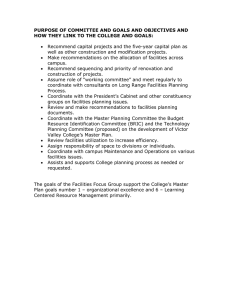

COORDINATE TRANSFORMATIONS

advertisement

COORDINATE

TRANSFORMATIONS

Members of a structural system

are typically oriented in differing

directions, e.g., Fig. 17.1. In order

to perform an analysis, the element stiffness equations need to

be expressed in a common coordinate system – typically the global

coordinate system. Once the

element equations are expressed

in a common coordinate system,

the equations for each element

comprising the structure can be

1

assembled.

Figure 17.1 – Frame Structure

(Kassimali, 1999)

2

Coordinate Transformations:

Frame Elements

Consider frame element m of Fig.

17.7.

Y

y

e

m

x

b

X

(a) Frame

Q6, u6

Q3, u3

m

Q1, u1

Q4, u4

Q5, u5

Figure 17.7: Local – Global

Coordinate Relationships

Q2, u2

(b) Local Coordinate End Forces

and Displacements

3

4

1

Figure 17.7 shows that the local –

global coordinate transformations

can be expressed as

Q x cos FX sin FY

Q y sin FX cos FY

(17.9)

Q z FZ

x = cos X + sin Y

y = -sin X + cos Y

and since z and Z are parallel, this

coordinate transformation is

expressed as

z=Z

Using the above coordinate

transformations, the end force and

displacement transformations can

be expressed as

5

T

where {Q}b Q1 Q2 Q3 =

beginning node local coordinate

force vector; {Q}e = <Q4 Q5 Q6>T =

end node local coordinate force

vector; {F}b = <F1 F2 F3>T =

beginning node global coordinate

force vector; {F}e = <F4 F5 F6>T =

end node global coordinate force

cos sin 0

vector; [t] = sin cos 0 =

0

1

0

local to global coordinate transformation matrix which is the same at

each end node for a straight

7

where x, X = 1 or 4; y, Y = 2 or 5;

and z, Z = 3 or 6.

Utilizing (17.9) for all six member

force components and expressing

the resulting transformations in

matrix form gives

Qb

Qe

[t] [0] Fb

[0] [t] F

e

or

{Q} = [T] {F}

(17.11)

member; {Q} = <<Q>b <Q>e>T =

element local coordinate force

vector; {F} = <<F>b <F>e>T =

element global coordinate force

[t] [0]

vector; and [T] =

=

[0] [t]

element local to global coordinate

transformation matrix.

Utilizing (17.9) for all six member

force components and expressing

the resulting transformations in

matrix form gives

8

2

The direction cosines used in the

transformation matrices can easily

be calculated from the nodal

geometry, i.e.

Xe X b

L

Ye Yb

sin

L

cos

(17.13)

(17.14)

{u} [T]{v}

It is also useful in matrix structural

analysis to calculate the global end

displacements and forces in terms

of the local coordinate end displacements and forces as shown in

Fig. D.

L (X e X b ) 2 (Ye Yb ) 2

Since the end displacements are

aligned with the end forces, the

local to global coordinate

displacement relationships are

Figure D: Global – Local

Coordinate Relationships

9

X = cos x - sin y

FX

FY

FZ

Y = sin x + cos y

Z = z

Applying the global – local

coordinate transformations to the

end node forces gives

cos sin 0 Q x

sin cos 0 Q

y

0

1 Qz

0

or

{F}node [t]T {Q}node

where node = b or e.

FX cos Q x sin Q y

FY sin Q x cos Q y

10

(17.15)

FZ Q z

where X, x = 1 or 4; Y, y = 2 or 5;

and Z, z = 3 or 6.

13

Expanding the global – local

coordinate transformation to both

end nodes leads to

{F}b

{F}

e

[t]T [0]

T

[0] [t]

{Q}b

{Q}e

14

3

or

T

{F} [T] {Q}

Continuous Beam Members

(17.17)

Similarly, the global coordinate

displacement vector is related to

the local coordinate displacement

vector as

{v} [T]T {u}

(17.18)

When analyzing continuous beam

structures, the axial displacement

and force degrees of freedom are

typically ignored since they are zero

unless there is axial loading and the

continuous beam is restrained

against longitudinal motion, i.e., is

not free to expand. Regardless, in

continuous beam structures the

local and global coordinate systems

typically coincide resulting in [tb] =

[I]2x2. This leads to

{Fb} = {Qb} and {vb} = {ub} (17.19)

15

14

Truss Members

Local – global force and

displacement relationships (see

Fig. 17.9):

