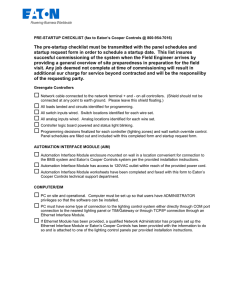

iLumin Pre-Startup Checklist Pre-requisites

advertisement

iLumin Pre-Startup Checklist Pre-requisites Pre-requisites – Items that must be completed prior to commissioning commencing It is assumed that the installer will have carried out the following prior to the commencement of system commissioning by Eaton’s Cooper Controls. If the installation is not complete at the time off commissioning, I understand that additional cost may incurred due to added time on site: The equipment has been mounted in accordance with the installation instructions provided with the equipment, All loads and power supplies have been tested prior to them being terminated at the equipment, The data cable has been installed between all items on the network and a record of the exact route recorded has been attached to the request for commissioning form that follows this document. Cooper Controls reserves the right not to terminate the data cable until this information is provided and verified as being correct, A record of which load circuits and type of loads are connected to each of the physical channels of each iLumin source controller has been attached to the request for commissioning form that follows this document. Failure to provide this information will lead to postponement of scheduling of the commissioning until it is received. Templates for these schedules can be obtained from Cooper Controls Technical Support department. All circuits have the final loads connected to them and have been seen to operate, All Source Controllers have been powered up and the installer responsible for the termination of the supply circuits and load circuits has checked these for tightness of the terminals and quality of the installation. Control cabling for dimmable HF ballast and low voltage controlled loads (0-10V) are correctly installed and routings known. Any special plugs required for the termination of power and data to controlled fittings are supplied and fitted. Please note, depending on equipment provided, additional information may be necessary for commissioning to be scheduled. Please contact Eaton’s Cooper Controls Technical Support department at 1-800-553-3879 to determine if additional information is necessary for your facility. Commissioning Method (All iLumin equipment is tested at the factory prior to shipping) Source Controller Supply and Load Terminations The termination of load and supply cables to iLumin equipment is the responsibility of the installing contractor. The installing contractor is responsible for the quality and tightness of all power terminations. These will be visually inspected by Eaton’s Cooper Controls when commissioning is carried out. Source Controller Load Circuit Testing Testing of load circuits and the loads themselves is the responsibility of others. The testing of circuits for Earth Loop Impedance, Insulation resistance, short circuit etc should all be carried out by qualified testers (not Cooper Controls) prior to connection to the iLumin Source Controller. Source Controller Performance Testing Testing of individual channels of Source Controllers will be limited to ascertaining that the channels connected to loads turn on and off and if dimmable, do so over the range from on to off in an acceptable manner appropriate for the type and quality of the load. More detailed testing of individual circuits will not be done on site by Eaton’s Cooper Controls unless a circuit is found not to perform correctly. This will be done to ascertain whether there is a fault with the channel of the source controller or with the load circuit. If a problem is found with the channel of the source controller, due to a manufacturing defect, this will be rectified by Eaton’s Cooper Controls as soon as possible. Should the nature of a fault indicate misuse of the equipment then this will be discussed with the client and a plan to rectify the problem agreed upon together with any costs involved. Network Cable termination and testing Unless otherwise agreed, the Eaton’s Cooper Controls commissioning engineer will carry out termination of iCANnet data cable. All control panel (switch plate) positions should be fitted with the appropriate backbox prior to the arrival of the Eaton’s Cooper Controls commissioning engineer. Testing of the network will take the form of ensuring that all devices attached to the network are visible on the computer once all terminations have been made. Configuration and Level Setting Once a full network has been obtained and all devices identified, configuration of the system can be carried out to provide the desired control. Testing of this will take the form of the monitoring of messages on the network using a computer and visual testing of the response of inputs from control panels and other controlling devices. Training As part of the site visit, Eaton’s Cooper Controls will train the end user on the use of the devices provided for the project. The installing contractor is responsible for informing the necessary personnel that this training will occur. Declaration We confirm that all pre-requisites detailed above have been satisfied and the project is now ready for commissioning by Eaton’s Cooper Controls. The job is or will be completely installed by the date requested. If the installation is not complete at the specified time, I understand that I will incur additional expenses from Eaton’s Cooper Controls for additional trips that may be required. Eaton’s Cooper Controls requires that a minimum of three weeks notice be provided, dependant on technician availability, to schedule commissionings. If three weeks notice is not provided, a FAST TRACK charge will be applied. Contact the technical support group for the possibility of scheduling the commissioning should 3 week notice not be available. In accordance with Eaton’s Cooper Controls’ terms and conditions this letter serves as written notification requesting a Field Service Engineer to perform a system start up beginning on the following date: Requested Commissioning Date: (Requested date subject to confirmation of technician availability). Lighting Designer, architect or other personnel will be available for scene level direction. Site personnel will be available for training on the above requested date. Integrator is available to test integration of components if an SI-2 system integrator has been purchased. Please provide integrator information: Name: Company: Phone #: Signature: