Industrial and City Wastes Bulletin Series March 1947

advertisement

p

ii

DOCUMENT

OREGON

Industrial and City

Wastes

By

FRED MERRYFIELD

W. B. BOLLEN

F. G. KACHELHOFFER

Bulletin Series

No. 22

March 1947

Cooperating A

Ic

Oregon State Sanita

League of Oreg

i

Engineering Experiment Station

Engineering Experiment Station

Oregon State System of Higher Education

Oregon State College

THE Oregon State Engineering Experiment Station was

established by act of the Board of Regents of the College

on May 4, 1927. It is the purpose of the Station to serve the

state in a manner broadly outlined by the following policy:

(1)To stimulate and elevate engineering education by

developing the research spirit in faculty and students.

(2) To serve the industries, utilities, professional engineers, public departments, and engineering teachers by making

investigations of interest to them.

(3) To publish and distribute by bulletins, circulars, and

technical articles in periodicals the results of such studies, surveys, tests, investigations, and researches as will be of greatest

benefit to the people of Oregon, and particularly to the state's

industries, utilities, and professional engineers.

To make available the results of the investigations conducted by the Station three types of publications are issued.

These are:

(1) Bulletins covering original investigations.

(2) Circulars giving compilations of useful data.

(3) Reprints giving more general distribution to scientific

papers or reports previously published elsewhere, as for example, in the proceedings of professional societies.

Single copies of publications are sent free on request to

residents of Oregon, to libraries, and to other experiment

stations exchanging publications. As long as available, additional copies, or copies to others, are sent at prices covering

cost of printing. The price of this bulletin is 40 cents.

For copies of publications or for other information address

Oregon State Engineering Experiment Station,

Corvallis, Oregon

Industrial and City Wastes

By

FRED MERRYFIELD

Professor of Sanitary Engineering

W. B. BOLLEN

Associate Professor of Bacteriology

Associate Bacteriologist, Agricultural Experiment Station

F. C. KACHELHOFFER

Instructor in Sanitary Engineering

Bulletin Series,

No. 22

March 1947

Cooperating Agencies

Oregon State Sanitary Authority

League of Oregon Cities

Engineering Experiment Station

Engineering Experiment Station

Oregon State System of Higher Education

Oregon State College

TABLE OF CONTENTS

Page

I.

Introduction

----------------------------------------------------------------------------------------------------------

1.Foreword

5

--------------------------------------------------------------------------------------------

5

Authorization ----------------------------------------------------------------------------------------

5

Acknowledgments

--------------------------------------------------------------------------------

6

Previous Work ------------------------------------------------------------------------------

7

Present Work ----------------------------------------------------------------------------------------

7

II. Methods of Study --------------------------------------------------------------------------------------

8

1. Industrial Waste Sampling ------------------------------------------------------------------

8

2.

3.

4.

5.

2. City Sewage Sampling ------------------------------------------------------------------------ 10

3. Tests

------------------------------------------------------------------------------------------------ 10

III.Results ------------------------------------------------------------------------------------------------------------ 15

1. Industrial Wastes ---------------------------------------------------------------------------- 15

2. City Wastes ---------------------------------------------------------------------------------------------- 19

IV. Conclusions .........................................

20

1. Industrial Wastes ...............

20

A. Wood Industries

..........

20

B. Food Processing

.........

20

C. Textiles .........................

21

D. Manufacturing

21

2. City Wastes

.........................

22

3. General ...................................

22

V. Appendix

Table 1. List of Canneries and Their Products ---------------------------------- 25

Table 2. Oregon Cannery Pack, 1945-46 ---------------------------------------------- 33

Table 3. List of Animal and Meat Processing Plants ...................... 35

Table 4. Analyses of Industrial Wastes ................................................ 39

Table 5. Correlation of BOD with Analytical Data ........................ 42

Table 6. Analyses of City Sewages ---------------------------------------------------------- 43

Table 7. Quantitative Flows of City Sewages -------------------------------------- 44

DEDICATION

This bulletin is dedicated to the city crews and

others who worked long and weary hours to turn their

labor into this report with its words and its tables of

it is particularly dedicated to a team of

youngsters, 70 to 75 years old, who were so spry as

arithmetic,

they moved quickly from point to point sampling sew-

age through a maze of traffic that they left a pho-

tographer gasping. Twelve hours a day they worked

under wartime pressures to make these and other

notes ready for their state when peace returned.

And to an 82-year-old gentleman, former

newspaper editor, who faithfully sampled, and in

meticulous hand, recorded the hourly flow of his town's

waste so that the kids might swim in the river again.

We picture him now on a warm August night in this

valley, when most of his townsfolk were asleep, sitting

in his boyish shelter made of slats and canvas on his

lawn, among his old and graceful trees, their limbs

outlined by a light hanging from a branch. . . . The

trees sway with the wind and the light casts shadows

on his notebook, clock, bucket, rope, and stick. The

alarm ringshe picks up his tools, removes the manhole cover nearby. Down goes the bucket, up comes

the waste. Poured, measured, he washes his hands

with the garden hose, and writes in his notes the love

of the river he has known so long.

To these men in particular we respectfully dedicate

this bulletin.

; )-:

fr

.

Industrial and City Wastes

By

FRED MERRYFIELD

Professor of Sanitary Engineering

W. B. BOLLEN

Associate Professor of Bacteriology

Associate Bacteriologist, Agricultural Experiment Station

F. C. KACHELHOFFER

Instructor in Sanitary Engineering

I. INTRODUCTION

1. Foreword. The material contained in this report amplifies

the data on municipal and industrial wastes which were presented in

Bulletin No. 19, and will be of extreme interest to state and municipal

authorities, industries, engineers, sportsmen, and the public. It confirms the fact that the problem of stream purification is not one for

which simple solutions are readily available. This information will

provide the Sanitary Authority with a useful guide on which its

pollution control activities can be based.

The cooperation of municipalities and industries in the studies

is to be commended. Without their ready and willing assistance, the

task of carrying this work to a successful conclusion would have

been extremely difficult. Their interest in the surveys has been a

stimulus to the stream conservation program in Oregon, and will

prove helpful in the restoration of our waters to their reasonable and

natural use. To the citizen who is primarily interested in the general

welfare of the state, it has been an indication that if the varied interests can work together to determine the magnitude of problems,

they can be depended upon to seek a satisfactory solution.

It is to be hoped that when more favorable conditions prevail,

the construction of treatment and disposal facilities for both municipal and industrial wastes will be undertaken without further delay.

CURTISS M. EvERTS, JR.

Oregon State Sanitary Authority

State Sanitary Engineer, Secretary

April 10, 1947

2. Authorization. On July 5, 1945, the Oregon State Sanitary

Authority authorized the Engineering Experiment Station to proceed

with special stream pollution studies in accordance with a program

proposed by them. A special appropriation of $5,800 was made

available to the Authority by the Forty-third Legislative Assembly

and was used for this purpose. Bulletin No. 22 and part of another

to follow are the result of studies carried on under this authorization.

6

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

3. Acknowledgments. The study and report were compiled

under the general supervision of S. H. Graf, Director of the Engineering Experiment Station, and Kenneth H. Spies, Acting State

Sanitary Engineer and Secretary of the State Sanitary Authority at

the time the investigations were undertaken. The cooperation of

Mr. H. F. Wendel, Chairman of the State Sanitary Authority, Mr.

Curtiss M. Everts, Jr., State Sanitary Engineer, Mr. Kenneth H.

Spies, formerly Acting State Sanitary Engineer and now Associate

Sanitary Engineer, and other members of the staff of the State Sanitary Authority is deeply appreciated. Messrs. Eugene J. Guldeman,

Matt Mimms, and Hallett Spring were responsible for some of the

field sampling and laboratory analyses under the direction of the

authors. Sampling and collection of city data were carried out by

city crews under the direction of Harold C. McCrea, City Manager

of Coos Bay, J. A. Parrish, City Recorder of Myrtle Point, Victor

R. Kern, City Manager of Monmouth, and W. S. Chambers, City

Councilman of Brownsville.