0

0

Q1 cos sin

0

cos sin

Q 2 0

{Qa} = [Ta] {Fa}

{ua} = [Ta] {va}

(a) Local Coordinate End Forces

F1

F

2

F3

F4

(17.21)

and Displacements for a Truss Member

(b) Global Coordinate End Forces

and Displacements for a Truss Member

Figure 17.9 Truss Member

Similarly,

{Fa } [Ta ]T {Qa }

{va } [Ta ]T {u a }

15

16

4

MEMBER STIFFNESS

RELATIONS IN GLOBAL

COORDINATES

To establish the global coordinate

representation of the element

stiffness equations, start by

substituting {u} = [T] {v} into

(17.4):

{Q} [k][T]{v} {Qf } (17.a)

which results in the force quantities being defined in the local

coordinate system and the

displacement vector expressed in

terms of the global coordinate

17

system. To transform the

matrix, i.e., the element stiffness

matrix coefficients aligned with the

global coordinate system and

K ij Fi v 1

j

force vectors into the global coordinate system, pre-multiply both

sides of (17.a) by [T]T

[T]T {Q} [T]T [k][T]{v}

[T]T {Qf }

(17.23)

Substituting {F} = [T]T {Q} into

(17.23):

{F} [T]T [k][T]{v} {Ff } (17.24)

where {Ff} = [T]T {Qf}.

Equation (17.24) in matrix form:

{F} [K]{v} {Ff }

(17.25)

where [K] = [T]T [k] [T] = global

coordinate element stiffness

18

For a continuous beam member

(also see discussion following

equation 1 and 17.19):

[T] = [Tb] = [I]4x4

with all other vk = 0 and k ≠ j.

All global coordinate stiffness

equations are expressed by (17.24)

and (17.25). However, for beam

and truss structures, the transformation matrix [T], displacement

vector {v}, and force vectors {F}

and {Ff} must be for these

members.

19

{v} = {vb} = {ub}

{F} = {Fb} = {Qb}

{Ff} = {Ffb} = {Qfb}

[K] = [Kbb] = [kbb]

(see 17.6)

20

5

For a truss member (also see

discussion following equations 1

and 17.21):

Structure Stiffness Relations

[T] = [Ta]

{v} = {va}

{F} = {Fa}

{Ff} = {Ffa}

[K] [K aa ] [Ta ]T [k aa ][Ta ]

c2

EA cs

L c 2

cs

c cos

s sin

cs

c 2

s2

cs

cs

c2

s 2

cs

cs

s 2

(17.29)

cs

s 2

The structure stiffness equations

can now be determined using the

global coordinate member stiffness

equations. Generation of the

structure stiffness equations is

based on the three basic

relationships of structural analysis:

(1) equilibrium, (2) constitutive

relationships, and (3) compatibility.

Specifically, the direct stiffness

procedure involves expressing:

21

22

(1)Node point equilibrium of the

element end forces meeting at

the node with the externally

applied nodal forces;

(2)Substituting the global coordinate constitutive (matrix

stiffness) equations for the

forces in terms of the stiffness

coefficients times the element

end displacements and fixedend force contributions; and

(3)Compatibility of the element

end displacements with the

structure displacement degrees

23

of freedom {d}.

Figure 17.10 – Illustration of Direct

Stiffness Analysis

24

6

Equilibrium Equations

Member Stiffness Relations

(Constitutive Equations)

FX P1 F4(1) F1(2)

2

P1 F4(1) F1(2)

(17.30a)

(m)

FY P2 F5(1) F2(2)

2

P2 F5(1) F2(2)

(17.30b)

M Z P3 F6(1) F3(2)

2

P3 F6(1) F3(2)

m

Since the end forces Fi in (17.30)

are unknown, the member

stiffness relations

F1

F

2

F3

F4

F5

F6

K11

K

21

K

31

K 41

K 51

K 61

K12

K13

K14

K15

K 22

K 32

K 23

K 33

K 24

K 34

K 25

K 35

K 42

K 43

K 44

K 45

K 52

K 62

K 53

K 63

K 54

K 64

K 55

K 65

(m)

v1

v

2

v

3

v4

v5

v6

(17.30c)

where superscripts (1), (2) designate

25

element (member) 1, 2; respectively.

are substituted into (17.30) to give

(m)

(m)

Ff1

F

f2

F

f3

Ff 4

Ff 5

Ff 6

(17.31)

26

Compatibility

Imposing the compatibility

(continuity) conditions

(1)

(1) (1)

(1) (1)

P1 K (1)

41 v1 K 42 v 2 K 43 v 3

(1)

(1) (1)

(1) (1)

(1)

K (1)

44 v 4 K 45 v 5 K 46 v 6 Ff 4

(2) (2)

(2) (2)

(2) (2)

K11

v1 K12

v 2 K13

v3

(1)

v1(1) v (1)

