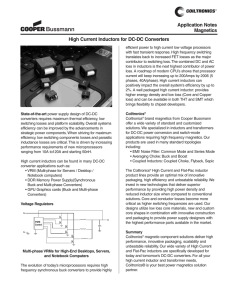

Application Notes Magnetics Power Inductors Improve Reliability in High Temperature Designs

advertisement

Application Notes Magnetics Power Inductors Improve Reliability in High Temperature Designs First calculate the needed inductance value: V = L * dI/dt where: V = Vin - Vout (voltage across the inductor) dT = On time of drive = Vout/Vin/frequency ∆I = Chosen above to be 20% Calculate the required inductance: L = V * dt / ∆I = (12-5)*(12/5/600k)/(0.2*4.5) L= 4.8 µH Choose 4.7 µH, the nearest standard value Recalculate ripple current at 23% using 4.7 µH Second determine peak to peak flux density, Bp-p: Bp-p = K * L * ∆I where: The Cooper Coiltronics® brand of High Current FP3™ power inductors from Cooper Bussmann is designed for high density, medium current applications using a high temperature iron powder core material. These inductors do not exhibit the thermal aging issue frequently associated with iron powder core inductors. In fact the FP3 core is rated for 200°C without thermal degradation. The FP3 family is rated for 155°C operation. The calculations below will allow users to take advantage of this high temperature capability. 5V 4.5A 12V Input K: K-factor from the adjacent table L: Inductance µH ∆I: Peak to peak ripple current (Amps) Bp-p = 105*4.7*0.23*4.5 = 510 Gauss Part Number FP3-R10-R FP3-R20-R FP3-R47-R FP3-R68-R FP3-1R0-R FP3-1R5-R FP3-2R0-R FP3-3R3-R FP3-4R7-R FP3-8R2-R FP3-150-R K-factor 803 482 344 268 219 185 161 127 105 78 59 PWM In this example, a buck regulator will be used to convert a 12V input to a 5V output with a load current of 4.5A. The operating frequency was chosen to be 600 kHz to reduce the size of the filter components, while still maintaining good efficiency. The converter is designed to have 20% ripple current, so a relatively low ESR output filter capacitor will be used, as is typical in switching power supplies. Next determine the total losses in the inductor: Total losses = DC loss + AC loss DC loss = I2 *DCR = 4.52 * 0.040 = 0.81 W (DCR from FP3 datasheet) AC loss from table at Bp-p of 510 = 0.15 W Total Loss = DC loss + AC loss = 0.96W Finally determine the temperature rise. Total loss = 0.96W, using the table, Temperature rise is 80°C Assuming an ambient temperature of 70°C, The temperature of the inductor is T = 70 +75 = 150°C Application Notes Magnetics Note the data assumes no cooling airflow. Cooling will reduce the temperature of the inductor. The FP3 is rated for 155°C operation. FP3 AC Loss at Frequency, kHz CoreLoss (W) CoreLoss vs. Flux Density 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10 0.00 250 200 300 400 500 600 700 800 900 1000 500 750 1000 1250 1500 1750 2000 2250 B p-p (Gauss) Temperature Rise (C) Temperature Rise vs. Watt Loss 140 130 120 110 100 90 80 70 60 50 40 30 20 10 0 0.12 0.24 0.36 0.48 0.61 0.73 0.85 0.97 1.09 1.21 1.33 1.45 1.57 Total Loss (W) FP3 App Note 3/07 © Cooper Electronic Technologies 2007 Visit us on the Web at www.cooperbussmann.com 1225 Broken Sound Pkwy. Suite F Boca Raton, FL 33487 Tel: +1-561-998-4100 Toll Free: +1-888-414-2645 Fax: +1-561-241-6640 This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this bulletin. Once a product has been selected, it should be tested by the user in all possible applications. Life Support Policy: Cooper Electronic Technologies does not authorize the use of any of its products for use in life support devices or systems without the express written approval of an officer of the Company. Life support systems are devices which support or sustain life, and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in significant injury to the user.