Waste samples were obtained with the cooperation of the following industries:

Western Oregon Packing Company

Eugene Fruit Growers Association

Apple Growers Association

Spencer Packing Company

Farmer's Co-op. Creamery

Benton County Flax Association

Rogers Canning Company

Smith Packing Company

Pendleton Woolen Mills

Hunt Brothers Packing Company

Oregon Fruit Products Company

Reid Murdoch Company

Blue Lake Corporation

Field Laboratory Division

Corvallis

Eugene

Hood River

Lebanon

McMinnville

Monroe

Milton

Pendleton

Pendleton

Salem

Salem

Salem

West Salem

U.S.D.A.

Mr. Herman Kehrli, Executive Secretary of the League of

Oregon Cities, gave generous help and cooperation.

Thanks are due members of the staff of Oregon State College,

particularly Dean G. W. Gleeson, Professors C. A. Mockmore and

Joseph Schulein of the Engineering School; Professor E. C. Gilbert,

Chairman of the Department of Chemistry; Mr. C. H. Bryant,

Curator of Chemistry Department Laboratories; Mr. E. G. Nelson,

Associate Agronomist, U. S. Department of Agriculture; and Pro-

fessors E. H. Wiegand, T. Onsdorff, and E. M. Litwiller of the

Food Technology Department.

INDUSTRIAL AND CITY WASTES

7

Apologies are due for the lateness of this bulletin, but the end

of hostilities, record student enrollments, laboratory displacement,

and other factors beyond control of the authors made it difficult to

complete the work.

4. Previous work. Previous results on industrial and city

wastes have been reported by the Engineering Experiment Station

in Bulletins 7 and 19, and mention has been made of some industrial

waste problems in Bulletins 1, 2, 6, and 20. For all practical purposes Bulletin 7, published in 1936, referred to the specific industrial

wastes of the pulp and paper industry and wastes of the flax industry.

Bulletin 19 referred to a few wastes of the canning industries,

though the major effort was concentrated on the city wastes and the

condition of the Willamette River.

5. Present work. This bulletin is a report on the continuation

of part of the pollution studies of 1944, extended in the summer and

fall of 1945 and in early 1946. During that period studies were

made on the wastes of the canning industries and the few cities which

did not have opportunity to cooperate in 1944 and were therefore not

reported in Bulletin 19, 1945.

The work carried on by the Station since the completion of the

work reported in Bulletin 19 was divided into Projects 62 and 63.

Purposes of Project 62 were to obtain more basic information on the

character of industrial and domestic wastes for the State of Oregon,

to acquaint industry with the extent of its disposal problem, and to

furnish cities with information on their domestic wastes and data on

industries within their city limits.

This work consisted of: (a) Investigation of the domestic

wastes of Coos Bay, Myrtle Point, Monmouth, and Brownsville.

(b) Investigation of the seasonal wastes of canneries, flax, and

several other industries in the State. (c) An attempt to determine

methods of treatment of some of the industrial wastes. This part of

the research was temporarily deferred because of lack of time

and funds.

Project 63 was divided into three parts: (a) Two separate in-

vestigations in August and September, 1945, of the stored waters

behind Cottage Grove and Fern Ridge dams. The former dam

stores water of the Coast Fork of the Willamette River, and the

latter dam stores the water of the Long Tom River, a direct tributary of the Willamette River. (b) A survey of the Willamette and

South Santiam Rivers to determine the ability of these streams to

reaerate themselves during the low flow period in August and September. (c) Weekly sampling and testing of the Willamette River

and its tributaries at the stations listed in Bulletins 2 and 19.

8

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

Funds for Projects 62 and 63-c were furnished by the Oregon

State Sanitary Authority and the Engineering Experiment Station,

and Project 63-a and b was financed by the U. S. Fish and Wildlife

Service together with the above-mentioned State Agencies. Results

of Project 63 are to be published in a later bulletin.

II. METHODS OF STUDY

1. Industrial waste sampling. Industrial wastes are acknowledged to be the larger and stronger sources of pollution of the

Willamette and several other rivers in the State. The disconcerting

fact concerning these wastes is their variety both in quality and

quantity throughout the year. This is particularly true of such seasonal industries as the canneries, other food processing plants, flax

retting plants, and in the nonseasonal woolen and linen mills.

Such industries as pulp and paper manufacture have been adequately enumerated and discussed in Bulletin 7, 1936. The flax industry, a seasonal process, has increased its flax production several

fold since 1936. A list of flax plants and their tank capacity is unavailable. Locations of canneries and allied plants as listed by the

Northwest Canners' Association for 1946, are shown in Table 1.

This table also states the kinds of products processed. A summary

of the quantities packed by these organizations for 1945 and 1946 is

contained in Table 2. A list of animal and meat processing plants is

shown in Table 3. This list was furnished by Mr. M. E. Knickerbocker, Chief of Division of Animal Industry, State Department of

Agriculture.

Large tonnages of pears, apples, prunes, and certain vegetables

are canned in the Pacific Northwest, some of which are peculiar to

this area. In addition, canning practices vary from place to place.

This is particularly true in the quantity of water used.

Since the problem of obtaining representative samples from

industry is difficult and costly, it was hoped that minor experiments

on these samples might also be carried out to determine what treatment might be necessary to reduce the pollutional load on the rivers.

This part of the project was deferred because so many different

samples were collected that the laboratory was completely occupied

with testing them for their strength. The samples were stored at

10 F to prevent loss of the samples, but even this expedient did

not allow the laboratory staff to make such treatment experiments in

addition to their duties in connection with Projects 62 and 63. While

some work has been carried on by the industry itself in the cannery

INDUSTRIAL AND CITY WASTES

9

wastes and investigations have been made in other states, there is

much work to be done on wastes peculiar to Oregon and the

Northwest.

It was not possible to collect samples from each industry, due

to their great number, and so representative groups were chosen

from each industry. Wherever permission was sought to sample an

industry's waste, the particular industry granted such request. There

is no question that all of the cannery, flax, and woolen establishments would have shown an equally fine cooperative spirit if a request

had been made of each one. The canneries and industry at large

were faced with severe labor and material shortages throughout the

sampling period. Unprecedented demands were being made on industry in the war effort and naturally the managements of such concerns could not devote as much time as they might have wished to

provide help in the sampling periods. These Oregon manufacturing

plants did, however, demonstrate their willingness to face the waste

disposal problem, and if coordination of these efforts could be

achieved, much time and money could be saved.

Two factors are pertinent in any waste research study: First,

the character of the waste, and second, the amount of liquid waste

per unit of material produced. It would seem that an investigation

of such wastes is a relatively simple matter, but unfortunately it is

impossible in some instances to obtain such information without

excessive extra cost.

In order to determine the character of the waste, it is essential

that the sample or samples collected be representative of the waste

throughout the day. If the manufacturing process is continuous,

parts of the individual processes may be discontinuous. Such processes, often called "batch processes," will change the quality of the

waste, and it is impossible in large plants to know when such batches

are being dumped except in mills where the batch is dumped once or

twice a day. At times throughout the day where five or six conveyor

lines are dumping wastes into the sewer, one of the lines may stop

for repairs or for lack of materials, and there is no practical method

of knowing at the sampling plant when such things happen. The

most difficult problem of all is to segregate the wastes of catch samples at a point where the waste is of one type only. Many plants,

canneries, woolen mills, creameries, and others discharge their wastes

from several machines into a common sewer which has been covered

over by earth, concrete, or planking. The management tsually has

no blueprints available to locate special manholes or individual sewer

lines, and usually the time spent in looking for such aids could be

used to more advantage in obtaining samples.

10

ENGINEERING 1X1'ERIMENT STATION BULLETIN No. 22

Since the wastes are usually organic and tend to decompose

rapidly, it is important that waste collected be kept cold until the

sampling is finished and it can be taken to the laboratory for analysis.

Unfortunately, not only the quality of the waste changes, but the

quantity also changes at the same time. ft is therefore necessary to

measure the flow wherever the opportunity is presented. To measure

the quantity is even more (lifficult than to determine the quality.

