper Power Systems representative. These instructions are intended for field installation of the vacuum interrupter replacement kits. Read and understand this instruction sheet and follow all locally-approved procedures and safety practices before installing and operating this equipment. Acceptance and Initial Inspection Each kit is in good condition at the factory and when accepted by the carrier for shipment. The Types VW, VWE, VWV 27kV and VWVE 27kV KRW710V Vacuum Interrupter Replacement Kit includes all the necessary parts to replace the vacuum interrupter to assure the operating rating. Refer to Service Information S280-77-1 Installation and Operation Instructions for procedures to remove recloser from operation. Upon receipt, inspect the carton for signs of damage. Unpack the kit(s) and inspect it thoroughly for damage incurred during shipment. If damage is discovered, file a claim with the carrier immediately. Handling and Storage Be careful during handling and storage of the kit to minimize the possibility of damage. If the kit is to be stored for any length of time prior to installation, provide a clean, dry storage area. 3 Types VW, VWE, VWV 27kV and VWVE 27kV; KRW710V Vacuum Interrupter Replacement Kit INSTALLATION Replacement Instructions Description Before beginning these procedures, de-energize and disconnect the recloser from the system. Make sure the low-voltage auxiliary power (if any) and the control cable have been disconnected. The existing vacuum interr upters, KA173VS and KA215VS, rated at 15.5kV max., and KA150VWS and KA227VS, rated at 27kV max., have been phased out of production and are no longer available for repairs. A typical installation in an oil insulated recloser is shown in Figure 1. Kit KRW710V has been established to replace existing interrupters with the new VSAM-612-1 vacuum interrupter, as shown in Table 1. A new interrupter installation is shown in Figure 2. TABLE 1. Available Kits Recloser Type Existing Interrupter Existing Interrupter Existing Replacement Interrupter Interrupter Kit KRW710V1 VW-VWE KA173VS Phase A & B KA215VS KA327VS VSAM-612-1 KA150VWS KA227VS KA327VS VSAM-612-1 VWV-VWVE Phase C KA150VWS KA227VS KA327VS VSAM-612-1 VW-VWE Phase C KA173VS KA327VS VSAM-612-1 VWV-VWVE Phase A & B Kit KRV710V2 4 KA215VS For installation and operation procedures, see: Service Information S280-30-1, Types W, WV27, WV38X, VW, VW27 and VWV38X Three-Phase, Hydraulically Controlled Installation and Operation Instructions; S28040-2 Type VWE Installation and Operation Instructions. For maintenance, see Service Information S280-30-7, Ty p e s V W, VWV27 and VWV38 Maintenance Instructions and S280-40-6 Types VWE and VWVE Maintenance. Removing Existing Interrupter Refer to Figure 1 and proceed as follows: 1. Make sure the recloser is tripped open by pulling down the yellow operating handle under the sleet hood to the LOCKOUT position. 2. Untank the recloser and allow the oil to drain off the mechanism. 3. Cut the four nylon tie straps that hold the vertical insulation barrier plate and the long bushing lead to the stringers and to the upper current exchange assembly plate. 4. Remove and discard the insulating barrier plate. Disconnect and discard the long bushing lead. 5. Loosen and remove the upper interrupter clamp. As the clamp is loosened, the contact rod will move downward into the interrupter due to atmospheric pressure acting on the bellows. Verify by observing the scribe mark on the contact rod; it will move downward from just below the clamping fingers on the contact rod to just above, or below, the guide plate on the interrupter. Note: If the contact rod does not move, it may be sticking in the clamping fingers of the current exchange, or the interrupter may have lost its vacuum. Use a screwdriver to gently spread the clamping fingers to free the contact rod. 6. Loosen and remove the lower interrupter clamp. 7. Remove and discard the hardware attaching the lower current exchange assembly to the three vertical stringers. 8. Remove and discard the lower current exchange assembly and the vacuum interrupter. 