2 v3 0

(2) (2)

(2) (2)

(2) (2)

(2)

K14

v 4 K15

v 5 K16

v 6 Ff1

v (1)

4

(1) (1)

(1) (1)

(1) (1)

P2 K51

v1 K 52

v 2 K53

v3

d1 ;

v 5(1)

d2 ;

(17.35)

v (1)

6

d3

(2)

v1(2) d1 ; v (2)

2 d 2 ; v 3 d3

(1) (1)

(1) (1)

(1) (1)

K54

v 4 K 55

v 5 K56

v 6 Ff(1)

5

(2) (2)

(2) (2)

(2) (2)

K 21 v1 K 22 v 2 K 23 v 3

(2)

(2) (2)

(2) (2)

(2)

K (2)

24 v 4 K 25 v 5 K 26 v 6 Ff 2

(2)

(2)

v (2)

4 v5 v6 0

(17.36)

on the constitutive equation version

of the equilibrium equations leads to

(1)

(1) (1)

(1) (1)

P3 K (1)

61 v1 K 62 v 2 K 63 v 3

(1)

(1) (1)

(1) (1)

(1)

K (1)

64 v 4 K 65 v 5 K 66 v 6 Ff 6

(2)

(2) (2)

(2) (2)

K (2)

31 v1 K 32 v 2 K 33 v 3

(2)

(2) (2)

(2) (2)

(2)

K (2)

34 v 4 K 35 v 5 K 36 v 6 Ff 3

K16

K 26

K 36

K 46

K 56

K 66

(2)

(1)

(2)

P1 (K (1)

44 K11 ) d1 (K 45 K12 ) d 2

(2)

(1)

(2)

(K (1)

46 K13 ) d 3 (Ff 4 Ff1 )

27

(17.39a)

28

7

(1)

(1)

(2)

P2 (K54

K (2)

21 ) d1 (K 55 K 22 ) d 2

(1)

(1)

(2)

(K 56

K (2)

23 )d 3 (Ff 5 Ff 2 )

(2)

(1)

(2)

P3 (K (1)

64 K 31 ) d1 (K 65 K 32 ) d 2

(2)

(1)

(2)

(K (1)

66 K 33 ) d 3 (Ff 6 Ff 3 )

(17.39b)

(17.39c)

Or collectively as

{P} [S]{d} {Pf }

[S]{d} ({P} {Pf }) {P} (17.41)

K (1) K (2)

11

44

(1)

[S] K 54 K (2)

21

(1)

(2)

K 64 K 31

(2)

K (1)

45 K12

(1)

K 55

K (2)

22

(2)

K (1)

65 K 32

(2)

K (1)

46 K13

(1)

K 56

K (2)

23

(2)

K (1)

66 K 33

29

Assembly of [S] and {Pf} Using

Member Code Numbers

The explicit details given for the direct

stiff-ness procedure highlights how the

basic equations of structural analysis are

utilized in matrix structural analysis. A

disadvantage of the procedure is that it

is tedious and not amenable to

F(1) F(2)

f1

f4

(2)

{Pf } Ff(1)

F

5

f2

(1) (2)

F Ff 3

f 6

P1 Pf1

{P} P2 Pf 2

P3 Pf 3

The structure stiffness coefficients

Sij are defined in the usual manner,

i.e., Sij Pi d 1 force at dof i due to

j

a unit displacement at j with all

other displacements dk = 0 and k≠j.

30

for frame members; and NNP

Number of Node Points, i.e., number

of nodes used in the 2D structure

discretization). The ID( , ) array

identifies the nodal equation

numbers in sequence:

ID(1,node) = X-axis nodal displ. number

ID(2,node) = Y-axis nodal displ. number

ID(3,node) = Nodal rotation displ. number

computer implementation.

Computer implementation is based

on using a “destination array”

ID(NNDF,NNP) (NNDF Number of

Nodal Degrees of Freedom, three

31

For example, consider the gable

frame structure shown on the next

slide. The destination array is also

shown on this slide.

32

8

The ID( , ) array along with the

element node number array

IEN(NEN, NEL) (NEN Number of

Element Nodes, which is two for

discrete structural elements; and

NEL Number of Elements used to

discretize the structure) is used to

construct the element location

matrix array LM(NEDF, NEL)

(NEDF Number of Element

Degrees of Freedom, which is six

for the 2D frame elements), i.e.,

Gable Frame Structure

1

ID

2

1

0

0

0

2

1

2

3

3

4

5

6

4

7

8

9

5

0

0

10

Node

3

34

33

LM(i, iel) = ID(i, IEN(1,iel)); 1 = b node

LM(j, iel) = ID(i, IEN(2,iel)); 2 = e node

i = 1, 2, 3 ; j = 4, 5, 6

iel = element number

The IEN( , ) and LM( , ) arrays for the

gable frame example are

iel

1

2

3

4

IEN

1

2

1

2

3

1

2

3

5

0

1

4

0

0

2

5

0

0

3

6

10

2

3

4

4

LM

4

1

4

7

7

5

6

2

5

8

8

3

6

9

9

The LM( , ) array is used to assemble

the global element stiffness matrix and

fixed-end force vector as illustrated on

the next two slides.