Every technique had to he drawn upon in order that some estimate

of the flow could be made. This estimate was necessary for not only

the prime purpose of expressing the quantity of waste per unit of

material produced, but also for representative sampling. It is necessary to collect, for quantitative analysis, samples in proportion to the

flow. In few industries was it possible at that time to measure the

amount of flow by weir or direct volume, therefore repeated float

tests were made to estimate velocities. Curves were drawn of quantity versus depth. Samples were then collected at short period inter-

valsfifteen minutes or less, for two or three hours---when it had

been established that prodpction in the plant was as normal as could

be expected. Considerable time was lost because of lack of labor,

material shortages, and occasional breakdowns. in several instances

field crews arrived at a plant only to find it shut down fcr one of the

foregoing causes. The composited samples were iced and delivered

to the laboratory the same day whenever possible. Pea wastes from

Eastern Oregon were brought by truck directly to the laboratory

without delay.

2. City sewage sampling. Sampling of city sewage was made

at hourly intervals throughout the 24-hour period, and the volume

of each sample was in proportion to the flow at that time. These

composite samples were collected at hourly intervals throughout a

24-hour period in the manner described in Bulletin 19, p 55-57. In

collecting samples at Coos Bay, samples were collected at low tide.

At Monmouth a weir was installed in the influent channel of the

sewage treatment plant and the head was recorded hourly. Float

tests and depth measurements were made at Myrtle Point but the

tide at Coos Bay prevented reasonable estimates of the flow in the

sewers there.

3. Tests.

The following laboratory tests were carried out on

the industrial wastes

A. Biological oxygen demand (BOD)

B. Hydrogen ion concentration (pH)

C. Settleable solids

1). Alkalinity

INDUSTRIAL AN!) Crrv WASTES

11

E. Acidity

F. Chlorides

G. Total solids

H. Suspended solids

I. Volatile solids

J. Dissolved solids

K. Carbohydrates

I . Total carbon

M. Nitrogen

Many of the industrial samples were stored at 10 F and

analyzed at later (kites when the laboratory could handle the tests in

a more orderly manner. A description of the first ten tests (A-J inclusive) is given in Bulletin 19, and reference here should be made

to pages 17-25 of that publication. Lee and Nichols dilution water

was used on all BOD tests on industrial wastes. (Lea & Nichols,

Influence of Substrate on BOD, SWJ 8, 435, 1936.)

CARBOHYDRATES

REDUCING SUGARS. The Shaffer-Sornogyi method as outlined

by Heinze and Murneek (Comparative Accuracy and Efficiency in

Determination of Carbohydrates in Plant Material. Fleinze, P. H.,

and Murneek, A. F.., 1940. Mo Agr Exp Sta Rsh Bul 314) was

employed to determine reducing sugars. Capacity of the copperiodometric reagent "50" was increased by raising the copper sulfate

content to 1.0 per cent and the potassium iodide to 0.5 per cent.

Titrations were made with 0.02 N sodium thiosulfate solution from

a burette graduated to 0.05 cc and dtiplicates were checked within

±0.05 cc, corresponding to 5 ppm sugar with a 10 cc sample. Preliminary treatment of blended subsamples was varied according to

concentration.

DILUTE WASTES, SI! OWING LITTLE OR NO SUSI'ENDED MATTER.

A 50 cc portion of sample was placed in a 100 cc volumetric flask

and clarified with zinc hydroxide by adding 10 cc of 10 per cent

ZnSO4 7 H20 and 10 cc 0.5N NaOH. (Browne, C. A. and Zerban, F. W., 1941. Sugar Analysis, P 890-891. John Wiley & Sons,

New York.) After mixing and making to volume the solution was

filtered through paper. Residual zinc ion was removed by adding a

few fine crystals of NaCO3, followed by shaking and filtering prior

to analysis. (Benedict, S. K., Jl Bio Chem 92, p 141-159, 1931. The

analysis of whole blood. II. The (letermination of sugar and saccharoids.)

Reducing sugar was determined on 10 cc aliquots of clarified

With sugar concentrations over 500

smaller aliquots or

filtrate.

fl1

12

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

suitable dilutions were employed. When less than 25 ppm sugar

were found, the determination was repeated on a ten-fold concentration of sample.

To'FAL SUGARS. A 25 cc aliquot of the clarified filtrate used for

reducing sugar was adjusted to pH 4.5, using bromcresolgreen indicator, and inverted with 1 cc invertase (Difco) for 1 hour at 25 C.

The solution was made up to 50 cc and reducing sugars were determined on aliquots as already described.

CONCENTRATED WASTES. Sugars were extracted with 80 per cent

alcohol. A 25 g sample was transferred to a 400 cc beaker with 200

cc 95 per cent ethanol; assuming the sample contained approximately

99 per cent water, the resulting solution was 80 per cent alcohol by

weight. The beaker was covered with a watch glass and boiled on a

water bath for two to three minutes. The solution was filtered

through a fritted glass crucible and the residue washed five times

with 10 cc portions of 80 per cent alcohol. The residue was reserved for starch determination. The alcoholic filtrate was evaporated till free from alcohol, adding small portions of water from

time to time. The solution was then transferred to a 100 cc volumetric flask, clarified with zinc hydroxide, and analyzed for reducing

sugar as previously described. Total sugars were determined on

the clarified filtrate as outlined under dilute wastes.

STARCH.

The residue from the alcohol extraction was trans-

ferred to a beaker with 20 to 25 cc cold water and evaporated to dry-

ness on a steam bath to remove alcohol. Then 10 cc water were

added and the beaker was covered and placed on the steam bath for

30 minutes. After cooling, digestion was effected by adding 1 cc of

1 per cent malt diastase (Merck) solution and incubating at 37.5 C

for 15 minutes. The digest was heated to boiling, filtered through

fritted glass, washed with hot water, and made up to 100 cc. Reducing sugar was determined on suitable aliquots.

TOTAL CARBON

Total carbon was determined by dry combustion. Samples of

heavy wastes were weighed directly in porcelain boats, while with

dilute wastes five or ten cc samples were used. After evaporation to

dryness on a steam plate, the residue was covered with 60-mesh

alundum and burned in a stream of oxygen in a combustion furnace

at 950 C. Evolved CO2 was absorbed in a Turner bulb containing

ascarite and weighed. Total carbon CO2 X 0.273.

INDUSTRIAL AND CITY WASTES

13

NITROGEN

Kjeldahl nitrogen was determined by a modification of the Gunning-Arnold procedure (Official and Tentative Methods of Analysis.

6th ed, p 27, Association of Official Agricultural Chemists, 1945)

using 10 g Hibbard's mixture. Distilled ammonia was absorbed in

saturated boric acid solution and titrated with N/14 H2SO4 in the

presence of methyl red-bromcresolgreen indicator.

NITRATE NITROGEN. Nitrate nitrogen was determined by the

phenoldisulfonic acid method (previous AOAC citation, p 631) on

aliquots of sample clarified by zinc hydroxide. Nitrate nitrogen was

determined on the clarified filtrate by the a-napthylamine-sulfanilic

acid method (previous AOAC citation, p 631).

AMMONIA.

Ammonia was determined by distilling 50 cc sam-

ples with phosphate buffer at pH 7.4 (Nichols, M. S. and Foote,

M. E., Distillation of Free Ammonia Nitrogen from Buffered Solutions, md & Eng Chem Anal ed 3, p 311-313, 1931). Absorption

and titration was carried out as for Kjeldahl nitrogen.

CARBON AND NITROGEN IN RELATION TO

BOD.

The BOD problem is a nutritional problem involving utilization

and decomposition of organic pollutional wastes by microorganisms.

Of the various factors involved, dissolved oxygen, carbon content of

substrate, and available nitrogen are most significant as affecting rate

and extent of decomposition. Growth and multiplication of the bacteria and other microorganisms require an assortment of the food elements characteristic of protoplasm in general. Among these elements,

carbon and nitrogen are prominent for two reasons: (1) Microbial

cell substance (dry basis) is composed of 45 to 55 per cent carbon

and 5 to 10 per cent nitrogen, these two elements thus comprising a

major part of the tissues; (2) supply of these two elements in assimilable form largely determines the growth or crop yield and the kind

or succession of organisms which develops. If either carbon or

nitrogen falls below nutritional requirements, growth is accordingly

retarded. Other food requirements, occasionally excepting phosphate, are in general adequately met when the carbon is supplied from

biological sources.