9. Remove and discard the three lower stringers. S280-30-10 Installing Replacement Interrupter Refer to Figure 2 and proceed as follows: 1. Install the three new stringers supplied with the kit. Note: When tightening, apply the plier jaws across either roll pin near the top of the stringer to prevent marring the surface. 2. Seat the stationary (bottom) contact rod of the replacement interrupter in the clamping fingers of the new lower current exchange plate and assemble the plate to the stringers making sure the moving (upper) contact rod of the interrupter is inserted into the clamping fingers of the contact operating rod. Note: There are two different lower current exchange plates furnished with the replacement kit. One is used for either A- or Bphase; the other for C-phase. Positioning the plates on the lower stringers will determine which plate is appropriate. 3. Secure the plate of the lower current exchange assembly to the stringers with the flat washer, split lockwasher and hex nut supplied in the kit. Note: Position the new spacer, included in the kit, on the stud end of the single stringer before the attaching hardware is installed. 4. Manually close the recloser using the T-handle closing tool (furnished as an accessory). A. Remove the cover plate on the source side of the recloser head. B. Insert the closing tool into the port and engage the pin to the main operating shaft. C. To close the recloser, raise the yellow handle (under the sleet hood) into the “up” or CLOSED position and turn the closing tool clockwise 1/4turn. 5. Coat the threads of the interrupter clamps and attaching screws with a light film of transformer oil and install, but do not tighten, the upper and lower interrupter clamps. 6. Position the upper and lower interrupter clamps up to the shoulder of the clamp fingers, so the clamping force will be applied to the center of each finger as shown in Figure 3. 7. Carefully rotate the interrupter so that one of the hex nuts (at the top of the interrupter) is centered directly beneath the gap created between the two halves of the clamp, as shown in Figure 3. 8. Evenly tighten the screws of both the upper and lower clamps to a torque of 8.5Nm (75 in-lbs). ! CAUTION: Equipment damage. Do not twist or apply radial pressure to the vacuum interrupter movable contact rod. Excessive twisting or pressure on the contact rod will damage the interrupter bellows, which can cause equipment failure. T211.0 Note: Clamps must be tight to prevent slippage of the interrupter contact rods in their current exchange connections. 9. Slip the insulating tubing over the long bushing leads. 10. Install and connect the insulated lead from the bottom of the bushing to the bracket on the lower current exchange assembly using existing hardware. 11. Install the new vertical insulating barrier plate between the long bushing lead and the stringer so that the 101,6mm (4 inch) dimension is obtained (see Figure 2). Secure the plate to the long bushing lead, the stringer, and the upper current exchange plate in “figure 8” configurations with three nylon wire ties provided in the kit. (See Figures 2 and 4). 12. Secure the lower portion of the long bushing lead to the stringer using a wire tie in a “figure 8” configuration. 13. Temporarily lower the recloser mechanism into the tank. Manually open and close the recloser two or three times. Then, with the unit in the open position, raise the mechanism out of the tank and check the contact gap. Make sure the upper and lower interrupter clamps are tightened securely. Verify contact movement as shown in Figure 5. Top of Interrupter Body Moving Contact Rod of Interrupter Clamping Force “F”Four Places F Guide Plate Lower Double Stringers F Nut Upper Current Exchange Plate Nylon Wire Ties Clamping Fingers (4) of Operating Rod Gap between Clamp Halves F Figure 3. Interrupter and Clamp Orientation. F Insulating Barrier Plate Long Bushing Lead Figure 4. Typical representation of nylon wire tie “figure 8” configuration. 