35

LM: (1,m) (2,m) (3,m) (4,m) (5,m) (6,m)

LM(1, m)

LM(2, m)

LM(3, m)

LM(4, m)

LM(5, m)

LM(6, m)

K11

K

21

K 31

K

41

K 51

K

61

K12

K 22

K 32

K13

K 23

K 33

K14

K 24

K 34

K15

K 25

K 35

K 42

K52

K 62

K 43

K 53

K 63

K 44

K 54

K 64

K 45

K 55

K 65

Ff1

F

f2

Ff 3

Ff 4

LM(5, m) Ff 5

LM(6, m) Ff 6

LM(1, m)

LM(2, m)

LM(3, m)

LM(4, m)

K16

K 26

K 36

K 46

K56

K 66

(m)

(m)

36

9

For the example gable frame:

(2)

S11 K (1)

44 K11

(2)

Pf1 Ff(1)

4 Ff1

(1)

S21 K 54

K (2)

21

(2)

Pf 2 Ff(1)

5 Ff 2

(4)

S9,9 K (3)

66 K 66

(4)

Pf 9 Ff(3)

6 Ff 6

(4)

S10,9 K 36

Pf10

Example Problems

Ff(4)

3

S9,10 K (4)

63

Truss

Frame

(4)

S10,10 K 33

37

38

Self-Straining: structure that is

internally strained and in a state of

stress while at rest without

sustaining any external loading

SUMMARY

Identify structure degrees of

freedom {d}

For each element:

Evaluate [k], {Qf}, and [T]

Calculate [K] = [T]T [k] [T]

{Ff} = [T]T {Qf}

Assemble [K] into [S]

Assemble {Ff} into {Pf}

Form nodal load vector {P}

Solve: [S] {d} = {P} – {Pf}

For each element:

Obtain {v} from {d} (compatibility)

Calculate {u} = [T] {v}

{Q} = [k] {u} + {Qf}

Determine support reactions by

considering support joint equilibrium

39

40

10

Temperature Restraint

Example

Problems

Displacements of Statically

Determinate Structures

41

Some Features of the

Stiffness Equations

An important characteristic of both

element and global (structure)

linear elastic stiffness equations is

that they are symmetric. Practically, this means that only the

main diagonal terms and

coefficients to one side of the main

diagonal need to be generated and

stored in a computer program.

Also note that the stiffness

(equilibrium) equation for a given

degree of freedom is influenced 43by

42

the degree of freedom is

influenced by the degrees of

freedom associated with the

elements connecting to that

degree of freedom. Thus, nonzero

coefficients in a given row of a

stiffness matrix consist only of the

main diagonal and coefficients

corresponding to degrees of

freedom at that node and at other

nodes on the on the elements

meeting at the node for which the

stiffness equation is being formed.

44

11

All other coefficients in the row are

zero. When there are many

degrees of freedom in the

complete structure, the stiffness

matrix may contain relatively few

nonzero terms, in which case it is

characterized as sparse or weakly

populated.

Banded Stiffness Equations

45

bandwidth. This is most easily

achieved by minimizing the nodal

difference between connected

elements. All commercial

structural and finite element codes

have built in schemes to minimize

the interaction of the stiffness

equations regardless of the userspecified input.

47

Clearly, it would be advantageous

in the solution phase of analysis to

cluster all nonzero coefficients

close to the main diagonal. This

isolation of the zero terms

facilitates their removal in the

solution process. This can be

done by numbering the degrees of

freedom in such a way that the

columnar distance of the term

most remote from the main

diagonal coefficient in each row is

minimized; i.e., by minimizing the

46

Indeterminacy

Cognizance of static indeterminacy

is not necessary in the direct stiffness approach. The displacement

approach uses the analogous

concept of kinematic

indeterminacy, refers to the

number of displacement degrees

of freedom that are required to

define the displacement response

of the structure to any load.

Stated another way, kinematic

indeterminacy equals the

48

12

number of displacement degrees

of freedom that must be

constrained at the nodes in

addition to the boundary

constraints (support conditions) to

reduce the system to one in which

all the nodal displacements are

zero or have predetermined

values, e.g., specified support

settlement.

It is fairly obvious that kinematic

indeterminacy is quite different

from static indeterminacy.

49

13