Carbon acquires additional, and from the quantitative standpoint, major importance in heterotrophic nutrition because it is

oxidized as the sole source of energy in catabolism. To synthesize

one part of carbon in tissue, the microbial cell must oxidize three to

ten parts for energy and requires approximately 0.1 part nitrogen, the

14

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

proportion varying with kind of microorganism and condition of

Under aerobic conditions bacteria assimilate almost 10 per

cent of the substrate carbon; anaerobically as little as 1 per cent may

be assimilated because anaerobic oxidations are less complete and

therefore less efficient in providing energy for synthesis.

Practically the BOD problem can be considered from the standpoint of complete oxidation and maximum free oxygen requirement.

In the presence of sufficient dissolved oxygen aerobic decomposition

can proceed and be complete; if dissolved oxygen is limited or absent, as in the presence of heavy pollutional loads, anaerobic oxidation will occur and by-products susceptible to further oxidation will

accumulate. Eventually these by-products will be completely oxidized

when, sooner or later, dissolved oxygen is again available. Whether

the decomposition is aerobic, rapid and complete, or whether it is

partly anaerobic and partly aerobic, occurring more or less stepwise

and perhaps quite prolonged, it eventually becomes complete and the

same amount of dissolved oxygen will be required in either case.

If available nitrogen in proportion to available carbon is limited,

growth.

the decomposition is slowed down to the rate determined by the

amount of nitrogenous cell substance that can be synthesized, includ-

ing repartition of the microbial nitrogen. Death and autolysis of

the cells liberate nitrogen compounds that can be utilized by subsequent generations but the growth rate, if dependent on this, is limited

accordingly.

While the figures for total carbon indicate the ultimate BOD,

the proportion of total nitrogen shows whether or not the decomposition may be limited in rate. This important relationship between

carbon and nitrogen is known as the carbon-nitrogen ratio (C/N).

It is a dominant factor controlling organic decomposition in soils,

and when the C/N ratio of the organic matter is wide, addition of

available nitrogen increases respiration. (Bollen, W. B. Soil respiration studies on the decomposition of native organic matter. Iowa

State College JI Science, 15, p 353-374, 1941).

For plant tissue, C/N ranges from 20 or 30 to 1 in legume hay

to 80 or 100 to I in cereal straw. All gradations between these extremes may be found in vegetable residues. Fruits, such as apples

and pears, are relatively high in carbohydrates and have a wide ratio;

grains and seeds generally are high in protein and have a narrow

ratio. The ratio of cells of microorganisms is narrower and more

constant, falling between 1/5 to 1/10 according to kind and age.

Bacteria are higher in protein than are molds; however, young active

cells of all microorganisms have a similar and relatively more narrow

ratio which explains their high nitrogen requirements.

INDUSTRIAL AND CITY WASTES

15

As decomposition of pollutional waste goes on, organic residues

are thoroughly worked over and eventually completely oxidized by a

succession of microorganisms. Large amounts of energy are required for the rapid synthesis concomitant with the multiplication of

the microorganisms. This results in dissipation of much carbon as

carbon dioxide and a rapid mineralization of the organic matter as

long as the C/N ratio is wide. Nitrogen is in great demand and is

rapidly synthesized into microbial tissue. If present in stifficient proportion to available carbon the activity proceeds at a maximum rate,

as long as nitrogen is available and as long as other factors, especially

dissolved oxygen, are not limiting. As the process goes on, the pro-

portion of carbon in the substrate decreases rapidly and the C/N

ratio becomes much narrower, approaching that of the microorganisms themselves. The organic end product is humus, consisting

largely of dead microbial cells and resistant residues, particularly

lignin.

Since many of the wastes chosen for study in this investigation

would obviously be high in carbohydrate and low in nitrogen, the

BOD determinations were made with the ammonia supplemented

mineralized phosphate-buffered dilution water of Lea and Nichols

(Lea, M. W., and Nichols, M. S. Influence of substrate on biochemical oxygen demand. Sew Wks JI 8, p 435-447, 1936). Ruchhoft (Ruchhoft, C. C., Report on the cooperative study of dilution

waters made for the Standard Methods Committee of the Federation

of Sewage Works Associations. Sew Wks Jl 13, p 669-680, 1941)

reports that this water is superior for the determination of BOD on

nitrogen-deficient wastes and is satisfactory for other types of pollution. Water from receiving streams was not used because it would

introduce chemical and biological variables.

Seeding with sewage or river water was not employed since it

has been shown (Sawyer, C. N., and Williamson, A. E., The selection of a dilution water for the determination of the BOD of industrial wastes. Sew Wks Jl 14, p 1000-1020, 1942) that natural seeding from the air, even though very limited may yield uniform and

dependable BOD results on carbohydrate solutions.

III. RESULTS

1. Industrial wastes. Water borne industrial wastes in Oregon are varied, but the greatest proportion of them can be classified

under the following product headings.

WooD. Pulp, paper, sawmill, and alcohol.

FooD AND BYPRODUcTS. Canned, frozen, dehydrated or

packed fruits and vegetables; dairy products; meat and

16

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

poultry packing; cereal manufacture; seafood preparation, freezing, and canning; and animal rendering

plants.

BEVERAGE.

Soft drinks and wastes from breweries and

distilleries.

TEXTILES. Woolens and linens.

Wastes from oil, soap, paint,

gas, plating and metal fabrications, chemical products.

MANUFACTURING PRODUCTS.

It can be seen from the foregoing that, with the exception of

manufacturing, the basic raw material from which the product is

made is organic in content. This material grown on land or in the

sea contains carbohydrates and nitrogenous matter incorporated with

mineral matter.

In any processing plant three general methods of production are

followed: the batch system, the continuous system, and the integrated batch or continuous systems. The latter systems are employed

in most industries since at some stage of manufacture it is necessary

to treat the material to be processed in bulk form. Pulp mills and

canneries, while apparently continuous in nature, use the batch

process in part of their operation. For this reason it is rather difficult

in the larger plants to obtain representative samples of the wastes

from the material produced. Many of the wastes are water conveyed and the water used is usually of excellent quality, since the

quality of the water has rather an important effect on the quality of

product. Because of this reason, and since water of good quality

has little or no organic demand, as expressed by the biochemical

oxygen demand, the strength of the waste produced is usually ex-

pressed in pounds of oxygen for 5 days or 20 days per unit of

product, whatever amount of water is used in producing such a

unit. For example, it is quite common practice to express the amount

of pulp produced by a pulp mill in tons per day, and therefore it is

logical to express the strength of the waste from a sulfite pulp mill

in pounds of 5 or 20 day oxygen demand per ton of pulp. Even

using this means of expression for organic strength, considerable

variation in samples is noted in the same plant and in other plants

processing the same materials. This is particularly true in the cannery, meat packing, and related industries where the raw product

varies both in quality and size. The amount of water varies decidedly

between similar plants and in the same plant, depending on its availability and cost.

While every effort was made to obtain representative samples,

considerable difficulty was encountered. Many of the industrial

sewers discharged their wastes into city sewers where the waste was

INDUSTRIAL AND CITY WASTES

17

mixed with city sewage at the next manhole. There is a natural

tendency on the part of the designers and constructors of many industrial plants to discharge condenser water in large volumes to

keep the sewers clean or to dispose of such waste easily. This is

unfortunate in many respects, since it makes the problem of sampling extremely uncertain, and if waste treatment is undertaken at the

plant or in conjunction with a city, larger and more costly tank

volume will need to be provided. There is a mistaken belief that

such condenser water dilution is an aid in sewage treatment. A review of Figure 12, p 37, Bulletin 19, published by this Station, shows

that even the Willamette River is not a large enough diluting body

of water for all the industries and cities along its banks. From the

above observation it would seem more economical to discharge the

condenser water which has little or no oxygen demand and is nontoxic, either directly into the river or its tributaries, or directly into

the storm sewers of the city.