5 Types VW, VWE, VWV 27kV and VWVE 27kV; KRW710V Vacuum Interrupter Replacement Kit Note: Verify contact movement by observing the movement of the scribe mark on the upper contact rod of the interrupter. When the recloser is open, the scribe mark will be approximately 15,8mm (5/8 inch) above the guide plate; when closed, the mark will travel 12,7mm (1/2 inch) downward. 14. Clean and examine the head gasket. Replace if cracked, cut or otherwise damaged, or if it is per manently deformed. TESTING Dielectric Withstand Test The High Potential Withstand Test provides information on the dielectric condition of the recloser and the vacuum integrity of the interrupters. Testing is performed at 75% of the rated low-frequency-withstand voltage (37.5 kV for VW and VWE reclosers, 45kV for VWV and VWVE reclosers). 15. Clean the gasket seat and retank the recloser. 16. Replace the head bolts and torque 47.5-74.6Nm (35-55 ftlbs). Apply the clamping force gradually and equally to each bolt in rotation to achieve an evenly distributed gasket-sealing pressure. 17. Check the oil level with the dipstick in the head. When necessary, fill the tank to the upper line on the dipstick using new, clean, dry transformer oil. 18. Before returning the recloser to service, perform a HighPotential Dielectric Withstand Test to ensure that the dielectric clearances within the tank have not been compromised. Upper Current Exchange Plate Upper Interrupter Clamp CAUTION: Radiation. At voltages up to the specified test voltages, the radiation emitted by the vacuum interrupter is negligible. However, above these voltages, radiation injurious to personnel can be emitted. See Service Information S280-90-1, Vacuum Interrupter Withstand Te s t Vo l t a g e R a t i n g s Information for further information. G109.2 ! TEST 1: Proceed as follows: 1. Manually close the main contacts of the recloser. 2. Electrically ground the recloser tank and head. 3. Connect the source-side bushings (1, 3, 5) together. 4. Apply proper test voltage to source side bushings. 5. The recloser should withstand test voltage for 60 seconds. Upper Contact Rod 15,8mm (5/8”) 3,18mm (1/8”) 12,7mm (1/2”) Travel Scribe Mark Scribe Mark Guide Plate Recloser (Closed) Recloser (Open) Figure 5. Verify contact movement by observing scribe mark travel. 6 TEST 2: Proceed as follows: 1. Manually close the main contacts of the recloser. 2. Electrically ground the recloser tank and head. 3. Ground Phase A (bushing 2) and Phase C (bushing 6). 4. Apply proper test voltage to Phase B (bushing 3). 5. The recloser should withstand test voltage for 60 seconds. TEST 3: Proceed as follows: 1. Open the main contacts of the recloser. 2. Electrically ground the recloser tank and head. 3. Connect and ground the three load-side bushings (2, 4, 6). 4. Connect the source-side bushings (1, 3, 5) together. 5. Apply proper test voltage to the source-side bushings. 6. The recloser should withstand the test voltage for 60 seconds. 7. Reverse the connections: ground the source-side bushings (1, 3, 5) and apply test voltage to the loadside bushings (2, 4, 6) for 60 seconds. 8. The recloser should withstand the test voltage for 60 seconds. S280-30-10 TEST RESULTS: The High Potential Withstand Tests provide information on the dielectric condition of the recloser and the vacuum integrity of the interrupters. A. If the recloser passes the closed-contacts tests (Tests 1 and 2), but fails the open-contacts test (Test 3), a deteriorated vacuum in one or more of the interrupters is most likely the cause. Retest each vacuum interrupter individually to determine the failed phase or phases, and replace the interrupter. Retest to confirm the success of the repair. B. If the recloser fails the closed-contacts tests (Tests 1 and 2), the cause is likely to be diminished electrical clearance or failed insulation. After analyzing, then correcting, the problem, retest to confirm the success of the repair. 7 Types VW, VWE, VWV 27kV and VWVE 27kV; KRW710V Vacuum Interrupter Replacement Kit ! SAFETY FOR LIFE P.O. Box 1640, Waukesha, WI 53187 www.cooperpower.com ©1997 Cooper Power Systems, Inc. Kyle® is a registered trademark of Cooper Industries, Inc. KA2048-267-01 Printed on Recycled Paper KRP 5/97