It is not to be inferred from the above statement that water used

in washing fruit or vegetables, which has a relatively large oxygen

demand, should also be dumped into such courses. There is another

mistaken belief that such wash water or screened waste waters used

to convey fruit and vegetables have no effect on the rivers and

streams. Such is not the case, since practically all such waters are

now drained directly or indirectly into the Willamette or other rivers,

and the depreciation of streams in Oregon since 1929 can be attributed to industrial and city growth. The former is unquestionably the

greater contributor to this degeneration.

Another means of expressing industrial waste load is to state

the strength of the waste in terms of population. This term "population equivalent" has been used for some time, and while it does not

present an entirely true picture it can be used as one criterion, along

with others, to express waste quality.

Figure 1 shows the kind and location of the main industrial

plants which contribute wastes directly or indirectly into the streams

of the State, with the exception of mining, dredging, and wood processing. Bulletin No. 7 covers the pulp and paper mill industry.

Table 1 lists the cannery industries, locations, and types of food

processed.

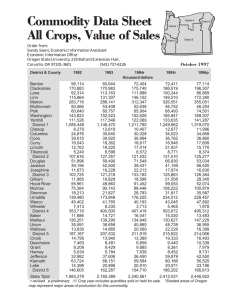

Table 2 lists the yearly packs of the fruit and vegetables for Ore-

gon in 1943 and 1946; for Oregon and Washington in 1945 and

1946; and for 1942-1946 for Oregon and Washington combined.

Table 3 gives the geographical distribution of the meat processing industry in Oregon in 1946.

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

18

:';

/5

\

WASHINGTON

TLLAMoTY 7J)T

0

Ia-

C)

I

CVALU-(

I.WALDPORT

I

J

.IEBXXON

0

.(

.(

\n s'm.

J

XE

LOCATION OF INDUSTRIES

AND

RELATED PRODUCTS

LEGEND

ROSEBUR

CMBIERIES ------PACKING ------FROZEN PRODUCTS---PROCESSED FOODS--- -C

VITAMIN OILS

CARBONATED BEVERAGES

FLAX RETTING --------

p

Figure 1.

FALLS

LOCATIONS OF INDUSTRIAL PLANTS.

The results of the laboratory analyses of industrial wastes in

1945 and 1946 are shown in considerable detail in Table 4. Data for

nitrites, nitrates, and ammonia are omitted. Nitrites, where found,

were in concentrations less than 1 ppm. Nitrates were found in only

one sample; this was pea waste to which sodium nitrate was added

for odor control. Ammonia nitrogen was found in many samples

but in few instances did this exceed 5 ppm. Kjeldahl nitrogen in

most instances accounted for practically all nitrogen reported under

total nitrogen.

The strength of the several wastes is expressed as BOD for

5- and 20-day periods. Where reliable measurements of the pack and

quantity of waste were obtainable, this oxygen demand has been expressed as population equivalent per 100 cases or per ton of material

processed. Theriault's investigations on the BOD of strictly domestic sewage, published in Public Health Bulletin 173, indicates that

INDUSTRIAL AND CITY WASTES

19

about 0.17 lb of atmospheric oxygen dissolved in water was required

to satisfy the 5-day per capita oxygen demand. Combined sewage,

free from industrial wastes, requires about 0.24 lb per capita per day

for the same period.

2. City wastes. The results of the tests made on city sewages

are shown in Table 6. The city of Brownsville is not included in this

list since only a small part of the city is adequately sewered.

The tests were made on 24-hour composite samples, gathered by

city sampling crews at regular intervals of one hour, except in the

case of Coos Bay, where hourly samples were obtained at low tide.

The composite samples taken in proportion to flow were iced and

tested immediately upon receipt at the laboratory. Sampling and

testing were carried on during the dry weather period from July 16

to September 21, 1945. The table shows the average, maximum, and

minimum results for the period in which 19 daily samples were obtained. Interpretation of the data shown in Table 6 with daily data

included has been filed in report form with the city concerned and

the State Sanitary Engineer for the State Sanitary Authority.

Records of flow of sewage by means of a 12-inch suppressed

rectangular weir were obtained at the Monmouth sewage treatment

plant. The data submitted indicate the efficiency of the plant as evidenced by the tests. Because of tidal action it was impossible in the

time allotted to make a satisfactory determination of flow in the Coos

Bay sewers.

Twenty-four cities, twenty-one listed in Bulletin 19 and three in

this bulletin, have furnished the State of Oregon with basic qualitative information. In all instances, depth measurements were made

in all cities at hourly intervals during sampling. All these basic data

including those where weir measurements were made are in reports

submitted to the City and State Sanitary Authority. Reduction of

such data to approximate flow records was achieved by measuring

the velocity repeatedly by floats in the actual sewers involved and

using the characteristic depth curves of open channels for the particular size and shape of sewer involved. Table 7 lists measurements

and computations of measurements of flow in the individual sewers

of most of the cities mentioned above. Sewers omitted were those

in which the installation of a weir was not feasible at the time, where

in a few instances the floats did not give good repetitive measurements, or where floats could not pass from manhole to manhole due

to obstructions.

No claim is made for accuracies of 5 per cent except in the cases

of the recording of the head on weirs at Pendleton, Salem, Springfield, and Hood River during normal flows. Float measurements are

20

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

at the best an approximation, but no float measurement was used

unless it could be reproduced several times. Float measurements

were made during low flows and medium flows wherever possible.

Distances of at least one block or more were used. The elapsed times

for the float observations were measured by the field crew with the

help of the city engineer or some delegated employee. Traffic hazards where trunk sewers were located in city streets and gas hazards

in deep sewers were avoided by special care in such cases. The

presence of gasoline and grease wastes in the sewage was noted by

the city employees. In spite of city ordinances and gas rationing

excessive amounts of automobile gasoline, solvents, and greases were

found in many sewers. The measurement of depth of sewage by

sampling crews was subject to error but every precaution was taken

by the field crews to instruct the crews in correct technique. Naturally the data received were no better than the men taking the measurements, but in practically all instances the work was faithfully done.

In most instances older men did the sampling work. Many hours

were spent reducing these quantitative data to intelligible information

and much of it had to be done whenever the opportunity offered.

The teaching demands due to the large influx of returning veterans

gave little or no opportunity for the culmination of the work until

now. It is hoped that this table will be of value even though the

accuracy is not of the best and the report has been delayed. The

accuracy of float measurements is probably within 15 per cent.

IV. CONCLUSIONS

1. Industrial wastes. An inspection of the map of Figure 1

reveals the following:

The wood industry can be divided, for all

practical purposes, into two sections. The pulp and paper

industry is located on the Willamette and Columbia Rivers.

WOOD INDUSTRIES.

Lumber production is scattered throughout the east and

west slopes of the Coast and Cascade ranges. There is

some lumber production in the Blue Mountains. The greatest number of sawmills is located near the smaller towns.

FOOD PROCESSING. The food processing industry, which consists of canneries, freezers, dehydrators, and brining, has

been divided into fruit, vegetables, and milk. Canneries,

dehydrators, and freezing units are, in general, located in

the Willamette Valley from Eugene to Portland; in the

Rogue River Valley, at or near Medford; in the Umatilla

Valley, at Pendleton and Athena; in the Walla Walla Val-

INDUSTRIAL AND CITY WASTES

21

ley at Milton-Freewater and Weston, and near the Smoke

River at Ontario and Nyssa.

Large canneries are located near Eugene, Salem, Portland, Hood River, and in the Pendleton area. It is interesting to note the tremendous increase in the canning and

freezing of peas in northeastern Oregon where the rivers

are small. Large fish canneries are on the Columbia. The

large meat packing plants are located at Portland, Salem,

and Albany and in many of the smaller towns one or more

small plants are located. The beverage industry is generally

local.

The woolen industry is located in Salem, Brownsville, Eugene, Stayton, and Oregon City in the Willamette

Valley, and in Pendleton. There are two linen mills in

Salem. Flax retting is scattered throughout the Willamette Valley, usually on tributary streams, but several have

TEXTILES.

shut down since 1946.

MANUFACTURING.

Manufacturing is carried on primarily in

Portland and vicinity.

It is evident from an examination of Table 2, which

shows the pack of Oregon canned fruits and vegetables, that

the canning industry is large. More than 14,000,000 cases

on a basis of 24 No. 2 cans per case were canned in 1946.

It should be pointed out that Table 4 must be used with considerable care. While every effort was made to obtain adequate samples

and reliable qualitative and quantitative data, there is evidence in the

table of wide variation in the quality of waste and the quantity of

waste produced per unit of product. Large variation in quantity of

waste is readily seen and at first glance it might be inferred that

there is decimal point inaccuracy; however, such is not the case.

When it is considered that the fruit or vegetable might be in contact

with water several times as long in one cannery as in another, it

becomes apparent that large variations are normal and to be expected.

For these reasons these data must be cautiously used.

In general the wastes from frozen apricots and from canned

beans and prunes are relatively weak when compared with beets,

corn, peaches, pears, and tomatoes. Beet, corn, and pea wastes are

apparently very strong, and if the offal of pears is ground and discharged along with the liquid waste, the resultant is as strong as

those mentioned above. The two samples of cherry waste from

widely separated canneries indicate the danger of acceptance of results on single samples.

22

ENGINEERING EXPERIMENT STATION BULLETIN No. 22

No reliable tabulations of milk, flax, or wool production were

These vary considerably locally. The flax industry, for

example, is in a state of flux and fluctuates from year to year. Considerable work in the midwest and eastern United States has established criteria for the meat packing industry. No reliable samples

were taken during this survey of such wastes, since it is extremely

difficult to obtain representative samples from small concerns. Meat

obtained.

processing in small plants is obviously on intermittent batch operation.

Several samplings were attempted at two plants with unsatisfactory

results.

While BOD determinations give the best index of pollutional

effects of wastes, they are time-consuming and tedious. If some

readily determinable physical or chemical property of wastes could

be shown to correlate with their BOD values, it would greatly facilitate a pollutional survey. The analytical data of Table 4 fail to show

any consistent correlation with BOD. The nearest approach to such

relationship is shown with dissolved solids. On placing the samples

in range groups as in Table 5, broad correlations become apparent

between BOD and dissolved solids, total carbon, and carbohydrates.

The widely diverse nature of the samples undoubtedly contributed to the lack of better correlation. The main factor in the discrepancies could well be the complexity of the BOD function itself,

which is dependent on biological agents and is influenced by numer-

ous physical and chemical factors of environment.

2. City wastes.

The quality of the city sewage indicates the

Monmouth sewage is weak and that the sewage treatment plant is

probably overloaded. Myrtle Point's sewage is normal in most in-

stances, but tends to be septic. There is considerable variation in the

pH and the acidity. Coos Bay sewage collected at low tide, is of low

to medium strength, which might be due to the extraordinarily high

chloride content.

Table 6, which shows the flow of sewages collected in 1944 and

the recorded flows at Springfield, Salem, Hood River, and Pendleton

in 1944-45, is too lengthy to examine in detail in this bulletin. There

is considerable evidence in the recorded flows to indicate that many

of these sewers carry enormous volumes of storm water. Some of

these sewers, however, are considered to be sanitary only. If such

is the case, then one or two deductions can be made. Illegal connections of roof and external house drainage must exist and some of the

sewers must have bad joints allowing ground water infiltration.

3. General. A careful evaluation of the several bulletins previously published by this Station and this bulletin would show that

INDUSTRIAL AND CITY WASTES

23

both cities and industries contribute to the degeneration of the rivers

in varying degrees. In general, the cities contribute large volumes

of grossly offensive materials which contaminate and pollute the

streams. The industrial problem is not as simple to evaluate as that

of the cities. Cities contribute in proportion to their population, in

addition industries discharge large volumes of wastes into city

sewers. The pulp and paper industry on a national scale is making

progress in studying remedial measures and methods of utilization

of the spent liquors. A large sum of money has been set aside for

such an investigation over a period of five years. This work was

undertaken in 1945. The pulp and paper industry contributes large

volumes of such wastes, particularly to the Willamette River. The

canning industry also contributes large volumes of waste which

pollute certain of the streams, in particular the Willamette, Umatilla,

and Walla Walla. Many canneries screen and haul the screenings

away from the plant and discharge the liquid waste either into the

rivers directly or indirectly through sewers or lagoons. Much money

has been spent by the individual canneries in this partial treatment,

but the treatment of the liquid waste for reduction of its strength is

still a problem for which no satisfactory answer has been developed

for all products. Scattered research work, some on a national scale

but mostly on an individual basis, has been attempted. Much work

remains to be done in treating such wastes as those from beet, pea,

pear, corn, peach, and squash plants, to name but a few. Some treat-

ments are known, but the cost is either excessive or has not been

made available to the industry at large.

Pilot plant operation over two or three years in the treatment of

these wastes is urgently needed.

Much money and time has been

spent in lagoon excavations and chemical treatment on the total

waste based on short term experiments at other plants. Some of the

canneries in this state are among the country's largest in certain products, and the amount of waste is extraordinary. It is possible that

real economies in treatment of waste can begin within the plant itself

where water, condenser and other, is apparently used in excess. Economic sanitation within a plant is one thing, and uneconomic profuse.

discharge of water for cleaning and washing is another. It is also

apparent that more economic use might be made of the offal which in

many instances represents a distinct loss to the industry and the

state.

It is more than likely that with adequate research many pres-

ent wastes could be transformed into useful and profitable byproducts.

Table 1. LIST OF CANNERIES AND THEIR PRODUCTS

Abbot, John

Plant location

Astoria, Rt. 2

Albany Canning Co.

Albany

Plant sold to Assoc. Frozen

Food Packers

(Seattle, Washington)

Albert's Products Co.

Portland

Company

1218 5. E. Grand

Alderman Farms

Allen Fruit Co., Inc.

Amalgamated Sugar Co.

Amherst, Jane, Co.

Dayton

Salem

Newberg

Nyssa

Portland

Products frozen or processed

loganberries .................................................

strawberries, green beans

Berries, peaches, Italian prunes, rhubarb, green beans, spinach, tomatoes

Berries, fruits

Crushed fruits

Berries, cherries,

corn, peas

pears,

prunes,

Fruits, vegetables

Glace and maraschino cherries, brine

cherries, fruit juices, dried prunes;

cabbage, carrots, onions, potatoes

Beet sugar

Hors d'oeuvres, meat sauces, chutneys,

American Fruit

Apple Growers Assoc.

Medford

Hood River

Bagley Canning Company

Ashland

Bandon Seafood & Cold

Storage Co.

Bandon

Barbey Packing Co.

Astoria

Ranier

Medford

Astoria

Snider, Hillsboro,

Woodburn

Blue Lake Producers

Co-operative

Blue Mountain Prune

Growers Assoc.

blackberries,

wild fruit preserve, orange

marmalade

1107 N. E. 47th

Beaver Creek Orchards

Bio Products, Ltd.

Bird's Eye

Products canned

Apples,

Salem

Apples, pears

Cider vinegar, brined cherries, apple

concentrate

Apples, cherries, peaches, pears

Cherries, peaches, pears, apple juice

corn, tomatoes, sauerkraut, tomato

juice, puree and hot sauce

.................................................

Fish

Salmon, tuna

Apples, pears

Vitamin oils, animal food

Peaches, pears, prunes, squash

Miscellaneous

Fruits, green beans, beets, carrots,

Berries, dehydrated vegetables

corn, pumpkin

Milton-Freewater

................................................

Prunes, apples, cherries, berries,

Table 1. LIST OF CANNERIES AND THEIR PRODUCTS (Continued)

Company

Bodle, R. D. Co.

Products canned

Plant location

Portland

Banks

Products frozen or pro cessed

Berries, cherries, currants, apricots,

peaches, prunes, rhubarb, asparagus,

beets, broccoli, brussels sprouts, carrots, peas, cauliflower, corn, spinach,

squash, succotash, zucchini

Briners of cherries

Ship fresh berries

Borden Company

California Conserving Co.

Albany

Medford

Corvallis

Scappoose

Salem

Milk

Apricots, cherries, peaches, plums,

vegetables, sauerkraut, pickles, relishes

Berries, fruits, vegetables

Carnation Co.

Columbia Fruit Growers

Hilisboro

The Dalles

Milk

Cherries, apricots, peaches, brined

cherries

Columbia Pickling & Packing

Co., Inc.

9333 N. E. 47th Ave.

Portland

Pickles, relish, kraut

Astoria

Depoe Bay

Newport

Astoria

Salmon, albacore, crab, shad

Coos Bay Asoc.

1111 N. E. 37th Ave.

Portland

Cranberry Canners, Inc.

North Bend

Oysters

Coquille

Cranberries

C. S.

Medford

Eugene

Chile con came, horseradish, salad

California Packing Corp.

Weatherly Building

Portland

0

Sold to Hunt's Foods, Inc.

Columbia River Packers

Assoc., Inc.

Columbia River Salmon Co.,

Cider, vinegar, sauces

Crab meat, salmon

Salmon, shad, tuna, sturgeon

Inc.

Daintec Brand Products

Dayton Evaporating & Packing Company

Apples, pears

Potato chips

dressing, pickles, syrup, tamales

Dayton

Dehydrated fruits, berries, vegetables, prunes

Table 1.

LIST OF CANNERIES AND THEIR PRoDucTs (Continued)

Company

Dickinson Company

401 Title & Trust Bldg.

Plant location

Portland

Products canned

Jellies, preserves

Domes, Henry W.

Rickreall

McCoy

Ocean Lake

Eugene

Junction City

Turkey meat

Dorchester House

Eugene Fruit Growers Assoc.

Marmalades

Cherries, berries,

pears,

Products frozen or processed

plums,

Feller

Goldstaub Pickling Co.

Marshfield

Aurora

Pickles, relish, kraut, honey, syrup,

salad dressing, chile con came

Gray & Co.

Portland

Jellies, jams

1305 N. W. Davis

Great Western Dehydration

Gresham Berry Growers, Inc.

t Haley Canning Co.

Hammark Fisheries

Hilltop Orchard

Hudson-Duncan & Co.

325 5. E. Water Ave.

Hunt Bros. Packing Co.

(Fullerton, Calif.)

Salem

Gresham

Hillsboro

Charleston

Eagle Creek

Dundee

The Dalles

Forest Grove

Salem

Brined cherries

quinces, green beans, beets, carrots,

corn, pumpkin, rhubarb

Salmon

Maraschino cherries, candied fruits

Vegetable dehydration

Berries, brined cherries

Berries

Chicken, beef

Crab meat

Peaches

Peaches, prunes

Cherries, berries, prunes

Apples, berries, apricots, cherries,

peaches, pears, prunes, plums, as-

Berries

paragus, green beans, peas, pumpkin,

spinach, tomatoes, rhubarb

Johnson Cider Co.

10105 N. E. Sandy

Kelley, Farquhar & Co.

(Tacoma, Wash.)

Portland

Kerr Conserving Co.

1805 S. E. 10th Ave.

Portland

Pickles, vinegar, cider, berry juices

Salem

Scenic

Berries, apricots, peaches, prunes,

asparagus, green beans, vegetables,

corn, peas, brined cherries

Jams,

jellies, apple butter,

fruit juices

berry

Berries

Table 1. LIST OF CANNERIES AND THEIR PRODUCTS (Continued)

Company

Lomb, F. G. & Co.

Lazy Days Food Products Co.

Libby, McNeil! & Libby

(San Francisco)

Love, Alice Products

1432 S. E. 34th Ave.

Luxury Food Products

2725 S. E. Division

MacLaughlin, R. I. & Co.

Marion Creamery

Martin Bros.

Mione Packing Company

Myrtle Creek Canning Co.

Modoc

Myron Root Company

Neptune Fish Products Co.

(Seattle, Wash.)

New England Fish Company

(Seattle, Wash.)

Plant location

Freewater

Milwaukie

Portland

Portland

Portland

Salem

Gresham

Beaverton

Salem

Milwaukie

McMinnville

Myrtle Creek

Medford

Medford

Astoria

Newport

Astoria

Products canned

Chile con came

Apples, apricots, berries, cherries,

peaches, pears, prunes, vegetables,

sauerkraut, tomatoes

Jellies, jams, marmalades

Chicken, dressing, pickles, relish

mince meat, vinegar, condiments

Cherries, berries, prunes

Dried milk

Chickens

Chicken, turkey

Tomatoes

Apples, pears

Apples, pears

Salmon, tuna

Smoked fish, salt kippered, salmon,

frozen salmon, halibut, sole, crab

meat

Apples, pears

Salmon, tuna, crab

Winchester Bay

N. & N.

Medford

McMinnvillc

Woodburn

Milk

Dundee

Walnuts, filberts

North Western Packing Co.

Portland

554 N. Columbia Blvd.

Oregon State College

Corvallis

Apricots, apples,

pumpkin, spinach

Berries, cherries,

prunes

Neatten Milk Products Inc.

North Marion Fruit Co., Inc.

North Pacific Nut Growers

Products frozen or processed

Apples, cherries, grapes, plums, asparagus, peas, lima beans, spinach

Table syrup

Jams, apple butter

Berries, prunes

Walnuts, filberts

Coop.

prunes,

pears,

beans .................................................

plums,

Fruit, berry juices, cider, jams, preserves, dried beans, prunes

Table 1. LIST OF CANNERIES AND THEIR PRODUCTS (Continued)

Company

Plant location

Products canned

Berries, cherries, apple sauce, prunes

Products frosen or processed

Apple butter, brined cherries, ber-

Oregon Fruit Products Co.

Salem

Oregon Mushroom Co.

Oswego Jelly Co.

Palmers American Chili Co.

2641 5. E. 81st

Paragon Packing Co.

Paulus Bros. Packing Co.

Milwaukie

Oswego

Pemade

Pendleton Canning & Frozen

Foods Co.

Medford

Pendleton

Perry Brothers

(Seattle, Wash.)

Plancich Fish Co.

300 N. W. 13th

Point Adams Pkg. Co.

Portland Canning Co. & Forest

Grove Canning Co.

Producers Cooperative

Stanfield

Poultry, eggs, butter

Portland

Crab meat, oysters

ries, plums

Mushrooms

Portland

Jellies, fruits

Chili con came, hash

Astoria

Salmon, tuna

Salem

Berries, pears, prunes, green beans,

carrots, juices

Peas, tomatoes

Fish

Berries, dried fruits, prunes, preserves

Apples, pears

Peaches, peas

Salmon, tuna, crab meat, shad, roe

Hammond

Sherwood

Prunes, green beans

Berries, prunes, green beans

Salem

Cherries, berries, pears, prunes

Berries, fruits, dried fruits, brined

cherries

Puritan Cider Works

West Salem

Apple juice, boiled cider, grape and

Ray Canning Company

Freewater

berry juice, honey

Apricots, peaches,

Package Company

plums,

prunes .................................................

green asparagus, tomatoes

Recdsport Packing Co.

Reedsport

Reid, Murdoch & Co.

(Chicago)

Salem

Retter

Rogers Canning Co.

Medford

Milton

Athena

Salmon, shad, shad roe, herring,

sardines

Berries, cherries, pears, peaches,

prunes, rhubarb, asparagus, green

Smoked salmon, shad, sardines

Jellies, preserves, fruit butters, brined

cherries

beans, lima beans, vegetables

Apples and pears

Peas, carrots

Table 1. LIST OF CANNERIES AND THEIR PRODUCTS (Continued)

Company

Rogue River Packing Corp.

Roseburg Canning Co.

Royal Canning Co. of Ore.

S. 0. S.

Schlesser Sales Co.

2315 5. W. 16th

Seaside Clam Co.

Sebastian Stuart Fish Co.

(Seattle)

Seufcrt Bros. Co.

Products frozen or processed

Plant location

Medford

Roseburg

Silverton

Medford

Portland

Products canned

Peaches, pears

Green beans, tomatoes, prunes

Prunes, green beans, corn, pumpkin

------------------------------------------------

Apples, pears

Dog and cat food

Warrenton

Astoria

Clams, crab meat

Salmon, tuna

Salt smoked fish

Seuferts

Salmon, apples, apricots, cherries

peaches, prunes, peas, tomatoes

(The Dalles)

.

.................................................

Crushed fruits, fountain syrups

Shaffner, S. E. Co.

4th and Glisan

Portland

Silvcr Thread Kraut & Pickle

Clackamas

Spinach

Smith Canning Co. of Ore.

Pendleton

Peaches,

Smith Frozen Foods

(Clearfield, Utah)

Pendleton

Spencer Dehydrators, Inc.

Spencer Packing Company

Lebanon

Lebanon

Springbrook Packing Co.,

Springbrook

Sauerkraut, dill pickles, sweet pickles, salt stock

Works

asparagus,

green

beans

pork and beans, peas, carrots, tomatoes, tomato catsup

Cooperative

Stanley's Food Products

1401 N. E. Alberta

Portland

Starr Fruit Products Co.

Portland

Stayton Canning Co.

Cooperative

Apples, apricots, cherries, berries,

peaches, green beans, beets, carrots,

corn, peas, spinach, tomatoes

Dehydrated beets, carrots, potatoes

Berries,

apricots,

pears,

cherries,

Berrie and fruit

peaches, prunes, pumpkin, tomatoes

Berries, cherries, peaches,

plums, prunes, tomatoes

pears,

Berries, evaporated berries and cher-

ries, brined cherries

Pickles, relish, mustard

Apples,

cherries, berries, peaches,

Salem

pears, plums, prunes, beans, toma

Stayton

toes

Cherries,

beans

berries,

prunes,

green

Berries,

beans

apricots,

Berries, brined beans

peaches,

green

Table 1. LIsT OF CANNERIES AND THEIR PRODUCTS (Continued)

Company

Steinfeld's Products Co.

7400 S. W. Macadam

Stidds, Inc.

231 5. W. Ankeny

Plant location

Portland

Portland

Products frozen or processed

Pickles, relish, kraut juice

Products canned

Sauerkraut

Tamales, chile con came, chicken

broth, vegetable dinner, chicken soup

with rice

Stoetz, Gideon Co.

Salem

Sun Valley Products Co.

3321 N. Vancouver

Portland

Sweetarts

328 N. S. Failing

Swift & Company

Tasty Foods Co.

7400 S. W. Macadam

The Dalles Coop. Growers

Thomas Quality Kitchen

Portland

Carbonated beverages, fountain

syrups

3325 5. E. Division

Tillamook Bay Fish Co.

Umatilla Canning Company

Union Fishermen's Coop.

Packing Co.

United Growers, Inc.

(Rt. 3)

Utah Canning Co.

(Ogden, Utah)

Van Camp Sea Food Co., Inc.

(Terminal Island, Calif.)

Vangoorda Laboratories

Fruit drinks, apple juice, beverage

base

Albany

Candied and glace fruit confections

Turkeys

Mayonnaise, salad dressing, sand-

Portland

The Dalles

Portland

Bay City

Milton

Astoria

wich spread, fruit pectin

Brined cherries

Chicken tamales, chile con came

lima beans and ham, table syrup

Inc.

Salmon, crab meat

Salmon, oysters

Peas

Salmon, tuna

Cured and frozen salmon

carrots,

Salem

Cherries, berries, prunes,

beets, tomatoes

Freewater

Asparagus, green beans, peas, carrots, beans, tomatoes, sauerkraut

Astoria

Sardines, tuna

Newport

Berries, apples,

vegetables

peaches,

prunes,

Fish oil, fish meal

Jams, jellies, preserves, orange marmalade, apple pectin, fruit concentrates

Portland

2511 S. W. Miles

Waldport Sea Food Company,

.................................................

Crab meat

Table 1. LIST OF CANNERIES AND THEIR PRODUCTS (Continued)

Company

Ware Food Products

East Burnside

Washington Dehydrated Food

Co. (Yakima)

Washington Fish & Oyster Co.

(Seattle)

Washington Packers, Inc.

Newport

Salmon, crab meat

Rainier

Berries, apples, apricots, cherries,

peaches, beans

fish

Salem

Berries, cherries, apples, green

beans, peas, brined cherries, vegetables

Berries, currants, dried cherries,

walnuts, filberts

Berries, cherries, prunes, corn on

the cob

Brined cherries

Portland

Horseradish, mustard

McMinnville

Astoria

Newport

Dehydrated potatoes

Sturgeon, kippered tuna

Portland

-

Corvallis

Corp.

Willamette Cherry Growers,

Salad dressing, pickles, relish, lemon

juice, maraschino cherries, mustard,

horseradish

Dehydrated apples, carrots, onions,

cabbage, squash, potatoes

Cured, salted, pickled fish, frozen

Freewater

(Sumner, Washington)

West Coast Fruit Co.

706 S. E. Union Ave.

Western Oregon Packing

Products frocn or processed

Products canned

Plant location

Portland

Cherries,

berries,

pears,

prunes, beets, carrots, corn

plums,

Inc.

Williams & Co.

2045 N. E. Union

Wright Dehydrating Co.

Wuori, Kris, & Son

Yaquina Bay Fish Co.

Yeager, Fred

(Rt. 7)

Portland

Crab meat, salmon, tuna

Pickles, sauerkraut

Table 2. OREGON AND WASHINGTON CANNERY PACK

Source: Northwest Canners Association

Bulletin No. 1697, March 20, 1947

A.

Commodity

Oregon canned fruits

24 No. 2 cans per case

Apples

Apple sauce

Apricots

Cherries, RA

Cherries, Bik

Cherries, RSP

Pears

Peaches

Prunes

Plums

Other fruit

Total

Berries

24 No. 2 cans per case

Blackberries

Boysen

Gooseberries

Logan

Raspberries, red

Strawberries

OREGON CANNERY PACK, 1945.46

Total, 1945

Total, 1946

205,921

100,498

13,377

209,268

161,369

44,137

1,238,486

147,915

1,242,858

9,924

59,134

101,989

126,397

141,748

400,581

308,093

41,060

1,675,699

303,411

2,675,561

8,100

77,795

3,432,887

5,860,434

13,547

22,992

4,977

5,991

3,009

5,279

3,221

50,258

25,195

6,343

25,854

3,706

3,228

15,308

270

59,016

130,161

1,880,091

1,275,901

810,420

236,000

2,014,188

208,381

32,854

120,530

5,320

6,583,685

2,020,025

1,079,738

921,276

400,748

3,394,653

216,030

62,447

133,065

123,366

8,353,850

10,075,588

14,344,445

Inc. in misc.

Young

Miscellaneous berries

Total

Canned vegetables

24 No. 29 cans per case

Beans, G + W

Beets

Carrots

Corn

Peas

Pumpkin

Spinach

+

squash

Tomatoes + juice

Miscellaneous vegetables

Total

Grand total

.

-------------------------

Table 2.

OREGON AND WASHINGTON CANNERY PACK (Continued)

Source: Northwest Canners Association

Bulletin No. 1697, March 20, 1947

B. TOTAL OREGON-WAS1{INGTON PACKS (ACTUAL CASES)

Commodity

Fruit

Berries

Vegetables

Total ---------------------------------------------------

24/2

24/2-i

6/10

644,274

132,492

11,670,938

7,702,520

448,216

2,141,202

83,949

2,150,630

12,447,704

8,150,736

4,375,781

Total 1946

actual

Total 1946

converted

24/2k

Total 1945

converted

24/2

376,887

40,014

97,597

10,864,883

256,455

14,514,643

10,291,613

185,819

15,547,474

6,320,628

80,074

12,234,476

514,498

25,635,981

26,024,906

18,635,178

Miscellaneous

Fruits and berries converted to 24 No. 2 cans per case.

Vegetables converted to 24 No. 2 cans per case.

C. TOTAL OREGON.WA5HINGTON PACKS-1942 THROUGH 1946 (ACTUAL CASES)

1942

1943

1944

1945

1946

Vegetables

8,565,491

10,431,993

7,308,441

13,222,099

6,714,482

12,198,051

6,731,888

11,636,618

11,121,338

14,514,643

Total

18,997,484

20,530,540

18,912,533

18,368,506

25,524,170

Commodity

Fruit and berries

---------------------------------------------------------------------------------------------------------

Table 3. LIST OF ANIMAL AND MEAT PROCESSING PLANTS

Data supplied by M. E. Knickerbocker, Chief

Division of Animal Industries,

State Department of Agriculture

Location